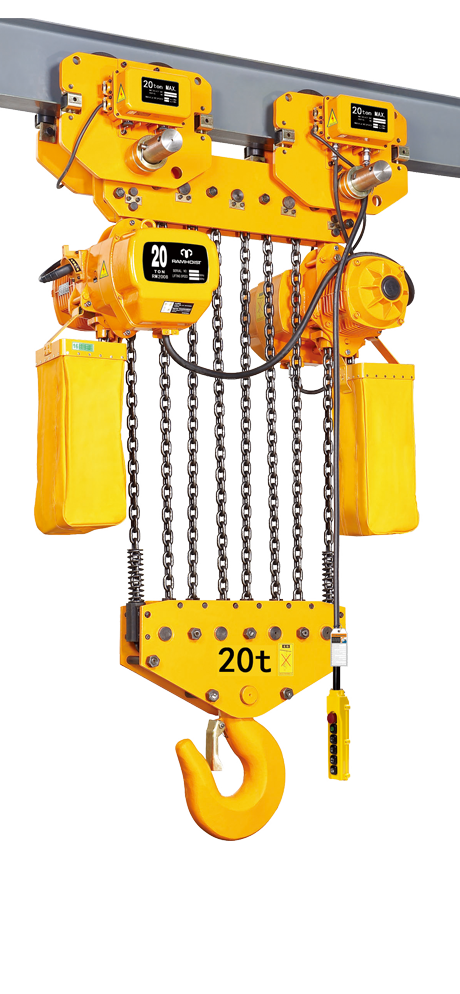

EU Electric Wire Rope Hoists, designed of frequency speed control and lower shock making it realize precision positioning easily, have experienced advanced professional technology and strict treatment to realize the perfect hoisting with the most elegant appearance. european electric wire rope hoists for sale is in promotion.

• Reasonable structure, light dead weight and huge lifting capacity and wide application

• Favorable and excellent performance, accurate, efficient and steady lifting and hoisting

• Smooth starting and stopping with safe and reliable traveling, easy for installation

• Lower hoist frame, building cost saving, labor saving, reducing energy consumption

• Convenient maintenance, great and high exchangeability for parts and components

• Low noise, less pollution and environment protection, conserve energy with electric

• Novel and Humanization design, totally enclosed semi-fluid, lifetime designing

• Modern design of motor, fan, gear, drum, brake combined with construction of the hoist

• Reasonable structure, elegant and exquisite appearance, customized products available

• Less distance between the hook for optimizing space utilization is specially designed

• High grade lubrication chosen and prolong reducer's life and the durable planetary gear

• Special designed brake which is stable and wearable with steadily run and minimum shake

• Imported first-class brand of electrical accessories with high strength steel wire rope

• Optional single speed, dual speeds and frequency available for convenient for operating

• Easily accessible control enclosure facilitates for maintenance and low failure rate

Capacity 1.6Ton-100Ton

Standard Lift 6 m

Use Lifting Up/Down, TraversingLeft/Rights

Drive Mode Motor

Certification CE, ISO9001

Working system Intermediate

Control method Pendent or remote control

Painting color As demand

Installation Overall rapid disassembly

Condition New

SlingType Wire Rope

Power Electric

Operation With pedant cable push button or remote control

PowerSupply 220v-700v, 50/60 Hz, 3 phase, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84251100

Package Wooden case

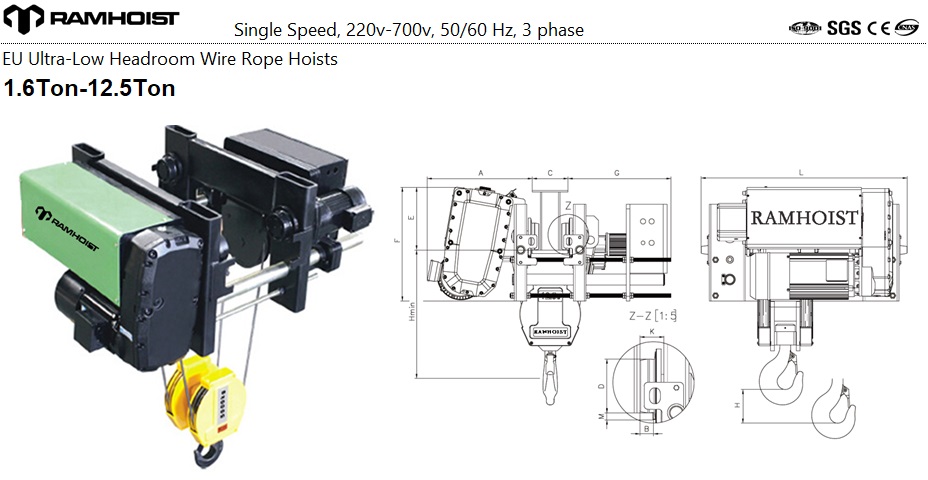

EU Electric Wire Rope Hoists refer to European Electric Wire Rope Hoists, designed of frequency speed control and lower shock making it realize precision positioning easily, have experienced advanced professional technology and strict treatment to realize the perfect hoisting with the most elegant appearance. The overall layout of European Electric Wire Rope Hoists are parallel C-type structure, whichmeans that the drum device is parallel with motor by reducer (roll arranged inparallel with motor through the gearbox. European Electric Wire Rope Hoists incombination of light flexible beam crane and swing-jib crane will better exertits advantages of lightweight and flexibility, fully realize the solutions to three-dimensional material handling and meet customer requirements for process layout and greatly improving production efficiency.

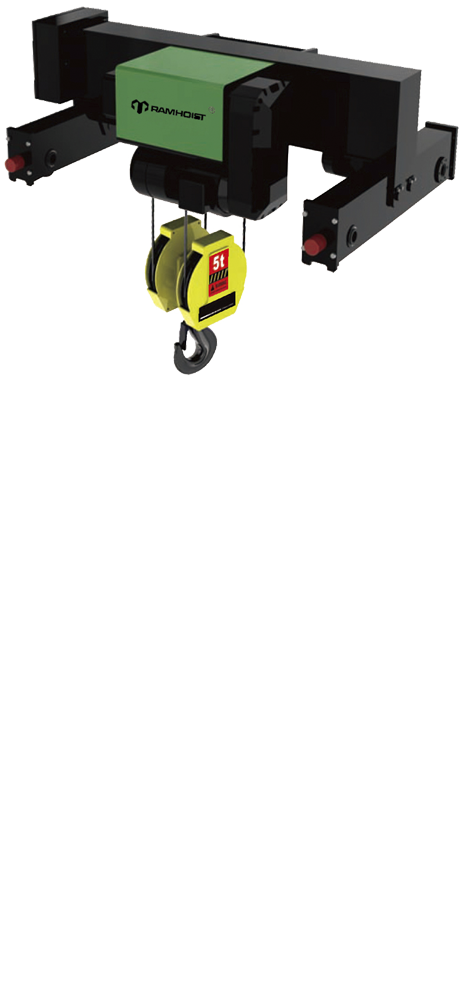

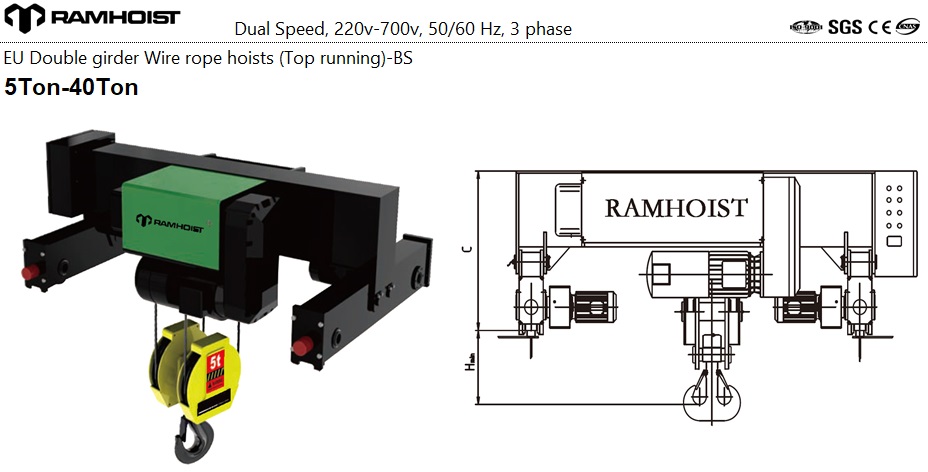

European Electric Wire Rope Hoists are equipped with Crabunits (Crab Unit Wire-Rope Hoisting systems) are for use on a double girder crane and are ideal for extra heavy duty lifting operations with higher safe working loads available. A crab unit spans the 2 girders and runs along the top edge. The electric wire rope Hoist sits on the crab trolley and the rope with hook will descend between the two girders to attach to the load. This type of hoisting system enables the maximum possible height of lift under the beam, however,because the unit sits on top of the beam, more height will be required above the cranes beam / girder, up into the roof space.

European Electric Wire Rope Hoists have a complex structure and bear force better and provides the lowest headroom (the shortest headroom) possible; this also make it easy to install and repair motor and reducer. compact, good force location, installation and maintenance of motor and reducer both are very convenient yet safe running, imported driver module is used and matched with different pulley ratio, contributed to rich product series, Electrical interface adopt aluminum alloy standard plug-in. Adopt unique anti-wheel turning round design, reduced dimensions and hoist weight.

Hoist motor, gearbox and drum form a compact and sturdy package and offers efficient use of floor space under the crane and increased lifting heights. Outstanding design features include the parallel configuration of rope drum and hoist motor, modular design and the functional arrangement of all component. Joints with direct fits between components such as hoist motor, gears,rope drum and limit switches save parts and improve reliability. Enclosed hoist housing protects the rope drum, rope guide and limit switch equipment from dirt and climatic conditions.

Taking up minimum space but providing maximum lifting height (in low headroom version for a maximum height of lift). The travelling trolley can be adjusted. The controller of FEM European electric wire rope hoists will performa self-test before starting, including the power supply voltage level, default phase, button zero status and validity of each safety device. It can be suspended on I- beam track for straight or curve traversing (straight or curveI-steel beam of Single-girder Cranes), or mounted on a fixed frame to liftheavy material. It can also be used together with Electric Hoist Double-beam, gantry crane and slewing cranes to hoist different items and so on.

All the driving units are imported from Germanyand which has 13 patents, adopts the European FEM and DIN design standards with advanced concept, The integrated and compact design of hoisting motor, reducer, reel and limit switch saves space for the user. Modular designof the electric control box increases the reliability of mechanism, effectively improve product performance and ensure product quality meanwhile reduces thetime and cost of installation and maintenance, makes it in the world leading list of electric wire rope hoist. It has more and faster hoist speed and various pulley ratios which can be selected, the standard traveling mechanism of trolley is controlled by converter, with speed of 20m/min, which makes a little swing and accurate position if hoisting items while trolley traveling as well as lifts precision and valuable items reliably.

The configurations are very advanced, such as Schneider electrical, ABM/Nord / SEW triple gear motor (three in one: motor,gear box, brake), galvanized high strength wire rope, self-adjusted disk brake,hard tooth reducer, programmable lifting limit switch, and so on. They can befitted on the top of the double girder trolley frame. It can be supplied alsoin transversal execution, The trolley is electrically operated and run on tworails this configuration allows to obtain the maximum hook path (height of lift).

European electric wire rope hoists are assembled from different independent units viz. Hoisting Gear Box, Hoisting Motor with brake,Rope Drum, Electric Control Panel and Traveling Trolley. Modern design ofmotor, fan, gear, drum, brake combined with construction of the hoist, All these units are separately accessible and promptly disassembled cost and downtime. The main difference with EU Double girder Wire rope hoists is themotor and structure, EU Double girder Wire rope hoist use Europe style motor,while this type uses traditional motor; EU Double girder Wire rope hoistuses and overall / integrated structure, while this type uses a frame plus a Foot-Mounted wire rope hoist.

Double Girder Electric Wire Rope Hoists designed for more intense operation for cranes with two girders, often known as Crab Units, the industrial quality hoists can be supplied with capacities up to150 Tones with single or dual speed capabilities as well as optional extended heights of lift. All of our Crab Units can be fitted with optional Radio Control Systems which are a popular choice in applications where the operator needs to be a safe distance from the load or to enable an alternative view of the load. European electric wire rope hoists with single and double lifting speed which can satisfy your different application, It is widely used in factories, workshop, mines, harbors, warehouses, cargo storage area and shops, double girder hoistcan be offered for special applications like hot metal handling and also where higher height of lift and cross travelling speeds are required. it can beused longer than the common hoist, which is the necessary machinery to raiselabor productivity, working efficiency improve working conditions. Not only are we able to supply, Ramhoist can also install your new Double Girder Electric Wire Rope Hoist and provide tailored maintenance packages at competitive pricesto make your hoisting experience hustle free. In the meanwhile, our company could produce other kinds of electric wire rope hoists, Such as the capacity is 16T, 20T; the lifting height is available from 30 meters to 100 meters more; single drum and hook pulley modify double drum and double hook pulley; Even the motor voltage may be modified accoding the client's requirement.

European electric wire rope hoists are widely applied for lifting cargoes in construction usage, workshop usage, container usage, mineral areausage. These are light and medium crane machineries, which can be fixed/ mountedon double girder/double beam, bridge crane, overhead crane, gantry cranes, portal crane and hanger crane providing advanced engineering solutions forcustomers. It can reduce plant height requirement for customer so as to save investment cost, It is usually installed on bridge crane and goliath crane, equipped with overload limiter, andreal-time load value is displayed in the screen to prompt the operator to prevent overloading, and extensively used in factories, workshops, warehouses, machine processing, steel production, material supply, machine factories,,equipment maintain, port, railway, civil aviation, electricity, and many other occasions to hoist materials directly, especially suitable for the pinpoint material transportation and bulk components precise assembly situations.

European electric wire rope hoists are also called Europe Double girder Wire rope hoists, Double girder Top Running Trolley Wire Rope Hoists, Top running double girder trolley hoists, Europe type wire rope hoists, Double rail crabs and simply composed by a hoist and a customized trolley, Trolley double drive unit, Double rail crane trolley with foot mounted wire rope hoist. Double girder overhead crane electric hoist lifting equipment, Double Rail Electric Wire Rope Lifting Hoist, Double Track Electric Wire Rope Hoist, Double Rail Wire rope Electric Hoist Trolley, Foot-Mounted wire rope together with the double rail trolley.

Main body frame is welded by professional profile, compact structure, good appearance, has many unique and innovation. Different mathematical models on different countries are used but all is light weight body structure and high flexibility which is updated by traditional electric wire rope hoist.

2.Gear box housing

Sealed Gear box housing is made by cast aluminum, light weight, good heat, dissipation, corrosion resistance (IP55). Hoist gear box hasspecially treated for high wear resistance. Each geared shaft assembly is supported on ball or roller bearings, to ensure smooth, low-friction operation. Gears (hoist and travel gearboxes) run in totally enclosed semi-fluid or oilbath lubrication, designed for the lifetime of the crane. Precision flatbeveled gear units in aluminum housings with case-hardened gears, high-gradesurface treatment ensure high reliability and smooth running with minimum of maintenance. There are NO open gears to lubricate.

3.Reducer

Reducer has compact structure, high precision, high strength hardened, which is imported from Germany and with aluminum alloy shell. Reducer’s gear precision ismore than seven grades, with low noise, smooth operation. Internal gear set magnet for the adsorption of transmission wearing scrap iron, reduces gear wearing. Reduceris seal design, no drain and ventilation holes, lubrication uses mineral oil. Coaxial, with three stages of reduction, with cylindrical gears made of thermally treated, highly resistant steel, helicoidally teeth. Dimensioned and made to withstand the phenomena of stress and wear, Robust compact, lightweight yet rugged, situated on the exterior, allowing ease of access. The helical teeth inall the gears are cut with great precision, in cemented steel, assuring silent running, great reliability and long life. The drive from the motor to the gearbox is direct, avoiding coupling devices which have a tendency to fail. All of the gears are lubricated by an oil bath in the interior of a closed casing (Triple reduction hoist gearing in an oil tight gear case), Triple reduction helical/spur gearing operates in oil bath lube for maximum gearing life, Three-step helical gearing in an oil bath with an additional planetary gearstep provides minimal maintenance requirements over the long life of the electric wire rope hoist. An OVERLOAD CUT-OFF device is integrated into the gearbox to prevent lifting loads in excess of the rated capacity.

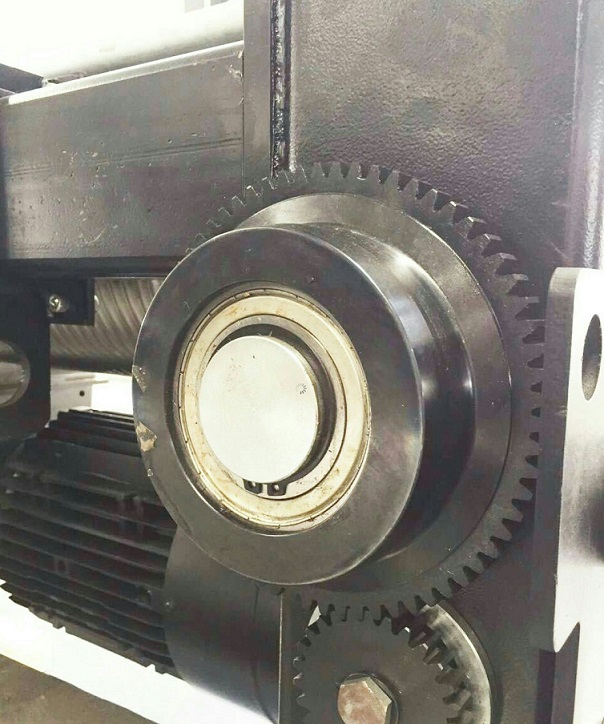

4. Gear

Its reducers with hard gear surface and adopt 3 level helical gears to slow down the speed, so it will have long life, low noise and high mechanical efficiency. European electric wire rope hoists adopt helical type, hardened and ground gears. Germany imported reducer gear and gear shaft using 42CrNiMo materials, low carbon alloy steel hardened by carburizing and tooth grinding processing technology, gear surface hardness is above 60HRC, and gear manufacturing precision level is above 6.

5. Wire rope & Drum

Drum is made of cast iron and seamless steelpipe processing, processed with wire rope slot--the precision machined grooves of the rope to prevent rope overlap. Its shell is welded with steel plate,The drum device is the central part of electric wire rope hoist. High strength line contactsteel wire rope, wire rope safety factor of more than 5 times, wire rope instandard hoist is a high quality 8-strand parallel closed rope. The inner andouter strands are closed in one operation. It has very high breaking load of morethan 2160 N/m2, good flexibility, good wear resistance and long service lifetime. This rope is suitable in all standard applications of material handling. Large diameter rope drum, Drum dia /rope dia=46, and rope pulleysextend the rope’s lifetime, ensuring accurate load positioning, hook drift +/-4mm per 1m.

Min. two dead rope turns while the hook is in the lowest position. A spring operated guide roll in the rope guide prevents slack rope.

6. Hoist Mechanism

Aluminum alloy shell with excellent heat dissipation, the statorframe is made of extruded aluminum to maximize the dissipation of heat together with the fan mounted on the back of the motor. Light weight,corrosion-resistant (IP55), lifting smoothly, low noise. We adopt multi polesmotor, inside with magnet brakes, safety and reliability, lifetime lubricated gearbox, maintenance free. Motors are equipped with safety limiter in both up and down directions. And the motor is Conic rotor brake motor, in order to adapt to the frequent direct start in the intermittent work. All European electric wire rope hoists' motors are equipped with imbedded bi-metallic thermal switch (or thermistors) in the windings to protect against overheating. Thermal sensors open an electric circuit when a predetermined temperature(~150°C) is reached. The thermal sensors used by ours meet VDE0631. Motors are imported from Germany, All motors incorporate a cylindrical rotor, electrical connection sustained rate of notless than 60%, insulation class F, minimum 40% ED duty, protection class IP54or IP55. And FEM European electric wire rope hoists have overheated protection and alarm functions. Lifting motor with squirrel-cage cylindrical 2/12 pole double speed brake motors---- Asynchronous squirrel cage motor(Synchronous speed 3000rpm) with two-speed pole changing (or frequency converter motors for variable speed control), speed ratio (fast and low speedratio) 6: 1, hoist work levels of FEM European electric wire rope hoists can reach M6. Running gear can adopts frequency control (frequency inverter for stepless control) with precise localization and minimum impact, Smart safety monitor recorder, 24/7recording each operation, such as ABB frequency inverter, running speed at 2 ~20m / min. Cross travel drives are designed to withstand unfavorable conditions such as low power supply or aggressive surroundings. The drives are operatingin variable speeds as standard for maximum demands for movement and positioning of lifted loads. Optimum speed, minimized swinging motion and sensitive positioning are combined to minimize cycle times. The geared motor is just inside the rope drum, which greatly save the headroom spaces and greatly increase the work space of the electric wire rope hoist and overhead crane.

7.Lifting Motor

Asynchronous three-phase, self-braking with tapered motor, The electric wire rope hoist has a cylindrical short circuit motor with an incorporated electromagnetic brake. They have high torque, heavy-duty hoist motor for smooth hoisting action. Positive action mechanical load lowering control brake, also acts as a part of the hoist holding brake system. The motor and brake have been designed for continuous service with high duty factors and cycles. The brakes are electromagnetic disc, with asbestos free flat faced linings. Dirt can not enter from outside, nor can brake dust escape from inside The brake block, which has a fan that guarantees the cooling of the brake itself and of themotor, moves axially with the motor shaft, They offer great reliability and automatic braking in the event of power failure (the braking function is activated automatically if the energy supply fails.). The friction linings arelong lasting and the brake is easy to regulate. Heavy-duty DC disc brake ratedat 200% torque, provides quick, positive stops and load holding. The DC brake does not oscillate like an AC brake. Protection IP 55 – Class F insulation. It has thermal probes for protection against overloading. The standard version motor has 2 speed options. The second speed has a relation on1/6 – other relations 1/2, 1/3, 1/4 are available on request.

8. Travelling geared motor

They are specially designed for crane application. With low torque drives providing gradual acceleration and smooth deceleration without excessives wing, the drive to the wheel is via a direct splined shaft.

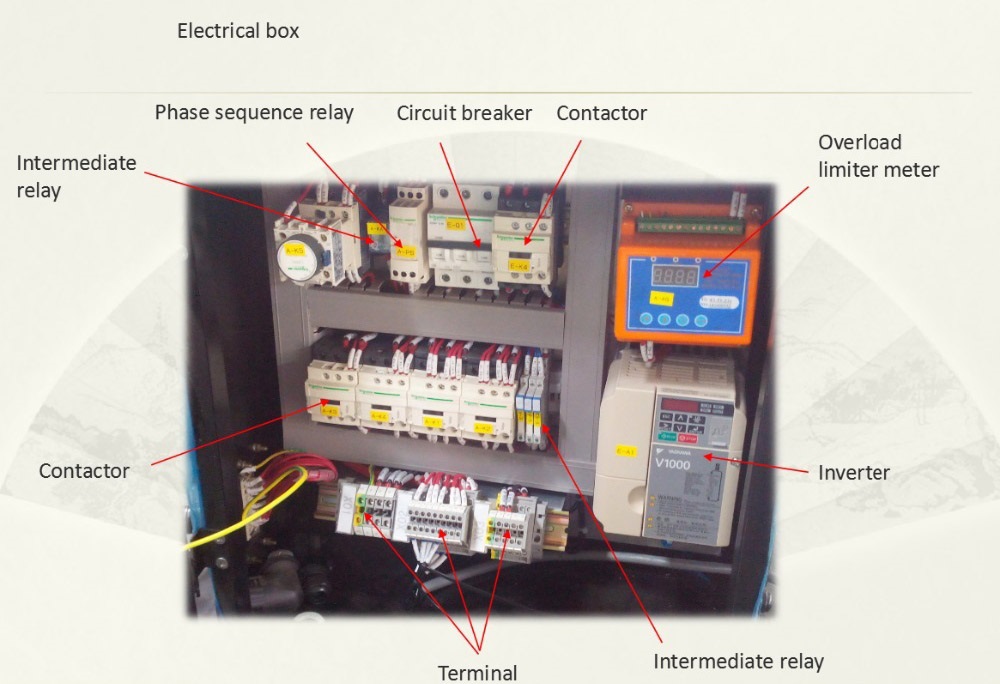

9. Control panel box

It contains one or more low voltage switch and matching control, measurement, signal, protection, regulation and other equipment, and the manufacturer is responsible for the complete structural components assembled together. It adopts top quality and famous brand: Siemens, Schneider, Shilling brand etc. Integrated electrical components - smallsize, low failure rate, low maintenance costs.

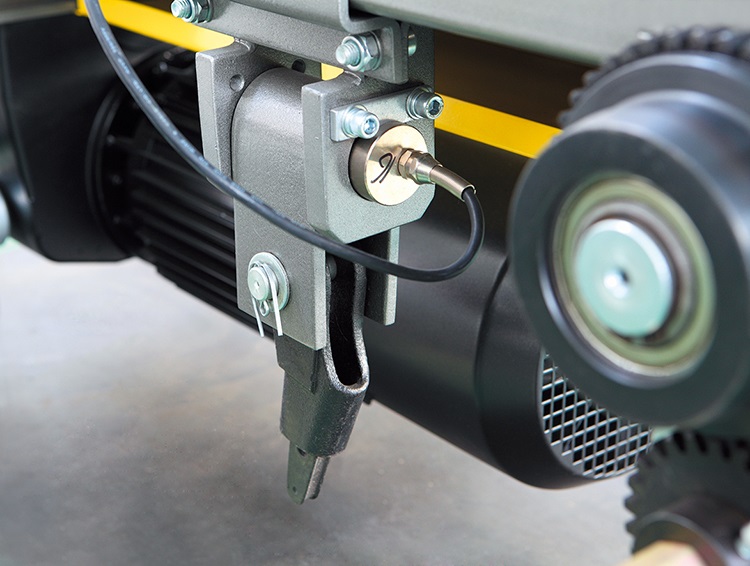

10. Position limiter device

Accurate rotated limit switch device, can automatically stop lift and down when the European electric wire rope hoists hook meet the upper/low position limiter device.

11. Rope Guide

Rope Guide is in two halves, ensuring easy accessibility. It encircles the Drum completely so that the rope may not uncoil even when the electric wire rope hoists is in unloaded condition. Standard rope guide is made of polyurethane which can minimize wearing of the rope (wear resistant). Heavy duty rope guide made of spherical cast iron (spheroidal graphite cast iron) is also available on request. It has a threaded ring made of spheroidal graphite cast iron and allows the rope to be wound well onto the drum. Cast steel alloy design provides extremely longwear life, unlimited temperature limitations, and resistance to side pull. The system automatically registers any play or wear which may occur, Reliable rope guide designed to minimize damage by keeping tension on the rope. The rope guide (heavy-duty) includes sliding backlash arms made of brass, which, actingon the staybolts of the hoist, they function as raise and lower limitswitches. The rope guide is modular cast iron with self lubricating graphite, which also gives particular resistance to wear. The rope guide is formed by two pieces, which can easily be assembled without special tools.

12. Brakes

Maintenance-free electromagnetic disc brake (Double-disk electromagnetic brake, Dual-diskelectromagnetic brakes, DC Electromagnetic disc brake, Heavy duty brake), fullycovered and dust proof, to be used on FEM European electric wire rope hoists, turning into braking status for outage to ensure safety (featuring automatic braking on power failure or it brakes when power off), No adjusting requirement for brake lining (The hoist motion brakes are adjustment free), maintenance free, Brake pad material (Brake lining) is environmental andnon-asbestos (asbestos-free), brake built-in electronic modular system allows the brake fast and agile, The hoist motor and brake are designed and manufactured to work together (All hoist motors are equipped with DC magnetic disk brakes- "Motor, Gearbox, Brake" integrated drive unit, this integrated driving unit has characteristics of compact structure, reliable and easy tomaintain compare with traditional trolley driving unit) so that the load willnot slip at any point of starting or stopping of the hoist or lower motions, brake torque is at least 1.8 times higher than the nominal torque of the motor andcould be adjustable, The minimum safety factor of FEM European electric wire rope hoists is 1.8; safety, environmental and normal brake times are not less than one million, emergency braking times not less than 500 allows long maintenance intervals, Even in high temperatures and long time running can also ensure safety braking.

13.Limited Switch

Adjustable geared, self re-setting electric wire rope hoists and lower limit switches are provided as standard to prevent over travel of hook. Automatic cut-off ofthe lifting and lowering motions are in the upper and lower limit positions. Rotated limit switch device can achieve fast and accurate positioning, it could not reached by ordinary products and thus ensure the efficient operation of the crane and efficiency improved. Security monitoring system equipped withoverload limiter, and displayed on the display with load tonnage, prompts the operator to prevent overloading. Inspection system will automatically doself-test before crane start, including the power supply voltage level, phase inspection, zero protection and each safety device protection, etc. Set lift limit switch, issued alarm when the hook near the upper and lower limit, automatically cut off the power when reach the upper and lower limit and automatic reset, so that the motor is running only in the opposite direction, to ensure that hook not breaking through the top.

14.Sensors

Sensors collect operational status and fault information, and real-time save memory, transferred to troubleshooting in the computer, optimizing the operation parameters.

15. Rope pulleys

Rope pulleys are made from spherical cast iron. Made of flexible steel, highly resistant to strain and wear. The minimum coefficient of use hasbeen chosen to conform to the ISO standard 4308-1. Non-twist ropes are used onour hoist Utilized in versions with more than 2 rope falls, and supported by two pivots which allow it to be orientated depending on the vertical axis of the rope. The return pulley is made of carbon steel. The rim has been grooved mechanically and the sheave rotates on bearings which are permanently lubricated.

16. Hook

The hook is closed type with high safety; it wrought with special high quality steel. Hook design accord with ergonomics principle to improve the safety and operability. The return pulley is made of carbon steel and the rim has been grooved mechanically. It rotates on bearings which are permanently lubricated. The load hook is made of highly resistant drop-forged steel (heat-treated forged) and is mounted on a swinging cross beam. It rotates on a thrust bearing and has asafety device to avoid unhooking. It is Full-swiveling and with spring loaded latch, Shrouded lower block to help prevent pinched fingers

17. Safety device

Buffer, current overload protection, overloaddevice, power failure protection

18. Trolley drive unit

19. Electric Cabinet

Electricals come from Schneider-electric Germany originally. A white metallic box located on the hoist frame, allowing easy access to the electrical components. All electric cable hoist controls housed in sturdy enclosure with easily accessible electrical components.

20. Lifting height limiter

With lifting height limiter, it can help the lifting safer in the limited range.

21. Overload limiter

With high sensitivity, overload limiter can be set by customers’ request. All European electric wire rope hoists are fitted with an electro mechanical load cell with a threshold level micro-switch as standard (electronic control). This load cell consists mainly of 2 parts: an electronic cell pin and a load cell unit (to be installed in the electric panel) It is adjustable within admissible tolerances, and can protect against excessive stresses, thus ensuring a higher degree of safety and longer service life of the hoist. The overload device constantly measures andchecks the values of the load and the dynamic and inertial effects due to its movement. Whenever the set levels is exceeded the micro-switch of the device starts by opening the control circuit of the lifting-controls device.

22. Wheel Assembly

European electric wire rope hoists use alloy steel wheel group after the whole heat treatment and the surface quenching process, outside the strong inside toughness. They have good comprehensive mechanical properties. Depend on the electric wire rope hoists model, the wheel material can be GG 60 for monorail hoists and GG 70 (modular cast iron with graphite structure) for bi-rail crabs.

23. Joint

It’s the connection between the self-braking motor and the reducer, allowing perfect axial sliding of the motor shaft.

24. PushButton Pendant

Manufactured from high impact polypropylene and provides double insulation. The various motions are controlled by pushbuttons which are color coded as well as being identified symbols.

25.Anchorage crosshead

Utilized in standard versions, and supported by two pivots which allow it to be orientated depending on the vertical axis of the rope. The overload device islocated between the plates of the transverse.

26. Wedgeanchorage

The anchorage is made of spheroidal graphite cast iron. The minimum coefficientfor use conforms to the FEM rule 9.661/86. Therope is secured with a wedge which stops it from unwinding.

27. Bearings

Anti-friction bearings throughout for along lasting hoist drive train, Maintenance-free rope drum bearing with central drive and single grooving are standard. Double-grooved rope drums areavailable as an option.

28. Oil level plug

Oil level plug permits easy inspection of oil level

Others

1. The safe working load (SWL) is particularly marked on the name plate and overhaul schedule.

2. Parameters

Working temperature -20C-+40Cdegree,

Humidity is 85%, altitude is 1000m below, no fire and explosion, no corrosive material and no dust.

The power supply is AC three-phase, frequency 50HZ, 380V (415v, 440v and 660v can be ordered as a requirement).

It can be designed in M4-M7 level.

3. Maintenance work is convenient and easy due to themaintenance-free design and less wear parts applied (there are minimum quick-wear parts)

4. Modular structure, can shorten the product development and manufacturing cycle, increase the product line, improve product quality, easy to reuse, upgrade, maintenance and product after the removal of waste, recycling and processing.

5. The utility model has the advantages that the lifting speed is slow and the speed is fast, and the utility model solves the harsh sound of slow and fast switching of the European hoist.

Bus control technology achieves large car control signaltransmission, reducing the failure rate.

The lifting mechanism can monitor the flow number, number and overload of each control point of action is normal or not, by recording the data from the remaining safe working cycle of hoist, hoist life detection.

6.Delay switch technology is used to ensure that the pole changing motor can beconverted to the slow speed from fast to slow, Play the role of anti - shock protection. Lifting frequency conversion with a safety circuit, even if theinverter failure will not occur safety incidents. The noise level emitted by a fully loaded hoist is normally less than 85 dB (A). However, the transmission of noise through metal structures and the reflection due a machine being located near a wall, are not included in the indicated value

7. Some tips:

①Check thehook

There is not crackle in hook of single girder bridge crane and sliding wheel shaft. Thread does not appear loose, bearing does not abrade and a crack must be replaced immediately. After the plate hook riveting, The gap between the plate and the plate is no more than 0.3mm. When the degree of critical section is more than 10% of the original height, that should be replaced.To do the hook test after maintenance, lift up the object with rated load of 1.25 times lasting for 10 minutes. As a result, the elastic opening of the hook is lower than the 0.25% of the size of the hook. And there is no permanent deformation and cracks after unloading.

②Check the wire rope

Check the number of broken wires in 1 lay. If more than 10% of the total number of steel wire, it should be replacement. When the attrition rate of steel wire is higher than that of the original diameter 40%, the whole wire rope is treated as scrap. The shrinkage of wire rope to 70% of the diameter ofthe rope and the rope core exposed, it should be scrapped. Clean the wire rope with kerosene. Use wire rope grease dip and coating to saturation.

③Repair of pulley block

The pulley shaft cannot crack. The attrition rate of shaft neck should be no more than 30% of the original diameter, the degree of conic is not higher than 5%. If all the conditions are not met, it should be replaced. Check pulley groove shape according to sample. Wear is not higher than the wall thickness of 30%, otherwise it is discarded and replaced.

After crane overhaul, the shaft hole of the defect can not be greater than 0.25cm² and the depth is less than 4mm.

④Hoist roller

When the lever of rope groove wear is higher than 2mm, it should be replaced. The thickness of the roller is not less than 81% of the original thickness after the overhaul. The center line of the roller shaft keep parallel with the bearing surface and center line in the two ends of the roller deviate less than 0.15mm.

Ensure that there is no crack on the surface of the roller, the degree of loss of roundness is not obvious and the clamp screws should be tightened. There is no crack on the roller shaft. After the overhaul, if the degree of wear isn’t higher than that of 5% of the original standard diameter, it should be replaced. Prior to impregnation 100%of our stators are tested. The test is executed according to DINEN60204-1(VDE0113) for the following:

Resistance between phases

Inductance of phases by an impulse voltage

Insulation between windings and PE with resistance measurement

Breakdown voltage (high voltage 2500V tester)

Completed motors are high voltage tested according to VDE0530: (test durationtime: 1 sec.)

UTest = (2 x UNom + 1000V) x 1.2

Optional encoders are available in European electric wire rope hoists (for frequency converter motors for variable speed control) and mounted directly to the fan shroud.

Specifications

Type | Capacity (t) | Lifting Speed(m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load (t) | I - beam (mm) | Classific-ation | Min. Radius ofRing Rail(m) | ||||||

Power(kw) | Rotation Speed(r/min) | Power(kw) | Rotation Speed(r/min) | Traversing Speed(m/min) | Diameter(mm) | |||||||||||

50Hz | 60Hz | 50Hz | 60Hz | |||||||||||||

EU2D | 1.6 | 10/1.6 | 12/1.9 | 6 | 3.2/0.45 | 1380 (50Hz) 1656 (60Hz) | 0.37/0.1 | 1380 (50Hz) 1656 (60Hz) | 20/5 | 24/6.0 | 7 | 2 | 94-180 | M5 | 2 | |

3.2 | 5/0.8 | 6/1.0 | 4 | M5 | 2 | |||||||||||

EU3D | 2.5 | 10/1.6 | 12/1.9 | 7.6/1.1 | 0.55/0.13 | 9 | 3.125 | 116-180 | M5 | 2 | ||||||

5 | 5/0.8 | 6/1.0 | 6.25 | M5 | 2.5 | |||||||||||

EU4D | 5 | 10/1,6 | 12/1,9 | 9.5/1.5 | 0.75/0.18 | 13 | 6.25 | 142-180 | M5 | 2.5 | ||||||

6.3 | 10/1,6 | 12/1,9 | 7.875 | M4 | 2.5 | |||||||||||

10 | 5.0/0.8 | 6.0/1.0 | 12.5/2.0 | 12.5 | M5 | 3 | ||||||||||

12.5 | 5.0/0.8 | 6.0/1.0 | 15.625 | M4 | 3 | |||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | F | G | Mmax | K | ||||||

Hmin | ||||||||||||||||

EU2D | 1.6 | 560 | 432 | 30 | 100 | 226 | 431 | 491 | 30 | 59 | ||||||

3.2 | 470 | |||||||||||||||

EU3D | 2.5 | 700 | 499 | 30 | 125 | 271 | 519 | 491 | 32 | 59 | ||||||

5 | 550 | |||||||||||||||

EU4D | 5 | 940 | 601 | 37 | 150 | 351 | 636 | 562 | 40 | 67 | ||||||

6.3 | 700 | |||||||||||||||

10 | 940 | |||||||||||||||

12.5 | 700 | |||||||||||||||

Specifications

Type | Capacity(t) | Lifting Speed(m/min) | Standard Lift(m) | LiftingMotor | Traversing Motor | Wire Rope | Test Load(t) | Trolley Gauge (mm) | Classific-ation | Wheel Dimension(mm) | Weight(kg) | ||||||

Power(kw) | Rotation Speed(r/min) | Power(kw) | Rotation Speed(r/min) | Traversing Speed(m/min) | Diameter(mm) | ||||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||||

EU3BS | 5 | 4/0.6 | 4.8/0.7 | 6 | 4.9/0.8 | 1380 (50Hz) 1656 (60Hz) | 2×0.37 | 1380 (50Hz) 1656 (60Hz) | 20/5 | 24/6 | 11 | 6.25 | 1400 | M5 | 125 | 5111 | |

EU4BS | 10 | 5/0.8 | 6/1.0 | 12.5/2.1 | 2×0.55 | 15 | 12.5 | 1400 | M5 | 160 | 1112 | ||||||

12.5 | 15.625 | M4 | 1112 | ||||||||||||||

EU5BS | 20 | 3.4/0.53 | 4.1/0.64 | 16/2.6 | 2×1.1 | 18 | 25 | 1600 | M5 | 200 | 1898 | ||||||

25 | 31.25 | M4 | 1898 | ||||||||||||||

EU6BS | 40 | 4.9/0.82 | 5.9/0.98 | 38 | 2×2.2 | 20 | 50 | 2000 | M4 | 315 | 2958 | ||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | C | D | |||||||||||

Hmin | |||||||||||||||||

EU3BS | 5 | 865 | 96 | 325 | 500 | 50 | |||||||||||

EU4BS | 10 | 880 | 110 | 339 | 600 | 65 | |||||||||||

12.5 | 1035 | ||||||||||||||||

EU5BS | 20 | 1165 | 120 | 349 | 900 | 75 | |||||||||||

25 | 1305 | ||||||||||||||||

EU6BS | 40 | 1450 | 145 | 374 | 1070 | 85 | |||||||||||

Specifications

Type | Capacity (t) | Lifting Speed(m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load(t) | Trolley Gauge(mm) | Classific-ation | Wheel Dimension(mm) | Weight(kg) | ||||||

Power(kw) | Rotation Speed(r/min) | Power(kw) | Rotation Speed(r/min) | Traversing Speed(m/min) | Diameter(mm) | ||||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||||

EU5BZ | 32 | 4.5/0.7 | 5.4/0.8 | 6 | 2×16/2.6 | 1380 (50Hz) 1656 (60Hz) | 2×1.5 | 1380 (50Hz) 1656 (60Hz) | 20/5 | 24/6 | 18 | 40 | 2000 | M5 | 250 | 3425 | |

40 | 50 | M4 | |||||||||||||||

40 | 3.4/0.53 | 4.1/0.64 | 2×2.2 | 50 | M5 | 315 | 3850 | ||||||||||

50 | 62.5 | M4 | |||||||||||||||

EU6BZ | 63 | 6.5/1.1 | 7.8/1.3 | 2×38 | 2×3 | 20 | 78.75 | M4 | 315 | 4930 | |||||||

63 | 4.9/0.82 | 5.9/0.98 | 2×3 | 78.75 | M5 | 315 | 5565 | ||||||||||

80 | 4.9/0.82 | 5.9/0.98 | 2×4 | 100 | M4 | 400 | 5565 | ||||||||||

80 | 4/0.66 | 4.8/0.79 | 2×4 | 100 | M5 | 400 | 6170 | ||||||||||

100 | 4/0.66 | 4.8/0.79 | 2×4 | 125 | M4 | 400 | 6170 | ||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | C | D | |||||||||||

Hmin | |||||||||||||||||

EU5BZ | 32 | 660 | 130 | 359 | 1100 | 75 | |||||||||||

40 | |||||||||||||||||

40 | 760 | 145 | 374 | 1150 | 85 | ||||||||||||

50 | |||||||||||||||||

EU6BZ | 63 | 820 | 145 | 374 | 1280 | 85 | |||||||||||

63 | 840 | 145 | 374 | 1330 | 85 | ||||||||||||

80 | 840 | 170 | 399 | 1330 | 95 | ||||||||||||

80 | 930 | 170 | 399 | 1330 | 95 | ||||||||||||

100 | 930 | 170 | 399 | 1330 | 95 | ||||||||||||