High quality good price passed ISO9001 FRP pultrusion round tube

Keyword:Pultrusion Tubes Time:2019-6-18 0:10:22

With the social progress of science and technology, the development of civil engineering disciplines, application and development to a large extent due to new materials and new technology and excellent properties, and FRP with its excellent mechanical properties and meet the needs of modern engineering structures to large span, tall, heavy and light development needs are more and more widely used in bridge engineering, civil construction, marine engineering, underground engineering, received wide attention in the field of structural engineering.

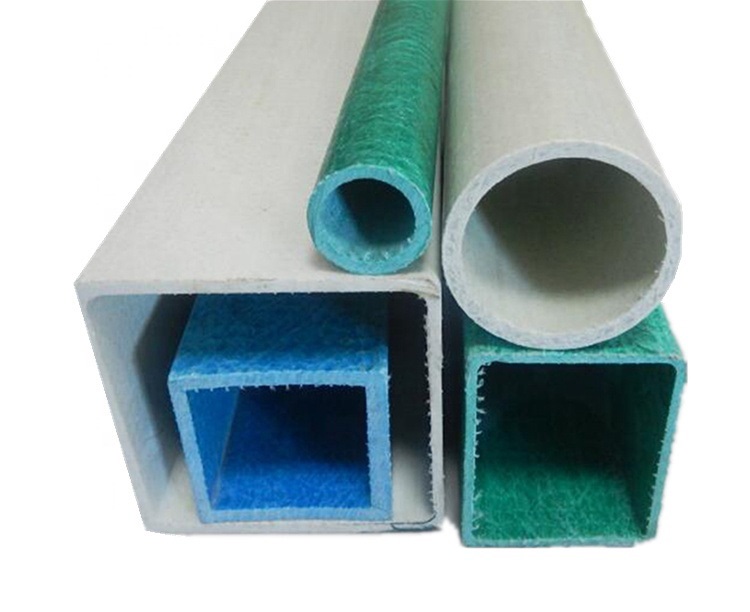

Shapes of FRP Pultrusion Tubes

Round Fiberglass Tubing

Expert supplier Ramhoist supplies hollow round tubing in a range of outside and inside diameters. Our production capabilities include small sizes from ½ inch diameter to 14 inches in diameter.

All of the standard tubing sizes are available including ¾”, 1”, 1.125”, 1.144”, 1.25”, 1.50”, 1.75”, 2” and 3: diameters. We have manufactured tubes with a thicknesses ranging from 0.080 inches (2.03mm) through 1” thick (25.4mm).

LPI can also manufacture telescoping tubes.

Square Fiberglass Tubing

Professional Exporter Ramhoist exports all of the industry standard and commercially available sizes of square tubing. The square tubing sizes range from 1” OD through 7.25” OD and we offer a variety of wall thicknesses from which to choose. Many of these tubes are available from stock.

Rectangular Fiberglass Tubing

China supplier Ramhoist wholesales various pultruded rectangular tubes for a wide range of customers and industries. There are literally hundreds of available sizes ranging in size from small rectangular tube insulators through large 4" x 12" rectangular tubes used in Pergolas.

Main Raw Material:

1.Reinforcement material: fiberglass, glass mat, continuous strand mat, surfacing mat, needled mat.

2.Basis material: unsaturated polyester resin, epoxy resin, vinylester resin.

The advantages of Pultrusion

1.The pultrusion process is a proven manufacturing method for obtaining high quality FRP profiles with consistently repeatable mechanical properties.

2.Some of the features of the pultrusion process are:

Complex shape and length capabilities

Precise positioning of reinforcements

Low scrap rates

Wide choice of reinforcements and resins

3.Pultrusion successfully combines a number of elements which can provide a wide variety and combination of properties and characteristics required by the final application of the product.

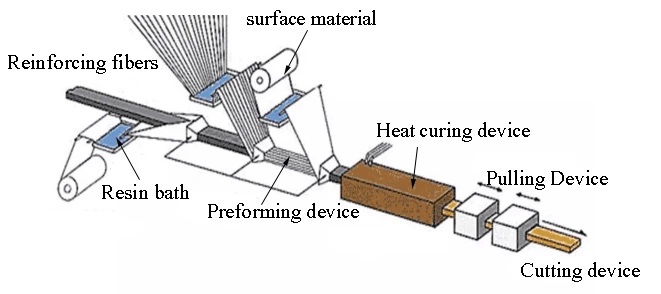

4.Pultrusion is a method of manufacturing either discrete or continuous lengths of fibre reinforced composites by pulling resin impregnated fibres through a series of forming guides.

5.They then pass through a heated die to cure the resin system, thus producing a rigid cured composite as it exits the die. The shape and dimensions of the end product are determined by the die cross section.

6.Pultrusion is an ideal process for the production of either solid or hollow constant cross section profiles.

The images of processing

Frp profile pultrusion machine Production Flow

Pultrusion is an automated process for manufacturing reinforced materials into continuous, constant cross-sectional profiles. In virtually every case, a continuous reinforcing fibre is integral to the process and the finished product. The basic operation consists of pulling a reinforcement through a resin impregnation bath or other facility, and then through a die to produce the finished profile.

Feedback: If you think our quality is good,pls do not hesitate to leave your positive feedback, I will give some discount to my logal customer, if there are some question during application, pls feel free to contact me to solve it.

These attractive properties make FRP the preferred choice of composite material for many uses in industries such as Construction/Industrial, Automotive, Consumer, Wastewater Treatment, Electrical, and Marine just to name a few.

Some specific applications found within these industries are as follows:

Construction/Industrial

Bridges

Bulkhead Frames

Cable Trays

Complete Building Systems

Cooling Tower Components

Flooring Supports

Pipe Supports

Pre-Fab Walkways, Platforms and Handrail Systems

Trusses & Joists

Wind blades

Window Frames

Automotive

Automobile Springs

Automotive Leaf Springs & Bumpers

Bus Components

Bus Window Latch Supports

Dunnage Bars

Roll-Up Doors/Roll-Up Door Panels

Spring Bumpers

Tank Supports

Truck/Trailer Wall Posts

Consumer

Ladders

Light Poles

Mop, Broom and Brush Handles

Pruning Poles

Rake/Shovel Handles

Wastewater Treatment

Cell Partitions

Scrubber Components

Travelling Water Screens

Water/Waste Water Treatment Sludge Flights

Electrical

Composite Utility Poles

Crossarms

Crossing Gate Arms

Electrical Enclosures

Mist Eliminators

Mounting Braces & Backboards

Switch Gear Components

Third Rail Coverboards

Walk-In Refrigeration Door Jambs

Marine

Boat Dock Power Posts

Fender Pilings

Sheetpiles

Sea Wall/Pylon Design