Advantages and structural features of European cranes

Keyword:European cranes, European mechanical crane Time:2018-11-27 17:04:47

Advantages and structural features of European cranes

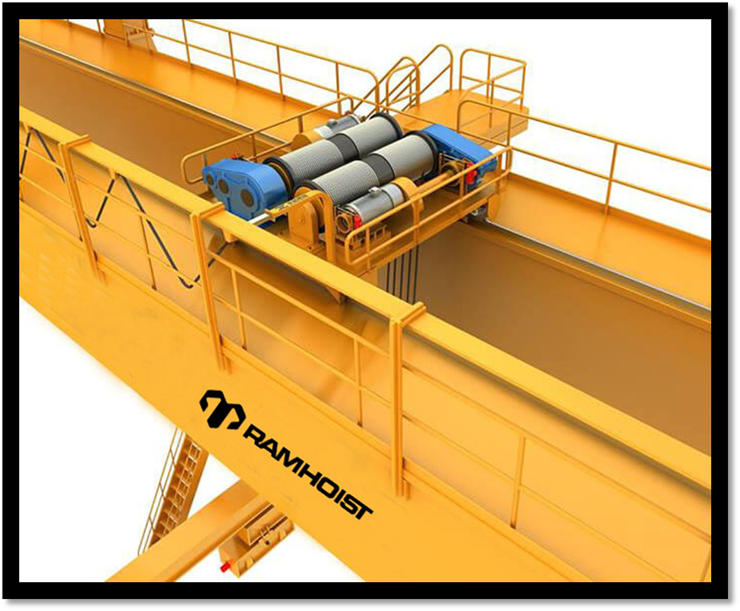

In recent years, the concept of European crane has been formed in industry, which distinguishes the traditional cranes of the former Soviet Union. Mainly include: bridge crane, Longmen crane, cantilever crane, flexible beam crane, explosion-proof crane and other industrial cranes.

The European mechanical crane is a high end crane with no definition of the present technical concept. It has all the advantages of the domestic crane. (based on the Soviet design and manufacture technology), it is similar to reliable, general, low price, and it combines the advanced European crane with compact structure, light weight, energy saving and low noise. With the characteristics of advanced technology, Chinese users especially like it.

According to the characteristics of bridge cranes proposed by China, it is a new definition of high-end gantry cranes. This type of crane is very needed in the market.

Based on the European lightweight and modular design concepts and advanced manufacturing processes, the European mechanical crane makes the whole crane compact and runs smoothly, improves the overall quality and performance of the crane, reduces the weight, reduces the height and energy efficiency, and greatly reduces the construction of the crane and the crane operation.

The advantages of European cranes

Customer investment has been greatly reduced, making full use of plant space and improving production efficiency.

We have a good combination of various specifications to meet the needs of our customers.

Ensure product design concepts are advanced, mature and safe.

To ensure the excellent performance of the crane is because we have advanced control technology and high quality key parts.

Three low includes low failure rate, low utilization rate, low maintenance cost in later stage.

Smart devices allow multiple functional interfaces to make function extension easier.

Cross section of the main girder of a European crane

The main girder adopts box type Ankang H steel structure, which is similar to the traditional first simple driving form and has greater weight.

Nondestructive flaw detection of main weld.

Homemade Q23 5B steel plate material.

A vertical line conforming to the national standard of China

Like traditional cranes, all steel plates are pre processed to achieve SA2.5 standardization.

It is usually done by automatic welding (MIG or semi-automatic welding) to complete inspection and cleaning before welding.

European Crane End Beam section

The end beam is welded by rectangular steel tube or steel plate. After molding, in order to ensure the national dimensional accuracy and tolerance. On the numerical control machine, the location of the end beam reaches the allowable deviation range.

Wheel double wheel flange, buffer and derailment protection device are equipped at each end beam.

The double beam crane is installed on the maintenance platform of the main beam driving side to repair the sidewalk.

In order to ensure the accuracy and steady operation of the whole machine. High strength bolt connection for main beam and end beam

The mainstream of market demand will be the location of European cranes.

Electric crane trolley | Electric Winch Trolley | Electric Hoist Trolley

Electric winch trolley and electric winch belongs to electric cranes trolley. Traditional electric hoist trolley and European electric hoist trolley belongs to electric hoists trolley.

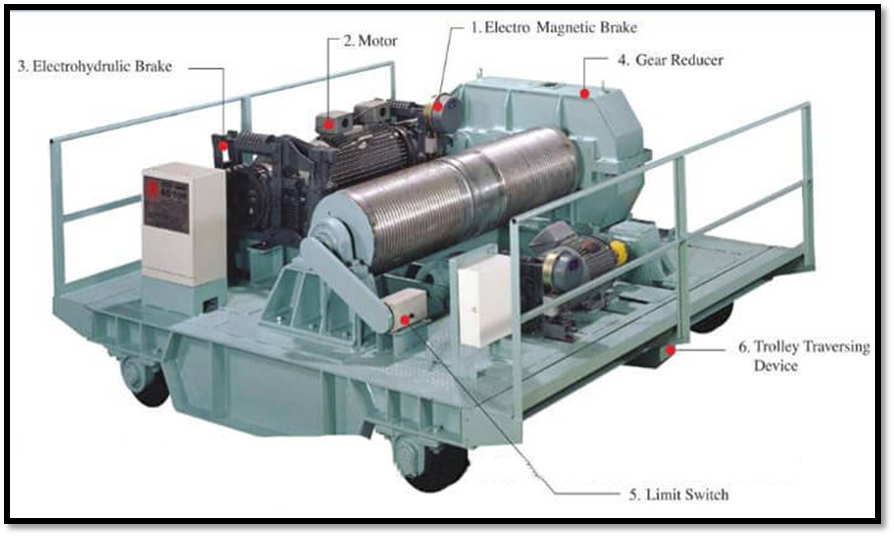

Electric Crane Trolley Structure

The electric crane trolley consists of the hoisting mechanism, the running mechanism of the trolley and the frame of the trolley. Besides some safety protection devices, the lifting mechanism also includes the motor, brake, reducer, roller and pulley.

By driving the drum with the reducer, the motor can roll the wire rope up and down from the drum and play the role of lifting heavy objects.

Crane trolley operation mechanism includes motor, brake, reducer, wheel set and so on. The function of the trolley frame is to support and install, and the frame of the lifting mechanism and the car running mechanism is usually welded structure.

Traditional electric hoist trolley VS European electric hoist trolley

The European winch trolley is a new type of crane which meets the FEM/DIN standard. It has the advantages of light weight, small wheel pressure, compact structure, low energy consumption, fast speed.

The limit distance between the shaft and the hook is smaller than the traditional electric hoist, so it has a better lifting height, thus increasing the working place of the existing warehouse.

Electric hoist VS Electric winch

The working lever of the electric winch car is higher than the electric hoist trolley. Therefore, electric winch cars should be selected for frequent operation, which can make life longer, but electric winches are more expensive.

Crane cart VS Crane trolley

Lifting cranes, bridge operating mechanisms and bridge metal structures constitute the traditional bridge cranes. The lifting mechanism, the trolley running mechanism and the trolley frame form a crane trolley.

A bridge crane is usually called a crane with a bridge operating mechanism, and the trolley is the operating part of the lifting mechanism. The crane trolley runs on the track of the workshop, while the crane trolley runs on the main girder track.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…