Electric Chain Hoists are new styles and small lifting equipment, which are ideals tool to lift heavy objects, load and unload, maintain equipment in warehouse, factory, logistics, building etc. the whole aluminum body and squirrel cage motor are produced according to high standard, electric chain hoist 1 ton and electric chain hoist 2 ton are most sold in china.

• Compact body, small cubage and light weight with enclosed structure

• Smooth, quiet, convenient and ergonomic operation with fast heat dissipation

• Extremely durable and are built for long lasting use, low maintenance and very little upkeep

• Integrated Motor and drive design for optimum space utilization, Upper/Lower Limit Switch

• High quality allocation for continuous use, Fully-enclosed gearing with oil bath lubrication

• Quality components such as adjustment free brakes, fan cooled motor

• Reliable safety, small in size with sleek appearance and unique rugged design

• Enhanced durability, great reliability with high quality, solid and strong, easy to service layout

• Powder coated exteriors and easy availability of spares for standardized electrical components

• Adopt high strength aluminum shell through compression casting formation

• Outside overload protector and thermal protector are available

• Easier maintenance with affordable price and great after-sale service

• Environmentally friendly with low noise and the least air pollution

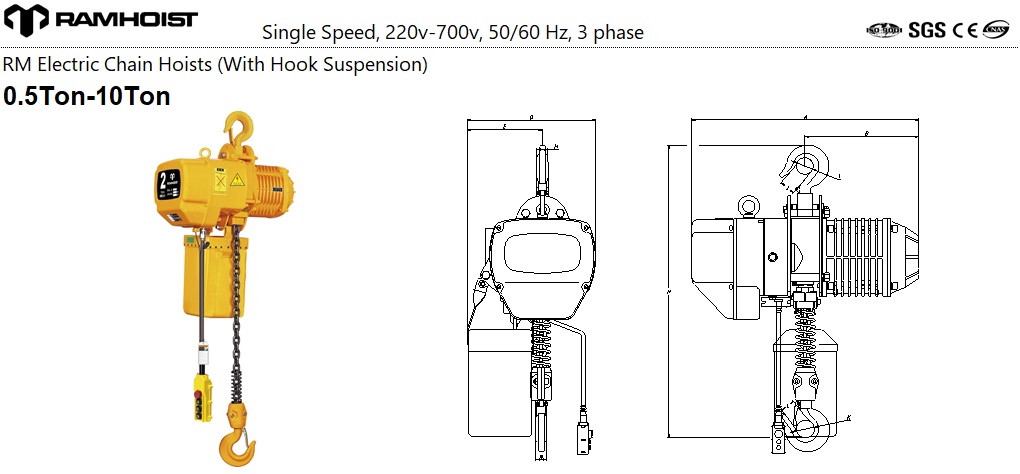

Capacity 0.5Ton-10Ton (With Hook Suspension)

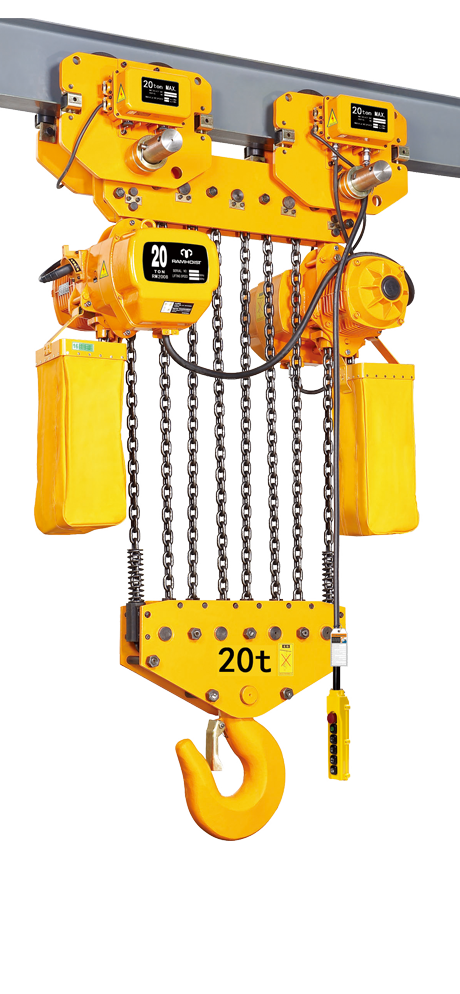

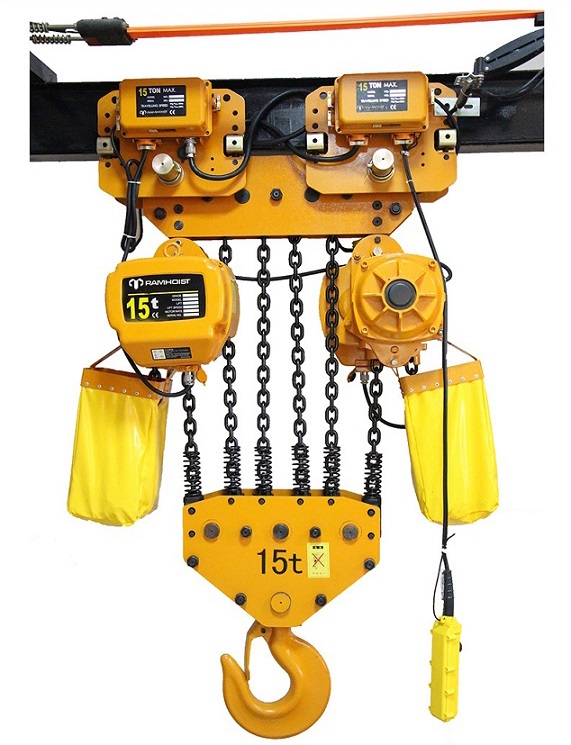

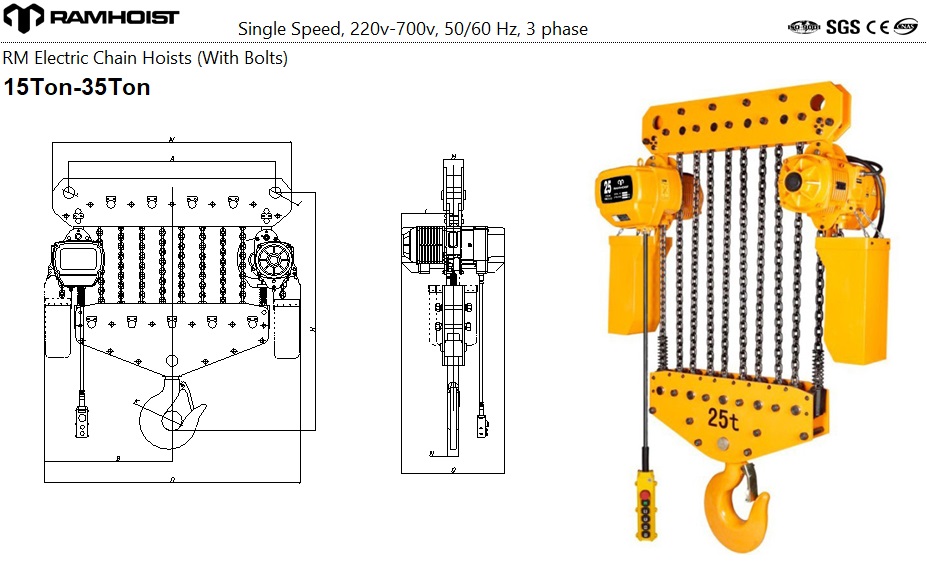

15Ton-35Ton (With Bolts)

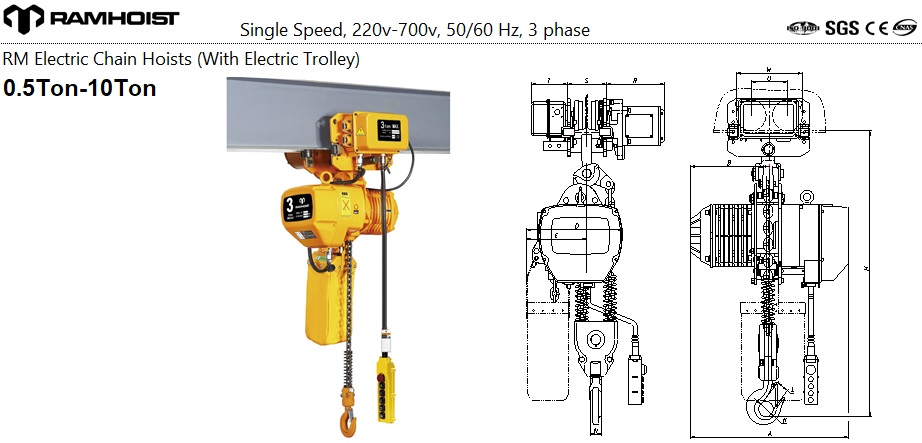

0.5Ton-10Ton (With Electric Trolley)

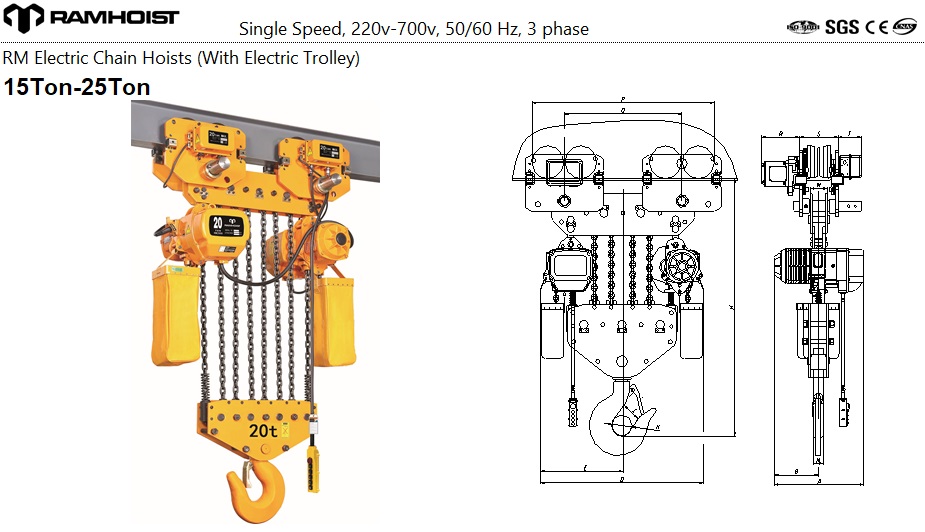

15Ton-25Ton (With Electric Trolley)

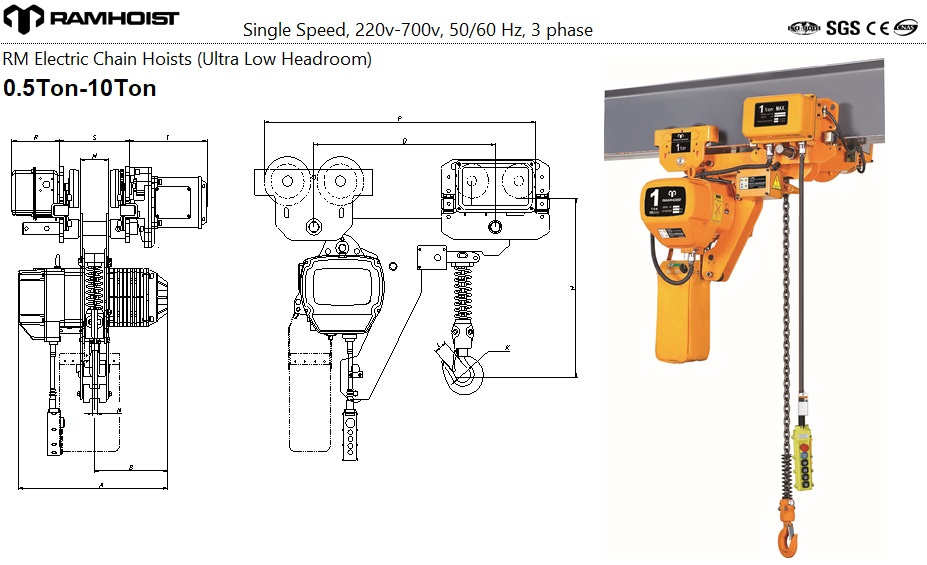

0.5Ton-10Ton (Ultra Low Headroom)

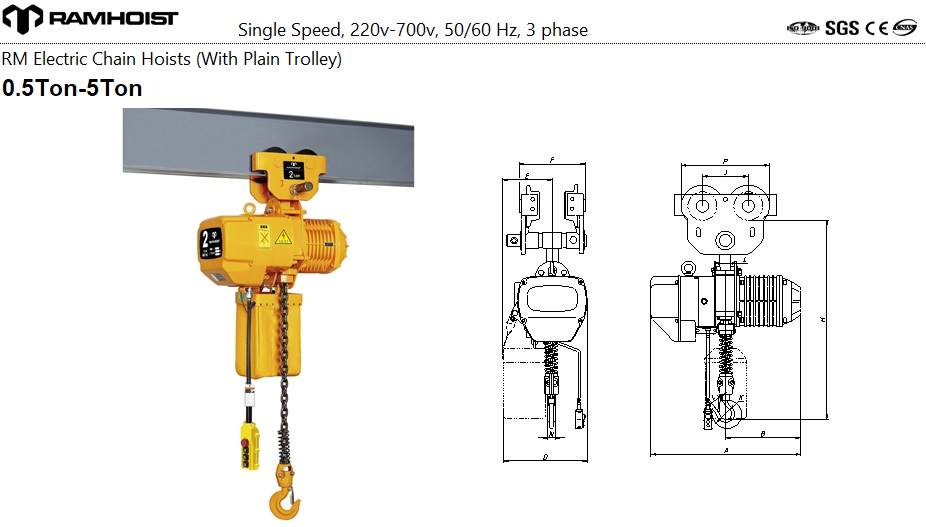

0.5Ton-5Ton (With Plain Trolley)

Standard Lift 3 m

Use Lifting Up/Down

Drive Mode Motor

Condition New

Fixation Hook, plain trolley, geared trolley or motorized trolley

Color Yellow, red, blue and orange

Sling Type Chain

Material Aluminum and casting iron

Safety factor 1.5 times

Pulling lifting advantage Hoist can be slant pulling

Motor insulation Class F

Certification CE, ISO9001

Working humidity 85%Rh or less

Operation With pedant cable push button or remote control

Power Supply 220v-700v, 50/60 Hz, 3 phases, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84251100

Package Plywood case, pallet

RM Electric Chain Hoists are new styles and small lifting equipment, which are ideals tool to lift heavy objects, load and unload, maintain equipment in warehouse, factory, logistics, building etc. this types of electric chain hoists adopt the whole aluminum body, which improve the anti-corrosion degree and heat dissipation effects of the hoist. Electric chain hoists uses squirrel cage motor for driving, hook suspension or lift trolleys are available as option (could be plain trolley, geared trolley or motorized trolley)

RM Electric Chain Hoists are available from 0.5t up to 35t with single speed or dual speed, which run on an electric power source and have a chain sling type, it is generally accepted by wordwide customers within the lifting equipment industry due to its same technology as Japanese KITO which designed for peak performance but with much lower price due to made-in-china, they are more specialized and probably better quality than most electric hoisting units presently available, with a wide range of styles and options, Ramhoist can be supplied to suit almost any application and environment—even on the toughest jobs in the toughest conditions.

RM Electric Chain Hoists’ quiet operation and minimal vibration lowers workplace noise pollution which reduces worker fatigue and extends their life, they are very robust. Our Electric Chain Hoists lets you get the job done safely and worry-free with best practical durability, Users can operate chain electric hoist on the ground or sit in the cabin through remote wireless control.

Ultra-low headroom electric chain hoists are typical of unique optimal structure in shortening the distance between the machine body and the beam tracks, which designed to have a shorter headroom than that of standard electric chain hoist, so they are most suitable for installation which requires a low ceiling of building or maximizes effective lift, especially suitable for use in temporarily erected plant buildings or the sites where expansion of effective hoisting spaces is required.

Every detail of RM Electric Chain Hoists was designed with customers in mind, from our ergonomic pushbutton control grip to our best-in-class design, from hoist motor to motor brake and gearbox, which have been designed to last for the designed working period of the hoist

RM Electric chain hoists are used in manufacturing, maintenance, and in distribution to transport materials, They are widely applied in factories, mines, agriculture, shipbuilding, machinery manufacturing, electronics, automobiles, work piece assembly, high-tech industrial and electric power, construction building site, workshops, chemical plants, electroplating factories, modern industrial production lines and other places logistics, docks and warehouses. They are also applied in gantry cranes, bridge cranes, tower cranes, single grinder cranes, lifting platforms, small cranes and other fields.

They are also called electric hoists, electric lifting hoists, monorail hoists, powered hoists, powered chain Hoists, trolley hoists, electric hoists with electric trolley, hanging electric hoists, chain hoists, manufacture hoisting equipment, hoist crane, engine hoists, lifting hoists, car hoists, fitness lifting hoists, clutch hoists, double brake hoists, dual limit switch hoists, single phase hoists, three phase hoists, gear hoists, electric hoists with bolts, Lug suspension type electric chain hoist, electric chain hoists with ultra low headroom, electric chain hoists with plain trolley and civil electric hoists.

We always keep research and update hoists and motors and cranes to be newest mature most advanced technology...

1. Shell

RM Electric chain hoists are all made of light aluminum alloy through compression casting formation which are quite solid and light but very hard. They can bear fast release heat and continuous use with the enclosed structure. Thanks to that unique future, they can be used in the terrible work environment with a high heat dissipation rate and all tightness design.

2. Support frame

The loading support frame consists of two steel plates, which is extremely sturdy. No guide frame ensures hoists lift and drag the weight diagonally

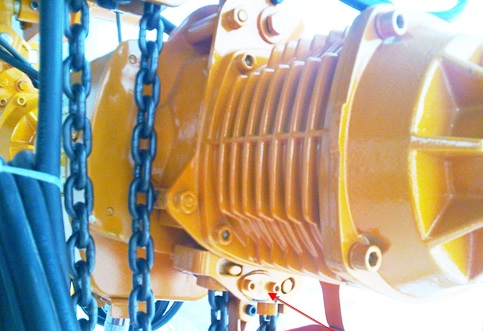

3. Motor

With a unique fin and fan cover, the fan motor is capable of adapting high frequency users as well as long time use. It uses squirrel cage motor for driving.

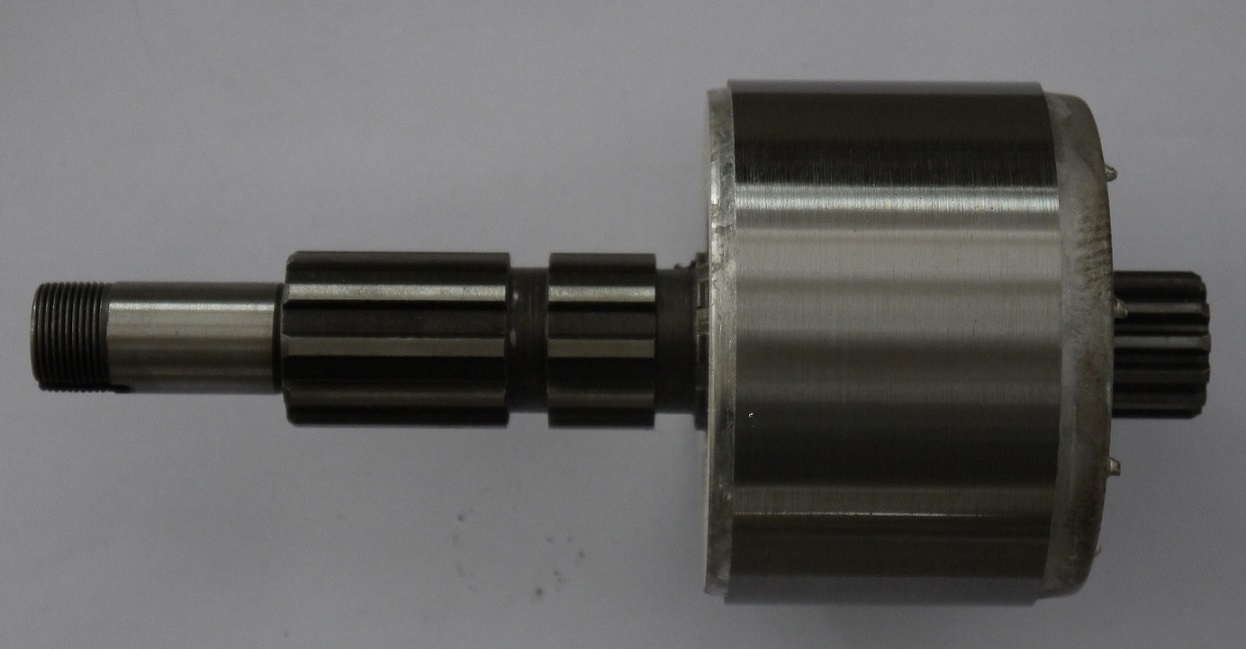

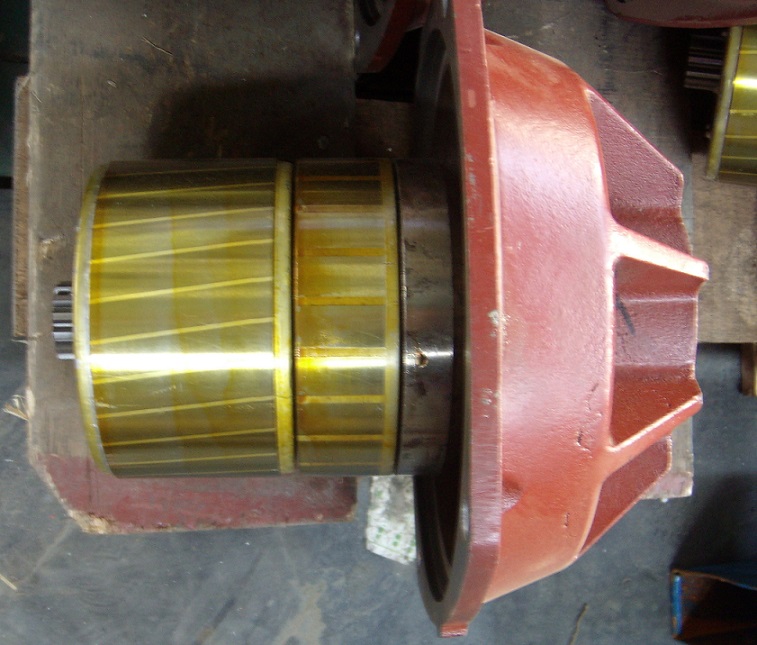

Motor rator

stator assembly

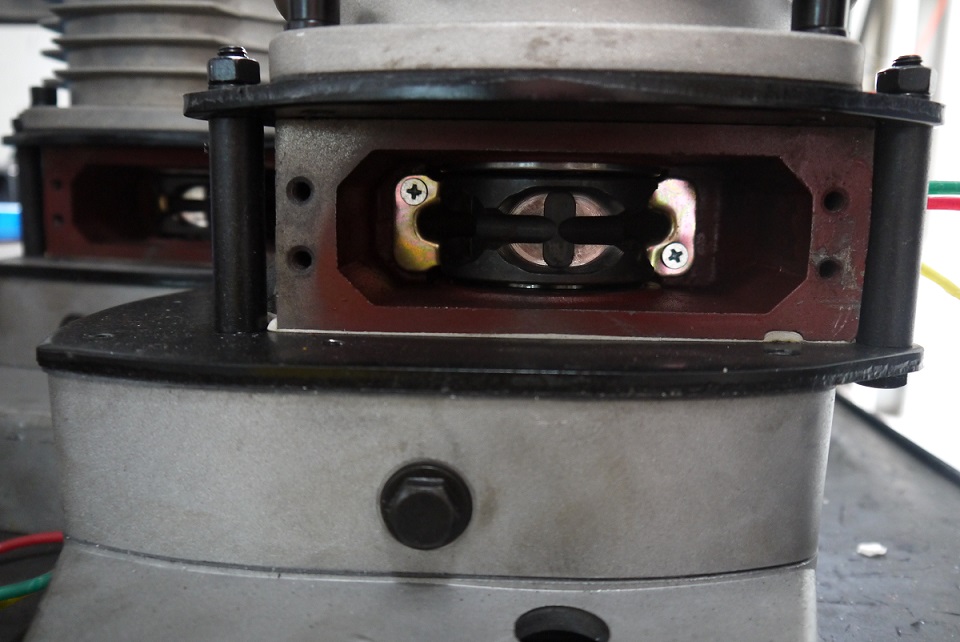

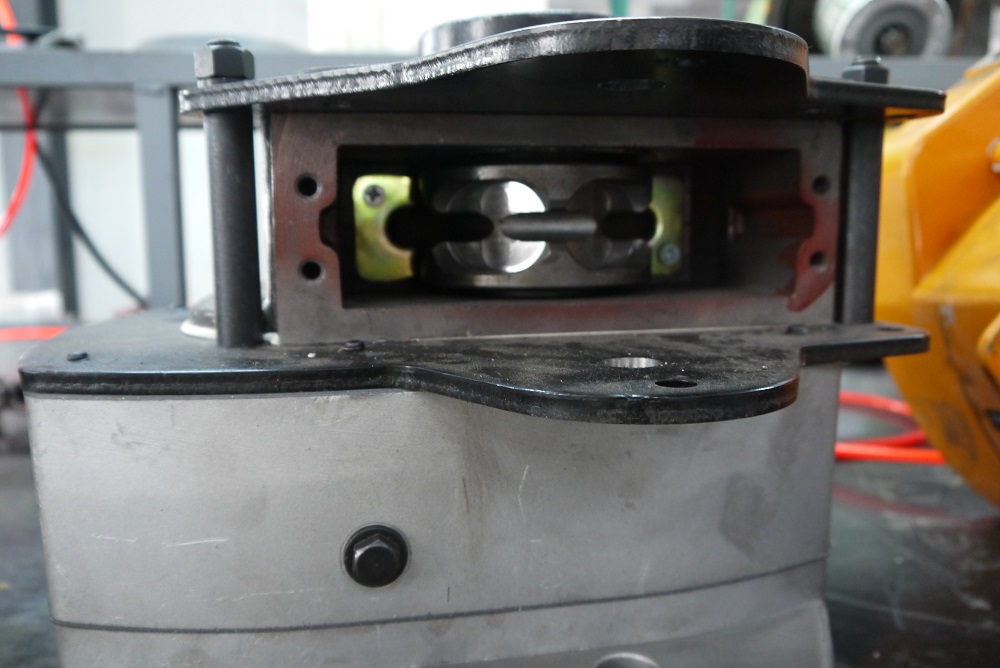

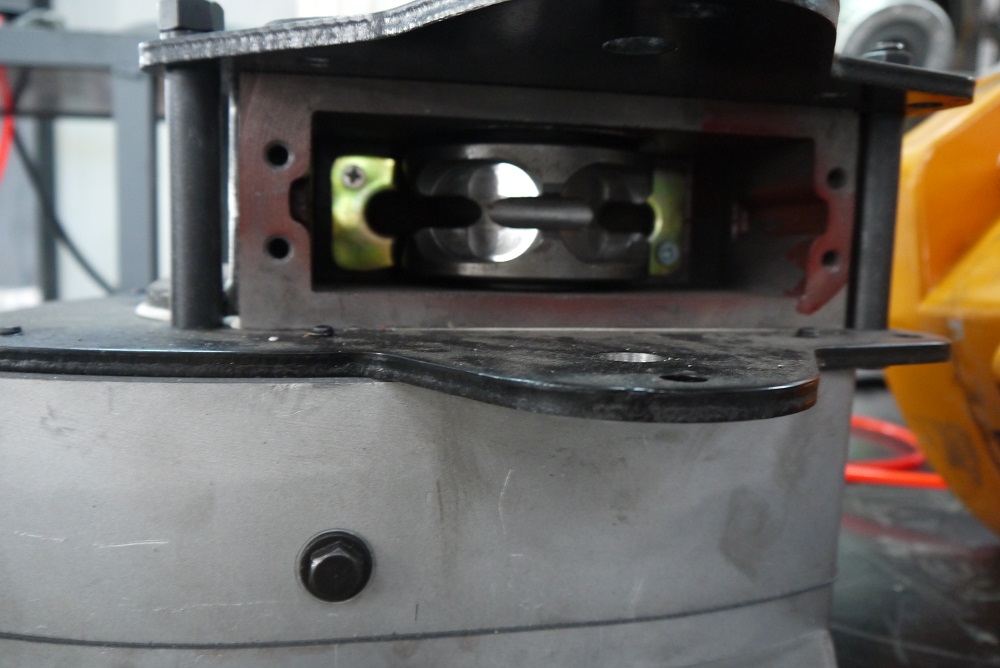

4. Side magnetic braking device

Electric magnetic hoists adopt the latest designs which are featured for generating magnetic force. This masterly structure ensure the hoist absolutely safety when the power off. And ensures it is safe when they are overload. Also it combines to the motor braking as the double brake system to strengthen security and durability. Brake can work immediately after electric power is cut off, thus ensuring the safety of the brake.

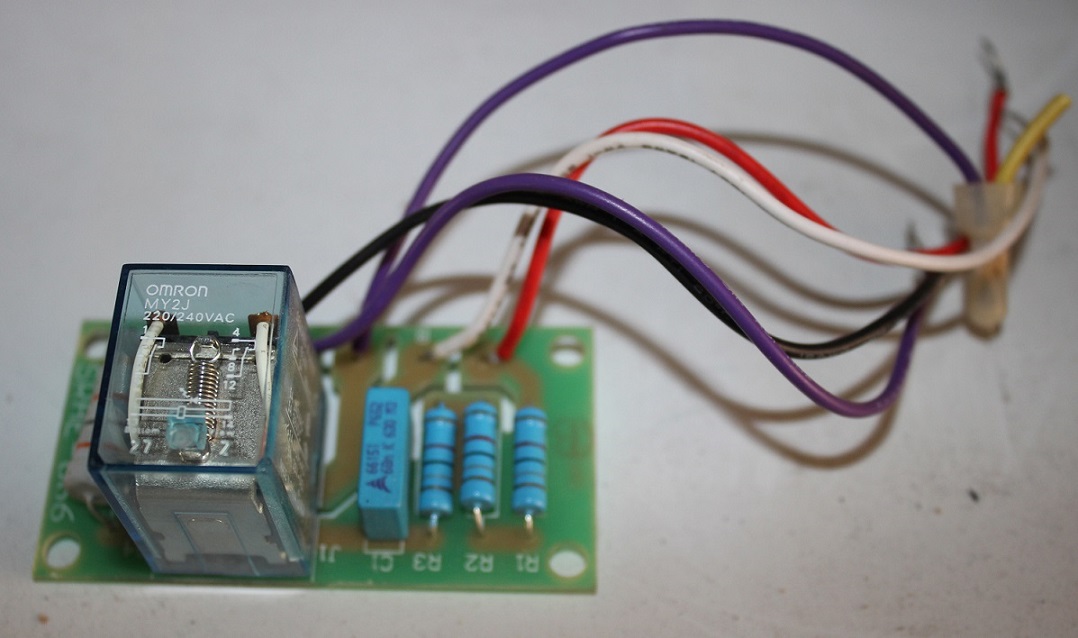

5. Inverse phase sequence protecting device|Antiphase protector

It is the special electrical installation which controls the circuit not to work in case of wiring error in the power supply. The advantage of the equipment is that when power-supply wiring mistake, the control circuit is unable to move to protect motor from being burned.

Middle quality

High quality

6. Limit switch

This limit switch device is installed where the weight is lifted on and off to make the motor to stop automatically so as to prohibit the chains from exceeding for safety. The limit switch can prevent the damages to body and load chain under over-winding. The limit switch adopt the electric device, and high sensitivity, minimizing the hook gap distance, it constitutes the double security mechanism.

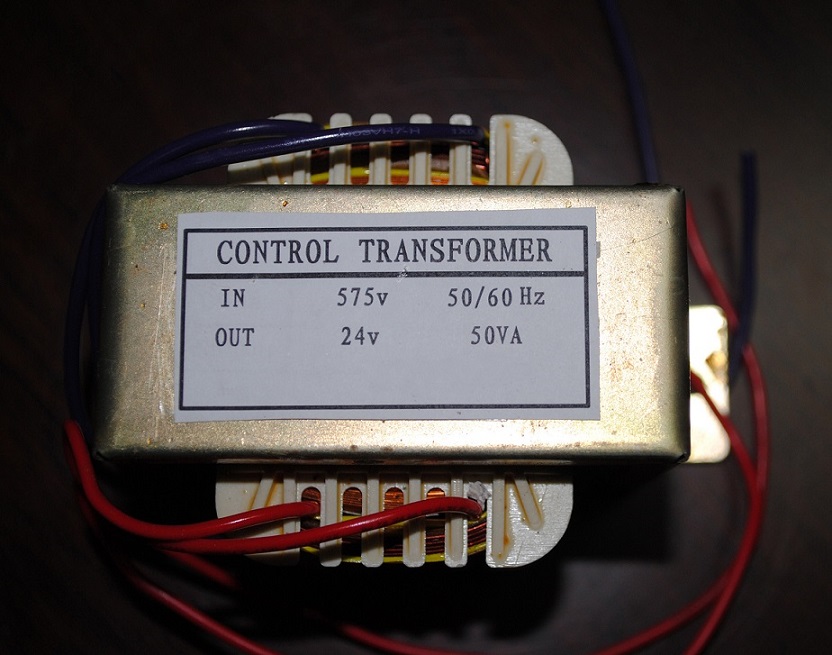

7. Transformer: 24V/36V transformer device

The equipment is used to prohibit the emergencies from occurring in case of the leakage in the switch, which guarantees safety while use in rain.

8. Gear

The gear is made of alloy steel and through the heat treatment.

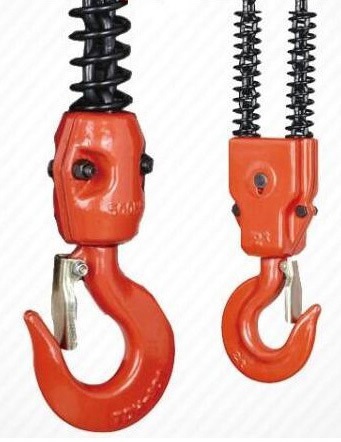

9. Hooks

The hooks are made by hot forging and heat treatment with perfect strength that is hard to break, the operation safety of the lower hook is ensured by its 360 degree rotation and safety tongue piece (latch). They are hot forging with perfect strength that is hard to break. And the hook is ensured by its 360 rotation.

10. Chain

Adopted heat-treatable steel alloy, these chains are safe approximately when used in the rain water, the sea water, under the chemical and other bad, there are Japanese FEC80 chain and Chinese grade80 chain

11. Chain bag/container

It is featured light, handsome and durable.

12. Chain wheel assembly|Unique chain sprocket & Guide structure

High strength chain sprocket & unique design for smooth chain feeding of RM electric chain hoist

13. Control pendant|Hand Switch

Waterproof push button is applied, which is light and durable, come with the E-stops. The button with a light soft operating sensation satisfied the operator not fatigued after a long period operation.

4 points for single speed electric chain hoist (electric hoist up and down, electric trolley right and left)

4 points for dual speed electric chain hoist (electric hoist up and down, electric trolley right and left)

6 points for single speed electric chain hoist (electric hoist up and down, electric trolley right and left, end truck front and back)

6 points for dual speed electric chain hoist (electric hoist up and down, electric trolley right and left, end truck front and back)

14. Spring

The rotation direction is right and heat treatment is HRC44-50, with surface oxidation treatment

15. Plug

16. Fan

The cooling fan is aimed at preventing motor over heat.

17. Hermetical treatment (opitional)

The hermetical treatment is also optional, we use non hole seal (normal one has hole) special for IP55 so that the water could not get in.

18. Outside overload protector (opitional)

The outside overload protectors are optional.

19. Thermal overload (Opitional)

Thermal overload protection can be installed in the motors in case of high temperature to prevent motor burnout due to excessive usage of RM electric chain hoist

There are two kinds of thermal overloads protection below:

1, built-out, built inside electric control cabinet.

2, built-in, built inside motor winding when wind.

Both above is to control circuit starting and let main circuit break when motor temperature arise to limit, it has protection application.

20. Tie down

21. Guide frame assembly

22. Wire connection parts for limit switch

23. Conductor bar(Conductor rail), Remote control and Hub

24. Link ring|Suspension bar

It’s for connecting plain trolley and electric chain hoist, Suspension bar is only used to connect hoist to Plain trolley.

25. Hanging ring|Suspension Eyelett

Suspension Eyelett is only used to connect electric chain hoist to MDT

Both Suspension bar and Suspension Eyelett’s size is different for different capacity and could not interchanged between plain trolley and MDT.

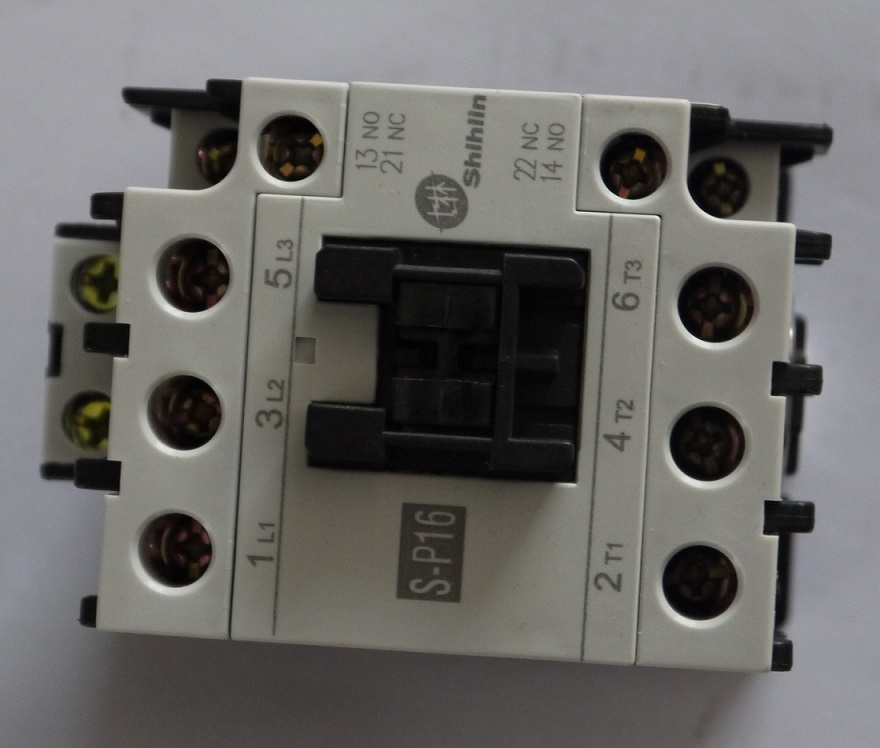

26. Schneider Contactor or Taiwan Shihlin contactor

27.Bearing

28. Connection

0.5t connecting

1.5t connecting

2t connecting

29. Kit adjustable for I beam

30. Adjustment value of brake

It is adjusted according to glide quantity measuring condition when rated loading is made on test bed, after using some time the glide quantity will increase, it could be adjusted by special tools for brake screw. We can supply a brake tools before delivery if needed. Trolley brake could not be adjusted (pad thickness is 4mm for all capacity trolley)

31. Gear box oil adding

It includes ISO46 refrigerating machine oil, 0.7L-3L according to different capacity. If oil leaking is in electric parts, need to clean firstly.

32. Classification

The insulation grade is F

Suspension varieties: Hook, manual trolley, motorized trolley

Operating temperature are range from -20 to 40 ℃ (-4 to 104 °F)

Operating humidity ranges from 85% RH or less.

33. Protection class

RM Electric chain Hoist and push button use IP54 (standard) IP55 for Hoist Body, IP55 for push button control. Standard one is for indoor use; it is suitable for outdoor operation but need to avoid direction. What’s more, the protection class should be improved (IP55) if for outdoor use, otherwise, motor may be burned.

IP 65 (防爆防尘)is also available upon to your request

34. Noise

Single/ dual speed: 81dB.

35. Single external strain relief for cable pendan

3 core

5 core

8 core

Whatever 3 core, 5 core or 8 core, it does not include wire rope, we take single speed for example:

3 core used in 2 points + emergency stop

5 core used in 4 points + emergency stop

8 core used in 6 points + emergency stop + start

36. Others

1. For Dual voltage, only single speed is available.

For Single voltage, dual speed is available.

(Reason: motor is too small and impossible for wiring 4 lines if dual voltage, dual speed)

2. There are many parameters and technical details which need consideration: capacity, standard lifting height, lifting speed, lifting motor including power, rotation speed, phases, voltage and frequency, operation motor, load chain falls, chain specification, test load, weight, beam, chain add weight meter and other parameters.

3. The speed can be divided into single speed, double speed or frequency inverter.

Different types

A.0.5Ton-10Ton (With Hook Suspension)

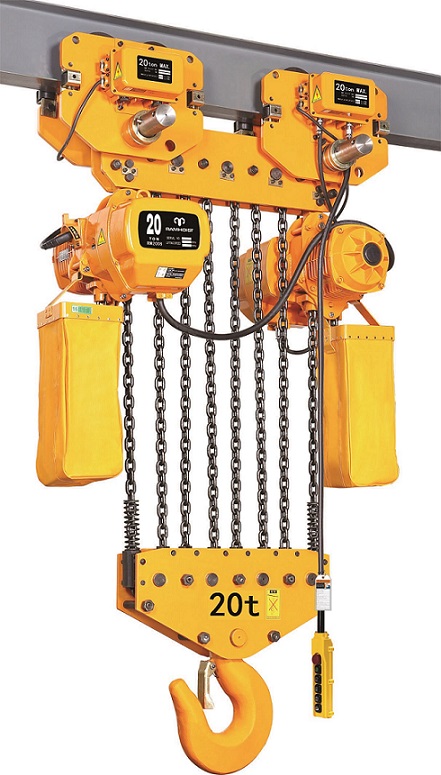

B.15Ton-35Ton (With Bolts)

C.0.5Ton-10Ton (With Electric Trolley)

D.15Ton-25Ton (With Electric Trolley)

E.0.5Ton-10Ton (Ultra Low Headroom)

F.0.5Ton-5Ton (With Plain Trolley)

Testing video of RM 3ton electric chain hoist Ultra Low Headroom: https://youtu.be/OZVMRz_VeIQ

|

Electrical chain hoist for stage [RM series but not (n)RM]

Site photos 1 of electric chain hoist

Site photos 2 of electric chain hoist

Site photos of 500kg dual speed electric chain hoists

Quote on remotes of two speed up-down electric chain hoist

Offer for Ultra Low Headroom electric chain hoist 3T (type: RM0302DL) and its spare parts

Motor assembly of 10T electric chain hoist needed to be changed

Need to replace the Longer shaft for bigger I beam width

Interested with Electric Trolley Chain Hoist with Dual Hook for our machine from Philippines

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Load Chain | Test Load (t) | Weight (kg) | Additional Weight per 1m Lift (kg) | ||||

50Hz | 60Hz | Power (kw) | Rotation Speed (r/min) | Diameter (mm)×chain falls | ||||||||

RM00501S | 0.5 | 6.8 | 8.2 | 3 | 0.75 | 1440 (50Hz) 1728 (60Hz) | 6.3 × 1 | 0.625 | 47 | 0.8 | ||

RM0101S | 1 | 6.6 | 7.9 | 1.5 | 7.1 × 1 | 1.25 | 61 | 1.1 | ||||

RM0102S | 1 | 3.4 | 4.1 | 0.75 | 6.3 × 2 | 1.25 | 52 | 1.6 | ||||

RM01501S | 1.5 | 8.8 | 10.6 | 3.0 | 10.0 × 1 | 1.875 | 108 | 2.3 | ||||

RM0201S | 2 | 6.6 | 7.9 | 3.0 | 10.0 × 1 | 2.5 | 115 | 2.3 | ||||

RM0202S | 2 | 3.3 | 4.0 | 1.5 | 7.1 × 2 | 2.5 | 73 | 2.2 | ||||

RM02501S | 2.5 | 5.4 | 6.5 | 3.0 | 11.2 × 1 | 3.125 | 116 | 2.8 | ||||

RM0301S | 3 | 5.4 | 6.5 | 3.0 | 11.2 × 1 | 3.75 | 122 | 2.8 | ||||

RM0302S | 3 | 4.4 | 5.3 | 3.0 | 10.0 × 2 | 3.75 | 131 | 4.7 | ||||

RM0303S | 3 | 2.2 | 2.6 | 1.5 | 7.1 × 3 | 3.75 | 85 | 3.3 | ||||

RM0502S | 5 | 2.7 | 3.2 | 3.0 | 11.2 × 2 | 6.25 | 151 | 5.6 | ||||

RM07503S | 7.5 | 1.8 | 2.2 | 3.0 | 11.2 × 3 | 9.4 | 266 | 8.4 | ||||

RM1004S | 10 | 2.7 | 3.2 | 3.0×2 | 11.2 × 4 | 12.5 | 300 | 11.2 | ||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | I | J | K | L | M | N |

H | ||||||||||||

RM00501S | 0.5 | 550 | 460 | 230 | 280 | 160 | Ф35 | 25 | Ф35 | 25 | 17 | 17 |

RM0101S | 1 | 650 | 520 | 260 | 300 | 176 | Ф40 | 31 | Ф40 | 31 | 22 | 22 |

RM0102S | 1 | 670 | 460 | 230 | 280 | 205 | Ф40 | 31 | Ф40 | 31 | 22 | 22 |

RM01501S | 1.5 | 800 | 615 | 295 | 430 | 265 | Ф47 | 40 | Ф47 | 38 | 30 | 30 |

RM0201S | 2 | 800 | 615 | 295 | 430 | 265 | Ф47 | 40 | Ф47 | 38 | 30 | 30 |

RM0202S | 2 | 835 | 520 | 260 | 300 | 236 | Ф47 | 38 | Ф47 | 38 | 30 | 30 |

RM02501S | 2.5 | 845 | 615 | 295 | 430 | 265 | Ф58 | 47 | Ф58 | 47 | 36 | 36 |

RM0301S | 3 | 845 | 615 | 295 | 430 | 265 | Ф58 | 47 | Ф58 | 47 | 36 | 36 |

RM0302S | 3 | 950 | 615 | 295 | 430 | 320 | Ф58 | 47 | Ф58 | 47 | 36 | 36 |

RM0303S | 3 | 950 | 520 | 260 | 350 | 205 | Ф59 | 48 | Ф59 | 48 | 35 | 35 |

RM0502S | 5 | 1030 | 615 | 295 | 430 | 325 | Ф60 | 48 | Ф60 | 48 | 43 | 43 |

RM07503S | 7.5 | 1200 | 615 | 295 | 505 | 320 | Ф85 | 31 | Ф85 | 80 | 85 | 55 |

RM1004S | 10 | 1400 | 630 | 315 | / | 890 | Ф85 | 80 | Ф85 | 80 | 104 | 55 |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Load Chain | Test Load (t) | Weight (kg) | Additional Weight per 1m Lift(kg) | ||||

50Hz | 60Hz | Power (kw) | Rotation Speed (r/min) | Diameter (mm)×chain falls | ||||||||

RM1506S | 15 | 1.8 | 2.2 | 3 | 3.0×2 | 1440 (50Hz) 1728 (60Hz) | 11.2 × 6 | 18.75 | 400 | 17 | ||

RM2008S | 20 | 1.4 | 1.7 | 3.0×2 | 11.2 × 8 | 25 | 480 | 22 | ||||

RM2510S | 25 | 1.1 | 1.3 | 3.0×2 | 11.2 × 10 | 31.25 | 540 | 28 | ||||

RM3012S | 30 | 0.9 | 1.1 | 3.0×2 | 11.2 × 12 | 37.5 | 1050 | 34 | ||||

RM3516S | 35 | 0.7 | 0.8 | 3.0×2 | 11.2 × 16 | 43.75 | 1250 | 45 | ||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | E | I | J | K | L | Q | M | N |

H | ||||||||||||

RM1506S | 15 | 1310 | 630 | 315 | 535 | Ф54 | Ф54 | Ф120 | 96 | 560 | 88 | 78 |

RM2008S | 20 | 1470 | 630 | 315 | 630 | Ф70 | Ф70 | Ф150 | 115 | 740 | 88 | 98 |

RM2510S | 25 | 1580 | 630 | 315 | 725 | Ф70 | Ф70 | Ф150 | 115 | 830 | 88 | 95 |

RM3012S | 30 | 1640 | 740 | 315 | 1300 | Ф100 | Ф100 | Ф140 | 95 | 440 | 217 | 130 |

RM3516S | 35 | 1790 | 740 | 315 | 1500 | Ф100 | Ф100 | Ф200 | 140 | 440 | 217 | 150 |

Specifications

Type | Capacit (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Load Chain | Test Load (t) | I - beam (mm) | Weight (kg) | Additional Weight per 1m Lift(kg) | |||||

Power (kw) | Rotation speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm)×chain falls | ||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||

RM00501S | 0.5 | 6.8 | 8.2 | 3 | 0.75 | 1440 (50Hz) 1728 (60Hz) | 0.4 | 1440 (50Hz) 1728 (60Hz) | 21 | 25 | 6.3 × 1 | 0.625 | 58-153 | 89 | 0.8 |

RM0101S | 1 | 6.6 | 7.9 | 1.5 | 0.4 | 7.1 × 1 | 1.25 | 58-153 | 103 | 1.1 | |||||

RM0102S | 1 | 3.4 | 4.1 | 0.75 | 0.4 | 6.3 × 2 | 1.25 | 58-153 | 101 | 1.6 | |||||

RM01501S | 1.5 | 8.8 | 10.6 | 3.0 | 0.4 | 10.0 × 1 | 1.875 | 82-178 | 157 | 2.3 | |||||

RM0201S | 2 | 6.6 | 7.9 | 3.0 | 0.4 | 10.0 × 1 | 2.5 | 82-178 | 164 | 2.3 | |||||

RM0202S | 2 | 3.3 | 4.0 | 1.5 | 0.4 | 7.1 × 2 | 2.5 | 82-178 | 122 | 2.2 | |||||

RM02501S | 2.5 | 5.4 | 6.5 | 3.0 | 0.75 | 11 | 13 | 11.2 × 1 | 3.125 | 100-178 | 177 | 2.8 | |||

RM0301S | 3 | 5.4 | 6.5 | 3.0 | 0.75 | 11.2 × 1 | 3.75 | 100-178 | 183 | 2.8 | |||||

RM0302S | 3 | 4.4 | 5.3 | 3.0 | 0.75 | 10.0 × 2 | 3.75 | 100-178 | 192 | 4.7 | |||||

RM0303S | 3 | 2.2 | 2.6 | 1.5 | 0.75 | 7.1 × 3 | 3.75 | 100-178 | 146 | 3.3 | |||||

RM0502S | 5 | 2.7 | 3.2 | 3.0 | 0.75 | 11.2 × 2 | 6.25 | 100-178 | 234 | 5.6 | |||||

RM07503S | 7.5 | 1.8 | 2.2 | 3.0 | 0.75 | 11.2 × 3 | 9.4 | 100-178 | 369 | 8.4 | |||||

RM1004S | 10 | 2.7 | 3.2 | 3.0×2 | 0.75 | 11.2 × 4 | 12.5 | 150-220 | 440 | 11.2 | |||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | I | K | L | N | W | U | R | T | |

H | |||||||||||||||

RM00501S | 0.5 | 630 | 460 | 230 | 280 | 160 | Ф35 | Ф35 | 25 | 17 | 206 | 111 | 142 | 231 | |

RM0101S | 1 | 650 | 520 | 260 | 300 | 176 | Ф40 | Ф40 | 32 | 24 | 206 | 111 | 142 | 231 | |

RM0102S | 1 | 695 | 460 | 230 | 280 | 205 | Ф40 | Ф40 | 31 | 24 | 206 | 111 | 142 | 231 | |

RM01501S | 1.5 | 770 | 615 | 295 | 430 | 265 | Ф47 | Ф47 | 40 | 30 | 237 | 127 | 142 | 231 | |

RM0201S | 2 | 770 | 615 | 295 | 430 | 265 | Ф47 | Ф47 | 40 | 30 | 237 | 127 | 142 | 231 | |

RM0202S | 2 | 815 | 520 | 260 | 300 | 236 | Ф36 | Ф47 | 38 | 30 | 237 | 127 | 142 | 231 | |

RM02501S | 2.5 | 830 | 615 | 295 | 430 | 265 | Ф58 | Ф58 | 48 | 36 | 265 | 140 | 142 | 231 | |

RM0301S | 3 | 830 | 615 | 295 | 430 | 265 | Ф58 | Ф58 | 48 | 36 | 265 | 140 | 142 | 231 | |

RM0302S | 3 | 930 | 615 | 295 | 430 | 320 | Ф43 | Ф58 | 47 | 36 | 265 | 140 | 142 | 231 | |

RM0303S | 3 | 940 | 520 | 260 | 350 | 205 | Ф43 | Ф58 | 47 | 36 | 265 | 140 | 142 | 231 | |

RM0502S | 5 | 1015 | 615 | 295 | 430 | 325 | Ф54 | Ф60 | 48 | 43 | 296 | 156 | 142 | 231 | |

RM07503S | 7.5 | 1200 | 615 | 295 | 505 | 320 | Ф54 | Ф85 | 80 | 55 | 295 | 156 | 142 | 231 | |

RM1004S | 10 | 1190 | 630 | 315 | / | 890 | Ф70 | Ф85 | 80 | 55 | 366 | 191 | 142 | 231 | |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Load Chain | Test Load (t) | I - beam (mm) | Weight (kg) | Additional Weight per 1m Lift(kg) | ||||||

Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm)×chain falls | |||||||||||

50Hz | 60Hz | 50Hz | 60Hz | |||||||||||||

RM1506S | 15 | 1.8 | 2.2 | 3 | 3.0×2 | 1440 (50Hz) 1728 (60Hz) | 0.75×2 | 1440 (50Hz) 1728 (60Hz) | 11 | 13 | 11.2 × 6 | 18.75 | 150-220 | 400 | 17 | |

RM2008S | 20 | 1.4 | 1.7 | 3.0×2 | 0.75×2 | 11.2 × 8 | 25 | 150-220 | 480 | 22 | ||||||

RM2510S | 25 | 1.1 | 1.3 | 3.0×2 | 0.75×2 | 11.2 × 10 | 31.25 | 150-220 | 540 | 28 | ||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | I | J | K | L | M | N | P | Q | R | T |

H | ||||||||||||||||

RM1506S | 15 | 1310 | 630 | 315 | 1070 | 535 | Ф54 | Ф54 | Ф120 | 96 | 88 | 78 | 926 | 560 | 142 | 231 |

RM2008S | 20 | 1470 | 630 | 315 | 1260 | 630 | Ф70 | Ф70 | Ф150 | 115 | 88 | 98 | 1106 | 740 | 142 | 231 |

RM2510S | 25 | 1580 | 630 | 315 | 1260 | 725 | Ф70 | Ф70 | Ф150 | 115 | 88 | 95 | 1280 | 830 | 142 | 231 |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Load Chain | Test Load (t) | I - beam (mm) | Additional Weight per 1m Lift (kg) | |||||||

Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm)×chain falls | |||||||||||

50Hz | 60Hz | 50Hz | 60Hz | |||||||||||||

RM00501SL | 0.5 | 6.8 | 8.2 | 3 | 0.75 | 1440 (50Hz) 1728 (60Hz) | 0.4 | 1440 (50Hz) 1728 (60Hz) | 21 | 25 | 6.3 × 1 | 0.625 | 58-153 | 0.8 | ||

RM0101SL | 1 | 6.6 | 7.9 | 1.5 | 0.4 | 7.1 × 1 | 1.25 | 58-153 | 1.1 | |||||||

RM01501SL | 1.5 | 8.8 | 10.6 | 3.0 | 0.4 | 10.0 × 1 | 1.875 | 82-178 | 2.3 | |||||||

RM0201SL | 2 | 6.6 | 7.9 | 3.0 | 0.4 | 10.0 × 1 | 2.5 | 82-178 | 2.3 | |||||||

RM0202SL | 2 | 3.3 | 4.0 | 1.5 | 0.4 | 7.1 × 2 | 2.5 | 82-178 | 2.2 | |||||||

RM02501SL | 2.5 | 5.4 | 6.5 | 3.0 | 0.75 | 11 | 13 | 11.2 × 1 | 3.125 | 100-178 | 2.8 | |||||

RM0301SL | 3 | 5.4 | 6.5 | 3.0 | 0.75 | 11.2 × 1 | 3.75 | 100-178 | 2.8 | |||||||

RM0302SL | 3 | 4.4 | 5.3 | 3.0 | 0.75 | 10.0 × 2 | 3.75 | 100-178 | 4.7 | |||||||

RM0502SL | 5 | 2.7 | 3.2 | 3.0 | 0.75 | 11.2 × 2 | 6.25 | 100-178 | 5.6 | |||||||

RM07503SL | 7.5 | 1.8 | 2.2 | 3.0 | 0.75 | 11.2 × 3 | 9.4 | 100-178 | 8.4 | |||||||

RM1004SL | 10 | 2.7 | 3.2 | 3.0×2 | 0.75 | 11.2 × 4 | 12.5 | 150-220 | 11.2 | |||||||

Dimensions (mm)

| Type | Capacity (t) | Headroom | A | B | D | E | I | J | K | L | M | N | P | Q | R | T |

| H | ||||||||||||||||

| RM00501SL | 0.5 | 440 | 460 | 230 | / | / | Ф31 | Ф31 | Ф35 | 25 | 52 | 17 | 585 | 400 | 142 | 231 |

| RM0101SL | 1 | 480 | 520 | 260 | / | / | Ф31 | Ф31 | Ф40 | 31 | 56 | 22 | 630 | 445 | 142 | 231 |

| RM01501SL | 1.5 | 570 | 615 | 295 | / | / | Ф31 | Ф36 | Ф47 | 38 | 66 | 30 | 720 | 505 | 142 | 231 |

| RM0201SL | 2 | 570 | 615 | 295 | / | / | Ф31 | Ф36 | Ф47 | 38 | 66 | 30 | 720 | 505 | 142 | 231 |

| RM0202SL | 2 | 535 | 520 | 260 | / | / | Ф31 | Ф36 | Ф47 | 38 | 56 | 30 | 665 | 445 | 142 | 231 |

| RM02501SL | 2.5 | 640 | 615 | 295 | / | / | Ф36 | Ф43 | Ф58 | 47 | 73 | 36 | 775 | 526 | 142 | 231 |

| RM0301SL | 3 | 640 | 615 | 295 | / | / | Ф36 | Ф43 | Ф58 | 47 | 73 | 36 | 775 | 526 | 142 | 231 |

| RM0302SL | 3 | 685 | 615 | 295 | / | / | Ф36 | Ф43 | Ф58 | 47 | 66 | 36 | 750 | 503 | 142 | 231 |

| RM0502SL | 5 | 740 | 615 | 295 | / | / | Ф43 | Ф54 | Ф60 | 48 | 73 | 43 | 825 | 541 | 142 | 231 |

| RM07503SL | 7.5 | 890 | 615 | 295 | / | / | Ф43 | Ф54 | Ф85 | 80 | 73 | 55 | 1020 | 730 | 142 | 231 |

| RM1004SL | 10 | 880 | 630 | 315 | 1640 | 820 | Ф54 | Ф54 | Ф85 | 80 | 85 | 55 | 926 | 630 | 142 | 231 |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Load Chain | Test Load (t) | I - beam (mm) | Weight (kg) | Additional Weight per 1m Lift (kg) | |||

50Hz | 60Hz | Power (kw) | Rotation Speed (r/min) | Diameter (mm)×chain falls | ||||||||

RM00501S | 0.5 | 6.8 | 8.2 | 3 | 0.75 | 1440 (50Hz) 1728 (60Hz) | 6.3 × 1 | 0.625 | 68-130 | 53 | 0.8 | |

RM0101S | 1 | 6.6 | 7.9 | 1.5 | 7.1 × 1 | 1.25 | 68-130 | 67 | 1.1 | |||

RM0102S | 1 | 3.4 | 4.1 | 0.75 | 6.3 × 2 | 1.25 | 68-130 | 67 | 1.6 | |||

RM01501S | 1.5 | 8.8 | 10.6 | 3.0 | 10.0 × 1 | 1.875 | 82-153 | 118 | 2.3 | |||

RM0201S | 2 | 6.6 | 7.9 | 3.0 | 10.0 × 1 | 2.5 | 82-153 | 125 | 2.3 | |||

RM0202S | 2 | 3.3 | 4.0 | 1.5 | 7.1 × 2 | 2.5 | 82-153 | 83 | 2.2 | |||

RM02501S | 2.5 | 5.4 | 6.5 | 3.0 | 11.2 × 1 | 3.125 | 82-153 | 132 | 2.8 | |||

RM0301S | 3 | 5.4 | 6.5 | 3.0 | 11.2 × 1 | 3.75 | 82-153 | 138 | 2.8 | |||

RM0302S | 3 | 4.4 | 5.3 | 3.0 | 10.0 × 2 | 3.75 | 82-153 | 147 | 4.7 | |||

RM0303S | 3 | 2.2 | 2.6 | 1.5 | 7.1 × 3 | 3.75 | 82-153 | 101 | 3.3 | |||

RM0502S | 5 | 2.7 | 3.2 | 3.0 | 11.2 × 2 | 6.25 | 100-178 | 181 | 5.6 | |||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | K | L | N | I | J | P |

H | ||||||||||||

RM00501S | 0.5 | 555 | 455 | 240 | 285 | 165 | Ф34 | 28 | 19 | Ф26 | 115 | 221 |

RM0101S | 1 | 635 | 520 | 260 | 300 | 176 | Ф42 | 32 | 24 | Ф26 | 115 | 221 |

RM0102S | 1 | 630 | 455 | 240 | 285 | 165 | Ф42 | 32 | 24 | Ф26 | 115 | 221 |

RM01501S | 1.5 | 764 | 615 | 295 | 430 | 265 | Ф49 | 40 | 30 | Ф31 | 138 | 265 |

RM0201S | 2 | 764 | 615 | 295 | 430 | 265 | Ф49 | 40 | 30 | Ф31 | 138 | 265 |

RM0202S | 2 | 800 | 520 | 260 | 300 | 236 | Ф49 | 40 | 30 | Ф31 | 138 | 265 |

RM02501S | 2.5 | 854 | 615 | 295 | 430 | 265 | Ф59 | 48 | 35 | Ф36 | 157 | 277 |

RM0301S | 3 | 854 | 615 | 295 | 430 | 265 | Ф59 | 48 | 35 | Ф36 | 157 | 277 |

RM0302S | 3 | 960 | 615 | 295 | 430 | 320 | Ф59 | 48 | 35 | Ф36 | 157 | 277 |

RM0303S | 3 | 968 | 520 | 260 | 350 | 205 | Ф59 | 48 | 35 | Ф36 | 157 | 277 |

RM0502S | 5 | 1007 | 615 | 295 | 430 | 325 | Ф60 | 48 | 43 | Ф43 | 178 | 332 |