Overview and working principle of RAMHOIST electric hoist

Keyword:electric hoist Time:2018-11-29 8:26:00

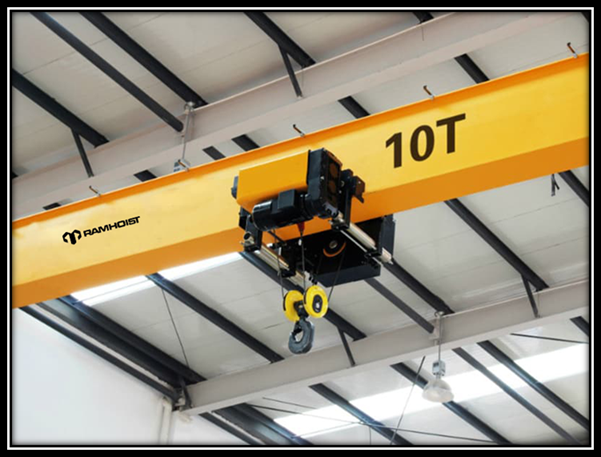

RAMHOIST electric hoist

Electric hoist is an electrical device for lifting, lowering or even moving heavy or clumsy objects. Their main function is to reduce the potential strain and injury of any person who needs to lift heavy objects when objects are too heavy for human to lift independently.

Electric hoists are widely used in many different types of work areas. Construction sites, warehouses, workshops, garage garage, dock and large ships are all suitable for their applications. But there are many other things that you do not expect. For example, lifting large tree piles or chandeliers for maintenance and cleaning can not be done.

What is the working principle of electric hoist? Initially, a solid bearing structure was connected to the crane.For example, mobile Longmen rack, cantilever crane or steel beam, or even a solid and stable anchor hook / eye are available. When lifting safely, the power control pad can be used to reduce the chain system of the hoist, near the items being lifted. If appropriate, this is directly fixed to the load.But another sling or sling is often used because they can surround the load around their center of gravity. This is to ensure that the balanced lift does not tilt. Then the sling is connected to the hoist chain hook, then you are ready to start slowly until you confirm its stability.

In order to prevent slippage and overload, most electric hoists will use some safety mechanism to solve the problem, but this is very dangerous.The hoist usually works with the clutch system, which allows the chain to slide under preset torque, thereby preventing overload. The overload limits of some electric hoists are operated by chains connected to the switch mechanism. Most modern cranes have safety cut-off switches. If there is a problem with the elevator, they can cut off the power immediately.

There are various reasons for using electric hoists. The main problem may be safety.The risk of injury can be greatly reduced by use. This is because the lifter takes all the weight, not the weight of the individual. We all know that if the lightest object is not correctly lifted, the neck or back will be easily deformed. This brings us the next advantage of cost effectiveness. The electric hoist is cost-effective, because first they can lift 3 or more than 4 elevators.As a result, human needs are reduced, and second, because they are significantly less injured and will have less sick time, so they do not reduce manpower and do not provide sick pay. Your electric hoist should last for a long time, and sometimes some problems can be easily repaired, and a qualified engineer should be selected to prove it is safe to use, usually for 6 months or 12 months of testing and inspection.

Therefore, the electric hoist seems to be a cost saving and safe way to lift all types of objects, whether large or large, light or heavy.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…