Removable Bags and Cases vacuum tube lifter for 35kg bags & cartons with a quick adapter

Keyword:Vacuum tube lifters Time:2019-5-10 16:42:15

Product Description

Bags and Cases Vacuum lifter Parameter:

1.Working Power: 380V, 50Hz

2.Max Loading Capacity: 120KG

3.Max Lifting Height: 2000mm

4.Max Working Radius: 2500mm

5.Lifting Speed: 0-60m/min

6.Noise: Less than 65db(A)

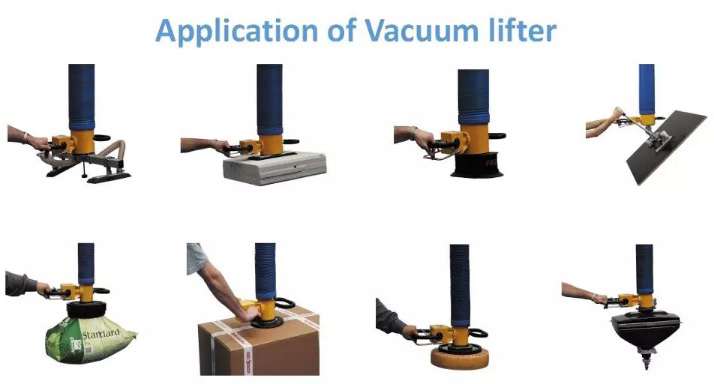

7.Vacuum lifter Appliance: For bags, Cases, Boxes, Nonwoven Roll, sheet metal, glass, granite, stone, timber, wood

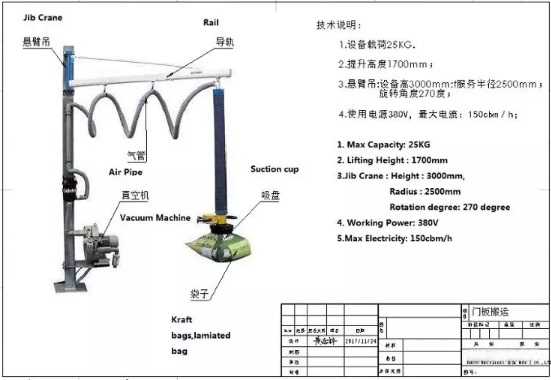

Kraft Bags and carton box handling vacuum lifter drawings

Vacuum blower: Siemens vacuum blower, model GS2.2, power supply 380V, 2.2KW, maximum vacuum flow 120cbm/h, maximum vacuum pressure -55kpa

Lifting tube: Diameter 140mm, tube length 3050mm, maximum lifting height 2100mm, maximum loading 35kg for semi-porous, 40kg for dense.

Double suction pads for carton box, the yoke length 400mm, mounted on the control housing by flange

A ball bearing integrated upper rotation jointer with single way valve to prevent the goods falling down in case of power lost.

Two-hands control unit with a rotation handle for up and down, the brake handle for release, the handle were extended for higher stack

A plastic vacuum filter mounted on the column.

A vacuum regulator mounted on the vacuum blower which protect the blower in case overheat, the preset vacuum pressure is -45kpa

8M vacuum feeding pipe of Diameter 52mm for vacuum connection

A vacuum filter standard for keep air clean

The lifter was designed for transportation or handling the materials at:

Max. Carrying capacity: 40kg for dense, 35kg for semi-porous

Vacuum lifter for various bags ,kraft bags and rice bags

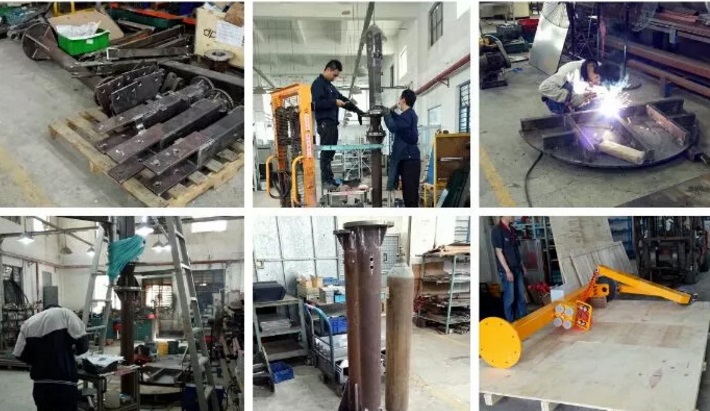

Vacuum lifter Production Process:

Every Component process of vacuum lifter is strictly producing and quality testing and confirm to promise equipment are in good conditions

1, The vacuum tube lifter is used to lift the heavy workpieces in the order picking area. It allows for quick, efficient handling. The tube lifter conforms to the latest ergonomic standards. Its ergonomic, single-handed operation allows the work to be performed without endangering the employees' health. The quick-change adapter is integrated as a standard component in the RAMHOIST vacuum tube lifter and allows all grippers to be changed in seconds, without the need for tools. This makes it possible to use a sack gripper for sacks and a double suction pad for cardboard boxes. The lifting system is rounded off with a crane system, which ensures flexibility within the working area.

2, The tube lifter facilitates effortless loading of the horizontal panel saw and can remove sheets from upright and horizontal storage without difficulty. The tube lifter is equipped with a pneumatic swiveling unit PSE with which the wooden sheets can be swiveled 90° to the right and left without jarring. The two suction cups of the double suction cup are fully adjustable on the crossbeams. This allows the tube lifter to be optimally adjusted to fit the work piece dimensions. The tube lifter is equipped with a radio control. It enables the operator to switch the pump on and off directly at the operating unit. With the radio remote control the company benefits from particularly low energy consumption. With the tube lifter mounted on a column-mounted slewing crane, a single employee is able to accomplish the work ergonomically.

The RAMHOIST vacuum tube lifter is equipped with an ergonomic operating element and intuitive control handle. The operator can raise and lower the workpiece by pressing the control handle.

3,The tube lifter is equipped with a flexible four head suction pad. For maximum flexibility, the suction pad on the cross beam can be moved to adapt it to the size of the workpiece. Furthermore, the vacuum tube lifter is also equipped with an optional swiveling unit. If required, the workpieces can be swiveled by 90° for further processing.

The vacuum tube lifter from RAMHOIST allowed this process step to be designed with ergonomics and the health of employees in mind.