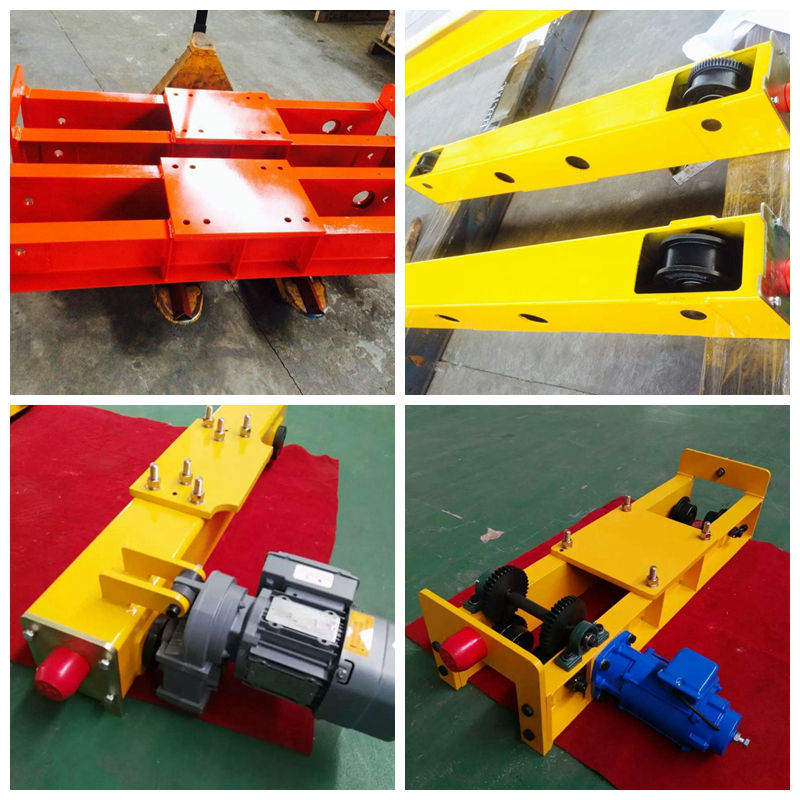

Different Capacities of End Trucks made in china

Keyword:End Trucks Time:2020-4-2 10:59:12

RAMHOIST end trucks are high quality components, designed for reliability and economy. The steel structure of the them is a torsion-resistant box girder, prepared to be connected to the crane girder. Precise machining and exact alignment of the crane girder mounting plates ensure unsurpassed travel characteristics and long life.

It is also called End carriage which is applicable for wide range of cranes, such as workshop overhead bridge crane, gantry crane, etc. An End Carriage in basic terms is one of the set of carriages that support the main crane gantry, they feature Drive units that transport the crane structure up and down the workshop length. They ride on the runway rail and move the bridge crane.

Our end Carriage can be supplied with a wide variety of drive options. single or two speed; They carry the hoist and bridge of the crane up and down the cranes' runway.

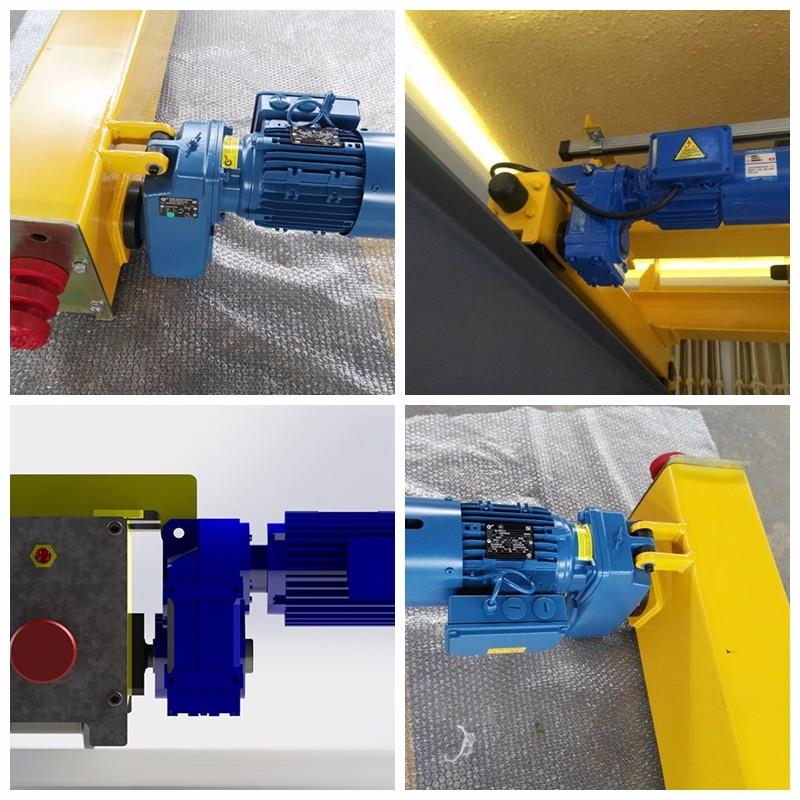

Features include Geared Brake Motor, Steel Frame Construction, Anti-Drop Plates & Rubber Stop, Travel Wheels.

Models include Top Running, Under Running, Motorized, Hand Geared and Push/Pull, Custom Builds, in other words, there are Top Running Advantage End Truck, Under hung Advantage End Truck, Custom End Trucks, Bogie Style End Trucks, Giant Custom End Trucks

There are two main designs:

Fixed Axle

A fixed axle has an exposed gear on the wheel.

Requires maintenance to keep the exposed gear lubricated.

Fixed axle end trucks are class C Duty cycle.

Rotating Axle

A rotating axle’s wheel is directly driven by the motor through a gear box.

Requires less maintenance.

Rotating axle end trucks are class D duty cycle.

Minimum of 10,000 hours of wheel bearing life.

They are available in a variety of top and under running designs and are specifically designed to suit your crane's application.

For assembly, maintenance, machining or general industrial operations, this end truck kits offer a medium duty, push end truck design that can be assembled for either top running or underhung cranes. Kits include: two end trucks; rubber bumpers; bridge beam fastener set; trolley stops; beam fabrication instructions; and assembly and installation guide.

Kit includes one set of end trucks ( new in box ) With rugged C-Channel design, anti-drop plates, high strength ductile iron cast precision travel wheels and a wide variety of resilient gear motors, both top running and under running end trucks are designed to perform under the most demanding conditions.

These Crane bridge kits contain all the parts needed to build underhung single girder crane bridges, except the bridge beam,cross shaft and trolley stop angles. An illustrated, easy-to-understand assembly manual is included in each kit.

All trucks are fully painted. Bridge fabrication prints are also included.

They are high quality components, designed for reliability and economy. The steel structure of the end truck is a torsion-resistant box girder, prepared to be connected to the crane girder. Precise machining and exact alignment of the crane girder mounting plates ensure unsurpassed travel characteristics and long life.

Fully machined frames are convertible for either top running or underhung use. Frames are fabricated from structural steel for optimal strength and rigidity. Wheels are ductile iron and precision machined to roll smoothly on either flat or tapered flanges. Each wheel features a shielded deep groove ball bearing. All-bolted for ease of assembly. Drop stops and rail sweeps standard. Max Span 24' on center between runways.

The Crane's end trucks and bogey assemblies are manufactured to the stringent quality requirements and international standards and equipment is factory tested prior to shipment.

They employs durable urethane wheels developed by KITO and an idling gear in reinforced nylon resin and reduces noise and vibrations in travel. Both the track wheel and track wheel axle are designed for easy detaching thus reducing installation maintenance time.

These popular end trucks meet the bearing life requirement of 10,000 service hours. Now, they are also available in standard bogie configurations that are both economical and easy to install.

UP end trucks provide similar benefits to the UM underhung motorized truck(Motor Driven Underhung End Trucks), but for push operation.

With the backup of high quality manufacturing facilities and solid technological strength, we have been pursuing the service principle of “quality first” for many years, providing qualified goods for customers

We are committed in providing our customers with quality and customized service.

We have the in-house capability to build specialized end trucks to meet your needs, and there is no limit to the types of applications we can produce. Most manufacturers offer standard end trucks only, and do not offer customization. With us, it does not matter what you need, because we can do it.

We can provide either normal type end carriage for your bridge crane or a set of custom end carriage for a particular application, Our experience in the design and manufacture of them for the material handling industry is quite extensive

We supply top running and under running end trucks in a rugged channel design for both single and double girder overhead cranes up to 20 tons.

A wide range of Crane End Carriage is available for customers’ choice. They are designed for single girder crane, double girder crane range from 1~50ton(standard), other capacity can be customized.