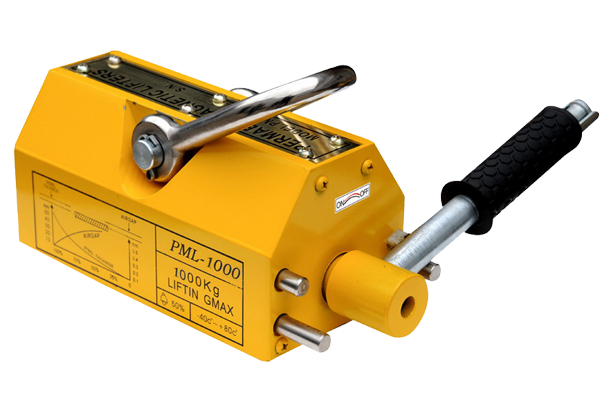

Permanent Magnetic Lifter(PML)|permanent lifting magnets, adopting steel or iron is an ideal and convenient lifting equipment with pressurizing structure which is hard and powerful to load, unload and move heavy objects such as ferrous materials and work pieces. Please contact us if you need permanent magnetic lifter operating instructions and permanent magnetic lifter price.

• Safe, light, reliable with compact structure and high strength and high efficiency

• Work without electric power but easy, quick and simple to operate and store

• Suitable for flat and round material and very high Lift to its weight ratio

• Time, space, and labor saving and electricity power-free for efficiency

• Permanent effective with constant and stable power continuously

• With high density, and long working life with excellent performance

• With exquisite design reasonable buckle and reasonable rotating shaft

• Adopt the high permanent magnet with high resistance to demonization

• Experience assembling, painting, labeling and other careful treatment

• Powerful lifting forces, constant magnetism, strength suction with no magnetic leak

• Professional appearance and reasonable price without maintenance, operating cost

• No pollution and environment-friendly and no damage to the work piece being lifted

• High-end technology with careful selection of material and testing

• Eliminate dangerous straps and sling for ensuring the high security

Capacity 0.1Ton-5Ton

Composite Node Magnet and steel

Max Breakaway Force 15000

Certification CE

Fixed form Bolt eye

Lifting eye type Reversed eye

Rope core type Steel core

Handle Length 145mm-650mm

Coating Chrome plated

Safety factor 3.5:1 or 3.0:1

Volume Small

Operating temperature Lower than 80

Color Yellow, green, red, blue, black

Magnet activation Locking on/off Handle

Use Moving and lifting Object

Drive Mode Manual

H.S. Code 8505119000

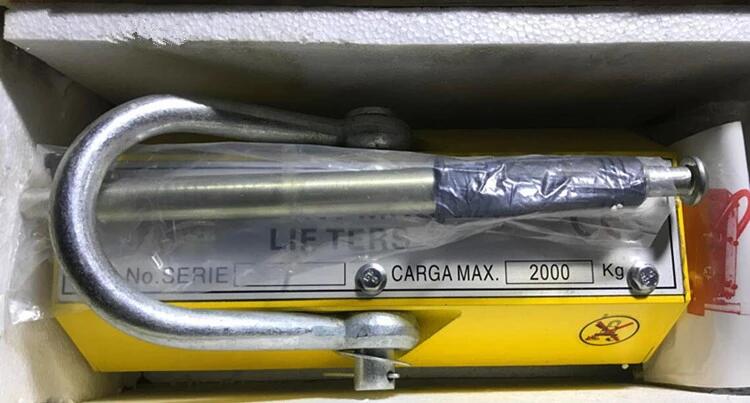

Package Plywood case(thick wooden plank)or carton

Permanent Magnetic Lifters(PML)|permanent lifting magnets, adopting steel or iron is an ideal and convenient lifting equipment with pressurizing structure which is hard and powerful to load, unload and move heavy objects such as ferrous materials and work pieces. Permanent Magnetic Lifters include various types and levels such as manual magnetic lifter and automatic magnetic lifter and are widely applied as hoist devices in industries and many other fields. One of the most prominent feature of permanent magnetic lifters is that no electricity is needed to operate the magnetic lifter, once operated there is less than 1% residual magnetism.

The permanent magnetic lifters' highest pulling force is 3.5 times greater than rated lifting capability. With the installation of the simple switch and safety bottom design, it allows for one handed operation. Before operation it is necessary to find out the percentage of the steel thickness of the component and capacity curve. And if the components surface roughness is less than 6.3um, the magnetic lifter surface gap will not exist, the lifter gap should be estimated. Then the need for slings, clamps and special lifting frames can be eliminated with the use of a magnetic lifter.

These two pole permanent magnetic lifters with two poles at the bottom of the lifter, using high grade magnets for producing strong magnetic flux path through the two poles. The lifter is placed on the MS or block that is to be lifted. With the turn for the handle on its on position, it ensures the completion for magnetic flux path through the MS body, which gets attached to the lifter. Made of two parts such as permanent sucker and discharge device, the magnetic force wire generated by the permanent magnet will go through the magnet-conductive plate and attract materials forming a closed circuit thus to achieve lifting steel materials.

We provide quality, safe and stable products to meet the highest industrial standards and we will offer reasonable price for ensuring the complete satisfaction of customers. We send all products for multi stage quality check-up before supplying to the customers to ensure better quality and performance of products. Furthermore, we employ the skilled workers and adopt advanced technology for producing and making the best products for you. We have a good reputation on the market both inland and overseas so that we are trustable.

They are also called permanent magnet lifter, permanent magnetic sheet metal lifter, permanent magnet lifting device, double magnetic circuit lifter, J Series Double Circuit Permanent Magnetic Lifter, Powerful Permanent Magnetic Lifter Hoist, Double Circuit Heavy Duty Lifting Magnet made with super strong neodymium magnets, permanent star lifter, Powerful Manual 600kg/1600lbs permanent magnetic lifter, Permanent Rare Earth Lifting Magnets.

Permanent magnetic lifters are widely applied for transportation, lifting flat mechanical parts, engine parts, semi-manufactured goods or cargoes and mould and steel in some manufacturing industries such as machine-building plants, shops, machining centers, docks, warehouses, shipping building industries and many other field and areas. For example, handling with casting, steel plates, billets, plates and rounds, steel ingots, steel sheet, block, rod, spare parts, punch sharper, plastic sharper and other magnetic objects or iron steel materials machinery accessory heavy blocks, cylinders, round bars, finished components without leaving any scratch marks, loading/unloading press molds and plastic molds and machines parts, cutting near flame, holding the iron plate and cylindrical steel durably and firmly during moving. Permanent Magnetic Lifter can be used with spreader beam hanging multiple magnets for long plates/pipes/bars and mobile cranes, which is suitable for being used to lift and transport.

1. Constitution

Permanent sucker: It consists of magnet-conductive plate and permanent magnet which generate magnetic force wire to go through the magnet-conductive plate, and form a closed circuit to lift.

Discharge device Handle. What’s more, thanks to the adoption special structure, it increases the scope of applications lifting flat steel and round steel. Using the computer simulating magnetic circuit, it has reasonable distribution of magnetic field depth magnetic penetration

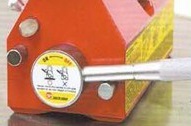

2. Manual Handle|Hand lever|Hand shake|Handle bar

The handle on the magnet features a lock-on/lock-off mechanism that requires the operator to manually switch between the two states (On and off) without extra power. The handle controls an inner magnetic system for safe and easy operation. When the handle is placed at the OFF position, the lifting magnet would have almost no magnetic pull. After you press the safety release button on the top of the handle and turn it to the ON position, the lifting magnet would then have magnetic attraction pull to a steel load. For better safety insurance, the handle is secured at this position by a lock pin. The lifting magnet would preserve full magnetic pull until you manually slide back the lock pin and turn the handle back to the OFF position. The magnets are activated / deactivated easily by turning a locking lever. In activated condition the hand lever will be safely locked and thus prevent unintended demagnetizing. This prevents the handle from being turned only ”partially on” and giving the operator a false sense of security that the magnet is holding safely, or from being accidentally bumped to the “off” position, dropping the load pre-maturely you can use very light force to roll the handle for opening so that you work will be more efficient.

3. Two poles|Two posts

These are at the base and produce strong magnetic flux path with high quality Magnets through the bottom poles. Turning so as to lift and discharging of materials is accomplished the handle to on and off positions. These are utilized widely for dependable lifting, stacking, or emptying of MS squares, adjust, or squePermanent Magnetic Lifter molds. It uses front line neodymium magnetic framework for consistent execution. The magnetic lifter is placed on the MS flat/block that is to be lifted.

4. “V” type groove|V-shape slot

The ‘V’ slots are incorporated into the holding face allowing it to be used to lift pipes or round bar work pieces. When lifting and handling cylindrical components, keeping the cylindrical surface contacts the “V” slot of lifter on two lines. The mirror surface is treated with high-end nameplate and adopts the an-it collision hand shank design.

5. Ring

Installed on the top of the lifter, the forging slip rings are lighter, more secure and are not easy to deformation and fracture. Besides, the ring wayward high and easy to wear.

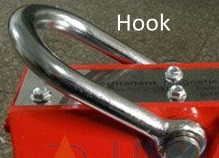

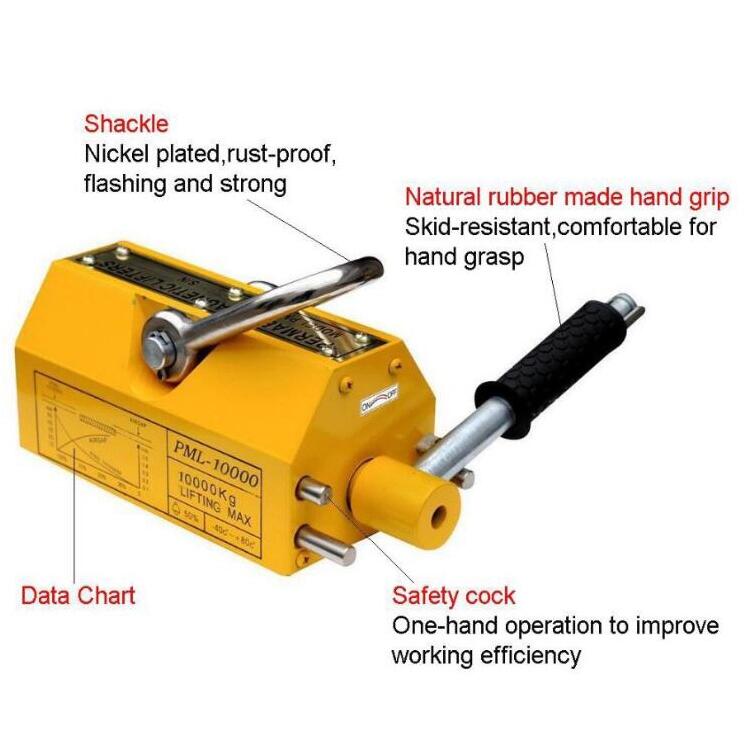

6. U-loop shackle hook

They are fixed on the top of magnetic component firmly, allowing for the easy attachment of slings and low residual magnetism for rapid handling. There is a rated shackle stamped with the Working Load Limit (W.L.L.); Test No.; Serial No.; Forged hook for high mechanical strength and durability. They have a lot of good qualities such as nickel plated, rust-proof, flashing and quite strong.

7. Magnet chuck

Make sure the center of magnet chuck and work weight coincides.

8. Crank

Before lifting, turn the crank from “-” to “+” to check if it’s auto-locked, then crane.

After finish lifting, turn the crank from “+” to “-”. Then the work piece will drop off.

9. B chamfer liner

When lifting round work-piece, keep B chamfer liner contact with the work piece adjacent angel. So the lifting force will be only 30%~50% lifting capacity.

10. Manual nozzle

Manual nozzle is tinguished by high efficiency, due to the low flow resistance, and inexpensive operation. They control the strong on and off the magnetic path of the permanent magnetic lifters, just by turning.

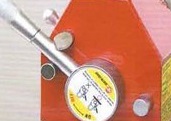

11. Curves

They are on the two sides of lifter.

12. on and off switch

It also equip with a safety switch in order to improve the working efficiency and ensure the safety for operation. With On and off switch, it is very easy and convenient to operate. The following example is suggestion for you. Operators have to change magnetic force by rotating the handle to achieve retention and release the work piece

On

Off

13. Security key|Safetu cock

Owing to the equiment of security key, it make the permanent magnectic lifters more safe and reliable. With one hand operation to iprove workingefficiency.

14. Rubber protection

The handle is protected by rubber in case of slippery and the gap and groove are designed especially for the comfortable fit to the hand. The rubber hand shank adopts high quality material which accords with artificial design with high quality chrome anti-rust handle lever.

15. Marks and tags

The limited load and the related information such as operation cautions, data chart or the structure can be printed or draw on the products for easy use and operation. With these marks, the customers can choose what they need more conveniently.

16. Bolts

Others

1. Conform to Chinese top standard (it EN 13155 TUV approved) (idt AS4991

2. Ambient air temperature no higher than 80℃.

3. Test certificate for safety factor from government approved third party

4.Factors that can decrease the magnet’s lifting ability

Load Surface Conditions: Any rough surface caused by air, dirt, paper, rust, paint and scale act will between the magnet and the load will hinder the magnetic lines of force flow from flowing easily. Find out the percentage that lifting capacity of the permanent magnetic lifters may reach from the air gap-lifting capacity curve shown in the performance chart. Combine these two factors and calculating the lifting capacity that the lifter may reach.

Load Length and Width: The increase of length or width of the load will make it not flat, and then the dropping will create an air gap to limit the flow of magnetic forces

Load Thickness: The thinner the load is, the less iron is applied, and then fewer lines of magnetic force flow. But thin magnetic-inductive material can also be lifted as long as their thickness is more than 5mm

Load Alloy: Influenced by the composition of steel component. Alloy which contains nonmagnetic materials such as ANSI304 is a poor conductor. So, we’d better choose those low carbon steels such as soft iron or mild steel.

5. Operation

Attach the permanent magnet lifter to suitably tested lifting equipment with the body hook. Then determine the load weight in the center of gravity. Once in position, move the magnet level fully anticlockwise until it is held captive by the level lock. After attached, rise and move the item to where it is required. Before lifting/moving, ensure the load is free, and lift the load a nominal distance to check balance and security of the load. Finally, use tag lines to control long or bulky load.

6. Caution

Keep surface fully clean

Wooden or non-magnetic surface won’t work

Make sure that the security moved flexibly and the security pin locked firmly.

Ferrous and casting is acceptable on the condition of enough flat area.

People are not allowed to stand under the steel sheet.

Keep off after finished.

Move smoothly without vibration Overload is banned

The temperature of work piece and ambient cannot over 80degree

Never move the handle to “ON” side, except on an iron object of holding

7. Maintenance

Paint oil/grease

Put it on thick wooden plank

8. The Little Permanent Magnetic Lifter weighing only 5.5 lbs. and safely lifts 220 lbs...With a 3.5X safety factor that’s 770lbs

The Big Permanent Magnetic Lifter lifts up to 6,600 lbs. With a 3.5X safety factor, 23,100 lbs.

MAXIMUM RATED LOADS

Calculate that the magnet will safely lift your material.

9. The Maximum Load (ML) is different for plate and round materials and also depends upon stock thickness carbon content and surface finished

Calculating Maximum Loads

Maximum lifting power is differs for plate and round materials, carbon content, thickness & surface finish.

Calculation Example: ELM-600, rated lifting power is 1,320 lbs.

The formula for calculating range of lifting capacity is: T x F x M x CapacityELM-600 Example: T8, F1, and M2, 90% x 125% x 85% x 1,320 = 1,263 lbs.

10. Electro Permanent Magnet System VS Electromagnet System

AS regard to the source of the magnetic force, Electro Permanent Magnet System is controlled by NdFeB or AlNiCo, while Electromagnet System is produced by electrical current flow. Besides, Electro Permanent Magnet System have two kings of magnetization and control the work load at the pole face while Electromagnet System just can control the work load only. Another difference is about demagnetization, Electro Permanent Magnet System doesn’t need to isolate but Electromagnet have to. And Electro Permanent Magnet System is free of electricity and more reliable than Electromagnet System. In terms of the maintenance and operational cost, Electro Permanent Magnet System is more economical because it consumes no electricity during operation and has long lifespan. When they have to lift 15tons objects, Electro Permanent Magnet System are more light weight than Electromagnet System. With simplified than electromagnetic separator without power supply and coolong system

11. The max pull-out force can reach 3.5 times of rated lifting capacity with high safety factor

Below is For small V but not big V (Difference: http://ramhoist.com/Lifting-Handling-Equipments2/2173.html)

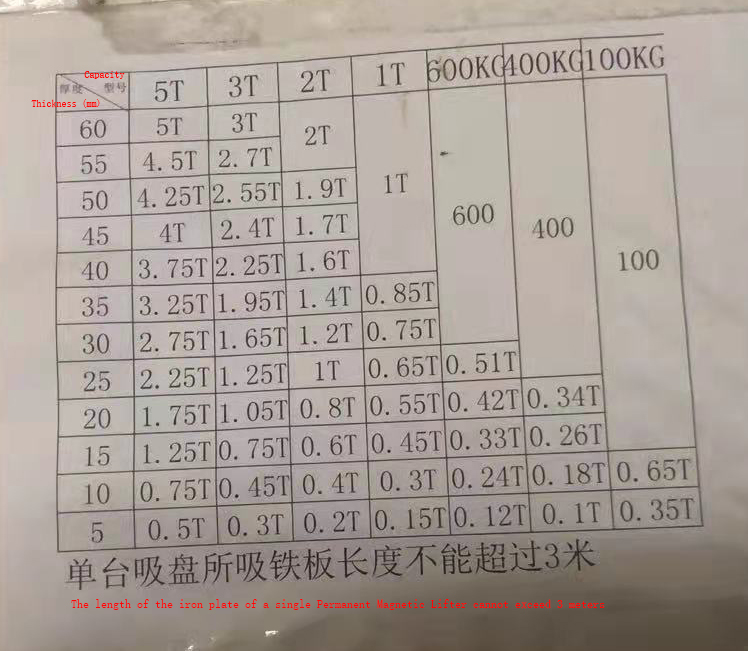

Remark: The length of the iron plate of a single Permanent Magnetic Lifter cannot exceed 3 meters

Before using, pls check the thickness and length of the steel plate you lift, in the above chart, there is Weight corresponding to thickness

Technical details of 10T Permanent Magnetic Lifter

Site photos of 10T Permanent Magnetic Lifter

Magnetic Lifters PML-1000 and PML-3000 adapted for use in subsea robotic vehicle

Inquiry for lifting magnet 600KG from UAE

Inquiry for 1ton and 2ton Small V type Permannet Magnetic Lifter from Pakistan

Problem of PML 1000 model Permanent Magnetic Lifter can't lift 1,035KG

Looking for suppliers for Permanent Magnet Lifter from Brazil

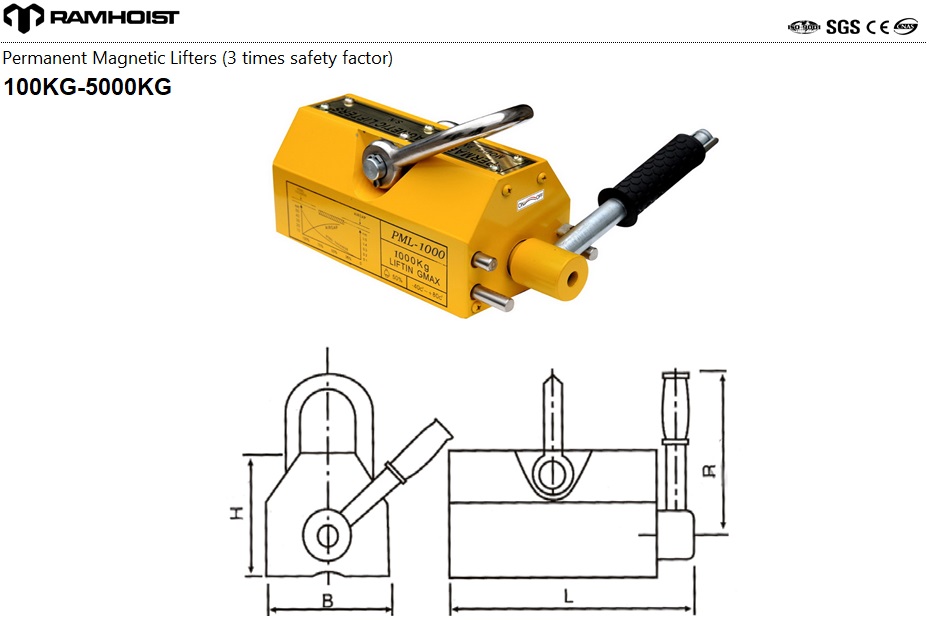

Specifications

Type | Capacity (kg) | Cylidrical Lifting Strength (kg) | Max Pull-off Strength (kg) | Weight (kg) |

PML-100 | 100 | 30 | 300 | 4 |

PML-200 | 200 | 60 | 600 | 6 |

PML-300 | 300 | 100 | 900 | 11 |

PML-400 | 400 | 120 | 1200 | 12 |

PML-500 | 500 | 150 | 1500 | 18 |

PML-600 | 600 | 200 | 1800 | 22 |

PML-1000 | 1000 | 300 | 3000 | 40 |

PML-1500 | 1500 | 500 | 3750 | 50 |

PML-2000 | 2000 | 600 | 5000 | 74 |

PML-3000 | 3000 | 1000 | 7500 | 93 |

PML-4000 | 4000 | 1200 | 10500 | 121 |

PML-5000 | 5000 | 1500 | 15000 | 213 |

Dimensions (mm)

Type | Capacity (kg) | L | B | R |

PML-100 | 100 | 90 | 63.5 | 145 |

PML-200 | 200 | 114 | 72 | 145 |

PML-300 | 300 | 165 | 88 | 176 |

PML-400 | 400 | 160 | 95 | 210 |

PML-500 | 500 | 216 | 118 | 219 |

PML-600 | 600 | 220 | 115 | 230 |

PML-1000 | 1000 | 260 | 145 | 280 |

PML-1500 | 1500 | 310 | 145 | 280 |

PML-2000 | 2000 | 340 | 160 | 410 |

PML-3000 | 3000 | 420 | 185 | 510 |

PML-4000 | 4000 | 480 | 200 | 510 |

PML-5000 | 5000 | 580 | 300 | 650 |

-

Farm jack is a small, light weight portable jack, suitable for off-road vehicles, trucks and other vehicles in …...

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...