How much do you know about ramhoist chain blocks?

Keyword:chain block Time:2018-12-4 21:57:39

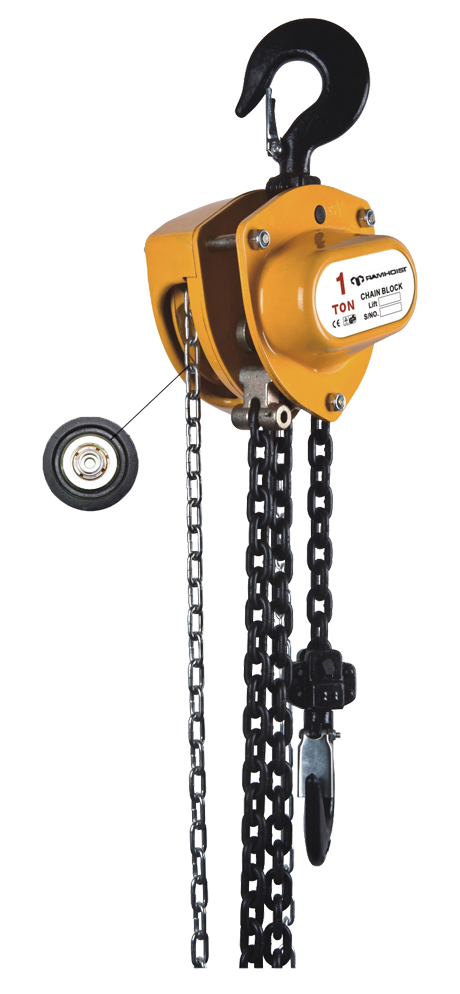

What is chain block? A chain block is a rather useful tool, which can lift a large amount of weight. To make sure that it is safe and reliable when lifting tons heavy loads, Chain blocks are made from durable, high grade steel, which can be sorted into three different part categories: lifting chains, lifting mechanism and hooks.

By using multiple larger and smaller gears in the chain block mechanism, a chain block uses a mechanical advantage to transform small force over a long distance to large force over a short distance. That is a simple physics behind a chain block which has been used for lifting heavy objects for a long time.

Chain block have two chain loops. One is hand chain and the other one is lifting chain. Hand chain sits on a wheel located in the lifting mechanism. You need use your hands to pull it when lifting a load. The wheel inside the lifting mechanism has special pockets that allow the hand chain to move the wheel. Lifting chain also loops the lifting mechanism and lifts or lowers a load. At the end of the chain, there is a grab hook. You can attach lifting chains or slings, a load leveler or load itself there. On the top of the chain blocks housing, a hook sits there. This hook is used to attach the hoist to a ceiling mount, trolley system or other construction within the bearing capacity of a hoist. Most chain blocks have swivel hooks, which can provide the possibility to be turned 360 degrees around to allow for easier mounting. The lifting mechanism consists of a cog, axle, drive shaft, gears and sprockets. There is also a chain stopper or brake on most chain blocks that prevents load from lowering under a load.

Chain block operator needs to pull down the hand chain to lift a load, this turns the cog and axle which goes through the lifting mechanism. Multiple gears inside the lifting mechanism are used to increase the mechanical work applied when pulling the hand chain for dozen times using gear ratio, allowing to easily lift loads with multiple ton capacity.

So when the hand chain is pulled, the cog which is rotated by the hand chain turns the drive shaft and gears which turn the load chain sprocket, this also rotates the load chain that is looped over the load chain sprocket and lifts a load. Larger gears move slower than smaller gears. So chain block lifts load much slower, compared to a hydraulic hoist. At the end of the lifting chain is a grab hook, which allows to easily attach and detach a load. Also, most chain block lifting mechanisms have a ratchet or braking system that prevents the load from slipping back, but allows to lower a load by pulling the other side of the hand chain.

When using chain blocks, great attention should be paid to controlling risks. Check weather conditions. The more windy or rainy the weather the conditions are, the more dangerous using a chain block becomes. High winds can make the chain block to sway while heavy rains can make the platform extremely slippery. A trained operator should have the ability to judge whether or not it is safe to use the chain block. Clear the ground below the chain block. If tools or equipment aren’t properly secured and fall from the block chain, people who don’t operate the chain block are also at risk of being injured. So it is important that the area around the chain block is properly cleared while the chain block is in use. Third, ensure mandatory general use and emergency safety procedures are in place, and that all people on site are aware of them. It is also important that these safety procedures are practiced before the chain block is operated in order to guarantee their effectiveness in case of an emergency.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…