Analysis of difference between grab crane and hook crane

Keyword:grab crane, hook crane Time:2018-11-27 17:22:39

Analysis of difference between grab crane and hook crane

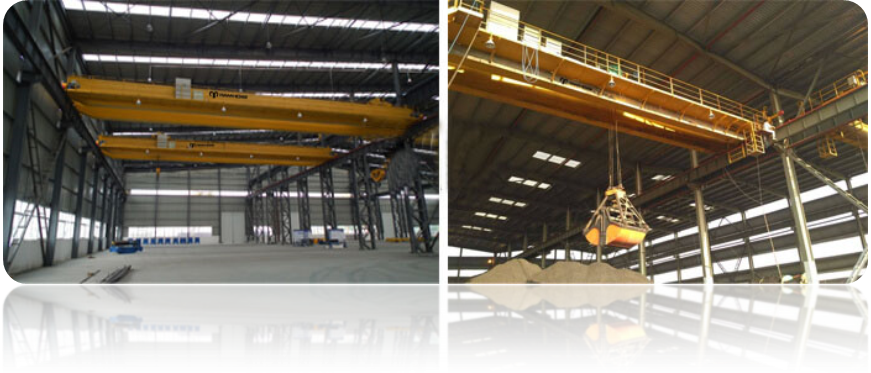

The lifting devices commonly used on cranes are clamshell and hook. Their function is to carry all parts of crane. There are obvious differences between grab crane and hook crane.

First of all, their differences in lifting capacity and carrying capacity can be used as lifting devices for cranes.

Under normal conditions, the hook crane can be directly suspended and connected to the hook and weight through a rope hook. It is mainly used to lift the whole weight, and it is necessary to bind or pack the weight before use.

Using the grab on a crane, it can grab and load the weight directly. Its principle is to lift heavy objects through the bite of the grab. Some bulk material or manual handling can be done with a grab crane, which saves the complex process of manual binding.

The difference between hoisting mechanism configuration is the next thing to say.

A crane usually has two sets of corresponding traction mechanisms, because it has a set of grab cranes that need to be operated and opened. The opening, closing and displacement of the grab usually rely on double drum winches to complete the separation and support. But one kind of crane only needs a set of traction mechanism to make the hook displacement enough. That is the hook crane, which carries a hook, and does not need to configure a double - roller winch to do anything else. However, our company has no corresponding crane at present.

Because the main part is to finish most of the bulk material such ordinary work, so the operation of the grab crane does not require too much professional level. It is mainly applied to the common hook crane, unlike the ordinary crane, because the grab crane has some special requirements for the capacity of the grab, so grab the grab. Heavy machinery is not readily available, and if necessary, orders must be made to the company before it can be traded.

Shellfish and multi petals are common shapes of cranes. In some similar environment such as sand, coal and mine, the grab crane can be used directly. The job is to grab and load materials such as stone and soil. A shell shaped grab is made of grass and wood. It can be used mainly in wood and straw processing plants to capture logs and bales. The advantage is to preserve the integrity of wood and bales.

A number of jaw opening and closing control multi flap grab, its role is to control the steel mill waste steel scraping and refining work of crawling materials, garbage disposal site and construction site of a large number of waste, as well as handling cars, car recycling stations. Car disintegration, refining, and recycling work in the G field, which uses high hardness and wearable steel to replace the bucket teeth to ensure long service life, and the valve shell can choose flaps, semi closed flaps, wide flaps, and narrow wings according to different working conditions.

The main difference between the grab bridge crane and the common hook bridge crane is that the former is the hook installed under the bridge crane, and the hooked hook can not complete the crawling operation by controlling the hook's opening and closing.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…