Winch-A good Assistant in Mining

Keyword:Winch Time:2019-1-18 16:17:04

Winches are light and small lifting equipments that use drums to wrap wire ropes or chains to lift or tow heavy objects.

Winch system mainly includes: main drum assembly, winch frame and shield assembly, angular transmission box assembly, turntable transmission device, main drum brake system, main brake cooling circulation system, water brake, water brake water circulation system, winch power input and output shield, crane anti-collision device and so on. The winch parts of the drilling and repairing machine are arranged on the pry seat of the power winch, which is compact in structure, convenient in installation and disassembly. In addition, I will introduce two winches to you from the aspects of speed and rope chain.

The first is the main mine twin-speed winch. Mining twin-speed winch is used for auxiliary transportation of underground mining face, fully mechanized mining equipment and all kinds of mechanical and electrical equipment, as well as dispatching of mining vehicles at underground mining face, bottom-entry yard, up and down hill, coal mine ground and other places, material transportation, and pillar roof caving in mining face.

The main features of the mine twin-speed winch are as follows: (1)Using the "double-axle and multi-stage" transmission characteristics, a large transmission ratio is achieved. (2) By using the transmission principle of "tooth-link" transmission system, not only the slow and fast speed are realized, but also the high speed ratio of fast and slow speed is realized, and the integration of fast and slow mine winches is well realized. (3) The structure of "long strip symmetry" is adopted to realize compact structure, beautiful and practical appearance, suitable for the operation of narrow space in underground coal mine, and convenient for the self-shifting of different working places. (4) High transmission efficiency, high working efficiency, large rope capacity and energy saving. (5) Easy to operate, easy to use and reliable double brake. (6) The structure and technology are simple, reliable and low cost. (7) Long service life and low maintenance cost.

These characteristics make the twin-speed winch in mining development to show its skills, widely loved by developers.

The second winch to be introduced is a new type of endless rope winch. The endless rope haulage winch is one of the auxiliary haulage equipments in mines. It can realize the haulage function of underground working equipments by using the wire rope reciprocating work. Because of its advantages of convenient installation, simple operation, less investment, low cost, long transportation distance and continuity of transportation, it plays a very important role in coal mine production as the main or auxiliary transport equipment.

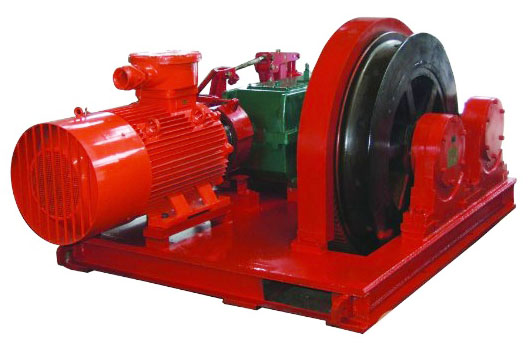

The structure of endless rope transport winch is composed of motor, coupling, electro-hydraulic brake, transmission, manual brake, drum device and base. The base is welded by channel steel. The motor, transmission and drum device are fixed on the base through bolt connection. The brake steel belts of the left and right two manual brakes hold brake wheel and internal gear respectively, and brake handle and brake base are welded on the base. When working, the motor transfers power to the transmission through the coupling. The output gear of the transmission engages with the large ring gear on the drum to drive the operation of the drum.

The endless rope winch has the following structural characteristics: (1) The whole machine has reasonable layout, novel and compact structure, small volume, less occupied area, and the direction of power input is vertical to the drum shaft. It can realize two-way operation, continuous transportation, long transportation distance and high efficiency.(2) The winch adopts a new type of transmission with originality. Change gear meshing transmission, transmission efficiency is high. It is a new type, high efficiency, high speed ratio and high load capacity deceleration device. (3) Manual braking function has been added, and its safety and reliability have been greatly improved. As the brake force decreases, the brake band force decreases, wear decreases and service life prolongs. Brake brake handle device is located at the end of winch, which is easy to operate. (4) The drum structure is symmetrical, supported on the drum shaft by a pair of self-aligning roller bearings. The supporting effect is good, the supporting stiffness is high, and the operation is stable. It can reduce the technological links, save materials and reduce costs.

The two winches mentioned above have their own characteristics, but they both have excellent performance in cost saving and convenient operation. Calling a winch has become an indispensable part of our daily mining production.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…