Problems needing attention in assembly process and operation of lifting machinery

Keyword:lifting machinery Time:2018-11-29 13:29:49

Users have always been concerned about the method and technology of assembly lifting machinery. So, when you assembles lifting machine, what machine components do you need to pay attention to?

Main points of attention:

The lifting machinery of assembly machinery must understand the use, structure and working principle of assembly machinery. They also need to study and understand the role of parts and their interconnections, and in the assembly process and technical requirements.

The lifting machinery of assembly machinery must understand the use, structure and working principle of assembly machinery. Research and understanding of the role of parts and their interconnections, and in the assembly process and technical requirements are also needed to be noted.

Receive and count all the components required, and prepare building materials, tools and equipment including lifting appliances.

In order to avoid reworking after assembly of unqualified parts. After cleaning and refurbishing all parts, further cleaning and technical inspection are needed, in particular, the hydraulic, pneumatic and lubrication channels should be clean and clean.

All parts and parts that can not be exchanged should be assembled or assembled in accordance with the marks of assembly, dismantling, repair or manufacture, and no disassembly is allowed. Important rotating parts can be tested according to requirements.

The surface of the moving parts should be rubbed with suitable lubricant. The oil filling tools must be cleaned and covered with dust.

Oil and sealant can be used to install various fillers to ensure sealing. Incapable of reversing in the seal process

During installation and positioning, it should be pushed by hand instead of forced by iron, forcing into about 3/4 long hands. Assembly parts should pay attention to the removal of corners, burrs and edges.

In order to ensure the quality of lifting assembly, the assembly gap, interference, flexibility, meshing and other requirements should be installed on the edge adjustment, proofreading and technical inspection.

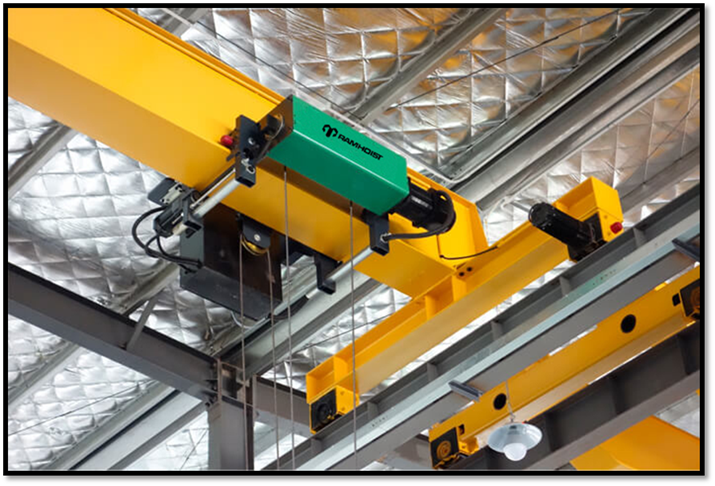

As the crane has a light weight, small wheel pressure characteristics, the new plant space can be designed to be smaller, more complete function.

The smaller plant means that the initial construction investment, as well as long-term heating, air conditioning and other maintenance costs can save a considerable amount of money.

The lifting machinery is generally moved by the lifting mechanism (the upper and lower movements of the brake parts), the operating mechanism (lifting machinery), the operating mechanism (lifting machinery), the metal mechanism, the power device, the steering control and the necessary auxiliary devices. IARE device combination.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…