Vacuum stone lifters are basically rubber materials. Why? Because rubber products have dense and soft properties, and have good elastic deformation recovery characteristics for reuse. This is used to form an indispensable condition for sealing between the lifter and the surface of the absorbed object, if hard. If the material is used to make suction cups, there is no way to seal them by soft deformation. The air that is difficult to extract must be drilled back from the gap between the suction cup and the surface of the object. In recent years, the demand for vacuum technology in industrial applications has become more and more extensive, and it has important applications in metallurgical industry, electronic industry and mechanical manufacturing. Because there are too many processes that can not be realized under atmospheric pressure, vacuum can be used to realize these processes that can not be realized. The application of vacuum technology in metallurgical industry: With the development of modern science and technology, especially the increasing requirement of aerospace technology for metal materials, vacuum technology is indispensable. Vacuum smelting is an important branch of vacuum metallurgy. It can accurately control the chemical composition of products, improve the purity of products and improve the as-cast structure of products. The application of vacuum technology in the field of electronic industry: With the development of microelectronics technology, the size of electronic components and circuits is getting smaller and smaller, and the integration degree is getting higher and higher, which makes vacuum technology more closely related to microelectronics technology and become an indispensable technology.

Vacuum stone lifter operation mode is fast and simple. It only takes a few seconds to replace manual suction and release by remote control, which greatly improves production efficiency and production speed. Because of the different production environments, the selection conditions of vacuum stone lifter also have many standards. First of all, for example, various related physical parameters, such as friction coefficient, suction size, lifter radius, and the shape of vacuum lifter, there are three kinds of common: flat type, corrugated type and vacuum lifter with special working principle. Thirdly, the material requirements of the manipulator vacuum stone chuck are varied. Some of them work at high temperature, they need high temperature resistant silicone rubber and other blanking, this material is also easier to grasp rough workpiece. The side made of polyurethane material is durable and wear resistant.

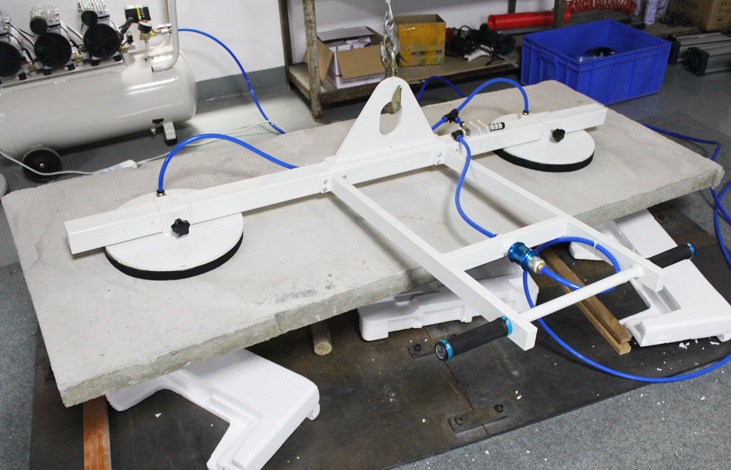

Connectors and appropriate compensating components can be used when connecting various vacuum stone lifters. A very compact vacuum suction solution can be assembled using integrated vacuum suction devices. When absorbing uneven surface or surface workpiece of arbitrary shape, the axis balancing suction head ensures that the suction head can fit perfectly on the surface of the sucked workpiece, thus obtaining a large amount of power. In vacuum technology, besides the vacuum lifter contacted with the workpiece, the operating components after the lifter also play an important role. By standardizing the combination of modules and components, vacuum lifters with higher efficiency can be combined. Stone lifters use advanced equipment to pull people down from the machine, and use automated production to completely replace manual work, which not only reduces labor costs, but also can improve the processing speed and quality accuracy of machine tools, enhance work efficiency, and bring more benefits to enterprises.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…