From installation to use, you have to understand the KBK track

Keyword:KBK track Time:2019-1-7 18:22:56

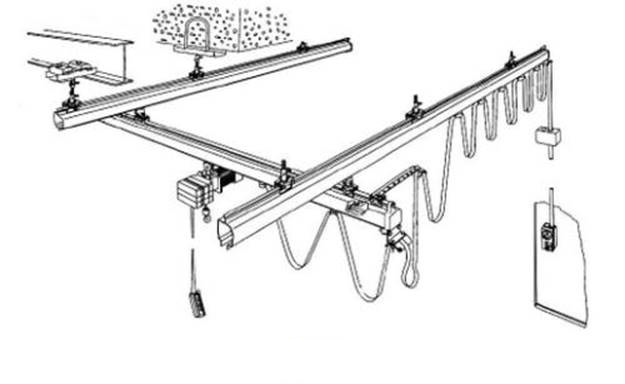

KBK track has a great influence on whether the crane can run efficiently and steadily, because the task of the track is mobile crane, which determines whether the crane can run efficiently. But in order to make the most of the efficiency of the track, we need to install the track according to the regulations and combined with the actual situation, so what standard should we install the KBK track according to?

The level of nuts used in KBK track should not be lower than 8.8. In order to ensure the track is firm, we need to install twin nuts and leak two or three rings of threads at the nut end. This is to mark the nuts for future maintenance.

The installation length of the KBK track should be appropriate, and there should be no intersection with other equipment during the whole installation of the track. This design is to enable the track to run without obstacles in the future, and to improve the overall efficiency of cranes.

In order to avoid the violent impact from the outside on both ends of the track, we should add the limit nuts at about 200 mm of the cover at both ends when we install them. This not only ensures the stability of both ends of the track, but also ensures the safety of the operator to a certain extent.

In the vertical direction of the limit nuts at both ends of the track, the upper hanging parts can not exceed 300 mm of the upper track, which we should pay great attention to during the installation process, because it involves the whole track system can run efficiently and steadily.

The lifting parts of KBK track must be installed on both sides of I-beam, and the lifting parts should be clamped under I-beam to fall into the correct position, and the ball sockets of the lifting parts should be arranged evenly.

Near the installation hole of secondary protection of track, the wire rope is not subjected to force and can‘t be larger than twice the diameter of the track wire. Only the wire rope with such specifications can meet the needs of the track in operation.

Common knowledge of KBK track operation instructions.

If you choose the customized KBK track, it is very important to find a professional, regular and experienced customization manufacturer. Especially for the production technology and equipment, we need to make repeated comparisons to ensure that the manufacturer has the ability to develop the production track independently.

Because each consumer group has different fields of use, we must pay attention to whether its environment meets the needs of this kind of equipment, and pay attention to whether the size of the track is in line with the operating environment, can it be convenient to operate?

Each type of track has its own limit, so we must not exceed the prescribed standards, otherwise it will not only bring damage to equipment, but also may lead to accidents.

Material selection is also very important, which directly affects the later use. Now the most common material of KBK track is stainless steel and aluminum alloy. It is suggested that we choose material according to our actual operating environment, so as to better meet the daily work needs.

When the KBK track is in operation, whether it is a staff member or not, it can not stand on the track, and it can‘t be under or around the track, so it is easy to cause casualties when the goods fall.

Every day after the completion of the operation, must be completed in accordance with the prescribed procedures, and ensure that the goods landed safely, the staff can start cleaning the site and equipment, and after things are organized, can leave the work site.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…