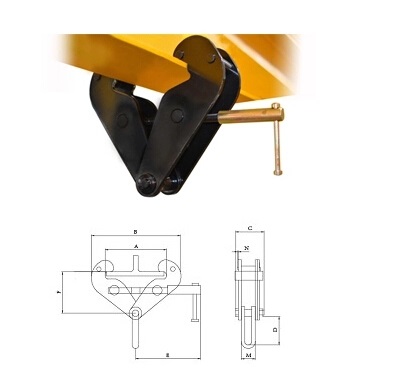

1t to 10t Adjustable I or H Steel Lifting Beam Clamp/Girder Clamp

Keyword:Lifting Clamps Time:2019-4-30 16:05:49

Lifting Beam Clamp

Description

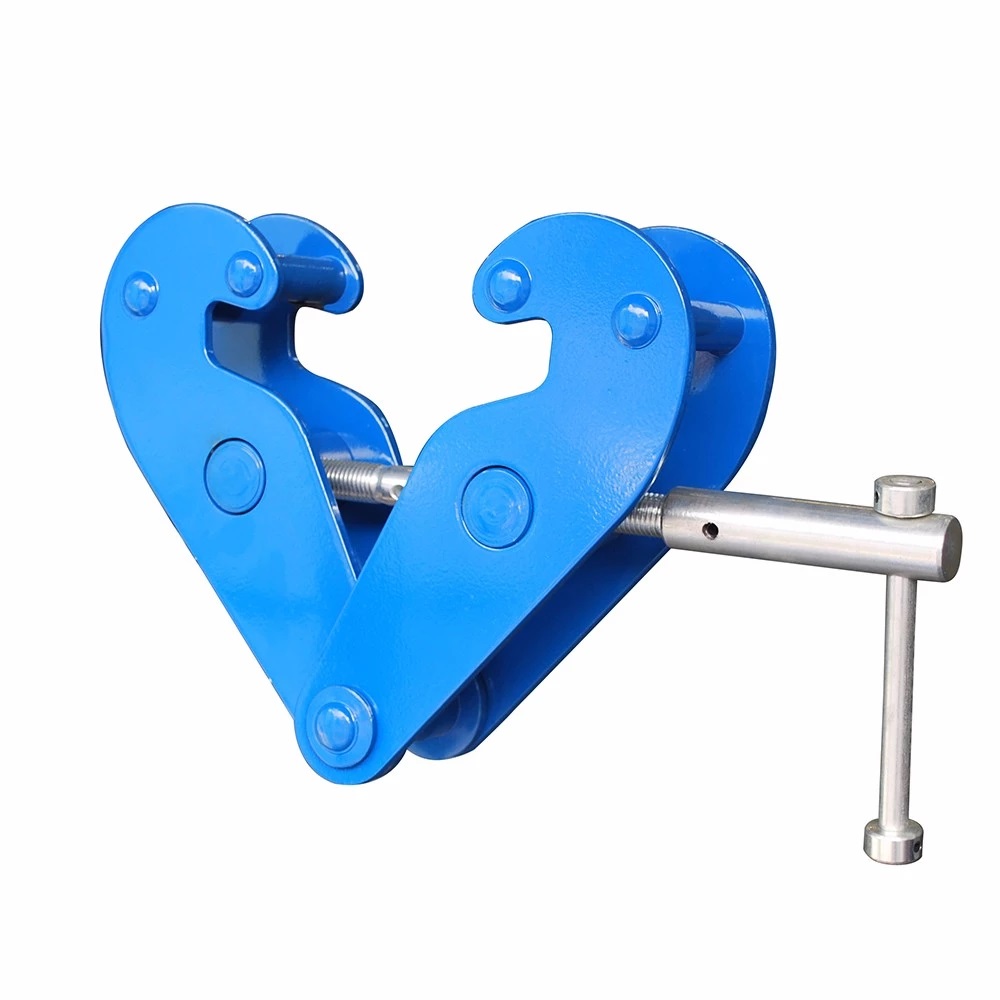

This beam clamps are truly versatile in application and may be used for lifting, pulling, or as anchor point. Designed specifically to provide maximum jaw grip adjustment.

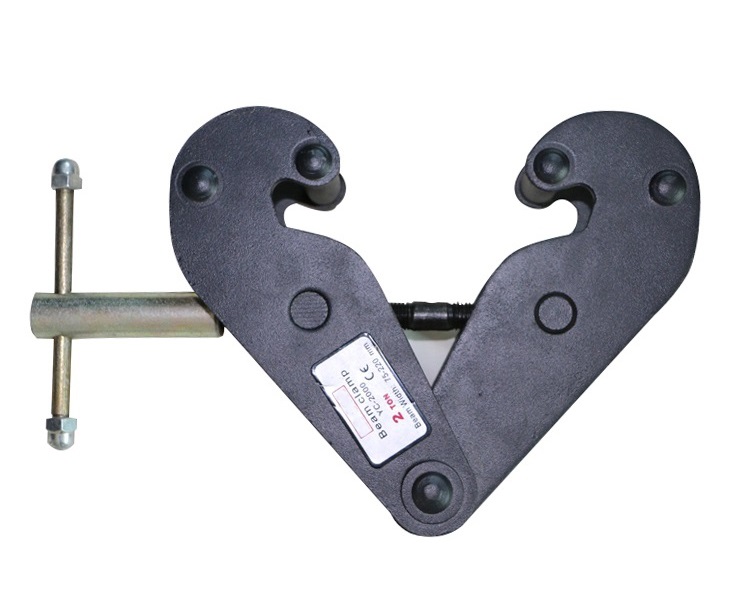

These products are engineered for practical use where mobility is essential. The Clamps are speedily applied and do not require additional tools or width adjusting components, such as spacing washers. The left and right-hand threaded adjusting bar ensures a secure grip on the beam flange.

Quick and versatile rigging point for hoisting equipment

Shackle suspension point

Highly flexible-for lifting, pulling or as an anchor point

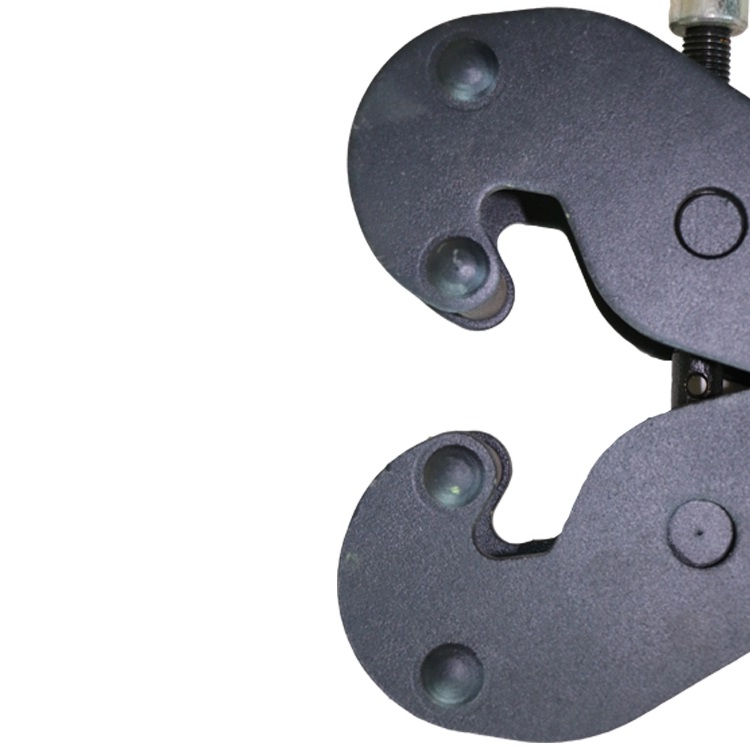

Multi directional adjusting screw spindle for easy attachment and safe and secure grip

Wide beam flange adjustment range

Provides a quick and versatile rigging point for hoisting equipment, pulley blocks or loads.

Flexible application due to the wide adjustment range

The central threaded spindle allows easy attachment and a safe and secure grip

The spindle can be secured against loosening

Features:

High quality alloy steel with low carbon.

Load range:1-10t

Safe factor:1.5 times working load limit

With safe and secure grip on the beam.

Easy and simple to install.

Beam width range: available in various styles.

Forbidden overload.

Provides a quick and versatile rigging point for hoisting equipment, pulley blocks or loads.

Flexible application due to wide adjustment range.

The central threaded spindle allows easy attachment and a safe and secure grip.

The spindle can be secured against loosening.

Option: Small dimensions for applications at beams with a low base height.

Use:

● Provides a quick and versatile rigging for hoisting equipment, pulley blocks or loads.

● Flexible application due to wide adjustment range.

● The central threaded spindle allows easy attachment and a safe secure grip.

● The spindle can be secured against loosening.

● Option: Small dimensions for applications at beams with a low base height.

Details:

Selecting the Correct Beam Clamp

Beam clamps are available in a range of capacities and designs. They may be adjustable or of fixed size, have scissor action, screw locking or bolt clamp fixing and be suitable for temporary or permanent applications. Select the beam clamp to be used and plan the lift taking the following into account:

Type of clamp - adjustable/non-adjustable - scissor, screw or bolt action.

Capacity and beam size or range of beam sizes.

Suitability of the beam.

Type of lifting appliance to be used.

If application is temporary or permanent.

NOTE: Beam clamps are generally intended for attachment to overhead beams to act as suspension points for lifting appliances. Some designs are suitable for attachment to the load to provide a lifting point. The supplier should be consulted for such applications which are excluded from these instructions.

How to use the beam clamp safety

● The lifting clamps are suitable for lifting and transporting of steel plates with a maximum hardness of 37 HrC (345HB,1166 N/mm²).

● The lifting clamps are suitable for usage in normal atmospheric conditions, between -40℃ and +100℃

● Never overload a clamp and prevent the jerking of loads.

● When loading always use the whole jaw depth.

● Never lift more than one plate at the same time.

● Always keep your distance during lifting and descending of a load.

● Prevent situations that anybody is under the load.

● Any welding to the clamp is forbidden, this can influence the hardness and toughness of the clamp.