Chinese Cranes Development

Keyword:crane, Materials Handling Time:2018-11-27 19:36:55

China draft international standards for crane for the first time

In 2016, Beijing Materials Handling Research Institute (as five National Standardization Technical Committee Secretariat undertake units) led international standards proposal "Crane Terminology - Part 4: jib cranes," After 19 full member voting formally by ISO / TC96 "crane technical Committee, it is a breakthrough of Chinese-led international standard crane which marking China has gradually had the right to address to the highest international stage of the crane.

The Institute is committed to promote China's lifting development by continuous efforts of the voter turnout was 100% and enhance handling equipment industry international standardization level. two international meetings was hosted by 23 groups, They made four cranes proposals for international standards.

China in ISO / TC96, ISO / TC101, ISO / TC110, ISO / TC111 of Cranes and technical committee for steel ring chain, chain hoists, parts Accessories are observed (0 members) before 2005.

After ten years of hard work, now Chinese membership not only in P-members but also successfully assumed the ISO / TC96 President of the International organization for Standardization and the International Secretariat, Crane Terminology - Part 4: jib crane," sign china integrate into global stage and reach international standardization work in the crane which enhances China's position.

Development of metallurgical crane

Metallurgical crane, as an important part of special crane, plays a huge role in the field of national production. With the rapid development and continuous progress of metallurgical industry and manufacturing technology in China, metallurgical crane technology has also been improved and improved.

The development history of metallurgical crane

As an important part of the safety of metallurgical industry, gold crane is an indispensable and important equipment for normal production. It has been paid much attention to is the reliability, safety and advanced nature of its work, but the reform and development of traditional metallurgical technology have been restricted. In the 30 years before opening up, the domestic metallurgical crane basically made some minor improvements and development under the former Soviet Union mode.Since the reform and opening up, many advanced technologies have been imported from abroad, and modern metallurgical cranes have also been improved and changed. According to the improvement and application of metallurgical technology in domestic metallurgical enterprises, we have put forward some views on the development trend of metallurgical cranes.

Metallurgical enterprises are called metallurgical cranes in ladle cranes and container crane, slab loading and unloading cranes, steel coil pliers, disc cranes and other bridge cranes serving metallurgical equipment level. After the change of traditional metallurgical cranes such as metallurgical enterprises, slab (ingot), rolling technology, stripping crane, soaking pit jig, rigid material Lifting crane, crane flat flame bridge crane and hoist shovel type crane, it has gradually become out of date. According to the analysis. Metallurgical enterprises, which have been widely applied to several cranes, are now making some preliminary analysis to explore the development trend.

The general trend of the development of metallurgical crane

One of the main trends of modern metallurgy cranes is lifting weight and speed. Social development has gradually increased the demand for metallurgical enterprises, which is not merely the satisfaction of the quantity required. The quality and variety of the products are the most important in metallurgy. The large demand for social demand has promoted the technological transformation and technological progress of metallurgical enterprises, and the large converter and continuous casting and rolling are gradually applied. The large and high speed of metallurgical crane technology has put forward higher requirements. It is a simple statistic for the development of domestic production enterprises mainly for metallurgical crane ladle cranes. It can be seen from the drawing that the lifting speed and lifting weight of the main hoisting hook within fifty years. T obviously improved.

At the beginning of 70 to 80s, with the development and maturity of the AC speed regulation technology, the famous crane manufacturers abroad have launched various institutional governance commitments in succession in the beginning of the year to 80s. The speed range varies with the speed control mode. At present, a large number of stator voltage regulation and variable frequency speed control systems are designed with lifting mechanism with stator voltage regulating mechanism and frequency conversion operation mechanism.

The use of speed control has the following obvious advantages:

In mechanism, when the mechanism is stationary, the brake is only 1/10 or 1/20 at idle speed starting or braking at normal speed, and the suspension is running smoothly, especially for the operation of the cast ladle crane.

Wear off brake blocks when reducing brake

Precise positioning of suspended matter

Reduce the impact of metal structure (bridge or trolley frame) and transmission system, and extend service life.

Effectively improve the operating conditions of the operator

After starting, it can reduce the impact of the power grid

The use of timing system for metallurgical crane also brings the following problems:

Cost increase

Its arrival has put forward higher requirements for maintenance electrician technology level. Even the use of speed control system will increase the cost of equipment and increase the difficulty of maintenance, but in the development of science and technology, its speed control system is gradually reduced, and the advantage of cost is more obvious. The change of speed control system has laid a solid foundation for the development of its working conditions.

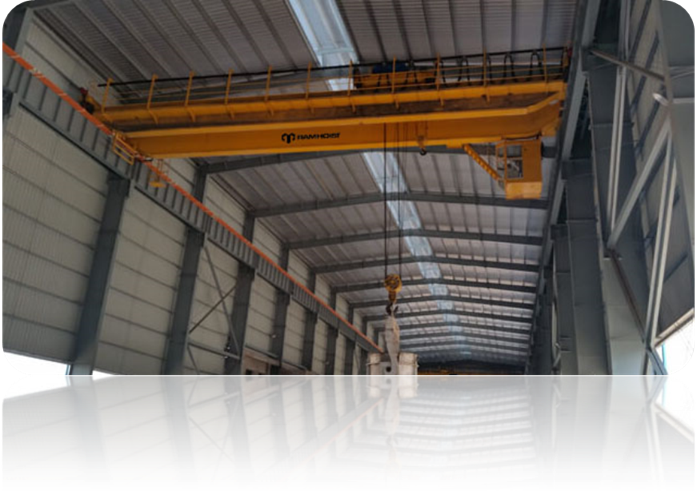

China has become an important global crane Market

China has become an important global crane market due to its rapid development of economy in recent years, the development includes petrochemical, energy, power etc which resulted in sustained and steady China crane and hoisting construction market upward, At present, A number of strong competitiveness and considerable scale of large hoisting Enterprises has emerged in Chinese lifting industry which not only take full participation in Key infrastructure construction in China but also expand the business to overseas markets. the crane market continues to rise recently which driven by the rapid development of the hoisting field in China.it has almost gathered all the world’s well-known manufacturing enterprises and most foreign crane companies have established assembly & manufacturing bases in China for promoting Localization Manufacturing System, foreign companies also invest and cooperate with chinese crane enterprisesto improve the business layout by more flexible expansion mode and throughdifferent ways. Chinese crane enterprises need to make great efforts for technical innovation against challenge of foreign ones and higher demand or users.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…