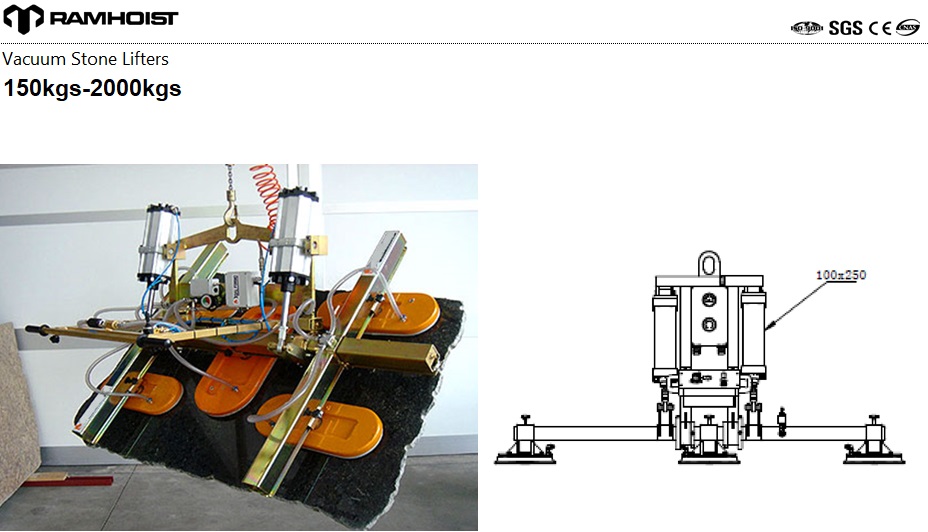

Vacuum stone lifters with pneumatic motions system, vacuum gripping system and safety protection system are designed as one kind of flexible lifting equipments mainly used for gripping, lifting, moving and placing materials, which work in a semi-automatic way. Stone vacuum lifters for sale is very competitive in china that result in stone vacuum lifter hire probability is fewer compare to those developed countries.

• Steady suction pressure guarantees a slab not to fall down in the course of work

• Two rubber vacuum suction pads prevent a slab from scratching once handled

• Equipped with batteries instead of being supplied with external power

• 0-90 degree flip moving and 0-360 degree rotation moving

• Tested by professional welders and engineers for safety and security

• Made up of pneumatic motions system, vacuum gripping system and safety protection system

• Buzzer and warning light units and vacuum pressure switch work to prompt operator treatment

• Slider valve with ON/OFF position for the attachment and release of material from vacuum pads

• Adjustable suction cups suitable for all dimensions of slab panels

• Decent price with competition under the high quality and on-time delivery with great package

• Unique technicians adopted and colours can be customized to meet customers’ requirements

• About 20 Hours maximum working period and a lot of labour can be saved

• Vacuum automatic compensation system is helpful for working safety and energy saving

• One year warranty granted on our top-than-ever commitment to customers

• Applied for steel boards, aluminum boards, plastic boards, stone slabs and wood panels

• Eliminate the risk of material breaking during shifting and make the operation more efficient

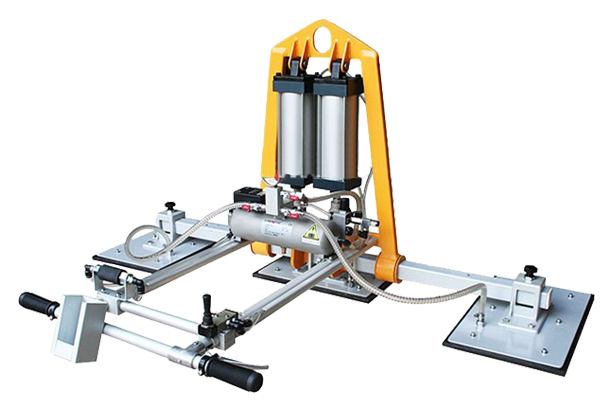

• Compressed air suction lifter for marble granite slab with 90 degree hydraulic angle

Loading capacity 150kg-2000kg

Color Yellow, blue, Bronze

Material Steel, stone, marble, granite slabs

Power input 380v, 50hz, 3phase

Pad dimension 230*300mm, 250*450mm, 400*500mm, 300*450mm, 350*550mm

Pad number 1~10

Required 5bar

Turning degree 0~85°

Vacuum on/off Manual

Vacuum flow 160L/M ~ 780L/M

Cylinder number 1~ 4

Condition New

Certification CE, SGS

Warranty One year

Rotation degree 0~360 degree

Flip degree 0~90 degree

HS Code 8428909090

Vacuum stone lifters with pneumatic motions system, vacuum gripping system and safety protection system are designed as one kind of flexible lifting equipments mainly used for gripping, lifting, moving and placing materials, which work in a semi-automatic way. Also can these lifters provide vacuum automatic compensation system for working safety and convenience and are suitable for lifting and handling glass, marble, plastic boards, metal sheets, steel boards, aluminum boards, coated boards and other plates. Besides, vacuum stone lifters driven by battery have the advantage of holding for a longer time thanks to their great flexibility and unique technology, while other common lifters cannot lessen labor and increase productivity to a great degree.

This series stone vacuum lifter is mainly designed for stone handling in workshop use. We provide two different types of handle machines: Air powered lifters are used for marbles and granite cutting machines are applied for feeding and unloading. As for quartz stone demolds, we would offer electric lifters for higher stability.

When using vacuum stone lifters, please turn the power switch to the working position and the meter will display the battery content. When the battery is low, please do not use the lifter. The compressed air switch is opened to "through", the injector starts to run, and the vacuum hand slide is kept in the "release" position, waiting until the pointer of the vacuum meter reaches the green area, which indicates that the vacuum system preserves enough vacuum and prepares for the work. The load pad is placed on the load surface to ensure that the spring buffer of all the gaskets is compressed, and all the suction pads are fully connected to the load. When the vacuum pressure reaches to the required vacuum, the vacuum manual slide valve is pushed to the "inhalation" position.

Vacuum stone lifters are also called vacuum slab lifters, stone lifting machines, electrical stone vacuum lifters, slab vacuum lifters, stone vacuum lifters, heavy duty stone lifters, granite lifting equipments, granite vacuum lifters, slab lifter equipments, vacuum lifters for granite slabs, vacuum lifters for marble slabs, vacuum lifter versatile pneumatic, vacuum lifter slim pneumatic, vacuum lifters for stone slabs, stone products vacuum lifter, stone handling vacuum lifters, vacuum paving stone lifter, pneumatic vacuum lifters for slabs.

They are widely applied for lifting, gripping, moving, placing and installing a large-size smooth or rough slab, and some situations where other types of lifters would fail, particularly through heavy industries such as plastic boards, ceramic plates, sheet metals, coated boards, steel boards, aluminium boards, stones slabs and laminated chipboards. They are also ideal vacuum stone lifting equipments for materials with different sizes and shapes such as table tops, sinks, clippings and marble shops or service providers in the works because of their adjustable structures which provide more flexibility in the movement. If you want to rent Vacuum stone lifters, Please contact us directly.

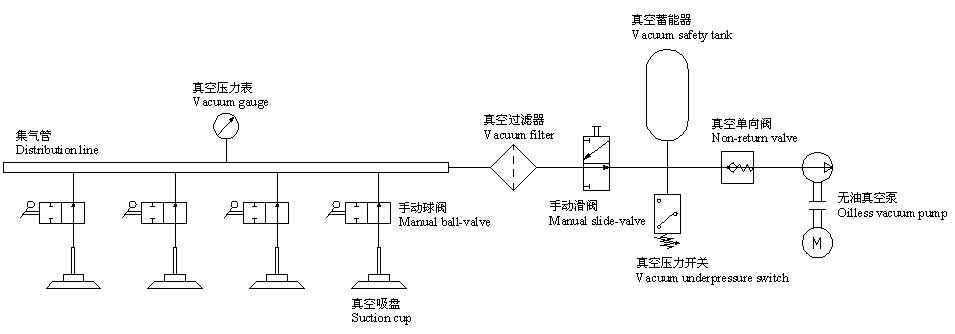

1.Vacuum tank

The vacuum tank is driven by the swirling rod body, which keeps the plunger moving in and over the air chamber. The gas in the tank enters the air chamber by the air hole and is discharged by the valve hole. And by restoring the original shape of the plunger by the elastic element, the lever can be operated with the lever and the air is pumped efficiently. So when the power fail suddenly, the pad always can holding the sheet instead of falling down less than 30 minutes and more.

2.Buzzer and warning light units

Buzzer is an integrated structure of electronic signal, using DC voltage power supply, widely used in computers, printers, copiers, alarm devices and other electronic products as sound devices. Buzzer is mainly divided into two types: piezoelectric buzzer and electromagnetic buzzer and the buzzer uses the letter "H" or "HA" in the circuit. In case of a power failure or vacuum leakage, warning unit can control the red warning lights on, At the same time a buzzer sounded, which prompts operator treatment in time.

3.Vacuum pressure switch

The vacuum switch is a kind of switch that detects the vacuum range and also known as the vacuum relay. The function is that when the vacuum degree produced in the actual work reaches the required conditions, the control circuit is automatically opened and closed, the electrical signal is issued, and the normal action of the vacuum adsorption mechanism is ordered. To detect the vacuum level, the switch control the vacuum’s starting and stopping points for power save.

4.Suction pad | Adjustable pad

A variety of suction pads made of sucker can be operated at high temperature. The pad made from silicone rubber is very suitable for grasping the rough surface. What’s more, the pad made of polyurethane is very durable. It is widely used in various vacuum suction equipment, such as in the building, paper industry and printing, glass and other industries, to carry out and carry thin and light items such as glass and paper.

5.Ball valve

The ball valve controls pad in individually and each suction pads are equipped with manual ball valve which can ensure a same equipment and handle various specifications plate. The ball valve is simple in structure, easy in position installation and convenient in loading and unloading, and does not change position due to vibration during use. It reduces time and increases economic benefits greatly. There are two kinds of billiard valves: jujube core and square. The square can be made into detachable, easy to repair and maintain, and reduce production cost. The product has been pressurized before the factory testing, and its air tightness has reached the national industry standard.

6.Air cylinder

The air cylinder is a cylindrical metal part which guides the piston to move straight and reciprocally in the cylinder. The air is transformed into mechanical energy through expansion in the engine cylinder, and the gas is compressed by the piston in the compressor cylinder to increase the pressure.

7.Spring cushion

The spring cushion mainly consists of bumper, spring and shell. Its characteristic is that the mechanism is simple and the use is reliable. When the Vacuum stone lifters hits the spring buffer, its energy mainly changes to the compression energy of the spring. The improved spring buffer with stop mechanism can prevent rebound. The structure and maintenance of the spring buffer are relatively simple, and there is no special requirement for working temperature. What’s more, suction pads are equipped with a spring cushion. When the plate is uneven, the spring effects buffer action and makes the suction pad strength evenly, so as to ensure suction and lifter safely and stably.

Others

1).Colors

The colors are various such as yellow, blue, bronze and others to meet customers’ requirements.

2).Choose the right Vacuum stone lifters for your needs:

①Pneumatically / electrically driven by vacuum system

②Pneumatically / manually / electrically function

③Tilting / rotation / both

④Automatic vacuum compensator and safety protection system needed for safety

3).Safety factor

There is a 2 times safety factor in the horizontal vacuum pump (energy saving and prolonging the life of the pump). When the vacuum reaches the specified pressure, the vacuum pump is automatically stopped to save energy. And when the vacuum pressure is insufficient, the vacuum pump is automatically restarted.

4).After-sale service

We promised to repair the Vacuum stone lifters regardless of if it was caused by defect or misuse only if you have a problem in the first 6 months of ownership. But the 6 months repair does not cover damage caused to Vacuum stone lifters.

5).Warranty

There is usually 12-month-warranty. Most of parts can be sold separately and we can provide some free part even if these parts are broken in expired warranty period.

6).Packaging

The film wrapping is designed for packaging. As to the packaging size, it depends on the machine you ordered.

7).Terms of payment

NET before consignment

8).Terms of delivery

Guangzhou Port

9.Delivery time

2 weeks after receipt of order

No matter what the applications for Stone industry you want to put Vacuum stone lifters to use, we are confident that you would find the lifters suited for you.

Classified by different use purpose, the lifters in stone handling could be divided into indoor use and outdoors use, classified by working method, the lifters could be divided into fixed and portable model, classified by power source, the lifters could be divided into electric power, battery power, pneumatic and self-power.

Workshop suited:

EPD:Electric power PPD:pneumatic power

Outdoors suited:

BPD:Battery power GPD:Self- power

Special Explanations:

Uneven or scratched surface maybe exist in Stone handling due to various usages and working conditions, normal solid suction pads cannot seal these rough surface effectively, as a result, High elastic foam rubber as sealing is adopted which is soft and long stroke to compensate the finedraw on surface, besides, safety valve is added for every solid suction pad which can close those pads work abnormally.

Workshop usage

EPD series: max loads 1000kg, mainly for quartz or other article stone separate from mold in workshop.

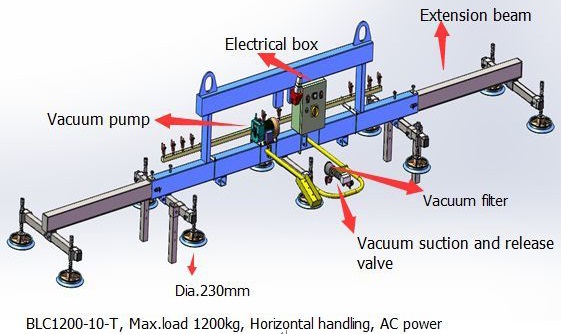

working principle drawing

PPD series--compressed Driven: Used for slabs handling in workshop; Max.Load 500kg;

PPD series Lifter uses vacuum generator for transforming the compressed air to vacuum, which seal the workpiece with high-flexible foam rubber suction pads, When the system reaches rated vacuum, the workpiece will be firmly gripped. The PPD series lifter is in light and compact shape and cannot damage vacuum generator even there is water on the slab surface, It is very suitable for loading or unloading load of polishing machine and cutting machine.

PPD series lifter can also be overturned by pneumatic or mechanical way

Outdoor installation: the installation is in open space in most case where no power supply, even in some application, the loads need to be moved for long distance. As a result, the battery power or gas engine power machine would be used for these applications.

BPD series is the vacuum lifter with high portability for load handling, the lifters were powered by battery and use a small DC vacuum pump for vacuum generation, the BPD vacuum lifter were designed only for the dense slabs, Maximum loads could be up to 300kg or more, the lifter could handle different size or material by using foam rubber suction pad, also used for shaped materials by customized pads.

BPD portable trolley series

This series is suited for longer distance transportation and larger stone installation. The different suction’s configuration can handle one piece or several pieces stone by one time. The Vacuum stone lifters with the Battery or petrol drive can be used in outdoor where electric power is unavailable.

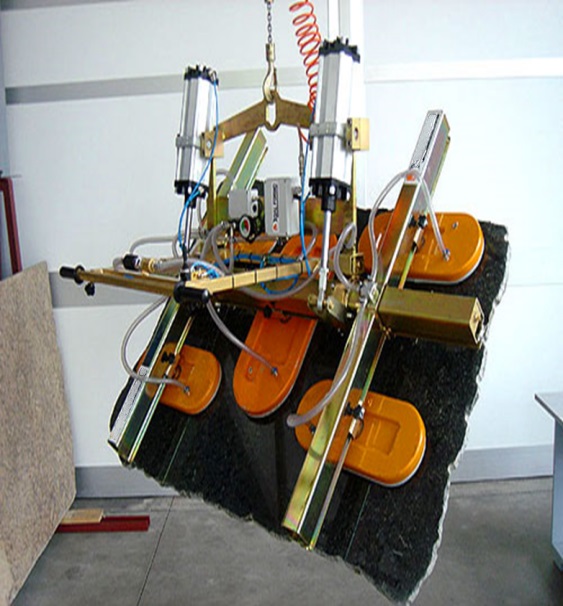

Other moving handling series

These series Vacuum stone lifters can hang on crane, fork even excavator machines to suck which can be installed on site.

Site Photos of Vacuum Stone Lifters

Inquiry for Vacuum Stone Lifters

User Manual For Vacuum Lifter PPD-MT500/3

Technical proposal for Vacuum Slab lifter Model No. PPD-MT300/1

Technical proposal for Vacuum Slab lifter Model No. PPD-PT350/2

Technical proposal for Vacuum Slab lifter Model No. PPD-MT500/3

Technical proposal for Vacuum Slab lifter Model No. PPD-PT500/3

Inquiry about Vacuum Stone Lifters PPT-PT300/2 (vsl30b) from India

Working video of Vacuum Stone Lifters PPT-PT300/2 (vsl30b): https://youtu.be/lSIogsHR26U

Slab lifting machine to lift the slab

Request for info and quotation for concrete slab vacuum lift & rotator from Singapore

Specifications

Type | Loading Capacity (kg) | Pad Dimension(mm) | Pad Number | Required | Turning Degree | Vacuum On/Off | Vacuum Flow(L/M) | Turning Unit | Cylinder Number |

VSL15 | 150 | 230*300 | 2 | 5bar | 0-85° | Manual | 160 | Manual tilting with lock for horizon and vertical | 1 |

VSL25 | 250 | 250*450 | 1 | 160 | Manual tilting with lock for horizon and vertical | 1 | |||

VSL30A | 300 | 400*500 | 1 | 160 | Manual tilting with lock for horizon and vertical | 1 | |||

VSL30B | 300 | 250*450 | 2 | 200 | Pneumatic tilting, tilting speed controllable by sense | 1 | |||

VSL35 | 350 | 230*300 | 5 | 200 | Manual tilting with lock for horizon and vertical | 1 | |||

VSL40 | 400 | 250*450 | 2 | 160 | Manual tilting with lock for horizon and vertical | 2 | |||

VSL50A | 500 | 250*450 | 3 | 200 | Manual tilting with lock for horizon and vertical | 2 | |||

VSL50B | 500 | 250*450 | 4 | 200 | Pneumatic tilting, tilting speed controllable by sense | 2 | |||

VSL50C | 500 | 300*450 | 6 | 300 | Pneumatic tilting, tilting speed controllable by sense | 2 | |||

VSL60 | 600 | 250*450*4;350*550*1 | 5 | 420 | Pneumatic tilting, tilting speed controllable by sense | 2 | |||

VSL120 | 1200 | 500*800 | 8 | 650 | Pneumatic tilting, tilting speed controllable by sense | 4 | |||

VSL200 | 2000 | 400*1500 | 10 | 780 | Pneumatic tilting, tilting speed controllable by sense | 4 |

-

Farm jack is a small, light weight portable jack, suitable for off-road vehicles, trucks and other vehicles in …...

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...