Inquiry for Air-Powered Dock leveler from Vietnam

Keyword:Air-Powered Dock leveler from Vietnam Time:2021-3-14 10:48:07

RAMHOIST:

QUOTATION SHEET Date: Mar.16th, 2021 | ||||

Model | Specifications | Quantity | Unit price | Total amount |

Air bag Stationary Dock Leveler | 1.Load Capacity:6.0ton 2.Platform Size:2200*2150mm 3. Up +300mm Down -300m 4. 220V 50HZ 1phase | 35sets |

2100USD/set |

73500USD |

Sales Conditions: | ||||

Payment Terms | 50% T/T in advance, 50%T/T before delivery. | |||

Package | Standard export package | |||

Delivery Time | 15-30 working days after advance payment . | |||

Warranty | 1 year warranty (not including wear parts) | |||

Validity of the quotation | Price validity to Apr10th. 2021. | |||

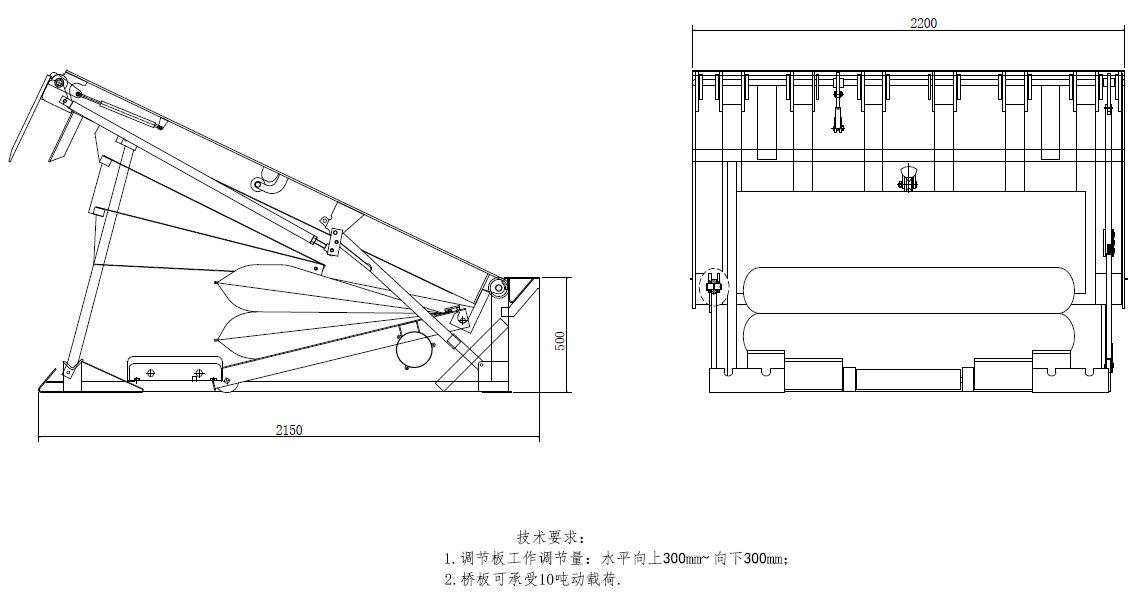

Specifications and Configurations of Air bag Stationary Dock Leveler | |

Platform Size | 2200*2150mm |

Overall size | 2200*2150*500mm |

Pit size | 2240*2150*510mm |

Load Capacity | 8.0 ton |

Lip Board | 400mm, 20mm steel plate |

Adjusting Height | Up 300mm, down 300mm |

Platform Plate | 8mm Q235B Steel checkered plate |

Power Unit | 1.5KW,220V/50Hz/Single phase |

Electric control | External electric control box, equipped with power switch, one-touch button, leakage protection, with waterproof and dustproof functions. |

Lifting system | 1) Double airbag lifting system. 2) Adopting the principle of low pressure and high volume inflation, the maximum pressure is 0.1 atmosphere, and the pressure is automatically balanced. 3) The air bag is made of industrial polyester fiber material. 4) The air bag should be strictly chemically resistant and resistant to acid and alkali corrosion. 5) The air bag shall be subjected to chemical treatment strictly to prevent damage by insects and dental animal. 6) Use times ≥ 200,000 times. 7) Working temperature: -50℃ to +65℃. |

8) Material breaking strength, welding strength and adhesion resistance to hydrostatic force, tested by cold crack temperature. 9) The equipment availability is greater than 99%. | |

Motor | 1) The motor is designed with a safety filter to prevent dust. 2) The motor itself can automatically clean the filter screen by air return. Motor power: 1.5KW; power supply: 220V/50Hz |

Body guards on both sides | Automatic expansion and contraction to ensure safety. |

Anti-collision glue | 2 pieces/set; specifications: 100mm×200mm×300mm. |

Surface treatment process | high-standard sandblasting or shot blasting process must be carried out before painting to eliminate internal stress formed in the welding process of the equipment. |

Support beam skeleton structure | A total of 8 "L"-shaped steels are arranged longitudinally, and open hinged joints are welded to the end plates. Strength guarantee. |

Features | 1) Vertical working range: 300MM above the platform, 300MM below the platform; and ensure sufficient lifting height to ensure that the loose leaf can be fully extended before contacting the bottom of the truck bed, which can achieve secondary height adjustment. 2) Automatic vertical adjustment: The board surface and loose leaf can be automatically adjusted up or down with the bottom of the truck during loading and unloading. 3) Loose-leaf layup operation: Loose-leaf layup is automatically extended to the bottom of the truck bed; extension length: not less than 400mm, outside the self-collision rubber pad: not less than 300mm. 4) The operation of the loading and unloading platform to the place below the cargo deck is also automatically completed. No more manual control is required. |

Structure | The structural design should be able to prevent deformation during operation; the front end of the loose- leaf slab must be grooved to reduce the damage to the tire of the material handling equipment. |

Rear connection board | The rear of the unloading platform is equipped with a fixed rear page safety design to avoid gaps or bumps at the rear of the unloading platform due to unbalanced loading and unloading of the truck. |

Technical drawing of Air-Powered Dock leveler (Air bag Stationary Dock Leveler)

Site phtos of Air-Powered Dock leveler (Air bag Stationary Dock Leveler)