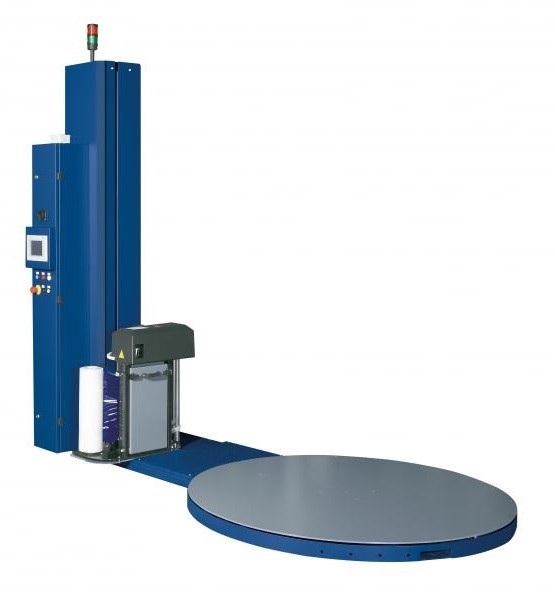

Automatic Stretch Film Pallet Wrap Packing Machine / shrink pallet wrapping machine

Keyword:Wrap Machines Time:2019-5-15 11:51:07

Product Description

Pallet stretch wrapping machine (Automatic Stretch Film Pallet Wrap Packing Machine / shrink pallet wrapping machine)

Widely used in glass products, hardware tool, electric product, paper, ceramic, chemical, food, beverage, building material and so on.

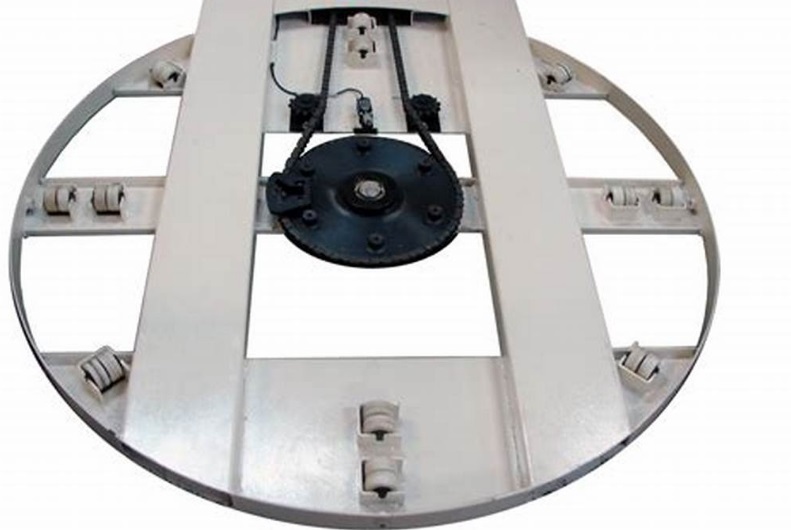

| Turntable diameter | 1650mm | Turntable height | 78mm |

Turntable weight capacity | 2000kgs | Turntable speed | 3-12rmp |

Other option | choose according to your needing | Ramp | have |

Photo-eye pallet height sensor: | have | 0-9 separate wrap count selectors | have |

Technical Data

Automatic cycle for film hooking, pallet wrapping, film cold cutting and film hot sealing

• Air device to blow up the film tail

• Electronic printed circuit board for the management of the cycle

• Frequency controller for carriage speed adjustment

• Frequency controller for arm rotation speed adjustment

• Power pre-stretch carriage

• Photocell to detect the pallet height

• Safety stop loop at the base of the mast

• Stop at 0 position

• Power board IP54

• Adjustable parameters by the control panel without password: cycle selection,

bottom laps, top laps, top sheet cycle parameters, rotation speed, carriage ascent speed, carriage descent speed, film tension, starting wrapping height

• 3 working cycles: ascent/descent; top sheet; layers

• Storage of 32 end user programs

• 3 working ways: semi-manual, semiautomatic, fixed height

• Stretching operation

• Acoustic warning at the cycle beginning and stop

• Auto-diagnostic

• Wrapped pallet counter

• Receiver for infrared/radio remote control

• Powder coating

• Braked arm at the end of the cycle

Main optional parts

Adjustable power pre-stretch

3000 mm max wrapping height

Remote control

Photocell for dark loads

Mechanical system to brake roll containers

Safety fences

Detailed images

Our Most Popular Rotary Arm Stretch Wrapper - Floor Mounted Frame

This machine concept keeps the load to be wrapped stationary while the stretch film carriage rotates around the load to apply the stretch film. The rotary arm stretch wrapper is the perfect solution in situations where the load is very unstable (very tall, too heavy, too light) or in a wash down environment.

Easy operation 3 STEP "EASY THREAD" film Loading Ensures Safety

Re-loading the Film roll on any carriage is not an easy task with many rotary arm pallet packing machines. With our "Easy Thread" access design, we make it simple and safer. Simply unlatch and open the access door, pull film tail past open access door and close the door. It's that simple!

Strong Structurer with Tough Quality for MAXIMUM STRENGHT

Strong-structural steel construction reflects the durability of this machine. HSS tubing provides a strong and light-weight arm minimizing the driving forces required to rotate the arm.

Steel weldment of arm assembly is designed form maximum strength while keeping the rotating weight to a minimum.

Our Most Popular Rotary Arm Stretch Wrapper - Floor Mounted Frame

This Rotary arm wrapping machine concept keeps the load to be wrapped stationary while the stretch film carriage rotates around the load to apply the stretch film. The rotary arm stretch wrapper is the perfect solution in situations where the load is very unstable (very tall, too heavy, too light) or in a wash down environment.

With 14 rpm stretch wrapping speed

The rotary arm pallet stretch wrapper is the fastest stretch wrapper in his class. Up to 35-40 pallets per hr. (based on load configuration and machine options), larger, variable speed drives control all motors for maximum flexibility, heavier, and faster wrapping than most competitive machines.

FILM SAVINGS - SEPARATE 1-9 TOP AND BOTTOM WRAP PROVIDES UP TO 15% FILM SAVINGS

The special designing pallet wrapping machine with separated 1-9 top and bottom wrap count provides up to 15% film savings. apply only the stretch film required at the top separately from the bottom compared to competitive models that applies a common amount to top-bottom regardless of need.