Automotive glass elevator consists of six parts

Keyword:glass elevator Time:2019-11-5 10:31:46

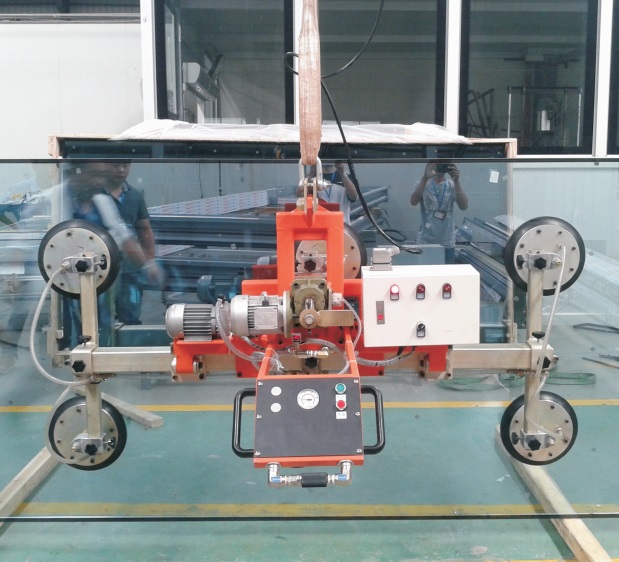

Automotive glass elevator consists of six parts

The basic working route of glass elevator is control mechanism transmission mechanism lifting mechanism glass supporting mechanism. The balance spring is used to balance the weight of the glass to reduce the control force. The stop spring installed between the pinion and the support seat is used to hold the glass (stop) to ensure that it stays at the required position. The automobile glass elevator generally consists of the following parts:

Control mechanism (rocker arm or electric control system), transmission mechanism (gear, gear plate or rack, gear soft shaft meshing mechanism), glass lifting mechanism (lifting arm, motion bracket), glass supporting mechanism (glass bracket) and stop spring, balance spring.

At present, most glass elevators are electric glass elevators. If you have the need of glass elevator, please contact us. Our company has many kinds and can eally meet your needs.

Although many new glass elevators are replaced by electric power, many automobiles still use manual glass elevators. Here are five terms for manual glass elevators:

1. Glass Lifter

It refers to the device that raises or drops the automobile window glass along the glass guide groove in a certain driving mode and can stay at any position as required.

2. Glass guide groove

It refers to the component that guides the glass when the window glass moves up and down.

3. Operation Parallelism

It refers to the distance difference between the two end points of the line segment and the corresponding end points before the movement when the length of the line parallel to the Z reference plane of the automobile coordinate system is 100mm on the window glass.

4. Effective travel

It refers to the part of the manual glass elevator whose upper and lower ends are subtracted by 20 mm in the limit stroke.

5. Simulated load

It refers to the load that simulates the sum of glass gravity and friction resistance between glass and guide groove in the movement of a real vehicle elevator.

Following is an introduction to the anti-clip electric glass elevator which automatically drops a distance after lifting to the top.

This phenomenon of electric glass is a very typical mistake of anti-clamping, mostly because maintenance personnel or car owners in the installation of lifts before the door, first connected to the power supply for lifting test (to determine the quality of the lifts in advance), just like this operation, so that the lifts completed in advance, record the large lift, so that installation. In the face of this situation, the solution is to turn on the automatic gear of the elevator switch (the second gear), cut off the power supply when the glass is rising or falling - unplug the plug connected with the motor from the motor (unplug the battery power supply thoroughly), and then learn again. It can be solved.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…