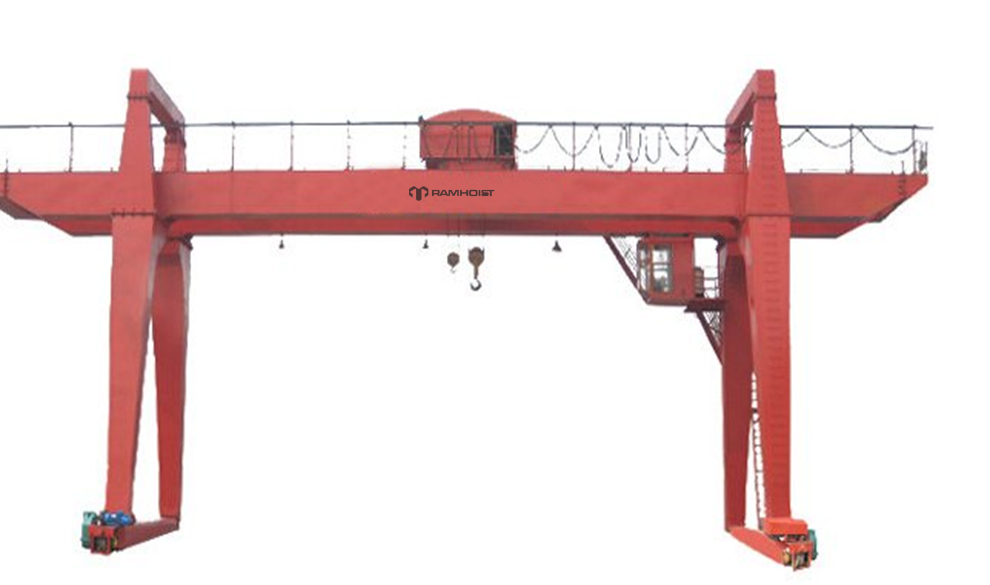

Different Capacities of Double Girder Gantry Cranes made in china

Keyword:Double Girder Gantry Cranes Time:2020-3-25 17:54:20

Electric double girder gantry crane is a common lifting equipment with tonnage of 0.5~500t. It is widely used in factory, mine, port, warehouse, and other material handling places to improve the efficiency of labor and improve the necessary machinery working conditions.

Double girder gantry crane or Double beam gantry crane is also a kind of Heavy duty gantry crane, and it is also capable of handling large and heavy loads in outdoor workplaces, the lifting capacity of the gantry cranes are up to hundreds of tons (up to 500 ton). The working class of the gantry crane is A5 and A6.

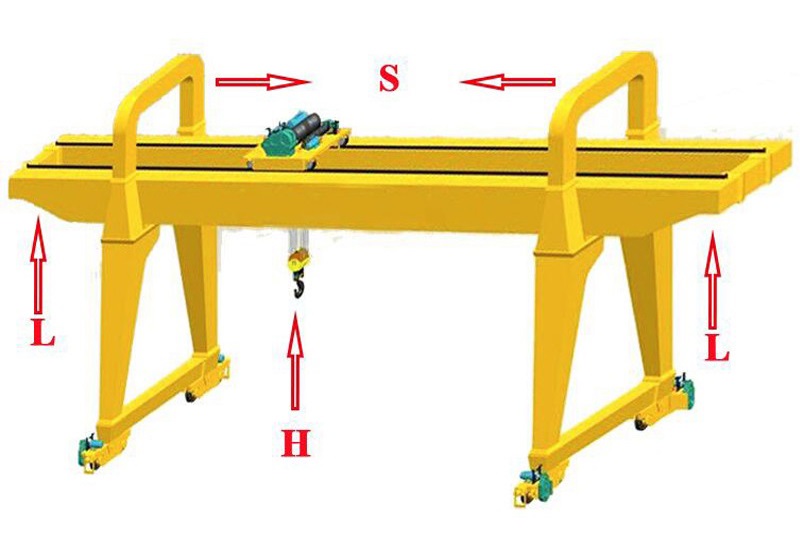

It mainly includes crane trolley, crane traveling mechanism, electrics, gantry frame (consisting of main beams, support legs, end beams, ground beams, walkway railing, trolley track, limit installation and cab installation) and so on. This kind of crane is usually used to lift large and heavy items on various occasions.

It is made up of bridge, trolley, crane traveling mechanism and electric system. All the procedures are finished in the operating room. Applies to the open warehouse or rail along for general handling and lifting work. Also can equipped with many lifting device for special work.

With double girder gantry cranes, the cost, the easiness of maintenance and reparation, no capacity limitation, no size limitation, the designing and production of desired features are possible because each branch of the company is being used in an efficient manner.

Double beam gantry crane carrying capacity is strong and the span can be very large. The overall stability is good. Compared with single girder gantry crane, the overall rigidity of the double form is stronger. Because the gantry crane has two girders, the entire structure has stronger stability.

The composition of the double beam gantry crane is basically the same as that of the overhead cranes, except that the main girders are supported by the legs.

The differences between double gantry crane and single girder cranes. When you are installing a gantry crane at your worksite, you have a couple different options. The first, and most common, is to install a single girder gantry crane. The other option is a double girder gantry crane. Double girder gantry crane is heavy gantry crane with double girders, which is widely used for general purpose. Double girder gantry crane are heavy duty crane, used at indoors and outdoors places where overhead crane runways are not practical.

We offer different types of gantry cranes for you to choose from. According to the trolley configuration, the cranes can be divided into single trolley and double trolley gantry crane. Usually, the double girder gantry crane is designed to move, lift or transport heavy materials that reach 200 ton or ever more. Compared with the single girder gantry crane, the double crane gantry girder holds bigger lifting capacity and higher working duty, so the double beam crane is widely used in stock yard, harbor, outside warehouse and rail terminal and so on.

RAMHOIST can specify, engineer, and build your cranes for the toughest applications. Each crane is designed to CMAA specifications. Features of Double Girder Gantry Crane Adopting to double girder box-type welded structures in order to enlarge working space. Using anisotropic rail cable conductive device. Different modes of power supply can be chosen such as cable reels and sliding wire mode.

Double girder gantry crane for sale are a type of crane built atop a gantry, which is a structure used to straddle an object or workspace. Gantry cranes can be operated from the ground via cable-connected control pendant, radio remote control or from cabin. In addition, multiple controls are possible by switching control from one mode to another.

A-type double girder gantry crane with hook are used for handling and lifting materials in open storage, stock ground, railway freight station, ports and so on. It can also carry out some special operations by equipped with various special lifting tools.

A-type can be with or without cantilevers as designed. When the crane has cantilevers , there will be saddle set on top of main beams of the crane to meet structure needs. If the span is greater than 35m, there will be rigid supporting legs and flexible supporting legs, and the latter are designed to compensate for structural deformation caused by temperature difference

U-type double girder gantry crane is a sort of heavy duty lifting equipment distinguished by the fact that it has larger space between legs than A-frame gantry crane, which enables it to lift and move large-sized goods like containers. Box type double girder gantry cranes composed of gantry, crane crab, trolley traveling mechanism, cab and electric control system, the gantry is box shape structure, the track is at the side of each girder and the leg is divided into type A and type U according to user's requirements.

Compared with the single girder crane, double girder gantry crane is more powerful and the gantry crane design is more complex. We attach great importance to product's reputation. So, we never try to attract customers by a low gantry crane price with the inferior quality