User Manual of Pallet Wrapping Machine

Keyword:Pallet Wrapping Machine Time:2020-11-23 14:10:08

User Manual English

Pallet Wrapping Machine

Contents

1. Information on the pallet Wrapping machine ….………….………….......1

2. Main Technical Index of the T Series …...…………...……..……….......2

3. Repair Guarantee to the Product. .…..….…..….…..….…..………..…..…3

4. Installation & Transport….……………………………………………......5

5. Operating Instructions to the Controlling Pane……………………….…..7

6. Equipment Maintenance……………………………………………….….8

7. Put into Use……………………………………………………………....9

8. Performance of the Functions & Others……. ………………………..….11

8-1 Error in Counting………………………………….………….............11

8-2 Instructions to the Operation of the Photoelectric Switch……….12

8-3 Sketch Picture of the Operation on Film. ………. ……...........…..... 12

8-4 Moveable Location-Limit Block……………. ………. …........…….13

8-5 Film-Stretching.………………. ………………. ........……….. ……13

9. Safety in the Use………………. ………. ……. ………………. ………14

10. Noise and Vibration……………. ………. ……. ………………. ….....15

11. Equipment failure and possible solutions…………. ………. …….…..16

12. Appendix…………………. ………. ……. ………………. …….. …...17

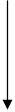

Appendix 1 Outlook of the Packager……………..………………...…..17

Appendix 2Warning Signs……….……………………………………..18

Appendix 3Picture of the Operating Panel………….……………….....18

§1 Information on the Pallet Wrapping Machines

1. With the LLDPE stretching film as the packing materials, this device is professional in the packing and wrapping of stock goods.

2. The packing cost will be reduced, a more convenient storage and transportation will be achieved and an easier recycle of the packing materials will be conducted with the application of the TP and Y series stretch wrapping machines, thus ensuring a less polluted environment. This is currently one of the popular environmental-friendly packing methods.

3. The application of this kind of packing method has extensively covered glass manufacturing, paper-making, mechanical manufacturing, the chemical industry and the food industry, especially the container goods transportation in foreign trade.

4. Besides the basic stock packager, has produced various stretch wrapping machines in such types as cylinder paper/shade cloth, cable, plane and cylinder radial. We also produce other packagers for brown paper, EPE, the ordinary PE film, etc. Please contact the marketing department of our company for details.

5. The product cannot be used on the outdoor or explosion environment

§2 Main Technical Index of the T Series

1.Packing Standard:

Min. Standard: 500mm(L) ×500mm(W)×500mm(H)

Model | Max. HT of the Goods / the Route(mm) | Turntable diameter (mm) |

1650F 1800F 2000F 2200F 2400F | 2000m/2400mm/2600mm/3000mm/3200mm | Ф1650mm/1800mm/2000mm/2200mm/2400mm |

2.Turntable loading:2000 kg(special type exclusive)

3. Materials:

Materials | Width | Thickness | Inner Core of the Film Scroll | Outer-Dia. |

LLDPE Stretching Film | 500 mm | 17-35μm | 76mm(3 inch) | ≤254 mm |

4.Power Supply:220V/50HZ 20A -1ph

The power must be separated and fixed, any temporary wire or co-wire with other devices is prohibited. The voltage is 220v. Please check the live wire, neutral wire and ground wire when connects. (Damages on the device or others caused by improper power supply are invalid in our repair guarantee.)

5.Power:1.55KW

6.Weight:650Kg

7.Working Speed:20-40loads/hour

8.Revolting Speed:0-12rpm/min

§3 Repair Guarantee to the Product

1. The manufacturer bears all the repairing costs of the product for one year since the very leaving of the product from the manufacturer under the prerequisite that all the installation, repairs and operation are in accordance with the set requirement. Users should bear other costs.

2.The manufacturer reserves the right to determine whether the non-performing component is to be repaired or changed.

3. The manufacturer reserves the right to search the causes of the failure.

4. Any damages, caused by improper usage (unqualified power, improper operation, etc.) or artificial factors, are excluded in the repair guarantee.

5. The manufacturer is not responsible for any losses except the packager itself.

6. The manufacturer is not responsible for the damages caused by the repairing of unqualified technicians.

7. The manufacturer bears no free requirements or improvements towards the packager that are excluded in this guarantee or the purchasing contract, except that the manufacturer is willing to do so to upgrade its products.

§4 Installation & Transport

1. Check and find whether the packager, its components and accessories listed in the encasement menu are all included and find whether there is any damage to the packager. (Please immediately negotiate with relevant transporting departments or contact the delivering party in case of any damage mentioned above.)

2. Check the qualification card to make sure that the product you purchased is qualified and meets your ordered requirements.

3. Open the package in the marked position (note: avoid any damage to the device); check the device and its accessories, following the random encasement menu.

4. Please read this instruction carefully before install, adjust and operate the device.

5. This device should be installed in a dry place where there is no dust, no leaking, no flammable or explosive chemical preparations or other things eroding. The surrounding temperature should range from –10 to 50oc.

6. Put the rotating-plate part of this device on a level up ground and connect the guiding erecting pole with the rotating-plate part properly. Install the sloping part (accessory, purchase independently) on the same level as the rotating-plate part; make sure that it is convenient for the loading and unloading of goods and that a sufficient location and space is preserved between the sloping part and the rotating-plate part. After this, install an expanding screw (self-provided by the client) to fix the device.

7. Adjust a proper level in installing the packager with cap device and make sure that the platen center is in the same line with the rotating-plate center.

8. Check other connecting parts to find whether the electric joint is less screwed or falls off. Please fix the less-screwing or falling-off accessories and wires in time.

9. A correct, stable, credible and fixed power supply is a must.

(Any temporary wire is prohibited.)

10. Connect generator wire(U2,V2,W2,PE) and the down-lead of the sensor(X0,24-,24+) with the line of the below terminal block. Only after the down-lead of the device is properly powered and a grounding test is carried out can the test operation be conducted. Pay attention to the positive and negative directions of the generator when connecting and make sure that the operation is manual when confirming the running directions.

11. Check and find whether there is damage to the location-limiting switch and its arms and the location-limiting block, whether they are in proper position and are operative normally.

12. The chains and decelerator of the device have already been lubricated or oiled before leaving the manufacture, please confirm before operation.

13. The photoelectrical switch does not in process and the film system is ascendable (for universal types) when no goods are loaded.

14. Switch on the power and turn on the air switch, power-controlling switch of the operating panel in the electric cabinet consecutively. The device will be ready for operation test and adjustment after it is powered and self-examined.

15. Transport the machine in two parts, one is the frame, the other is the turntable. But the two parts is together

§5 Operating Instructions to the textscr

Please refer to Appendix 3--- Picture of the Operating Panel

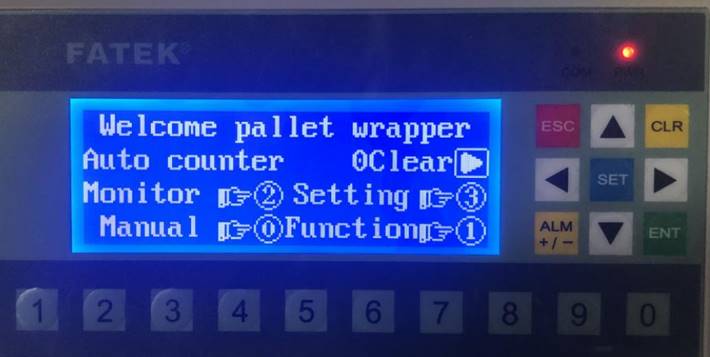

The introduction of the main menu

Auto counter:It is a counting function that comes with the machine, counting is in automatic state, it will shows the number of the pallet loads you wrap together

Press 0,1,2,3 ,then the textscr page will go to corresponding page.But usually don’t need press 2.(If machine have problem,then we can press 2 to check)

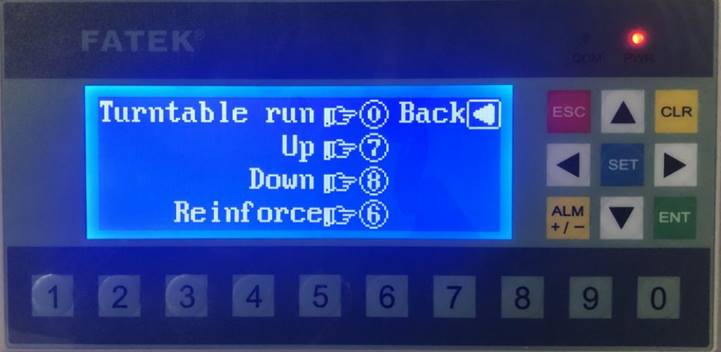

***Press 0, then page go to the manual page. Picture like below:

Turntable run: Press 0, then turntable will be running; Press again,the turntable will be stop.

Up:Press 7, the film carriage will go up

Down: Press 8,the film carriage will go down

Reinforce: It refers in auto wrapping mode, press 6,the film carriage will stop, and wrapping another cycles in the stop position.(Partially reinforced wrapping, the wrapping cycles can setting in the parameter setting ie: Reinforce times )

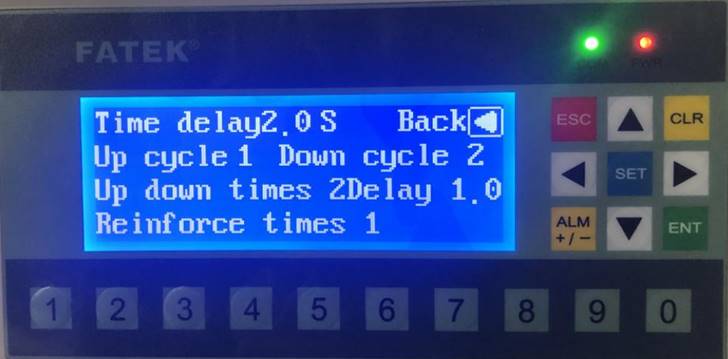

***Press 3, then page go to the setting page.Picture like below:

Time delay: setting the time delay when the film system arrive to the highest position(ie: setting 2 second, then after the photoeye sensor the height of the cargo, delay 2 second, then the film carriage will stop)

Up cycle:(the layer you want to wrap at the top of the loads):press the set on the right, the cursor will glitter, then you can input the figure.

Down cycle:(the layer you want to wrap at the bottom of the loads):Press the set on the right.the cursor will glitter, then you can input the figure

Up-down times :(the times of layer of Traverse, up-down)If it set 1, the film carriage will rise to the upper limit and then stop. If it set 2, it means that the film carriage will drop to the lower limit after reaching the upper limit. In general mind, it means that the film carriage will go up and then go back and forth. By analogy, setting an odd number means that the film carriage stops up, and setting an even number of times means the film carriage stops down.

Delay: it only use the wrapping cycle in 1,3,5,7 etc. We usually setting 99s, then film carriage will go down from the highest position to the origin position.

Reinforce times: setting the wrapping cycles when press the reinforce

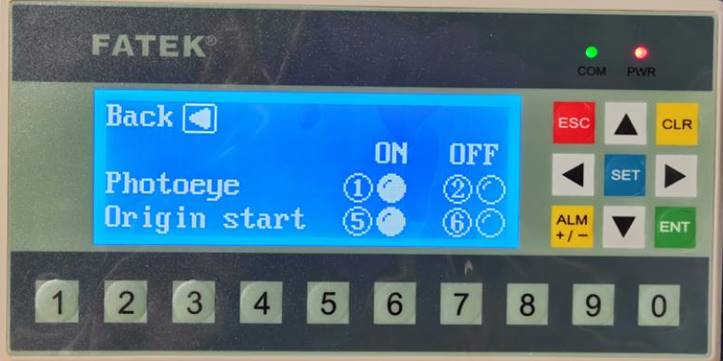

***Press 1, then page go to the function page.Picture like below:

Back: Press![]() Page will go to home page.

Page will go to home page.

Photoeye: Press 1, photoeye valid,press 2,photoeye invalid

Origin start: Press 2,Turntable will be start at the origin place directly

Press 6,Turntable must find the origin first, then start wrapping.

***Press 2, then page go to the monitor page.Picture like below:

Press Next page, page will go to below:

These two pages don’t need to check if the machine working fine. If machine have problem,please check the electrical drawing and check the monitor page.

§6 Equipment Maintenance

1. Keep the space between the inner chain and the outer one lubricated by daubing the H20-HJ40 chemical oil. Tense the chains to eliminate the wobble in the ascending-and-descending process of the film system.

2. When the turntable slows or skids, open the cover of the generator, loosen the four connecting screws on the decelerating panel and adjust them to tense the screws clockwise till get the needed tension. Then switch those four screws tightly.

3. The carriage up-down process, the driving of the turntable and the film system are motivated by the activator with worm wheel and worm. Please obey the following instructions in process:

a) Apply the lubricated oiled decelerator. The deepness of the oil should be the same as the full-gear height of the worm if the worm is below the worm wheel or beside it. If the worm is above the worm wheel, that deepness should be 1/3 of the height of the outer diameter of the worm.

b) It is recommended to use synthesized worm oil 200# (the viscosity is 320 when the temperature is 40oc)

c) That deepness should be half of the height of the oil mirror if there is one. The central distance a=63mm and it is suggested to add 400ml.

d) The oil should be renewed after a 7-14 days of maiden operation. After this, the oil should be renewed once annually.

e)The surrounding temperature should range from –40 to +40oc. The lubricating oil should be the one with low freezing point when the temperature is below 0oc.

4. Load the goods stably and handle them slightly to avoid the distortion of the under-pan or the shortening of the life of the components.

5. The height of the goods should not exceed the set one. Otherwise, the packing will be undermined.

6. To ensure a normal operation, the electric cabinet should be closed tightly and the components and the joints of wiring should be cleaned and checked periodically.

§7 Put into Use

1 . Manual Operation:

Lower the film system to the bottom, load goods on the turntable and put the film scroll on the scroll seat. Thread the film properly in accordance with the requirements (see film-threading methods §8-3) and then start the turntable generator to activate the turntable and the film will wrap the bottom part of the goods. When the wrap amount meets the requirement, press the carriage up button to lift the film system to the required location (photoelectrical height-measuring is effective) and press the carriage down button to lower the film system to the bottom. Repeating the above-mentioned process will complete the packing, press the stop button to halt after this. It is suggested that manual operation is mainly for the adjusting on the machine.

2. Automatic Operation:

Restore the machine in its initiative state, load goods, thread the film properly and set the top circle amount and the bottom circle amount, up-down times, ,then press the auto-start button, the whole process will be completed automatically. To enforce enwinding, press the auto-Start button during the ascending or descending in the auto-process. Auto-running is strongly recommended in this machine.

3. Brief Introduction to the Auto-Running

Press auto-start when the machine is in its initiation (see the auto-run of §5) and the rotating-plate begins to speed-up (performs constant running when reaches its max. speed). When the film outputs with the running of the turntable , the turntable begins to count and the film system begins to ascend when the number meet the set parameter on the bottom. Re-press the auto-start during the ascending process of the film system, the ascending will pause and the turntable will run and count the circle amount The film system continues its ascending process after the enforcement meet the set parameter. The film system ascends till the goods beyond the irradiation of the photoelectric switch. The times should be counted as 1 and the rotating-plate continues to run and count. The film system begins to descend when the machine meet the set roof circle amount and stops at the bottom. The times should be counted as 1 again and the machine begins to count the bottom circle amount. The ascending and descending process repeats till reaches the set parameter and then the packing is complete. The rotating-plate decelerates slowly and stops at the initial checking and measuring point.

§8 Performance of the Functions & Others

8-1.Error in Counting

The counting begins when the film system reaches its highest location in the auto-process, if at this time the sensor and the testing point are not at the same place, usually the roof circle amount does not appear as a integer. To ensure that the error is no more than half a circle, the circle amount can be increased or decreased, depending on the specific situation. The counting on the bottom circle amount after a circulation occurs as the mentioned-above.

8-2.Instructions to the Operation of the Photoelectric Switch (SICK)

8-2-1 It is suggested that the set parameter of the photoelectric switch should not be adjusted frequently under the usual circumstance, for that will cause mal-action of the machine or damage to the switch.

8-2-2 The photoelectric switch will be ineffective under the sun or the halogen light and if the goods are colored glass items, items with low reflection, items with large space between their components and transparent items. In this condition, the switch should be adjusted in accordance with the methods mentioned . If this method does not work, then use the spare location-limiting block (§8-5) and turn the button in the electric cabinet to OFF to screen the photoelectric switch. The effect of this method is the same as or even better than that of the height-measuring by the photoelectric switch. The above-mentioned button must be turned to ON if the automatic height-measuring method is adopted.

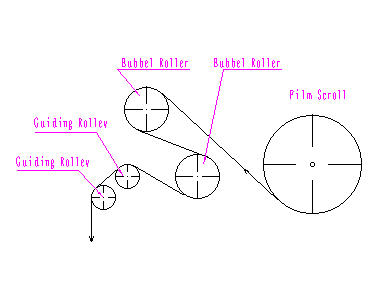

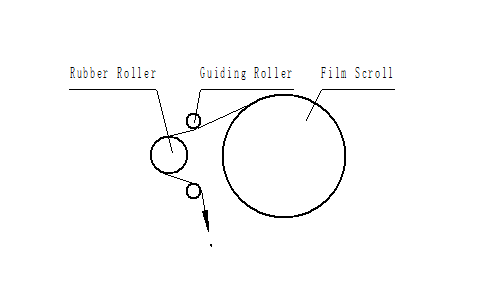

8-3.Sketch Picture of the Operation on the Film: Please thread the film as guided below.

Diagram 1 (Pre-Streching)

Diagram 2 (Block-Streching)

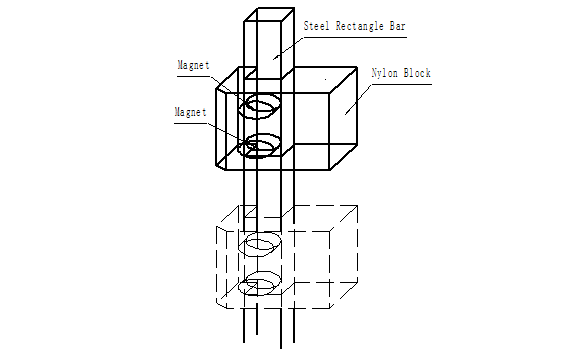

8-4、Movable Location-limiting Block

As showed in Diagram 5, the location-limiting block, which moves freely along the location-limiting guiding-bar, is made of nylon block embedded with magnet. This block moves freely between the upper fixed location-limiting block and the lower one to meet the requirements of the client when the function of the height-measuring photoelectric switch is contained.

Diagram 5 Movable Location-Limiting Block

8-5、Film-Stretching

8-5-1 Capability Features of the LLDPE Stretching Film

The film brings backpressure to the being packed, thus protecting the latter. The backpressure of the film is produced by the stretching. The cohesion reduces skidding and causes a repeating effect, forming a dynamic coat.

0-40% Min. memory

40-75% Memory begins to react

75-100% Medium backpressure

100-200% Backpressure that easily attains max. percentage

200-250% It is suggested to chose proper films and stretching equipment to attain max. stretching

250%+ Affected by the stress, the film begins to intensely loose

300%+ Memory damaged, the film only equals to plastic film

8-5-2 Pre-Stretch:

According to the capabilities of the stretching film listed in §8-6-1, only the pre-stretching proportion of the pre-stretcher is set at 1:2.5 can the pre-stretcher perform its best. The pre-stretching proportion of this packager is based on the above-mentioned and is in conformity with the requirements of film tension in §5 Operating Instructions to the Controlling Panel, according to the test conclusion. The result will be the best when it is wrapped above the goods. The spring amount in the width of the film is about 10%.

8-5-3 Block-Stretch:

Generally the result of the block-stretching method does not match that of the pre-stretching, for the protraction of the film produced by the former method is counteracted by the width and thickness of the film. The requirements vary in accordance with the specific packing method. With a relatively strong single-layer restriction and a lower cohesion, the block-stretching method can enhance the part placement

§9 Safety in the Use

1. Test on the voltage of the controlling panel of direct current generator and that of the meg-powder arrester or between the PLC inputting point and the ground wire is prohibited.

2. Check and find whether there are less-crowdedness or fall-off in the joint between different components periodically during the normal performance of the machine. If any, restore them to their original.

3. Moving or removing the fixed upper or lower location-limiting block is prohibited!

4. The rotating-plate of the machine should run clockwise.

5. Standing or piling goods below the film system is strictly prohibited!

6. To avoid damaging the rubber roller or hurting the finger, do not put hand or other things into the film system when the roller is running!

7. The operator should stay in a safe place and keep a certain distance from the rotating-plate during the process of the machine. To avoid any hurt on the people in case of goods falling-down, the operator should not approach the machine until a process is completed and the machine stops. A safety isolating net (self-provided by the client or ordered separately) should be installed if necessary.

8. To avoid any damage to the machine or any hurt on the people by the leakage, the ground wire connecting or the neutral wire connecting should be firm and reliable (a mixed connection of the neutral and ground wire is prohibited).

9. The re-installation of and the re-test on the machine should be carried out by professionals after the removal of the machine from its original place. The machine should not be put into operation before its safety capability is re-tested by professionals.

10. The checking on the electrical equipment and its joints and the cleaning of the electric cabinet should be carried out periodically.

§10 Noise and Vibration

This noise level of the machine don’t exceed 70 dB (A) during normal working. The vibration level is low and the machine will not harm the operator for vibration。The peak C-weighted sound pressure at workstation is 69pa.

§11 Equipment failure and possible solutions:

Possible failure

| Possible Cause

| Solution

|

Press “ auto start”,the machine don’t work。 | 1、 main power is off 2 、CPS is off 3 、”pause”is on 4 、”E-stop”is on 5 、PLC is broken 6、power line don’t connect 7、Wiring is not connected

| 1.Check the external power supply, re-transmission 2.switch the key switch or the air switch 3.Release the “pause” 4.Release the “E-stop”。 5.change the PLC 6.Re-connecting the power 7.Checking the wiring |

Turntable don’t move | 1、inverter is burn,No display 2、the parameter of the inverter is wrong 3、the turntable motor is broken 4、Knob is broken 5、 PLC don’t have the output 6、chain is broken | 1.Change 2.Re-set according to the technician 3.Check the motor of the turntable 4.Change 5.Change 6.Check the chain whether out of the chain wheel |

Turntable moves by manual | The time of inverter soft start is too long,re-set again | Re-set |

Turntable move all the time | 1、Limit-switch is not reset 2、PLC’s dot is broken 3、Proximity switch is broken 4、manual/auto start do in the same time | 1.Reset 2.Re-enter the program, or replace PLC 3.Change 4.Close the manual operation |

Big noisy of turntable rotation | 1、the floor is not flat 2、riding wheel wear down | 1.Change the place 2.Change the riding wheel |

Inverter overload warning display

| 1、 Voltage is not steady 2、 Cargo overload | 1.Improve the power quality or adjust the inverter parameter 2. Reduce the weight of the goods |

Film tension can’t adjust | 1.DC converter box damaged 2、potentiometer is broken 3、DC motor is broken 4、the chain of the film carriage is loosen | 1.Change 2.Change 3.Change 4.Tightened the chain

|

Appendix 11-2 Sketch Picture on the Installation & Hauling—Diagram 8 (pictures of machines with cap-device or ordered come later)

Diagram 8 Sketch Picture on the Installation & Hauling of the YK Series

Appendix 11-3 Outlook of the Packager -Diagram 10(Standard Universal Type)

Diagram 10 Axis Side-Watch on the T Series Packager

Appendix 11-4 Warning signs

Be careful

Danger,Electricity

Be careful your hands