Industrial 10 Ton Double Girder Top Running Electric Overhead Bridge Crane Kit

Keyword:Crane kits Time:2019-4-13 0:12:59

The Cranes are designed in accordance with ISO 9001:2000 ISO 14001:2004 and OHSAS 18001. The crane girder is produced by robot welding to get integrated structure and light dead weight. The wheels of crane crab, main beam and end carriage are produced in our special Vacuum casting workshop (No sand inclusion technic) which makes our wheels more elastic and outer surface hard-wearing and durable.

Detailed description

1.Main girder

It is per IS 807/IS 317/IS80

These are fabricated; plate box in construction or standard I-beams of M.S. rolled steel sections bolted to end carriages. Box girders are fabricated by Q345B steel.

2.Crane wheels

Two nos. Straight tread type, End-8 forged steel, double flanged LT wheels are protected in each of two end carriages. These wheels are supported on steel Axies/L-blocks.

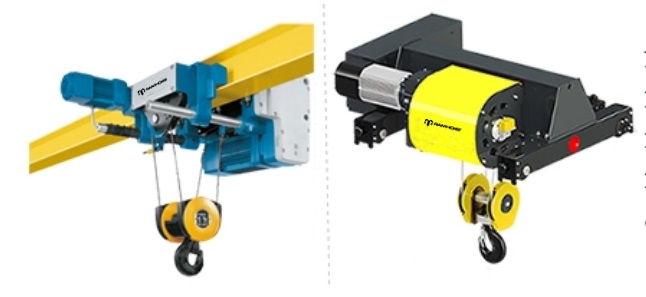

3.Electric Hoist

Higher lifting speed for faster handing. High efficiency due to 20% longer service life. Compact design for optimum utilisation of space.

4.Crane hooks

The rope sheaves are fully guarded with protective steel casting. All sheaves rotate and ball bearing. The pulley is thick and dilated than domestic common pulley.

5.Electric box

Modular design, easy to install and maintain, reliable operation, fuse less circuitry, ducted wiring and compact terminals. Motor overload protection to prevent overloading.

Safety components of crane kits

Traveling limit switch

Protect the crane before it crash the object.

Lifting limit switch

For lifting protection, prevent the hook from knocking the hoist.

Overload limit switch

For lifting protection, monitor the crane situation.