360 Degrees Rotation Indoor Outdoor Mini Lifting 1ton Engine Hoist Crane with Diesel Engine for Construction

Keyword:Mini Construction Cranes Time:2019-4-16 10:39:03

The difference of some parts of our engine for Mini construction cranes between other company and us.

Note: About the below picture, the left picture belongs to other company, the right picture belongs to our company.

1.Engine Cover

Our company: The material of the engine cover adopts the national standard JIS ISO2006 aluminum alloy ADC12, based on the acceptance standard of GB/T1085 casting aluminum alloy pinhole.

Other factory: The material of the engine cover mostly adopts the recycling mix aluminum.

2.Engine Stator

Ours: The stator wires apply with the180-grade ultra high temperaturer enameled wire and F-grade low insulating varnish which can effectively solve problems of electricity leakage and multilevel copper winding.

Others: The stator is made with the inferior copper wires which have the disadvantages of thin wire, small power of the engine and lower strength which lead the strong engine heating so that the engine is easy to burn.

3.The back cover of the engine

Ours: We adopt the ADC12 material to make the engine much more effective.

Others: They adopt the inferior material and rough machine.

4.Gearbox case

Ours: The gearbox case much bigger and thicken and have long lifespan more than 3 years. The bearings on the gearbox case also become much bigger. What's more, our factory design 2 oil-filling holes on the one side of gearbox case so that it is convenient to fill oil and extend the lifespan of the gearbox case usage.

Others: It is the old-style gearbox case which has the features of small weight and thinner case and short lifespan so that it can easily to get broken. And there is one filling hole on the gearbox case, so it is not convenient to fill oil.

5.Rotor

Ours: The engine rotors increase 10% in diameter and length and apply with 600-grades sheet steel which can decrease the electricity loss so that the engine is powerful in the continuous work.

Others: The engine rotors are thinner and shorter and apply with the ordinary steel plate and iron plate as the raw material which can increase the electrical and make the engine produce heat particularly fast so that the engine has no spark in work after a short while.

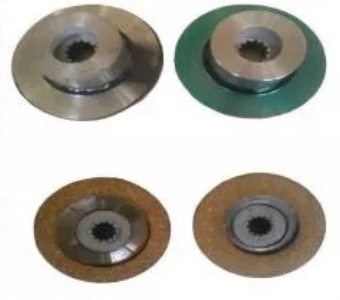

6.Brake Block

Ours: The brake block applies with the synthetic rubber res in as the raw which can make the brake much more stable, safe and durable.

Others: The brake block is the ordinary material which can lead the brake synchronized and unstable so that it often break the goods when the brakes in the work.

7.Capacitance

Ours: We use the anti-bending snap ro prolong the lifespan of the cables button core adopts the flame retardant material. All the touching points are silver. The appliances adopts the special high voltage membrane.

Others: The touching points of the capacitance are pure copper kind, the inner are copper kind.

8.Fan Blade and Fan Cover

Ours: We adopt the high quality nylon engineering material, the fan blade has a good performance of the heat-resistance and coldness-resistance. Ours is equipped with the real standard copper wire, it is not easy to bum and has long lifespan. The 2 fans on the both sides of the engine can help the engine to efficiently dissipate heat, which can effectively control the engine's temperature and extend the working time and guarantee the working efficiently.

Others: They mostly adopt the recycling material so that the performance can not be guaranteed. It is the non-standard aluminum core fan.