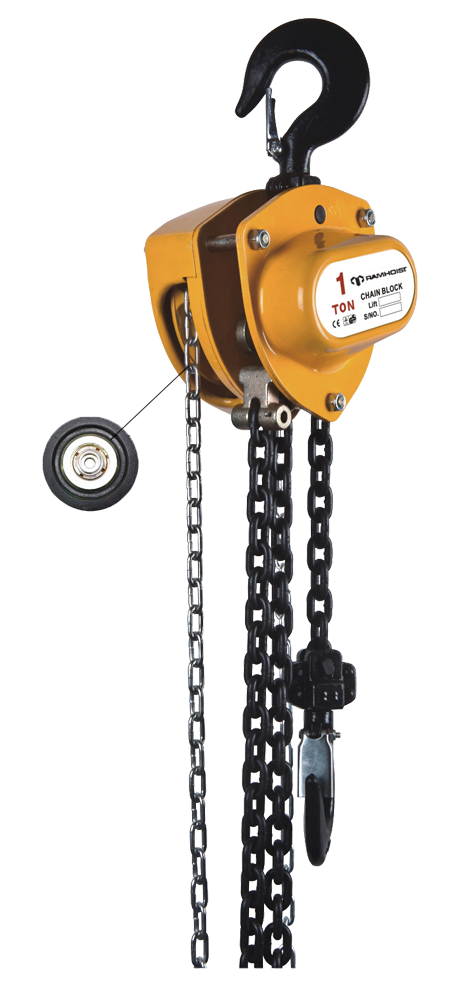

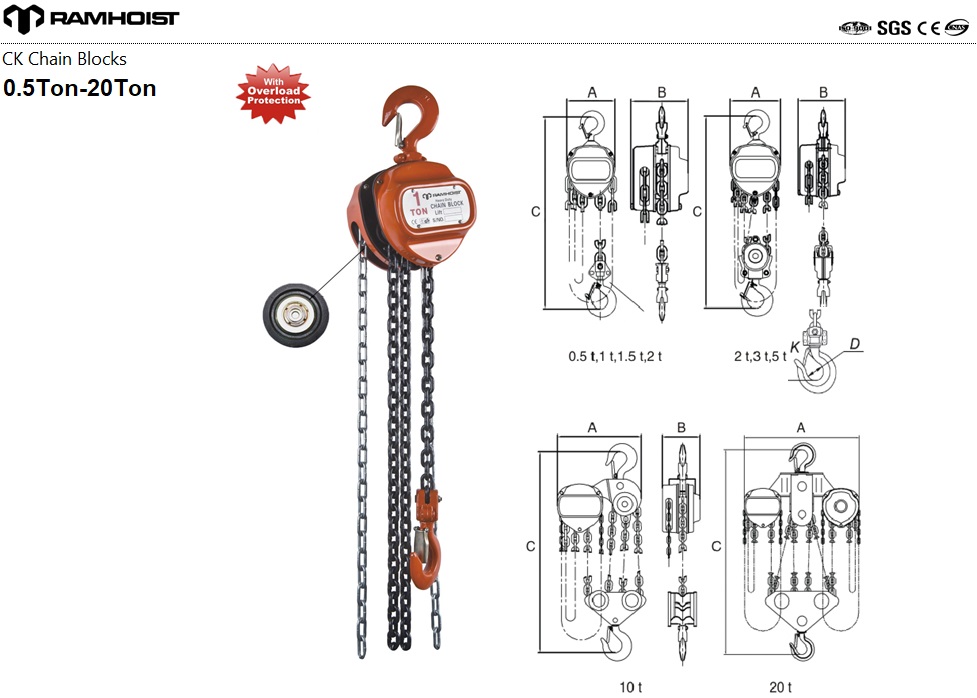

CK chain blocks are the products of the advanced technology of the world in the form of HS-C hand chain blocks. for some customers, it is called chain block pulley. In addition to the traditional features of the HS-C type chain hoists, CK type hand chain blocks have more small hand pull, high safety factor, elegant appearance,more suitable with thicker cover and stronger hooks, which is the best type in triangle type.

• With overload protection avoiding the overloading and ensuring safe working

• Durable and pretty appearance, high quality, as well as unique and exquisite design

• High reliability, need small hand pull force, low cost in repair and maintenance

• Premium grade alloy load chain and zinc plated hand chain fully meet the standard

• Special designed top hook can back out easily and can be installed with trolley directly

• Light in weigh, small in size, easy and comfortable handing with excellent performance

• Overload device with concealed structure protects itself from external damaging effect

• Rapid and stable work and be easily restored, easy to carry, and also easy to handle

• Reducing the load under rated capacity without readjustment is available in blocks

• Provide customers with excellent after-sale serve, market agent support and protection

• Drop-forged and expertly heat treated hooks for great strength and long wearing

• Manufactured by alloy metal and completed with surface hardness treatment

• Long lifespan, hard strength, high efficient, high safety factor and low failure rate

• Hooks could be attached onto the hoist without changing any hoist structure

• Suggest using at frequent overload operation environment to ensure users' safety

Capacity 0.5Ton-20Ton

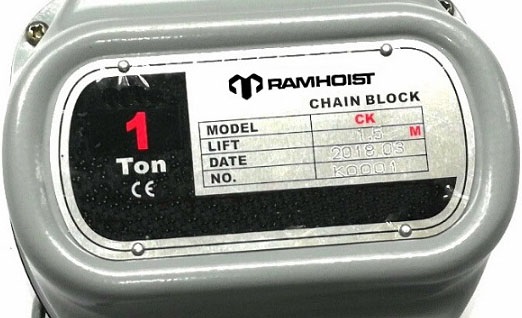

Type CK Chain hoist

Condition New

Chain G80 load chain

Certification CE, GS

Color Orange or as required

Inner part detail Double pawl

Lifting chain surface treatment Blacken

Hand chain surface treatment Galvanized

Material Forged alloy steel

Lifting speed Depend on operator

Use Lifting Up/Down

Drive Mode Gear

Sling Type Chain

Application Tower cranes, single cranes, lifting platforms, small cranes

Operation Hand Operated

H.S. Code 84251900

Package Plywood box, wood case

CK chain blocks are the products of the advanced technology of the world in the form of HS-C hand chain blocks. In addition to the traditional features of the HS-C type chain hoists, CK type hand chain blocks have more small hand pull, high safety factor, elegant appearance, more suitable with thicker cover and stronger hooks, which is the best type in triangle type. CK chain blocks have high working efficiency and require low hand pulling force and the safety factor is 4:1.

CK chain blocks are most efficient manual chain hoists, which are very ideal for standard industrial duty, standby maintenance or in locations where electrical power is not available. CK chain blocks belong to triangular types, and have many names for type here such as HSZ-CK, HSZ-K, HS-V, HSZ-A620, all mean the same block. When lifting the weight by hand, pull the chain and sprocket by hand clockwise to rotate, and press the friction ratchet wheel and brake seat into one unit to rotate together. Then, the gear wheel, the short shaft of tooth and the spline hole gear are turned by the long shaft of tooth. In this way, the lifting chain wheel installed on the spline hole gear can drive the lifting chain and lift the weight smoothly. When descending, pull the chain counterclockwise. The brake seat is separated from the brake block, and the ratchet wheel is still under the action of the pawl. The hand pull gourd generally adopts the ratchet friction disc type one-way brake, which can brake by itself under the load, and the pawl meshes with the ratchet wheel under the action of the spring.

Besides the traditional characteristics of HS series chain blocks, it has special advantage below: standard Load limiter automatic overload protection, the cover has been redesigned to protect the gear case and the extended edge of the cover can improve the abrasion resistance of the cover, adopting the deep groove ball bearing of load chain sprocket, pulling is smaller, with rugged steel load bars connected directly to hoist frame. As the fixed pulley of the upgraded version, the hand-pulled block inherits the advantages of the fixed pulley completely. Meanwhile, it adopts the combination of the reducer of reverse brake and chain pulley group to arrange the two-stage positive gear rotating structure symmetrically, which is simple, durable and efficient.

In general, CK chain blocks have great quality and high efficiency while operating, and the chain will not easy to break with long life, and can greatly decrease the labor of users. All accessories, such as hooks, connectors etc. are produced by special hot forging. G80 lifting chain is made of high grade alloy steel that are carefully chosen and sophisticated multi-process heat-treatment techniques have been developed to keep the G80. Compared with other blocks, their rust-resistant rate has been improved once. They can deal with tough industrial works thanks to their flexibility and great adaptability. What’s more, all of the parameters of CK chain blocks have been strictly tested including size, weight, and dimensions in order to ensure the perfect products can be delivered. We promised to provide the best products to our customers. What’s more, the special load test make the load limit is1.5 times more than the original load limit.

CK series manual blocks are easy-handled and easy-operated, portable cranes machines, which are widely used both indoors and outdoors. They are suitable for loading cargoes and installing machines, hoisting and unloading goods in factories, mining mountains, construction sites, agricultural production, wharfs, shipping, warehouses, especially fit for the outdoor works and areas where there is no power supply. In these areas, they have very important influences and applications. They can hang on the top of the buildings or the beam of cranes, and they can also be used with trolleys to realize the lift of heavy goods both in left and right.

CK chain blocks are also called CK chain hoist with load protection, chain block puller, chain block pulley, chain pulley, Hand manual pulley chain block block, chain puller hoist block, HSC chain blocks, HS-C chain blocks, CK type manual chain hoists, CK series chain hoist pulley blocks, CK CPB, CK series chain hoist is based on the HS series.

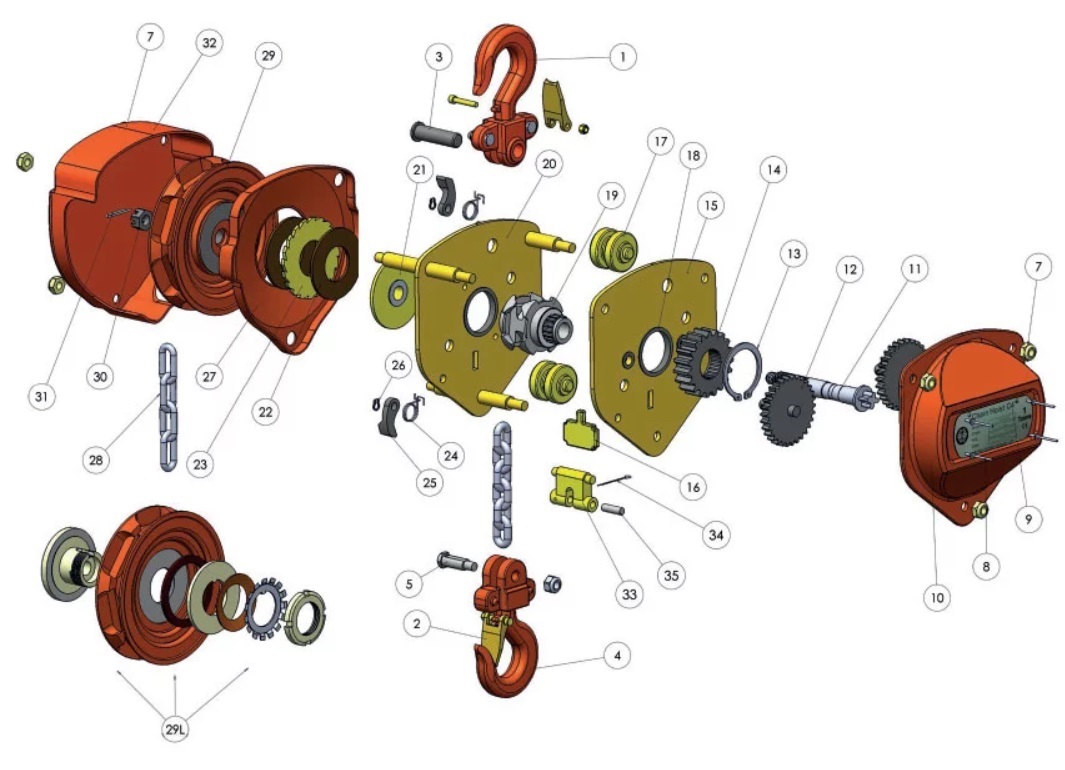

1. Hooks

Both the up and down hooks are forged and are equipped with latch in case of falling and ensuring the safety. The high intensity hooks made of alloy steel can bear overload and won’t break, even it may deformed under over strength, it won’t easy to break down. So they have high safety factor and adopt new design, which make the goods won’t leave the hooks. Because they are fitted with heavy duty safety latches, fitting groove and inspection points, they are reliable. Besides, hooks with safety latches securely can rotate freely 360 degrees.

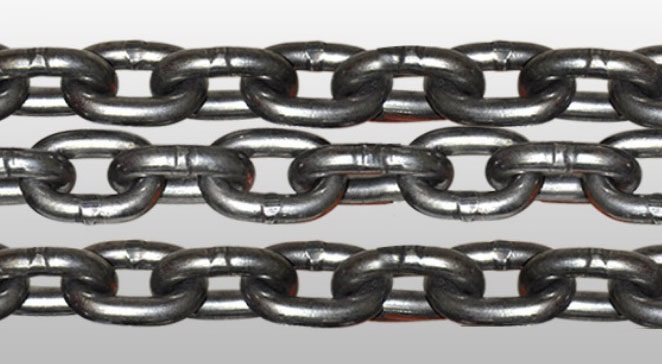

2. Hand Chain

The hand chain cover and slots accurately guide the hand chain. It adopts the high intensity alloy steel chains for large area. The opening month is exquisitely designed for hanging, and the chain looks great and compact but strong. Fitted with High strength grade 80 alloy steel load chain with black finish for corrosion resistance.

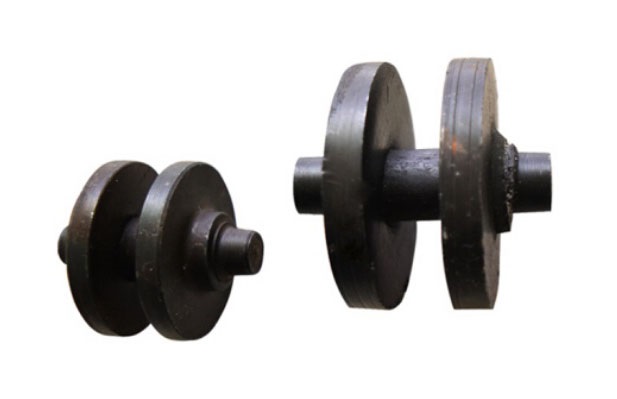

3.Sheave | Pulley

The load sheave is hardened with four precision machined chain pockets. The sealed bearing pulley have high strength. Besides, good-quality pulley can highly provide our customers a long service life of the products.

4. Roller Bearings

The roller bearings are equipped for smooth operation and low wear. The gears and bearings experienced heat treatment so that they have high intensity, which makes our products having a using life as long as possible.

5. Gears

The stage reduction gears are available, and the hardened gears and pinions are roller bearings supported, thus increase efficiency. The gears and bearings experienced heat treatment. They are innovated symmetrical arrayed high-speed synchronous gears, and are made from international standard gear steel. Compared with common gears, they are more wearable, steadier, and more laborsaving.

6. Gear Box

The gear box is hardened which adopt rugged construction featuring steel gear case and hand wheel cover for the hand chain operation.

7. Enclosed Housing

CK chain blocks adopt fully enclosed stamped steel housing allowing outdoor use. They have rust construction and the surface is painted with powder. What’s more, framework of the products has slight design, and is more beautiful with less weight and smaller work area.

8. Load Brake

The blocks adopt automatic double pawl brake system. And the fully enclosed automatic load brake with asbestos ensure free friction disc, and also can stop the operations immediately when something happened.

9. Roller

All components are mounted on roller of ball bearings to reduce friction and increase efficiency. Heavy duty guide rollers are equipped for avoiding slippage of load chain.

10.Shaft

High quality shaft is an necessary component in our products, which is used to make sure the smooth and reliable operations of lifting loads.

11. Marks

The marks such as capacity, brands and logos even warnings are printed on it. It is stainless steel riveted nameplate, and has the function of warning workers in some dangerous circumstances.

12. Bolts

Bolts are used to fix the main components of our blocks, which play an important part in products, and also are vital parts to ensure the security of blocks.

13. Inner Structure

Main components are all made of high-class alloy steel, with high precision and security. Made of high-classed steel, they are more firmly and dexterous. Reasonable inner structure has the good technology of rustproof, which makes our products become more durable and reliable.

14. Chain Sprocket

Machined chain sprocket and gears provide smoother, more efficient operation. Chain sprocket made from the steel of high material, is used to absolutely ensure the operations in the process of loading assignments.

15. Limit Switch

CK chain blocks utilize limit switch component in designation to fully protect chain from potential or possible danger, and ensure more security to our products.

16. End Anchor

The high quality end anchor which is fully meet the European standard, is designed to touch the hoist plate, so that it can withstand more force and dangers. Besides, it also can make the blocks become more stronger and durable.

17. Plastic Plating

Our plastic plating is made by advanced plastic plating technology inside and outside, it looks like a new one after years of operation.

Others

1.Exploded diagram

2.Operations

①Moving products from one place to another

②Uprooting trees

③Installing under-water pump

④Laying Conduits and pipelines

3.Cautions

①In order to prevent CK chain blocks from the corrosion, operators are supposed to clear them up and paint them with oil, place them on dry areas after using up.

②Before starting use the blocks, the friction surface of brake must keep clean and operators have to inspect the brake for ensuring the safety.

③No matter the maintenance and test, they require professional workers. Also, the bearing and gears need oil to lubricate.

④CK chain blocks must experience clearing up and strict inspection to ensure the safe operation and when the brake is stable, we can believe in them.

⑤The components of brake require frequent test in order to avoid the failure possibility and the self-falling phenomenon.

⑥For the sake of convenience of assembly, one of the hand chains is an open chain (no soldering is allowed)

⑦The roller of the left and right bearing of the hoist sprocket can be attached with butter to the inner ring of the bearing which has been pressed on the shaft neck of the hoist sprocket, and then put into the outer ring of the bearing of the wall plate

⑧When installing the brake device, the hand pull gourd should be paid attention to the good meshing between the ratchet gear slot and the pawl's claws. The spring should control the ratchet flexibly and reliably. After installing the hand chain wheel, the hand chain wheel should be rotated clockwise

4.Standard Components

5. Overload protection (Optional)

6.There is another china blocks as follows which is very similar to CK chain blocks.

Specifications

Type | Capacity (t) | Standard Lift (m) | Effort required to lift full load (N) | Load Chain | Test Load(t) | Weight (kg) | Additional Weight per 1m Lift(kg) |

Diameter (mm) ×chain falls | |||||||

CK005 | 0.5 | 2.5 | 221 | 6 × 1 | 0.75 | 9 | 1.7 |

CK01 | 1 | 304 | 6 × 1 | 1.5 | 11.5 | 1.7 | |

CK015 | 1.5 | 343 | 8 × 1 | 2.25 | 17.5 | 2.3 | |

CK02 | 2 | 3 | 410 | 6× 2 | 3 | 16 | 3.4 |

CK03 | 3 | 343 | 8× 2 | 4.5 | 27 | 4.6 | |

CK05 | 5 | 414 | 10 × 2 | 7.5 | 43 | 5.6 | |

CK10 | 10 | 414 | 10 × 4 | 15 | 75 | 11.2 | |

CK20 | 20 | 414 × 2 | 10 × 8 | 30 | 185 | 22.4 |

Dimensions (mm)

Type | Capacity (t) | A | B | C | D | K | |

CK005 | 0.5 | 113 | 125 | 270 | 35 | 30 | |

CK01 | 1 | 131 | 150 | 317 | 40 | 34 | |

CK015 | 1.5 | 146 | 183 | 398 | 45 | 38 | |

CK02 | 2 | 131 | 150 | 414 | 50 | 41 | |

CK03 | 3 | 146 | 183 | 465 | 58 | 48 | |

CK05 | 5 | 169 | 213 | 636 | 64 | 52 | |

CK10 | 10 | 169 | 405 | 750 | 85 | 64 | |

CK20 | 20 | 191 | 515 | 100 | 110 | 85 | |