Optimum welding performance for electric hoist and crane

Keyword:welding performance Time:2018-11-28 14:52:27

Welding performance for electric hoist and crane is very import, what technology we adopt decide the quality and how many year it will be used.

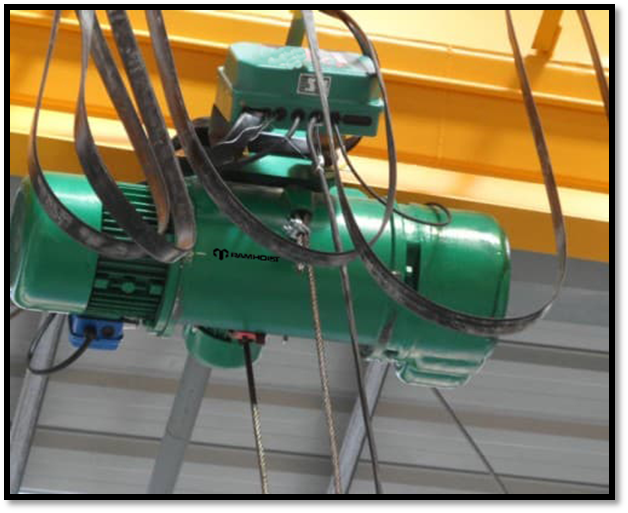

Electric hoist

There are two ways to satisfy customers' requirements for welding products. They can take two different responses, positive and proactive. Whether it is a person or a machine, reactivity means that the actual welding process capability of each ship parts welding system is not planned or analyzed.

It is not unusual for some companies to carry out numerous inspections and repairs to the welds, and various hull structures have been carried out in large amounts of redundancy and subjective inspection at present.

Real time seam tracking and adaptive processing are typical stiffener welder by bracket, welding equipment and heavy clamping device. Historically, the correct connection to maintain the line position is accomplished by manual jogging wires or using the detection seam. Now there is a more intelligent welding method, which is to do a qualified welding joint in the tolerance range, which can track the laser visual weld. This method optimizes the quality of the welding and is more suitable for the welding process. To achieve precision welding, the traditional method can not keep pace with it, and it is difficult to achieve.

The next is closed loop control. It is a laser mixing process starting from high-power laser and gas metal arc welding equipment. If you want to reduce distortion and weld more accurately, choose this way. A manufacturer deploys a closed loop control system in order to achieve optimal control and quality. This system is designed to measure weld solidification after weld formation, and then feedback the information to constant correction. You can also adjust your travel speed and laser or GMAW parameters according to your needs.

The last is the conclusion of the study. If you want to get a perfect job opportunity, you should consider the design of automatic process and inspection. For example, how to get the best welding performance, and consider the welding process and its ability in planning stage for manufacturing process design.

Single girder gantry cranes

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…