China manufacturer DHP type electric chain hoist for group lifting

Keyword:DHP Electric Chain Hoists Time:2019-10-16 22:57:03

Product description

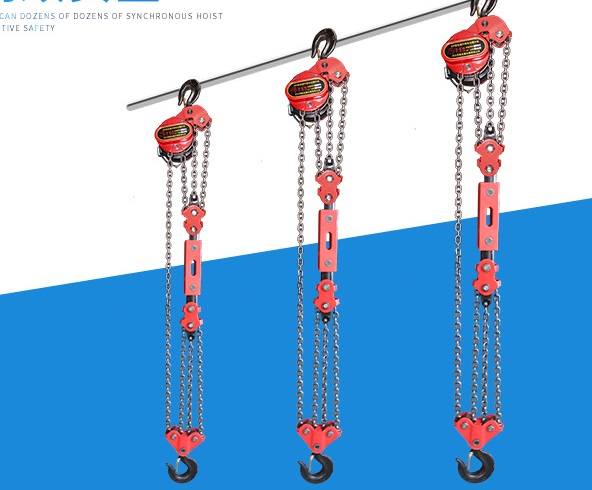

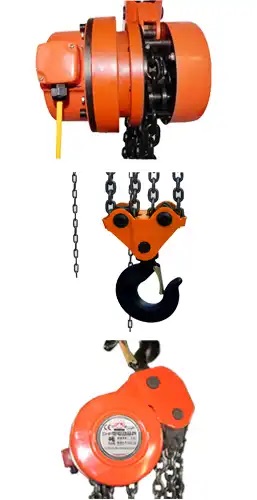

DHP electric chain hoist made in china is also known as "climbing frame electric hoist", "welding pot electric hoist", "oil tank electric hoist", "group hoist electric hoist", etc. DHP electric chain hoist has a number of technical patents, product related qualifications, sales growth. All products produced by eagle are insured by PICC, the people's property insurance company of China.

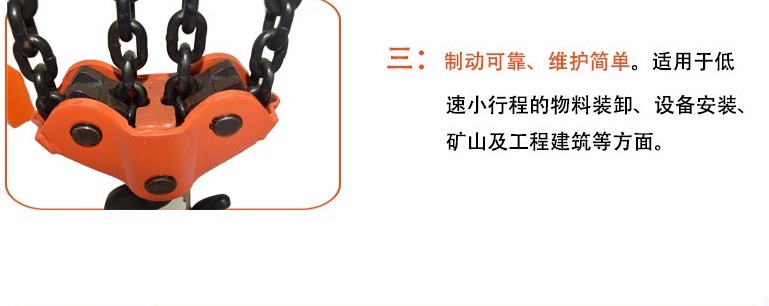

1. The motor adopts disc brake motor with brake device, braking rapidly and positioning accurately.

2. The reducer adopts the planetary gear structure, the gear adopts the diamond sutra heat treatment, the precision work is produced, the noise is low, the service life is long, the operation is stable.

3. The gearbox and the outer shell of the external impact will not be damaged when the shell of alloy steel is used.

4. The product structure is compact, easy to use and safe and reliable.

Model DHP5T DHP7.5T DHP10T DHP20T DHP30T

Rated load(T) 5 7.5 10 20 30

Test load(Gn) 1.25 1.25 1.25 1.25 1.25

Motor power(kw) 0.5 0.5 0.5 0.5 0.75

Supply voltage 380v 50Hz

Hoisting speed(m/min) 0.09 0.18 0.12 0.09 0.09 0.06

Minimum distance between two hooks(mm) 200 600 660 730 1040 1480

Line number of lifting chain 2 3 4 8 12

Standard lifting height(m) 3

Diameter of lifting chain round steel(mm) 10 10 10 10 10

Net weight(kg) 58 70 95 195 285

Packing gross weight(kg) 69 80 108 225 325

Packing dimensions (length x width x height)cm 56x40x40 50x42x49 61x48x48 70x60x44 95x81x53

Lifting height increases by 1 meters per additional weight(kg) 4.4 6.6 8.8 17.6 25.2

Usage rules:

1. Do not overload use.

2. It is forbidden to slant and pull, and it is strictly forbidden to walk or stay near the weight when lifting or lifting.

3. When the hoist does not rotate or have abnormal sound, it should stop immediately and then uninstall the inspection.

4. Frequent use, refueling once per week, continue to use, refueling once a month.

5. Collision and percussion-lifting machines shall be strictly prohibited and the storage areas shall be dry and ventilated.

6. The maintenance of this product shall be carried out by professional personnel and shall be operated by professionals with certain mechanical and electrical knowledge and shall carefully read the product instructions before use.

7. Before using, check whether the power supply meets the requirements and operate according to the standard of the electrician, and the correct operation can be performed after checking correctly.

8. Check whether the brake is reliable before use, check periodically whether the parts are normal and should be free of loose and oil leakage.

9. The test operation check whether the chain wheel and the chain are engaged, and there is no chain phenomenon allowed.

Our company can also produce all kinds of non-target electric hoist and manual hoist according to customers' samples and design drawings to meet the different needs of customers. We adhere to the principle of the first productive forces and strictly enforce the quality standards, from the purchase of raw materials to the transportation of goods. Our goal is to meet 100% of the hoists quality and ensure the quality of the hoists.