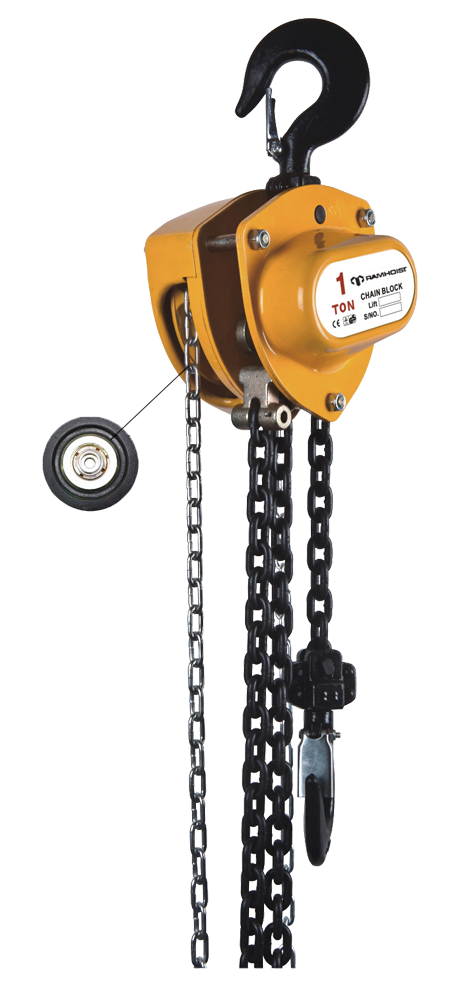

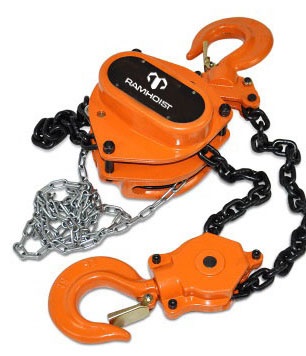

VD chain blocks with high efficiency and small and hand pulling, are portable lifting device which are easily operated by hand with safe operation, durable in service with light weight and fine appearance. VD chain blocks are same technology as kito chain blocks but price is much lower.

• Equipped with best quality hardening gear and chain won’t become stuck in troubles

• Adopt unique slot turbine design ad elegant appearance enjoying famous reputation

• Chain with high tension alloy galvanized material which resistant to rust and break

• High quality alloy hook with 360 degree rotation function used in confined space

• The hard and sturdy shell is solid enough and durable for protecting the inner parts

• Comfortable handle slip-resistant with rubber gripping and smooth touch feeling

• Up/down lever switch to up or down or neutral position adjust optionally the height

• Heavy duty and compact design which completely meet the related international standard

• Reliable, excellent disc brake, premium grade alloy load chain and galvanized hand chain

• The drop forged and heat treated hooks have a great strength and long wearing

• Triangle shape, economical, safe and reasonable structure as well as stable operation

• Samples and complete after-sale service, designed products and trial order are available

• With wider hooks opening makes easier handling and working for convenience

• 12 months warranty is the most reliable commitment we can provide to the customers

• Common-used parts, universal and strong compatibility and excellent performance

• Power coating highly provides a long lasting finish even in some hostile environments

• Double pawl and double guide rollers enhance products’ performance, safety and reliability

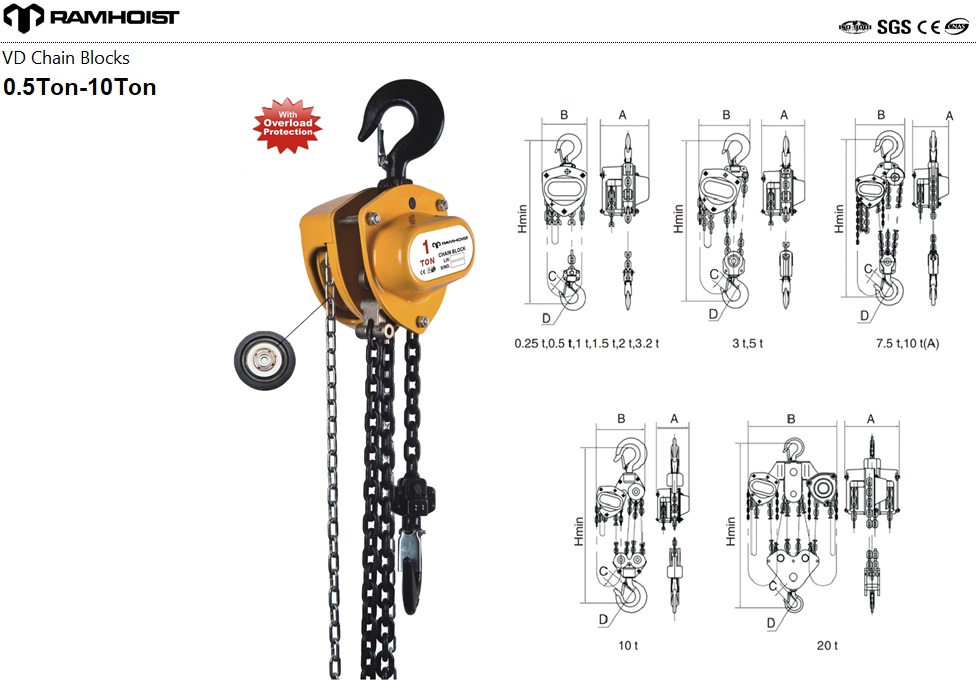

Capacity 0.5Ton-10Ton

Standard Lift 2.5m, 3 m

Application Construction hoisting

After-sale service Available

Color As your requirements

Hook material Alloy steel

Power source Hand chain

Load chain Black, 4 times brake force

Lift speed Controlled by yourself

Test load 1.5 times

Use Lifting Up/Down

Drive Mode Gear

Sling Type Chain

Operation Hand Operated

H.S. Code 84251900

Package Wooden case, carton box

VD chain blocks with high efficiency and small and hand pulling, are portable lifting device which are easily operated by hand with safe operation, durable in service with light weight and fine appearance. Sturdiness and reliability go hand when it comes to the VD chain blocks’ range, which feature a steel construction and comes with a gear case enclosure and hand wheel cover for optimum safety. VD chain blocks will provide you happy operation and excellent performance and you can keep regulators happy and boost productivity in one fell swoop.

A key feature of the VD chain blocks is the unique hand-wheel design that allows operators to be located at the side or even above the hoist without the fear of jamming. Unique curling design enables the hand chain to successfully feed directly into the wheel sprocket from many directions and angles, also featuring all-steel construction and fully-enclosed gearing. VD chain blocks are fitted with thrust bearings on lower hook assemblies. This feature allows units to rotate easily while suspended, preventing the load chain from twisting. Besides, they are plastic spray specially, and the permanent smooth film surface gets the ornamental and anti-corrosive effect.

Quality of VD chain blocks start at the top and having direct oversight at the factory helps lifting stay on top. All products are inspected, calibrated and load-tested at the main facility where the test certification is generated. This includes overload protection settings that are critical in saving property and lives. Thanks to overload protection, it is a safety mechanism design built into a product to protect it and its operators from potential damage. It also helps the user to determine the weight of their load. What’s more, overload protection assembly will allow the hoist to be lowered while the brakes hold the load. This means the load can be safely lowered and a higher-rated hoist can be used instead. However there are special considerations when it comes to overload protection with hoists, they are not all created equal. Calibration, if not done correctly, will only have overload protection by name. This is why VD chain blocks bring in all manufactured products from carefully screened and trained factories. A video showing a chain hoist triple-tested at 50 percent overload demonstrates how clever and innovative designs save cargo, equipment and lives. What’ more, the products fully meet the standard ASME B30.16 and NASA-STD-8719.9.

Using special testing, the overload limiter is factory-set at approximately 50 percent over the rated load. As the load hits 50 percent over the rated load, the overload engages, which prevents operators from using a cheater pipe or other mechanical advantages to create more leverage while eliminating the chance for hoist failure and injury. Repetitive overload stresses will eventually begin to stretch hooks, chain and interior components of the hoist, any of these could be dangerous and life threatening. Overload protection takes the guesswork out of the operators’ hands. The inherent safety built in assures that if a user guessed wrong it won’t result in hoist failure.

Another feature that saves time and money is that the VD chain blocks don’t need to be recalibrated after an overload is activated, as it automatically recalibrates the setting with no other adjustments. VD manual Chain Block is one of the most popular lifting hoists throughout the world, which is promoted from the Japanese model, patent model with revolutionary designs, special designed top hook can back out easily and can be installed with trolley directly. Premium grade alloy load chain and zinc plated hand chain as standard. Drop-forged and expertly heat treated hooks for great strength and long wearing.

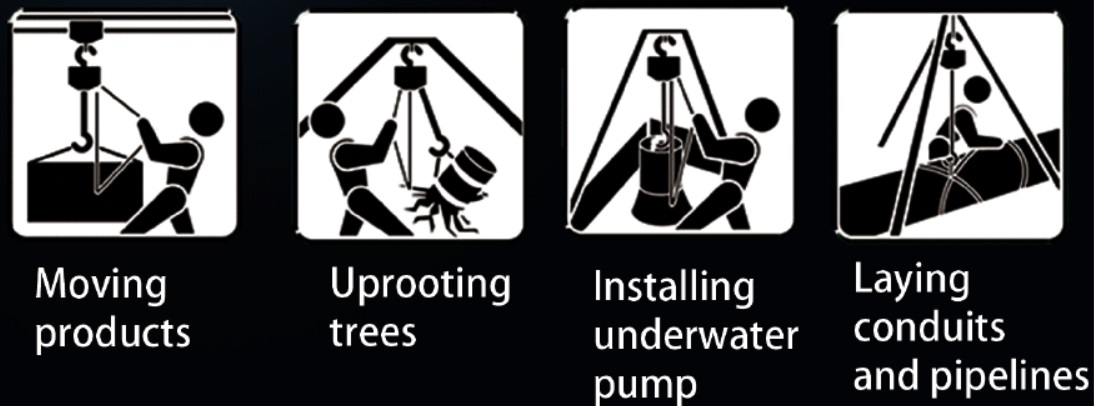

VD chain blocks are popular among industrial fields for cranes such as travelling cranes and jib cranes. They can be used in factories, heavy industries, building construction, mining sites, agricultural and some areas where there is no power supply. This kind of chain blocks can also be attached to a trolley of any type as a traveling chain block.

VD chain blocks are also called VD chain blocks, Kito chain blocks, Kito chain hoists, chain blocks, hand chain hoists, VD manual chain hoists, KT series chain hoists. This is KITO type and has many names for type here such as VC-D, HSZ-CD, HSZ-KT, HS-R, CB, CB-II, HSZ-A810, all mean the same manual chain hoist.

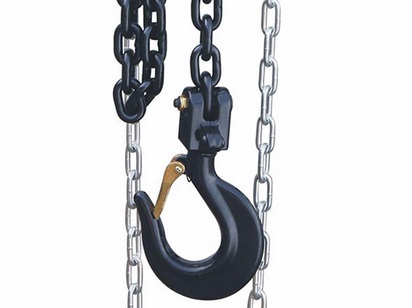

1. Hooks

VD chain blocks adopt tensile safety hooks, forged alloy steel hooks cast steel safety latches. Both the top and bottom hooks are made of high tensile alloy steel with special treatment which guarantees the hook will not break and deform gradually under a sudden extra-load. Load hooks are heat treated and fracture resistant. In case of dangerous overloading or abuse, the hook does not fracture but will slowly yield or bended. Besides, the opening month is widened or that the hook opening degree is increased so that they can be applied in many other situations. Furthermore, it is easy to install and disassemble.

2. Encloser

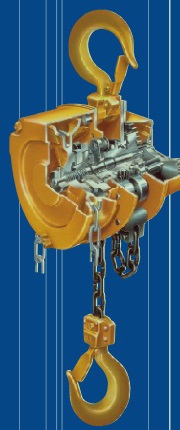

VD chain blocks adopt the double thickening design and the special tensile professional skills to the cover/enclosure which makes it resistant to the hit and rust or rainwater and not easy to break. Therefore, it can protect the inner mechanism well. It also use the special design of triangular spline long shaft design long axle structure which easy to disassemble, and it can widely applied in outdoors. Special heat treated top and bottom hooks have enough strength and toughness for hard job. The design of the bottom hook, with relatively large dimensions, makes it easy to stabilize a load in proper position. Bottom yoke with protecting guard features a guard protecting the chain pin and nut form damage, enhancing safety. The braking mechanism which makes up heart of the hoists, is enclosed in a double cover: the brake covers and wheel covers. These protective covers can not only keep out weather elements but also help to prevent mud and dust from entering internal mechanisms. Hand chain guide attached to the wheel cover provides durability and smooth operating.

Hand zipper disk cover use a special crimping process, which ensure to prevent the loud noise while the hand zipper is leaning or horizontal, at the same time, it improves the intensity. Also, hand zipper plate use deep groove design which will never card chain and available in many situations.

3. Construction

All steel construction, impact resistant covers that provide durability and protection. VD chain blocks adopt light weight and robust construction. The upper and down construction use forged framework which has elegant and beautiful appearance and high intensity. The alloy steel shell is very strong and not easy to break. Also, the triangle shape is stable for the whole structure. Cause the exquisite structure, they are durable for use and can be applied in many tough situations and are resistant to water and rust, even corrosion-proof.

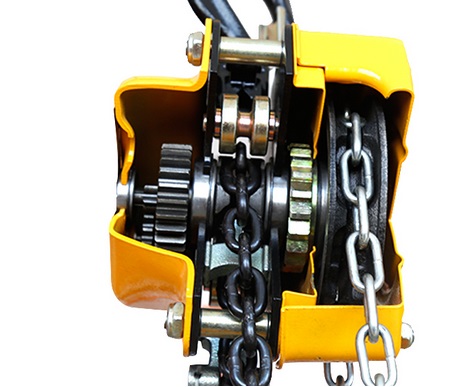

4. Gear

VD chain blocks adopt the best tenth shape rotating gears and all use low alloy steel and exquisite professional producing. Experienced the carbon and heat treatment and special surface treatment, it makes the surface clean, tidy, hard, corrosion-resistant and rust-proof, and they are durable in use. They can also make the full use and efficiency of the machine. AS a result of Ram hoist research and development for a long time, Ramhoist is successful in developing compact but highly efficient and durable gears. We adopt Japanese technology, symmetrical arrayed high-speed synchronous gears, and made according to international standard gear steel, steadier, and more laborsaving.

5. Chain

The chains adopt the high intensity chains and the lifting efficiency has been improved 3 times. Thanks to the special design of the lead, the pull force need less compare to the same products. What’s more, chain guide mechanism in flanged load sheave and guide roller facilitate smooth movement of the load chain.

6. Multi-point Support

VD chain blocks adopt multi-point support structure, which makes the operating system more reasonable, convenient and flexible to rotate and have a low rate to fail. The triangle structure is very stable, so the support is very strong.

7. Double-pawl Braking

In order to improve the safety factor to a high level, VD chain blocks adopt double-pawl braking system in case of the emergency. It adopts double-pawl mechanism to further increase of sureness. In case one of pawl is damaged, the other maintains its functions. Ramhoist dry type asbestos with free mechanical brake ensured strong brake performance.

8. Overload Protection Wheel

Good quality overload protection wheel plays a vital role in the process of lifting loads, which can highly ensure the security to products, especially in some dangerous circumstances.

9. Guide Wheel

Lifting chain wheel, made of high quality alloy steel, uses special bearings at both ends, which has high precision and high intensity with great flexibility to rotate. Besides, compact structure of guide wheel provides a long using life to our products.

10. Bearing | Roller Bearing

Thrust bearing allows easy rotation of load while suspended and prevents load chain twisting. The bearing mechanism increases mechanical efficiency. Using of unique ball and needle bearing remarkably increases mechanical efficiency and produces high output power with minimum manual input. The roller bearing on the gear cover has low friction, low resistance and high stability. Besides, the wheel cover and the support plate are integrated.

11. Shaft

The shaft is made of good quality steel, which is located on the wheels. And it has the function of making sure the operations of VD chain blocks.

12. Gear Case

VD chain blocks are equipped with gear case and hand wheel cover which is resistant to external shocks. Both sides of the hoist are covered with a thick steel gear case, processed with highest level technology, and with a strengthened wheel cover. They have ideal shape and rigidity to maintain bearing alignment and withstand external shock.

13. Stopper

Stopper assembly prevents excessive lowering of a load and also keeps load chain from exiting if over lowered. When you feel a noticeable increase in pull force to lower the load, you may realize that you cannot lower the load any further.

14. Inner Structure

Inner structure is designed and manufactured by professional workers. And compact structure makes the products become more safe and reliable.

15. End Anchor

End anchor is a necessary component in VD chain blocks. It is easy to disassemble, and highly protect the load assignments from potential or possible dangers.

16. Ratchet Disk

Ratchet disk is used in our VD chain blocks. It can highly stop the products immediately when the operations of lifting loads, especially in some hostile enviornments.

17. Unique Elastic Clutch

Unique elastic clutch adopts professional technology, which makes it lift goods at any height. It also make the lifting loads become more efficient.

Others

1. Provided service

◊ We offer sample and trial order is OK.

◊ We offer quality assurance contract and complete after-sale service.

◊ We offer confidentiality agreement "business secret contract” for your design safe.

◊ We have more than 50 professional technical team. After a large amount of developments, today we are one of the leading companies in our field, we have professional mature design team, quality control team, production management team and sales service team.

2. VD series chain block (chain hoist) is our newly supplied product, which is advanced in design, reliable in quality and superior in appliance. It possesses good performances as model HSZ series chain block and in equilateral triangle appearance, looking more special and nice.

3. Components

Fully forged Hooks

With Double guide wheels

With G80 load chains of high quality which can be galvanized/blacked as per option

Automatic double pawl braking system

Lightweight robust construction

Low effort to lift maximum load

ISO high grade alloy load chain

Zinc plated hand chain as standard

Extra thick asbestos free friction discs

Double cover protection (optional) black or galvanized load chain

Durable backed enamel paint protection

Overload protection device available upon request

4. Caution

①Special attention should be paid to ensure the good contact between wheels and flange surfaces.

②When the hook is overload, it will become deformed slowly instead of suddenly fracturing.

5. Package

6. Usage

Specifications

Type | Capacity(t) | Standard Lift (m) | Effort required to lift full load (N) | Load Chain | Test Load (t) | Weight(kg) | Additional Weight per 1m Lift(kg) |

Diameter (mm) ×chain falls | |||||||

VD005 | 0.5 | 2.5 | 200 | 5 × 1 | 0.75 | 11 | 1.5 |

VD01 | 1 | 320 | 6.3 × 1 | 1.5 | 12.5 | 1.8 | |

VD015 | 1.5 | 360 | 7.1 × 1 | 2.25 | 17.8 | 2.1 | |

VD02 | 2 | 365 | 8× 1 | 3 | 19.5 | 2.3 | |

VD03 | 3 | 3 | 385 | 7.1× 2 | 4.5 | 29 | 4.2 |

VD05 | 5 | 435 | 9 × 2 | 7.5 | 41.3 | 5.1 | |

VD10 | 10 | 435 | 9 × 4 | 15 | 78.5 | 10.2 |

Dimensions (mm)

Type | Capacity (t) | A | B | C | D | H | |

VD005 | 0.5 | 132 | 148 | 23 | 35 | 345 | |

VD01 | 1 | 151 | 172 | 27 | 40 | 376 | |

VD015 | 1.5 | 173 | 196 | 33 | 45 | 442 | |

VD02 | 2 | 175 | 210 | 35 | 50 | 470 | |

VD03 | 3 | 176 | 230 | 39 | 55 | 565 | |

VD05 | 5 | 189 | 280 | 45 | 65 | 688 | |

VD10 | 10 | 189 | 463 | 54 | 75 | 765 | |