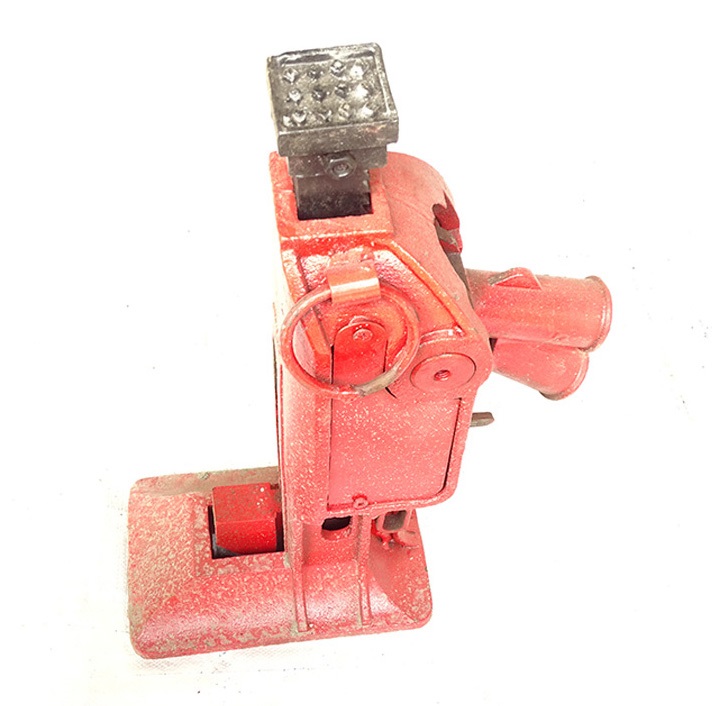

Different capacities of Track jacks made in china

Keyword:Track jacks Time:2021-1-15 16:13:12

Track Jack for Lifting & Maintaining Railway Tracks and other purpose. capacity, size and height are available as per client's requirement.

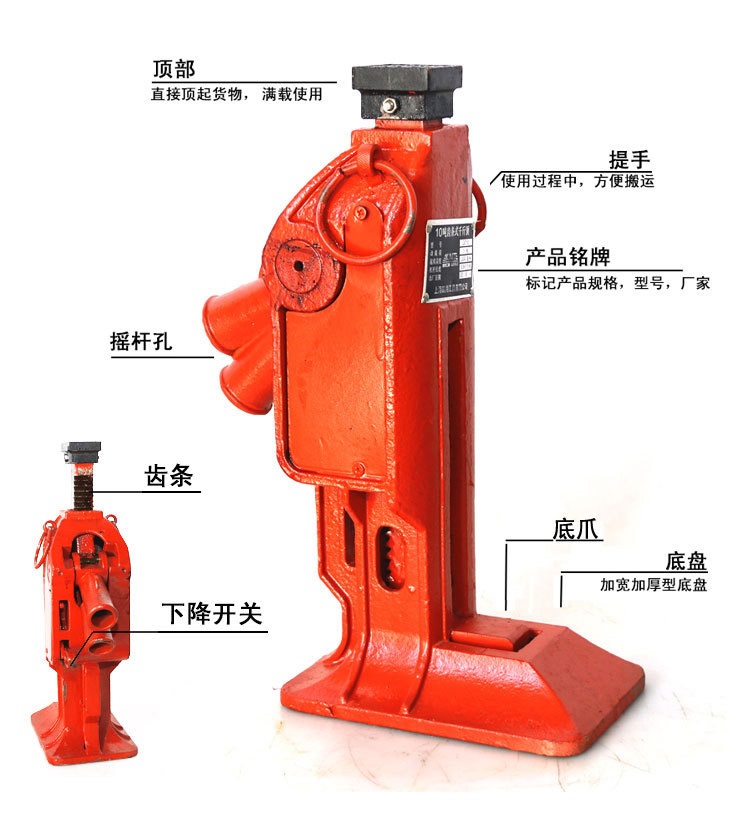

Mechanical track jack provides low handle effort. Can be used for lifting (vertical) or pushing (horizontal) applications. Forged and heat treated components for strength and long service life.

Quick-trip mechanism allows load to be instantly dropped.

Rugged construction permits full capacity to be used on the toe or cap of the jack. Jack works on same principle as automobile tire jack: load is raised or lowered "tooth by tooth." Jack cannot be tripped under load.

Mechanical track jack is a non-infringing light weight, powerful track jack. Which is specially designed, developed and manufactured for the maintenance of bg & mg concrete sleeper tracks of railways. it is made of special steel has simple mechanism and requires minimum displacement of ballast for setting in position for operation. It is the most efficient and convenient equipment in the hands of permanent way engineers.

Mechanical track jack is the simplest & sturdiest types of the jacks, which is a good tool used widely in many lifting fields. it is widely used in Oil Fields, Railway Track Work, Ship Yards, Mining Operation, Construction & Heavy Duty Industrial Maintenance & Establishments.

The track jack has simple structure, easily to use safe and reliable. It can be used with many same jacks. We are readily involved in offering to our patrons a vast range of Mechanical Track Jack that is available in diverse specifications.

Track Jack is used to lift the track on the railway. These jacks can be used to lifting both on down and up strocks. They also can be lowered tooth by tooth, and also can be made to tripped off by just moving the trip control.

Value Added Feature: Compact, lightweight & versatile

With lifting points on the toe and on the top, these jacks are extremely rugged. Base, toe and pumping assembly swivel independently, allowing the jack to work in confined spaces. Toe jacks comply with ASME

B30.1 standards and include pressure relieve valves to prevent overloading. In addition to be used vertically for lifting, the jack can also be used horizontally for pushing & separating.

Robust construction with a single block steel body and wearing parts such as the column, the toe and the base plate are of high resistance special steel.

Ergonomic and removable handle for transport (25 t model is fitted with rollers).

Working Load applied on toe and head.

Pressure valve to avoid overloading.

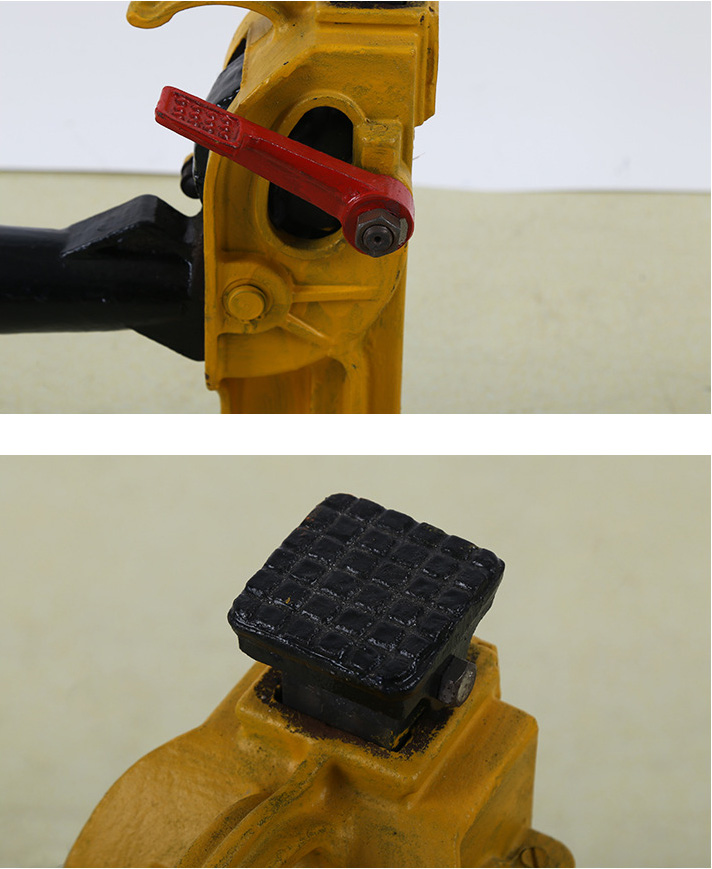

A release button controls lowering operations.

Toe can swivel 360° around the axis of the jack.

Operation in both vertical and horizontal position (vertical position only for 25t unit)

Minimum clearance only between floor and toe.

Easy maintenance of the hydraulic circuit.

Removable operating lever.

How to get rid of the trouble:

Adjust the middle nut of the spring package if the rack meets difficulty when moves upward or descends When obstructed upwards , adjust downward; when obstructed downward adjust upward , The range of the adjustment should be between 1 mmto 2 mm.

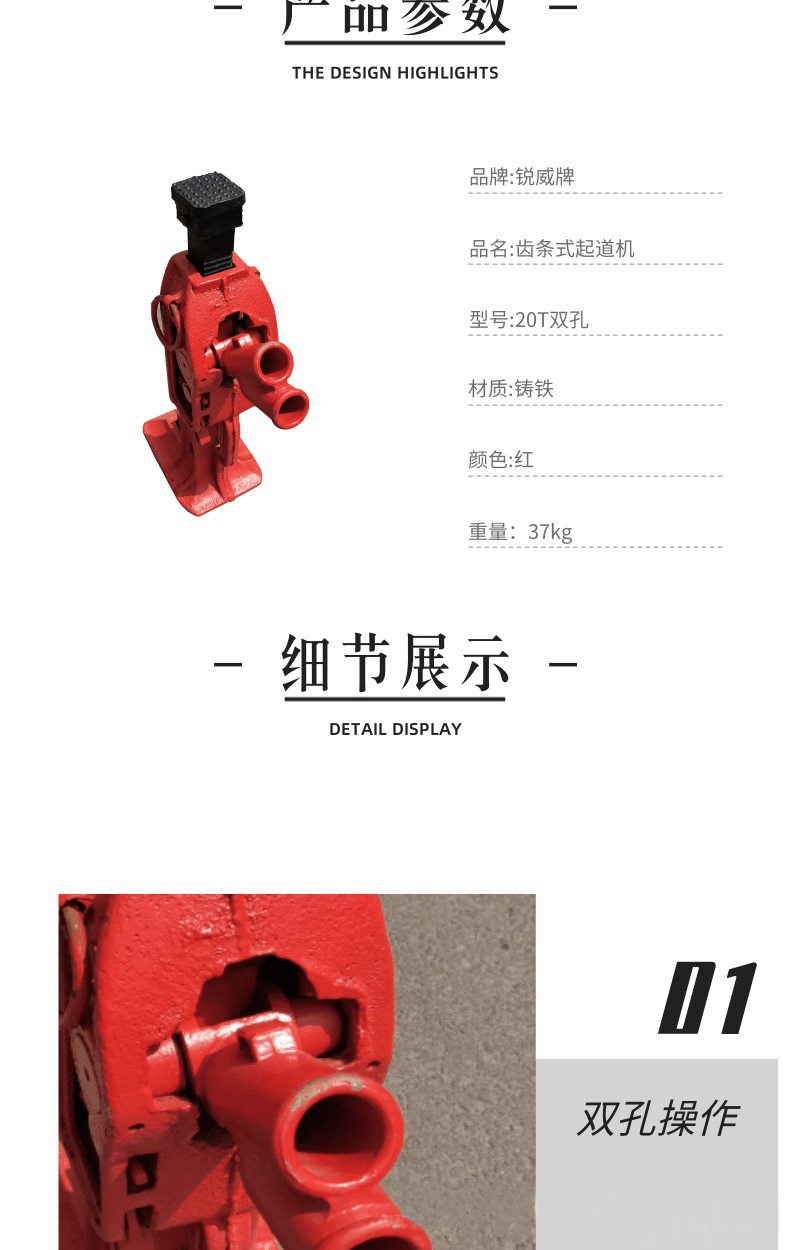

QD mechanical rail jack is also called mechanical railway jack, rail lifting jack, track lifting jack, rack type track jack, handle-type mechanical jack, manual rail jack, hand track jack, Tracking lifting and lining machine, there are 5tons mechanical rail jack, 10tons mechanical rail jack, 15tons mechanical rail jack and 20ton track rail jack.

Feature

1. good quality

2. it is suitable in all kinds of the rail steel

3. easy to operation and store

4. good performance for price ratio

Specifications

Apply to the complementary set, an axle railway bridge installation, and vehicles, equipment, heavy lifting with.

The structure is simple, easy to use, safe and reliable, and many machine etc. It is a kind of hoisting tools that are widely used.

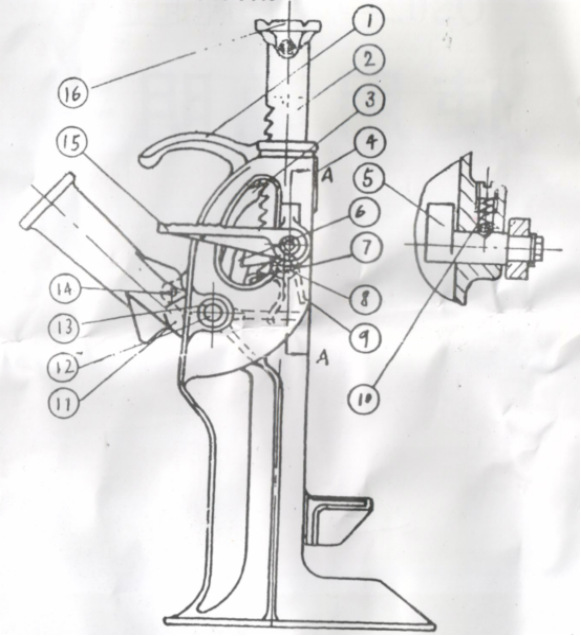

Principle of work: the machine is manual type one type of hoisting tools, compact structure, reasonable use a joystick to move up and down swinging the claw, with the tooth claw, promote the linkage with rack up or down, and then the weight

Mechanical track jack provides low handle effort. Can be used for lifting (vertical) or pushing (horizontal) applications.

Forged and heat treated components for strength and long service life. Does not accept lining bar for handle.

Does not accept lining bar for handle

A railroad jack is a very heavy-duty ratchet type of jack used to raise rail cars. The ratcheting action of the railroad jack allows the user to raise the car in small increments and lock the jack into position. With a solid footing cast into the railroad jack housing and a grooved tongue to engage the railway car or locomotive, the railroad jack is very stable while in use and provides a certain amount of confidence for the operator.

It has two different sockets for jacking in close quarters. It will also support the full rated capacity on the toe or the cap.

Railroad jack used on the Railway, Jack is created from iron and has heavy rusting.

Strong steel housing ensures long life and durability. The jack has a low toe height and large stable base.

The operating procedure of the track jack:

Before using the jack, remove it from long-term storage if needed and check its completion.

Check the oil and its level in the jack reservoir. If necessary, fill in the new clear oil through the filler plug.

Bleed the air from closed cavities by pumping the jack with the drain valve

Check the jack operation in the lifting and lowering modes.

To raise the railway track, place the jack lifting arm under the rail until the rail foot touches the jack body, while the lifting arm fully go under the rail foot. Due to the high pressure on the ground

when lifting and straightening, use strong wooden pads which are larger than the size of the jack base. The straightening of the railway track can be done with the upper lifting arm.

Move the handle to lift or move the load to the required position. The drain valve must be turned all the way down.

When lifting or moving the load, ensure the correct position of the vertical axis of the jack.

Release the jack from the load by turning the drain valve counterclockwise.

After finishing work, do not leave the jack with the lift raised up, because the piston rod and operating cylinder liner may corrode. It is necessary to clean the jack of dirt, wipe it with a rag, cover the piston rod with the grease, open the drain valve and lower the lift down to the stop.

Your safety is your personal responsibility. Always follow the correct procedures.

Technical parameter

Model | Max lifting capacity of the top | Max lifting capacity of foot-hoot | Lifting height | Total height (include the height of the machine) | Foot-hook | NW | Dimensionm |

QD5 | 5T | 2.5T | 160mm | 345mm | 43mm | 17kg | 191×130×384 mm |

QD10 | 10T | 5T | 180mm | 410mm | 45mm | 24kg | 230×154×418 mm |

QD15 | 15T | 7.5T | 280mm | 580mm | 60mm | 37kg | 260×135×590 mm |

QD20 | 20T | 10T | 350mm | 680mm | 75mm | 43kg | 280×140×630 m |