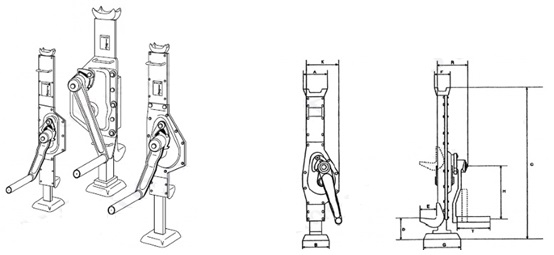

Mechanical Jacks are mechanical devices with manual drive for lifting loads which specially designed according to the latest regulations on the safety with fixed lifting claw or adjustable lifting claws fitting many areas applications like tight or confined places. There are differnet types of mechanical jacks, from small mechanical jacks to mechanical jacks heavy duty, Please check carefully before buying.

• Smooth lifting ability, low operating force, easy and reliable operation

• Used in vertical or horizontal positions with super high efficiency

• With two applicable supports stands and much higher lifting range

• Sturdy structure, small volume, light weight and quick lift performance

• Adopt high quality material CRS plate for durable use and reliability

• Low expenditure of force through optimal ratio with standard components

• Compact, rugged,ultralight design, simple maintenance and long service life

• Wear-resistant, high convenience, time saving, labor saving, large lifting tonnage

• High safety, easy for storage and portable to handle and carry, ideal for work

• Have very wide and versatile range of applications to use

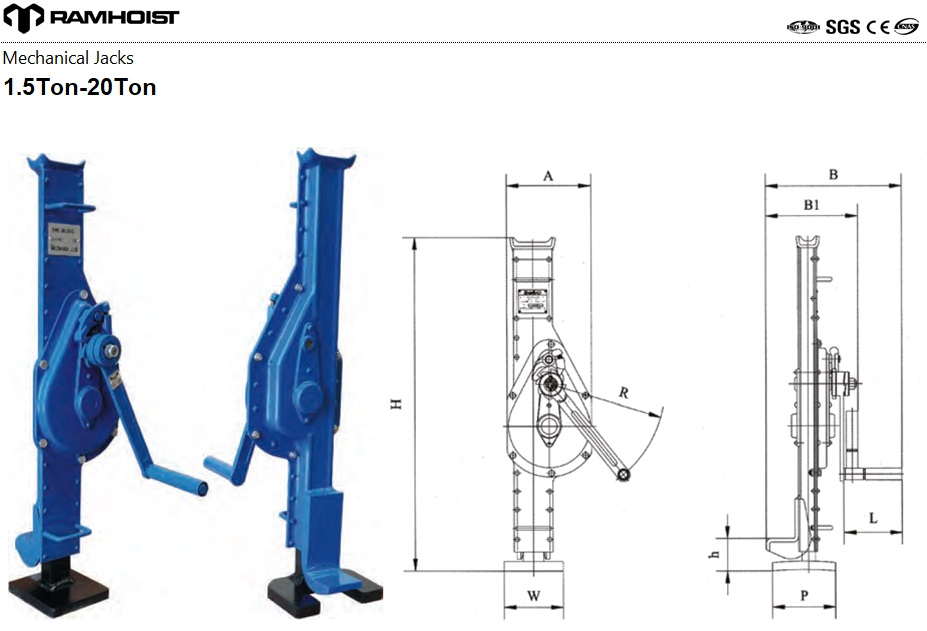

Capacity 1.5Ton-20Ton

Max. Lifting Height >400mm

Use Lifting Up/Down, automotive Repair Tools

Drive Mode Gear

Item Mechanical jack

Material Steel

Color Blue, red, and orange

Certification CE, ISO

Power source Lever

Condition New

Structure Sturdy

Orifice Single or double

Warranty 12 months

Power Supply Lever

Stroke 50-300mm

Max pressure 70 Mpa / 700 Bar

Handle Turning Radius 250-300mm

H.S. Code 84254210

Package Carton, Plywood Case or Pallet

Mechanical Jacks are mechanical devices with manual drive for lifting loads which specially designed according to the latest regulations on the safety with fixed lifting claw or adjustable lifting claws fitting many areas applications like tight or confined places. Designed by mechanical transmission principle, mechanical jacks have controllable lifting or lowering speed and they overcome overcomes the shortcoming of the common hydraulic jacks whose lowering height and speed is out of control when oil leaking. With two applicable supports stands, compact structure with top-quality all steel, mechanical jacks offer convenient operation and their range are quite higher.

All machined parts including gear wheels, the pinions and the racks are made of heat treated steel hardened. This kind of Geared mechanical jacks are stronger and more steady than normal jacks, and the lifting height is much higher, compare with other jacks they can be used in different directions and now it is a replacement of conventional jacks, It seems more and more popular than normal floor jack or scissor jack due to its reliability and multiple purposes according to sales volume. Standard features include folding handle, two carrying handles and a large base plate without seals to leak. Rack mechanical jacks are fitted with braked safety hand cranks (crank handle or safety handle x 2, rack jack is operated by a crank handle) with low expenditure of force but high efficiency and minimum turning force less than 25kg required to lift full load of all rated capacity through the optimal ratio for lifting the jack shaft along the rack which is foldable/collapsible for easy transport & storage and lowered toe with extra stability for improved usability in practice.

Industrial mechanical jack with reliable structure are proven in the most demanding operating environments. Railway employees dig our jacks into ballast in autumn, dig them out in the spring and continue using them in current track maintenance; demonstrate simplicity and reliability of jacks with rack-and-pinion drive well. It is purely mechanical structure that allows using the rack jack in the most heavy conditions (in contrast to "gentle" hydraulic jacks, rack jacks do not require lubricating oil, are tolerant to extreme temperatures, hostile environment conditions, humidity and dust), another advantage is its versatility. Rack jacks are used for pre-hanging of parts for construction, during installation, maintenance and handling operations as well as in the process of wagon and track repair. One might also move loads horizontally using a rack jack.

They are also called mechanical hoisting jacks, rack jacks, Ratchet Track Jacks, auto brake mechanical jack, mechanical ratchet jacks, geared jack,mechanical screw jacks, Mechanical rail jacks, mechanical car jacks, pulling mechanical jacks, mechanical jack hoists, mechanical steel jacks, steel rack jacks, mechanical lifting jacks, mechanical lift rack jacks, Mechanical type manual jack, Mechanical steel jack, mechanical car floor lifting jack, Heavy duty mechanical steel jacks, Pinion Jack, manual lifting jack, mechanical small manual types car jacks, mechanical toe jacks, mechanical track jacks, mechanical ratchet jacks, track jacks for railway or lifting.

They are widely applied for repairing and supporting in railway relaying, maintenance, cargo loading-unloading, machinery & bridge installation and hoisting operations, industrial sectors, machinery shops, workshops, factories, warehouse, docks, railway projects, shipyards, agriculture, mining, construction, automobile (vehicles/jeeps/quads/off-road vehicles/truck, mainly designed for fast lifting and convenient servicing of vehicles), casting machinery and transportation equipment and other areas and fields.

1. Structure (housing)

Mechanical jacks have top quality, robust, sturdy steel structure (Heavy duty all steel structure-- high-tensile alloy steel) making high safety, durability, stability and long life (will last for more than 5 years). Besides, they adopt durable baked paint rust free finish.

2. Load lock

Load lock is provided as standard, self locking function ensures the safety

3. Brake

The load is held in every position by safe and reliable load pressure brake (auto-brake and sensitive brake system) which protects the user all the time, the safe function of the load pressure brake is only guaranteed, depending on design (safety crank, safety ratchet crank), with loads off approx. 5% up to 10% of the nominal load.

4. Gear

They have low gearing tolerance with smooth transmission and free of jerks. With high quality spur gear, precise worked crank gear as well as additional worked pawl offers a very long service life possible. The steel jacks are toothed rack winches with spur gear (carburized alloy steel gear).

5. Gear rack

Gear rack is smooth and straight. The rack and pinion design of this jack makes for a low maintenance, safe, easy to use and precise alternative to hydraulic versions, Due to reasons of safe position, it is only suited for lifting loads on one side.

6. Foldable Handle

The folding handle (carrying handle/collapsible lever/ operation lever) of the crank reduces the overall dimension of the jack during transportation. Handles for transportation are available on all models, 2-Pieces of Handles provide maximum results with minimal effort, and foldable rocker handle tight design provides easy operation and simple maintenance. Anti-kick back operation lever can reduces the risk of operation and offers easy operation and simple maintenance, Self-locking, anti-kickback operating lever reduces injuries.

7. Saddle

Heavy duty saddle are designed for secure lifts and they have the ability to accurately position the load at a certain height

8. Screw

Heat-treated, range diameter extension screw extends range and allows easy height adjustment.

9. Friction pads

Special friction pads allow smooth and safe lowering of the load;

10. Overload

Safety overload system prevents Mechanical jacks from being used beyond its rated capacity

11. Head and Toe

Working Load Limit applied on head and toe except special one. The capacity of the toe is 2/3 of the head and load can be positioned on the head or the claw part and a long service life is ensured via a robust steel housing and spur gears. The toe height of the claw can be adjusted to the required mounting or maintenance application by adjustable lifting claw type, during operation the device performs smooth movement of heavy loads and allows to stop cargo precisely stops exactly at a predetermined height. They are suitable for lifting loads of any type on both the "toe" as the "head" (Head and/or Toe Lift--- can lift either with the fixed toe or on the clawed head and you can choose different position for different situation,

12. Carrrying handles

13. Ratchet and Pawl

Mechanical jacks for lifting cars are equipped with double pawl brake system which ensures quick safe and reliable braking in case of emergency. Lifting of mechanical jacks are controlled by a crank operating through a ratchet wheel with a double retaining catch which gives the jack additional safety. Lowering is by a locked ratchet which holding the load by friction discs, the lifting and lowering speed is manpowered and controllable (controlled by worker).

14. Base and post

Thanks to the fabricated from hard cast steel base, it increasinglt impove strength, which provide a sturdy support for the whole machine.

Others

With milled rack, geared wheels and tempered parts of driving gear.

All construction components standardized.

Rack jack are tested with 150% overload.

Warnings:

①Do not exceed the rated capacity and overload is forbidden.

②Before operation, please check the flexibility of the ratchet pawls.

③Be sure the manual mechanical jack is on complete balance when operating, do not put it on beveled, arc or uneven surfaces. The jack must be placed on hard plain grounds.

④Before lifting, please be sure the support stand supports the goods completely.

⑤When several jacks are used at the same time, please be sure of the same lift or down. The whole operation course should be directed.

⑥It is forbidden to put any parts of body under lifting goods.

⑦If working force is abnormal in operation, please stop working immediately to inspect all related transmit components.

⑧Lubricate parts applied regularly.

⑨The upper support should be on bottom position when the jack is not used.

⑩Do not use defective jacks or inadequate packing etc. and ensure the floor is capable of withstanding the imposed loads.

ALWAYS:

• Store and handle jacks correctly.

• Inspect jacks before use and before placing into storage.

• Ensure the surface on which the jack is placed is level, even and capable of taking the imposed loads.

• Ensure the load is capable of withstanding the forces imposed by the jacking operation.

• Use packing capable of withstanding the imposed loads without crushing. Lift and lower in small stages using support packing to minimize load falls or the load coming onto a single jack.

• Ensure the jack is positioned so that the load is applied to the jack in the correct plane.

NEVER:

• Obliquely load jacks.

• Raise the load higher than necessary.

• Over extend the jack.

• Leave a load supported solely on jacks.

• Reach under a load supported by jacks.

• Work or climb on a load supported by jacks.

Selecting the Correct Jack

Jacks may be hydraulic or mechanical in operation and are available in a range of capacities and designs. Select the jack to be used and plan the lift taking the following into account:

Type of jack - hydraulic, ratchet, screw, and journal. Capacity, closed height, lifting height, overall dimensions.

Accessories - toe or claw attachment - screwed ram and locking collar - calibrated gauges for load/pressure measurement.

Packing to be used during the jacking operation and/or to support the load when raised.

Storing and Handling Jacks

①Never return damaged jacks to storage. They should be clean and, where necessary, protected from corrosion.

②Jacks should be stored upright with the ram, rack, screw or journal lowered so that it is protected from damage whilst in store.

③Operating levers, handles, tommy bars etc. should be removed, clearly identified and stored separately.

Jacks should be handled with care.

Using Jacks Safely

①Most jacking operations require the use of multiple jacks. Care is needed as it is not possible to raise or lower jacks in perfect unison. This results in an uneven loading condition with the load being transferred from one jack to another. It can be more hazardous when lowering as the jack being lowered transfers its share to the other jacks. The capacity of the jacks should be adequate to account for this. Steps should be taken to ensure the load is kept level within the limits of operation.

②Where necessary use floor plates to spread the load over a wider area. Avoid hidden dangers such as buried cables, pipes and ducts which may affect the load bearing capability of the floor. The surface on which the jacks are placed should be level and even allowing it to sit firmly without tilting or rocking. Use packers if necessary. The head of the jack should be in full, firm contact with the jacking point of the load. Use packers if necessary to prevent the head of the jack from slipping. Do not obliquely load the jack. Never raise a load higher than necessary. Special care is also necessary when lowering loads. Use a system of jacking and packing to ensure the load will not tilt or fall in the event of jack failure. Never over extend a jack.

③Never leave a load supported on jacks. Use packing, screwed collars, trestles etc which are capable of withstanding the imposed load without crushing. Never reach under, work or climb on a load supported by jacks. Always keep hands and toes clear.

In-service Inspection and Maintenance

①Mechanical jacks should be cleaned to remove any dirt or debris paying particular attention to racks, screws, the area around top ram seals etc. Hydraulic oil levels should be checked and the oil topped up or drained and replaced. Moving mechanical components should be lubricated etc. Care is necessary in the case of ratchet jacks as excessive grease can cause the holding pawl to stick or become retarded in operation allowing the rack to free fall thus dropping the load.

②Regularly inspect jacks and, in the event of the following defects, refer the jack to a Competent Person for thorough examination: jack fails to lift or lower; load slips or creeps down; damaged, cracked or distorted body; base cracked, distorted or does not sit solidly on the floor; operating lever/handle bent or cracked; toe or claw attachment cracked or distorted. In the case of hydraulic jacks: oil leaks; ram scored, nicked or distorted; release valve inoperative. In the case of mechanical jacks: rack teeth or screws chipped, worn or corroded; swivel head seized.

Difference between cheap series and high series meachnical jacks

Specifications

Type | Capacity (t) | Lifting Height (mm) | Min. Start Jacking Height (mm) | Turning Radius of Handle | Effort required to lift full load (N) | Test Load (t) | Weight (kg) | ||

Upper Bracket | Lower Bracket | ||||||||

MJ015 | 1.5 | 350 | 725 | 70 | 250 | 106 | 1.84 | 13 | |

MJ03 | 3 | 350 | 725 | 75 | 250 | 148 | 3.68 | 20 | |

MJ05 | 5 | 300 | 725 | 75 | 250 | 216 | 6.13 | 27 | |

MJ10 | 10 | 300 | 800 | 85 | 300 | 336 | 12.25 | 43 | |

MJ16 | 16 | 400 | 950 | 95 | 300 | 345 | 19.6 | 68 | |

MJ20 | 20 | 400 | 950 | 110 | 300 | 360 | 24.5 | 93 | |

Dimensions (mm)

Type | Capacity (t) | A | B | B1 | H | h | L | W | P |

MJ015 | 1.5 | 125 | 286 | 188 | 722 | 68 | 130 | 130/160 | 140 |

MJ03 | 3 | 185 | 304 | 204 | 724 | 72 | 130 | 130/170 | 140/150 |

MJ05 | 5 | 192 | 330 | 232 | 724 | 74 | 130 | 150/200 | 170 |

MJ10 | 10 | 220 | 472 | 254 | 796 | 82 | 250 | 150/220 | 170 |

MJ16 | 16 | 380 | 510 | 300 | 950 | 110 | 250 | 200 | 230 |

MJ20 | 20 | 380 | 510 | 300 | 950 | 110 | 250 | 200 | 230 |

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...

-

...

-

...