Structure and Function of Mechanical Hydraulic Oil Pump

Keyword:mechanical jacks Time:2019-11-8 13:12:51

Structure and Function of Mechanical Hydraulic Oil Pump

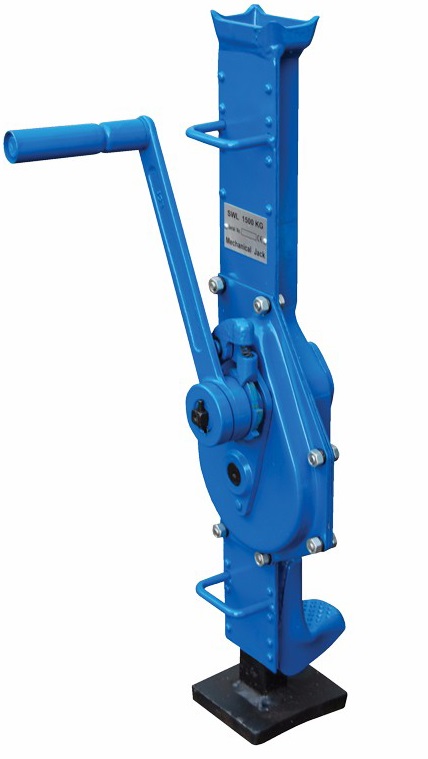

Before using mechanical jacks, it is necessary to check whether the jacks are normal, whether the components are flexible, add lubricants, and correctly estimate the weight of heavy objects, select appropriate tonnage jacks, and avoid overloading. Adjust the supporting method on the rocker, first rotate the rocker clockwise with your hands, so that the lifting sleeve can quickly lift the top weight. Insert the handle into the rocker hole, move the handle up and down, and the weight rises accordingly. When the red warning line appears on the lifting sleeve, the handle should be stopped immediately. If the supporting teeth are turned in the opposite direction, the weight will begin to drop.

In the use of mechanical jacks, we need to pay attention to the following three points: First, keep the body surface clean regularly, regularly check whether the internal structure is in good condition, so as to make the pinion in the rocker flexible and reliable and lift sleeve freely. 2. The friction surface between the lifting sleeve and the shell must be oiled at any time. The other oil injection holes should be oiled and lubricated regularly. 3. In order to take into account the safety in use, avoid overloading and working with illness, it is not appropriate to use multiple sets to avoid danger.

Our company will introduce the structure and function of mechanical hydraulic oil pump for you.

Mechanical hydraulic oil pump consists of the following parts: 1. pump body part; 2. handle part: 3. rubber pipe part; 4. oil storage tank; 5. back seat part.

Pump body part: The pump body part is the main part of the oil pump. The high-pressure working chamber, low-pressure working chamber, two one-way valves, high-pressure valves (safety valves), low-pressure valves, unloading valves, two check valves and oil intake are all above. The holes are organically connected. The two one-way valves are designed to prevent pressure oil reflux, and their specifications and functions are the same. The functions of low pressure valves and high pressure valves are pressure control. The pressure is controlled at 1 Mpa and 63 Mpa, respectively. The two balls at the oil inlet are check valves. After the work is finished, the unloading valve is opened and the pressure oil flow is returned to the oil storage pipe to complete the unloading work.

Handle part: mainly composed of pressure bar and pressure handle. The pump body and plunger are connected by two pins. The hand power acts on the pressure rod and drives the plunger to move back and forth to generate the pressure of the oil. There are M20 *1.5 screw holes on the press handle, which are used for vertical installation of the press rod. Vertical or horizontal positions can be selected according to the convenience of operation.

Rubber hose part: It is a part that connects the oil pump and cylinder to convey pressure oil. When not in use, the rubber pipe is separated from the oil cylinder, the head of the rubber pipe is blocked by a rubber cap, and the joint of the oil cylinder is blocked by a joint to prevent dirt from entering the oil pipe and the oil cylinder.

Oil injection and deflation devices are installed on the back seat or oil tank. When the oil pump works, it is necessary to loosen the gas screw, so as to avoid negative pressure in the oil tank, which will affect the normal work, and tighten the gas screw after the work is finished. Install a hook at the back end to lock the pressure bar with the hook when carrying the oil pump.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…