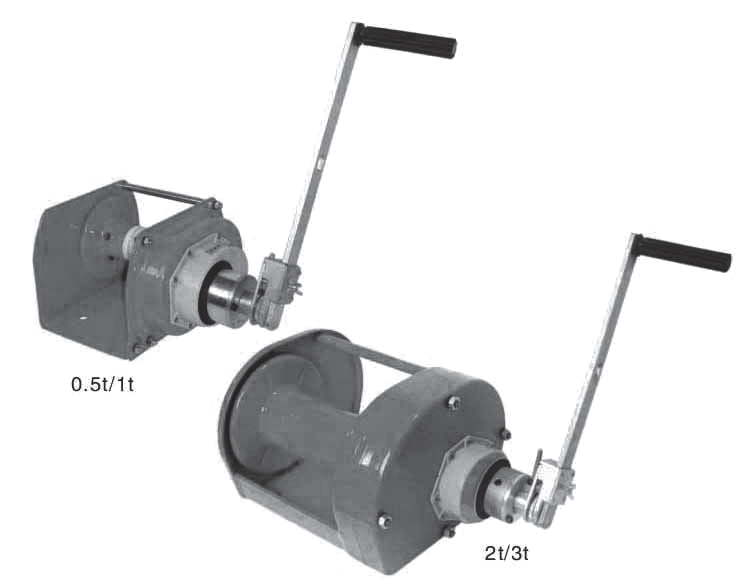

Operation Manual of MW Series Winch (heavy duty manual winch)

Keyword:MW Series Winch (heavy duty manual winch) Time:2021-9-6 16:11:50

MW Series Winch

Operation Manual

Contents

1, Application

2, Features

3, Technical Specifications

4, Safe Warning

5, Operation Method and Precautions

6, Maintenance

1, Application

MW Series Winch is a new kind of manual winch. Compared with other winches, it is more easy and convenient in operation. It is widely used to lift, pull and stretch in the cross-country cars, yachts and other vessels. It is also used to drag loads, lift and lower loads, and install facilities, and in other opened field. It is the necessary tools in the mine, forestry, transportation, environment protection, fire protection and other field.

2, Product Features

MW Series Winch has the following advantages in design and manufacturing.

a) The gear box is designed with close structure to avoid the foreign body entering into gear box or braking mechanism in operation, and affect normal operation. With more safe in use.

b) To adopt double friction discs, new braking pawl and change over ratchet mechanism ensuring the stability of braking and saving efforts when using the handle. The winch is applied in the special condition as the friction disc is made of the raw material of environment protection.

c) The connection of handle is fitted with change over ratchet. During the operation, according the working need, the winch may be turned circle by transforming the pawl and also operate the handle back and forth in any position and angle of the circle. To let turning operation change to levering operation. The winch is more advantage in the narrow space.

d) The handle is adopted freely structure and may free adjust the length of handle to safe the effort when necessary.

e) The large drum may contain more cable, which is more suitable for pulling, dragging, lifting and lowering the goods in the long distance.

3, Technical Specifications

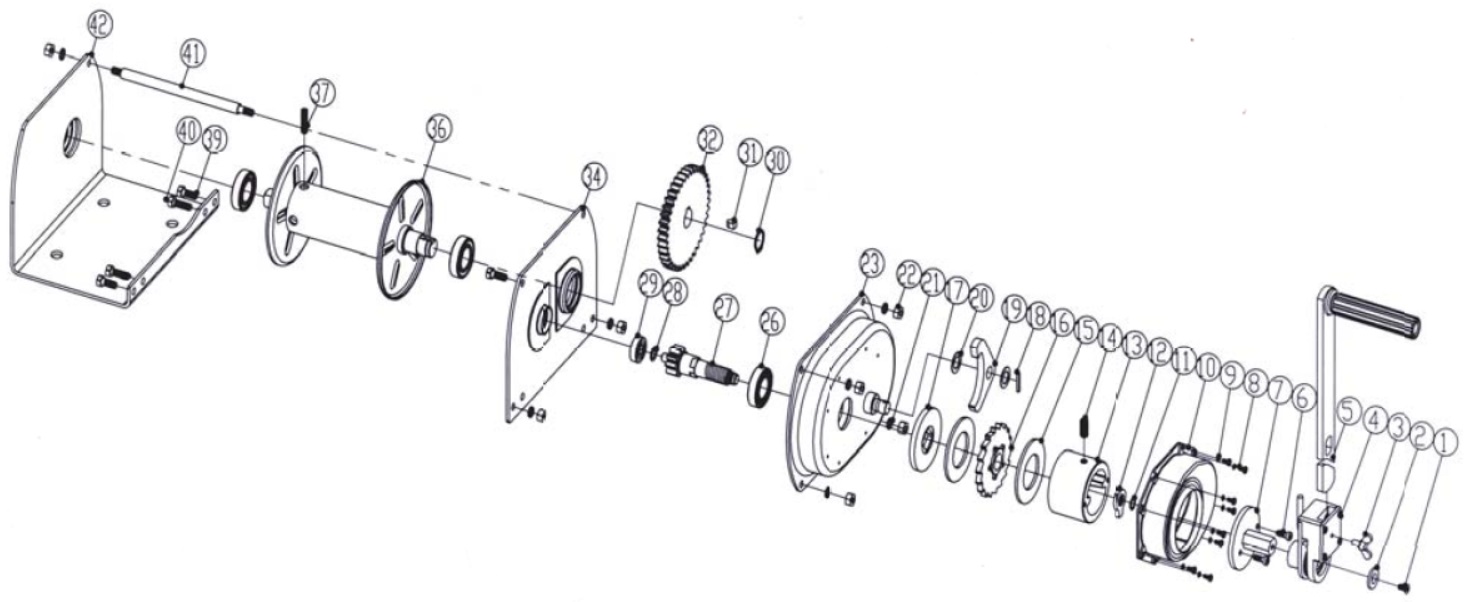

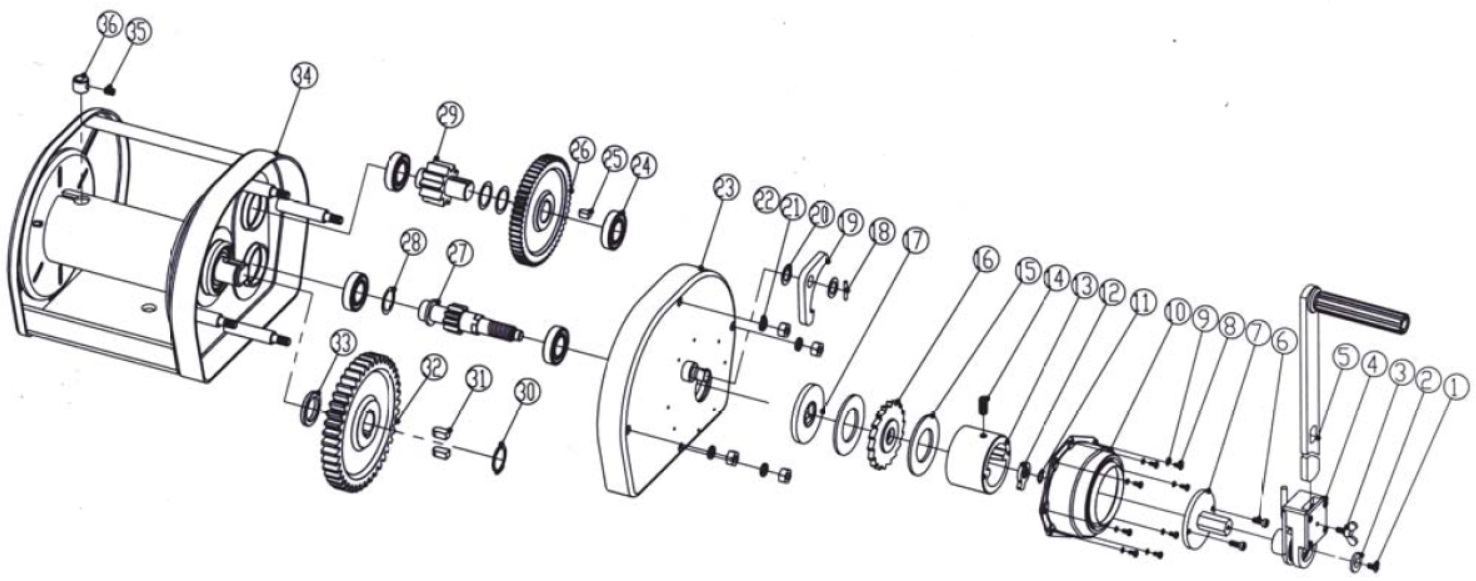

a) The exploded view of spare parts: Capacity: 0.5T/1T

Capacity: 2T/3T

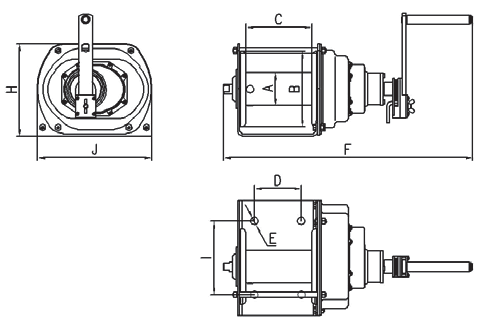

b) The parameter of performance

Model | 0.5 t | 1 t | 2 t | 3 t | |||||||

KN | 0.5 | 1 | 2 | 3 | |||||||

Test Load KN | 6.125 | 12.25 | 24.5 | 36.75 | |||||||

Cable dia.(mm) X L.(m) | Ø6.3*40 | Ø8*40 | Ø9*40 | Ø12.5*40 | |||||||

Speed ratio | 4.33:1 | 12.19:1 | 22.68:1 | 29.16:1 | |||||||

The max. handle length mm | 350 | 350 | 350 | 350 | |||||||

Hang pressure load N | 120 | 120 | 120 | 120 | |||||||

Overall dimension mm | A | Ï60 | Ï76 | Ï90 | Ï100 | ||||||

B | Ï140 | Ï175 | Ï190 | Ï230 | |||||||

C | 150 | 154 | 195 | 205 | |||||||

D | 100 | 110 | 155 | 155 | |||||||

E | Ï15 | Ï18 | Ï18 | Ï18 | |||||||

F | 403 | 443 | 490 | 549 | |||||||

H | 182 | 214 | 230 | 296 | |||||||

I | 130 | 170 | 170 | 170 | |||||||

J | 245 | 266 | 300 | 365 | |||||||

Net weight | Kg. | 14.4 | 19.7 | 25.1 | 44.3 | ||||||

Due to the continuous improvement of our product development, its construction may be slightly different from the specification.

4, Safe warning

a) Do not use on overload.

b) Before operation, inspect if the direction of the dragging of cable is correct per different size and do dynamic and static test with small loads. During the test, the drum should be turned at least one complete revolution. The winch may be operated after confirmation of normal working.

c) It is the necessary to trial lift when the goods approaches to the max. load, not too high off the ground when doing the trial lifting. It may be operated after security.

d) Do not use winch for lifting people or loads over people.

e) Inspect the condition of installation periodically, check the winch installation to ensure that all bolts on the frame are tight.

f) Do not hold a load on a trailer with winch cable to stretch or lift avoiding the wear or broken and permanent bending of the cable.

g) Inspect cable frequently, a frayed cable with broken strands should be replaced immediately. Use gloves or suitable protection when handling the defective cable.

h) Never replace cable with fabric rope of any kind or with a cable other than the type specified in this manual.

i) It is a good idea to lay a heavy blanket or jacket over the cable about 4.5 meter from the hook end when pulling in severe conditions. If a cable failure should occur, the weight of the cloth will act as damper and prevent broken cable from whipping.

j) If used as vehicle winch, do not move your vehicle to assist the winch, the combination of the winch and the vehicle pulling together could overload the cable.

k) To ensure correct and safe operation of your winch, please carefully read the manual and keep the labels and direction labels clear and visible. Failure to comply with all of these warnings may cause serious injury and/or damage to property.

5, Operation method and precautions

A, Installation consideration

a) Each winch must be mounted firmly and securely and stable foundation with such bolts as specified bellows. The length of bolts are depended on the thickness of steel plate (see form 1)

Size | Bolts | Class |

0.5t | M12 | 8.8 |

1 t | M16 | 8.8 |

2 t | M16 | 8.8 |

3 t | M16 | 8.8 |

b) When installing, make the bolts with screw end go through the basic steel plate from the winch framework, adding washer and spring washers. After tighten, the valid length of the bolts out of nuts at least 4-6mm.

c) All bolts installed do not affect and block the normal running of the winch.

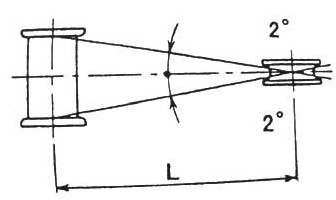

d) To protect cable from excessive wear or being smashed when cable is wound in confusion or overlapping on drum. Each fleeting angle must be below 2° and pulley should be in the center line of and inside drum.

e) To dragging the loads in the short distance should meet the following requirement. (see form 2 and fig.1).

Size | Cable length |

0.5 t | 220cm |

1 t | 230cm |

2 t | 290cm |

3 t | 300cm |

( form 2)

(fig.1) (fig.2)

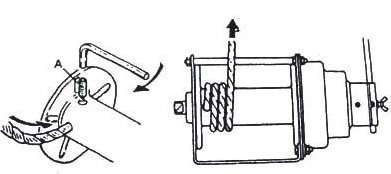

B, The winch should be located at a height which allows ergonomic use of appliance, preferable with the winch center at waist height. Installations with winch center at chest height or above will require particular assessment and possible de-rating. (see fig.2)

C, Before installing cable

a) Insert the handle into the handle socket and tighten the thumb screw.

b) Turn the handle in a clockwise direction, As you turn the handle, a noticeable clicking sound should be heard.

c) Turn the handle in a counter-clockwise direction, clicking sound should stop and the handle should turn smoothly.

D, Precautions

a) Pay particular attention to the accompanying diagrams and the orientation of the cable and the direction of load with each type.

b) Prepare the cable conforming to the capacity of your type of winch.

c) The cable should be long enough to be possible to keep a minimum of three turns of cable on the drum assembly, Without such three coils of cable, the load will work directly on the cable installing hole on the drum and consequently the cable may be forcibly and dangerously torn off from the drum.

E, Cable installation

a) Cable installation for 0.5t winch (see fig.3)

Loosen retainer bolt or grub screw and insert the cable end into the drum assembly about 57mm deep until the cable end stops.

Tighten retainer bolt firmly.(required torque:115 kgf·cm )

(fig.3) (fig.4)

b) Cable installation for 1t winch (see fig.4)

Loosen retainer bolt or grub screw and insert the cable end into the drum assembly about 72mm deep until the cable end stops.

Tighten retainer bolt firmly. (required torque:115 kgIgcm )

c) Cable installation for 2t to 3t winch (see fig.5)

Insert cable end through cable sleeve until end protrudes 10mm, tighten retaining screw firmly with hex.

Insert cable sleeve into hole on cable drum and slide to hook cable sleeve on groove.

(fig.5 )

F, Operation method

a) Insert the handle into the handle retainer (socket) and tighten the thumb screw. Turn the handle in a clockwise direction to take in cable. You should hear a clicking sound. This is the operation situation of lifting and dragging.

a) Turn the handle in a counter-clockwise to let cable out. This is the states of unloading and unwinding cable.

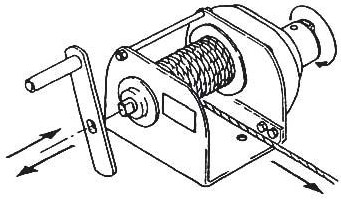

a) The winding direction is switched over with a change lever. When no load, the operator may wind or unwind cables quickly by choosing the handle at another end, inserted with the handle quickly winding cables in the counter-clockwise direction, and unwinding the cables in clockwise direction ( see fig.6 )

Note: Do not quickly turn the handle left to unload the goods as it may cause serious danger/injury.

( fig.6 ) ( fig.7 )

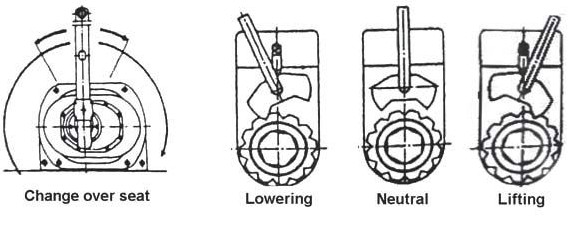

G, The unique and operation method of change over seat

a) Change over seat is as an accessory of winch. Its main performance is make the process of dragging, lifting and pulling with the operation of handle being turned-around by the transforming the change ratchet and pawl. Change to other device that it may be operated back and forth in any angle.

b) The device has more advantages in the narrow space. Operation more convenient and more save efforts.

c) See the figure of change over seat ( fig.7 )

d) Lowering with the change lever turn left.

e) Neutral position with the change lever in the middle position.

f) Lifting with the change lever turn right.

6, Maintenance

A, After operated for a long time, the winch is found to be slipped or its braking performance being reduced, the winch should be repaired in time.

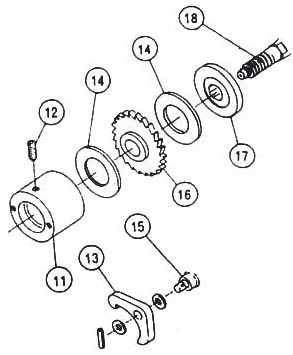

B, When the thickness of brake discs (No.14) were worn from 3.5mm to 2.6mm, they need to be replaced. (see fig. 8)

When assembling, pay attention to the touch surface between the discs and its neighbor rubbing parts. There is no any water and grease. Keep the braking area are clean and dry. Keep the threaded parts of the ratchet ( No.11 ) and the pinion ( No.18 ) clean with a brush. The threaded area may be lubricated with a light machine oil to keep the running freely and to ensure the rapid change of the braking performance. When assembling, keep the rubbing surface of ratchet ( No. 11 ), ratchet disc ( No.16 ) and disc hub ( No.17 ) clean and dry. Without any grease and water. If they show excessive wear, they must be replaced. When assembling, pawl pin and pawl should have no any rusty and other situations affecting quick swing. The parts may be lubricated with a light machine oil.

( fig.8 ) ( fig.9 ) ( fig.10 )

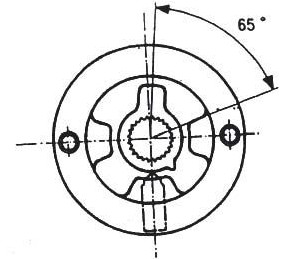

C, The installation of the ratchet stopper and the ratchet

Locking the ratchet to make the installing position reach 65°, which located in the position of ratchet stopper ( No.10 ) dragged, adjust the reasonable gap between spherical screw and ratchet stopper( No.10 ), allowing it sliding and not to jump out. ( see fig.9 )

D, During re-assembly of the winch, pay carefully attention to the angle of the ratchet stopper. After the ratchet has been tightened fully, place the ratchet stopper on the shaft at 45° angle.

E, If lock-up occurs, tap the handle stem with a rubber mallet. The winch is disassembled per the exploded view.

|