Why does Ramhoist recommend the cantilever crane to customers?

Keyword:cantilever crane Time:2018-12-2 11:51:08

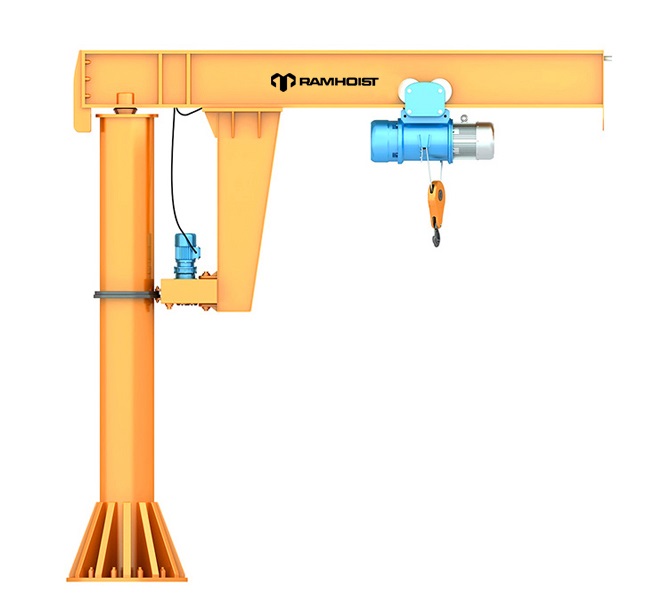

Cantilever crane | boom crane | Jib crane

In the past few years, two workers have been able to complete manual operations with cooperation. However, with the increasing labor intensity, workers began to complain. Considering their think, we used robots and automation equipment, but the cost is too high and can only be abandoned at last, then cantilever crane (also called boom crane or jib crane) appears which is very appealing in a production environment that increases worker productivity, reduce workplace injuries, and improve safety to ensure maximum equipment and worker utilization is achieved. It is a type of overhead lifting device with capacities ranges anywhere from 0.25 tons to 15 tons and fairly simple ergonomic in design that can be used as a primary lifting device within a facility to create highly productive work cells or used to supplement larger overhead cranes which often used in a smaller work cell area for repetitive and unique lifting tasks. It takes up little space and help factories make the most use of available floor space, easily and with a quick return on their investment. cantilever crane is extremely versatile and can also be paired with overhead bridge cranes to maximize production. Wall Mounted and Free Standing configurations are available and that it can be installed to accommodate about any building’s design and production layout. Please contact us for Articulating jib crane design for your applications.

Operation steps and methods of cantilever crane in engine parts manufacturing

A cantilever crane with a weight of 250Kg and a span of 4 meters is recommended for our customers. The electric hoist can be assisted.

The station is a processing center. It is a circular area with a radius of 4 meters. The engine parts between the main parts running between the pallets and the machines on the workpiece with the column arm stand are less than 75 kilograms per piece of work.

The tool that conveyed the whole tray's workpiece to the material area is a forklift. The second step will use electric hoist to lift the workpiece to the machine tool processing platform and process the machine. Finally, the work piece will also be used in electric hoist.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…