Experienced Lever Hoist OEM Service Supplier

Keyword:Lever Hoist Time:2019-6-15 21:55:36

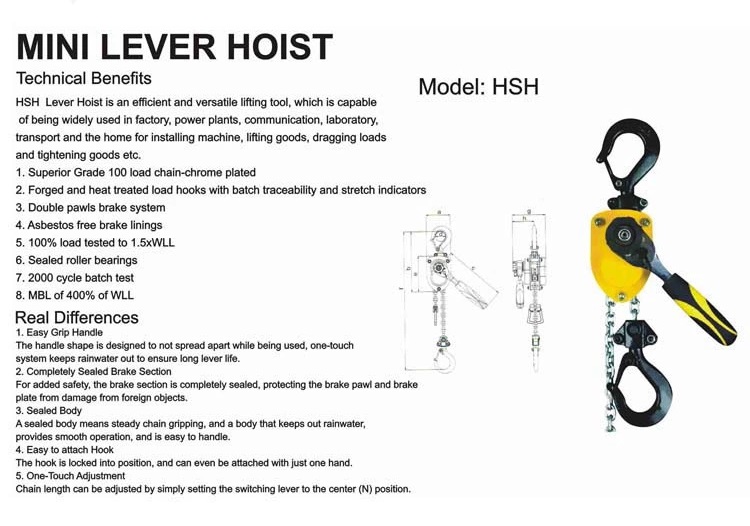

HSH lever hoists 2

Brief introduction

HSH 0.25ton to 1.5ton mini hand lever hoist are simple, portable and convenient manual lifting tools. They are manual lever hoists used to lift and pull loads. It utilizes a ratchet and pawl mechanical configuration to incrementally raise or lower a load or to apply or release tension, The product is very easy to install. For lifting, the hoists are usually attached to clamps or trolleys.

Features:

1. All structural steel.

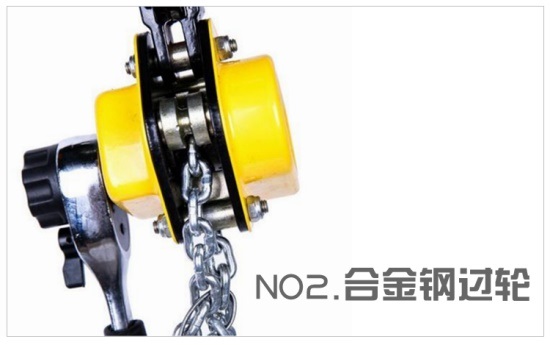

2. Lever hoists' covers are made of high strength alloy steel which are impact-resistance, well protect the inside parts.

3. All gear rotation.

4. There are bearings or bushings in the rotation of the gear and shaft.

5. The surface of the product is sprayed with plastic.

6. Professional alloy hooks can satisfy the overload of products.

7. Upper and lower hooks are made of high strength cast alloy steel and heat treated, which prevent the hooks breaking even when overloading, with safety latch.

A Lever Hoist is a piece of high-quality equipment used to lift and lower heavy loads without the aid of machinery. Lever Hoists have the ability to lift items in most positions, including horizontally. Different from the Chain Block or Hoist, which can only lift items vertically, the Lever Hoist's ability to lift items horizontally is a great benefit.

A Level Hoist is usually fitted with a heavy-duty safety cap to hold your items comfortably and a top swivel connection which will allow easy lifting from all angles. The hand wheel can then be turned to release or retract as much chain length as required. The ratchet lever attached to the side of the lever hoist allows the chain to be free-willed when placed in the neutral position. When placed in the up position, it tightens the chain allowing the load to be lifted with the tension.

Finally, to lift the load, crank the heavy-duty lever until your load has reached a suitable height. To lower the load, the ratchet lever must be switched to the downward position and the heavy-duty lever cranked to lower the chain.

It has the advantages of safety, reliability, durability, good performance, easy maintenance, small size, light weight, convenient carrying, small hand force, high efficiency, perfect structure, beautiful appearance, etc.

Lever hoists are usually used when the user is required to hoist the load up towards the top hook where the user is positioned and has access to operate the ratchet lever. If hoisting from ground level, you might require a chain block (Hand Chain Hoist).

Why should you use a lever hoist?

-

Portability is the principal reason for use of a lever hoist.

-

Initial cost is another important reason why lever hoists are often chosen over powered hoists.

-

Lever hoists provide excellent spotting capability.

-

They need little maintenance.

-

Reparability for premium models is excellent.

-

Flexibility of operation.

-

A lever hoist has no electrical components to cause sparks or arcing in explosive classified areas.

When should you use a lever hoist?

-

When the lift is not vertical.

-

When portability and flexibility are the key concern.

-

When initial cost is an overriding concern.

-

When precise spotting of the load is required.

-

When electric or air power is not readily available.

-

For temporary uses such as installations, portable job boxes, etc.

Which lever hoist should you use?

-

Use an economy model when initial cost is important but reparability and high efficiency are not.

-

Use a premium model when dependability and quality are important considerations.

-

Use one with a rated capacity no greater than the structure on which it will be placed.

-

Use one with a capacity sufficient for the job at hand.

-

Use one with an effort required, that is suitable for the operator.

General Lever Hoist Selection Tips

-

Warning: Lever hoists are the cause of most hoist related accidents in the workplace. Often this is due to overloading of the hoist through the use of a leverage aid (such as a cheater bar). These leverage aids can severely overload the hoist and cause failures of the hoisting mechanism, including dropping the load. If the load cannot be lifted without a leverage aid, please select a higher capacity hoist or contact a rigging or hoist expert for help.

-

Premium lever hoists differ from the economy models in the amount of machining done, and quality of materials used in the manufacturing process. Better materials and more machine work have a higher cost but produce a more efficient and reliable hoist.