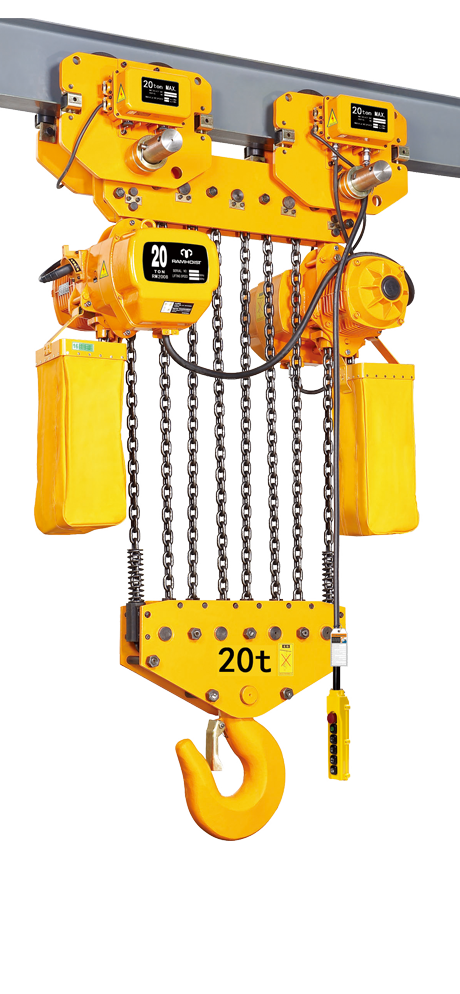

Electric Chain Hoists are new type electric chain hoists which further builds upon previous RM series, To ensure safety, it adds overload clutch inside (built in friction clutch/safety clutch/ slip clutch/ overload limit) rather than Overload Protector outside the hoist (optional for RM series), We are electric chain hoists suppliers focus on electric hoists, Electric Chain Hoists

• Can be controlled separately, each forward, reverse and easy to use

• Smooth & Ergonomic Operation, enhanced durability

• High strength and full aluminum body makes the hoist super light and portable

• Robust construction, small limit size, beautiful appearance, excellent quality, good performance

• High efficient, High security, high reliability, high precision, high work level, lower fault rate

• Improve the degree of corrosion and heat dissipation effect, Low effort to lift maximum load

• Both the top and bottom hooks are made of high tensile alloy steel with special treatment

• 360° swivel bottom hook with built-in bearing, for easy positioning

• Compact, high efficient and heavy-duty motor, low power consumption

• Beautiful & high strength steel or plastic chain container which has outstanding durability

• CE and ISO high grade and super-strength alloy load chain

• Standard upper limit switch protects the hoist from overlifting, stabilising shaft

• Advanced fail-safe pull rotor brake is self-adjusting and virtually maintenance free

• Durable baked enamel paint protection, Ability to accommodate long lift

• Friction clutch protects the hoist against over travel and overload damage

• Heat treated steel wheels are hardened for long, trouble-free life

• Overload protection device available upon request, Suspender for close connected suspension

• Excellent after-sale serve, market agent support and protection

• Sample order and trail order are acceptable

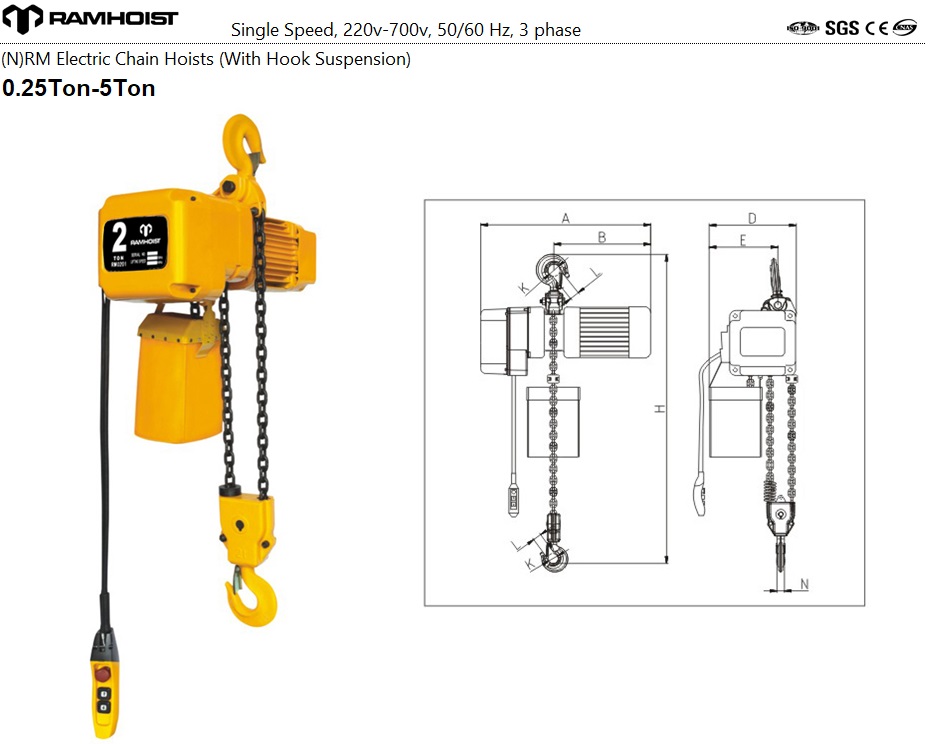

Capacity 0.25Ton-5Ton (With Hook Suspension)

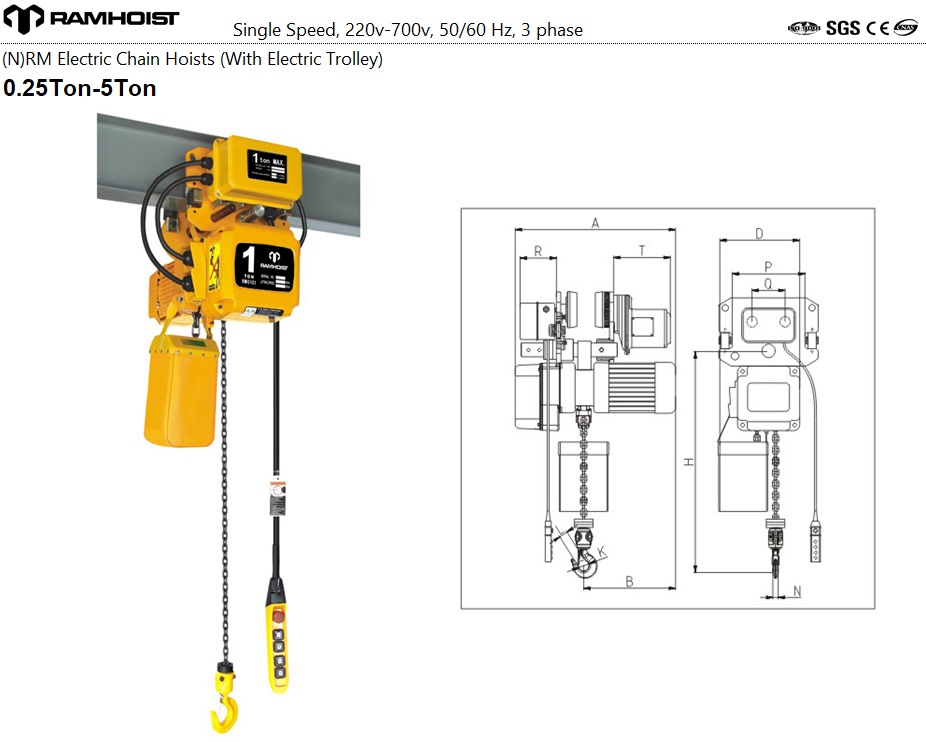

0.25Ton-5Ton (With Electric Trolley)

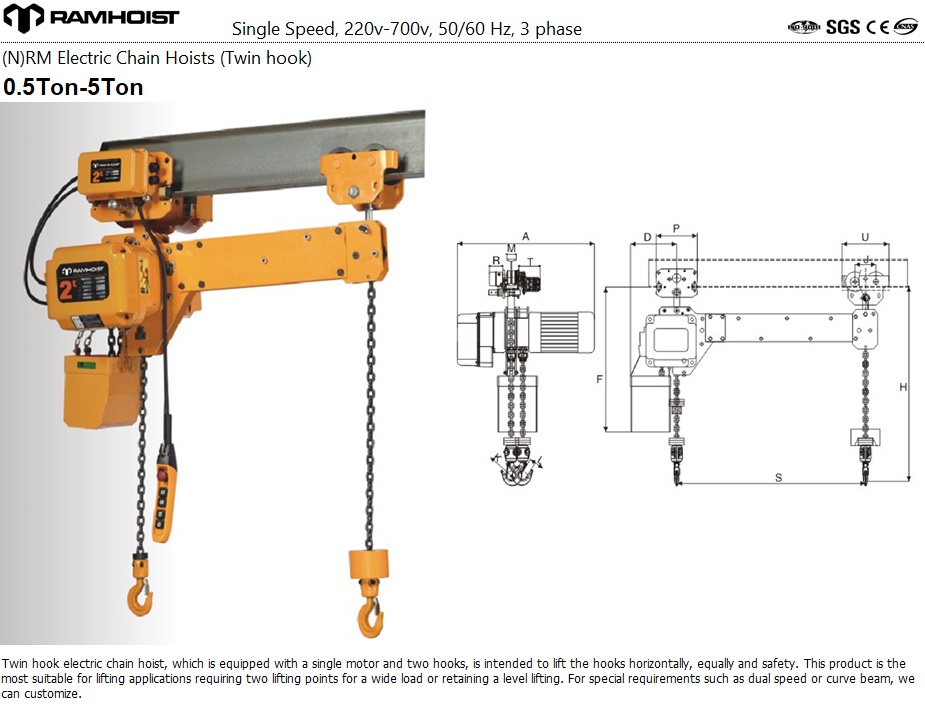

0.5Ton-5Ton (Twin hook)

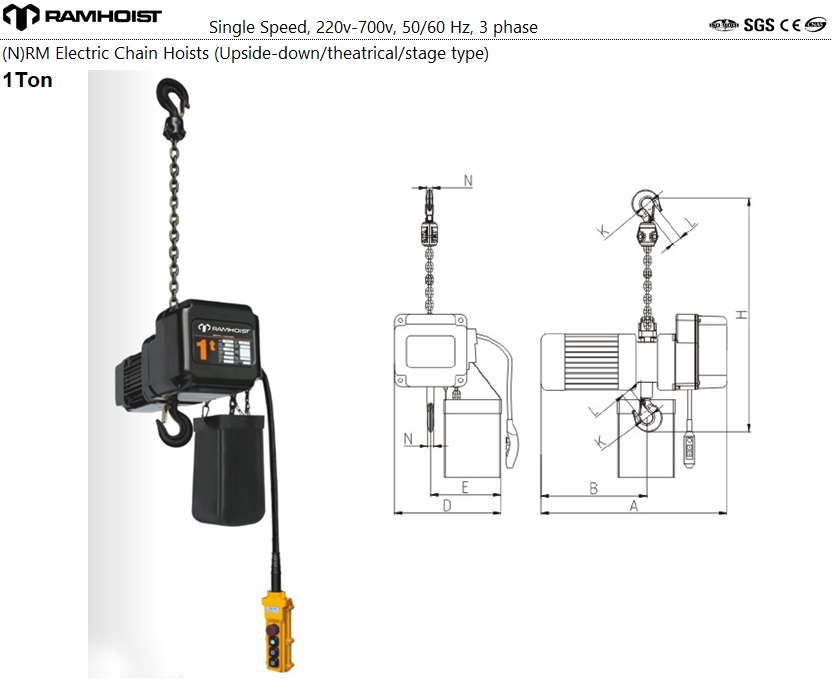

1Ton (Upside-down)

Standard Lift 3 m

Use Lifting Up/Down, Traversing Left/Right

Drive Mode Motor

Sling Type Chain

Way Stationary or Moveable

Operation With pedant cable push button or remote control

Power Supply 220v-700v, 50/60 Hz, 3 phase, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84251100

Package Plywood case

(N)RM Electric Chain Hoists are new type electric chain hoists which further builds upon previous RM series, To ensure safety, it adds overload clutch inside (built in friction clutch/safety clutch/ slip clutch/ overload limit) rather than Overload Protector outside the hoist(optional for RM series), with the upper-lower limit switch (Our limit switch do not need adjustment since it is automatical adjust), it is more safe and reliable than RM series.

Uniquely-designed push button control on the basis of ergonomics, enhanced durability of load chain, improved ease of maintenance as well as support for the environment achieve higher safety and working efficiency, this series, therefore, provide long-period stable operation, which is essential for improving production efficiency. Due to further improved durability, the increased product service life and reduced running costs have resulted in minimizing the lifetime cost.

Stage chain hoist is a special used stage lifting equipment and theater equipment which ensures safe and accurate positioning for speakers, lighting systems, stage facilities, scenery, etc. Electric stage chain hoist have single and double chain, usually max. lifting capacity is 1 ton based on single phase; If power supply is three phase, the stage chain hoist can be customized design according to clients’ demands. Normally, Its surface is painted yellow color, 36V control voltage, the bidirectional and all-weather use and design, equipped with adjustable screw type limit switch.

Stage special electric hoist also called stage rigging or Stage Lifting Hoist is in strict accordance with the tour, roving exhibitions request design production, surface treatment, bright black lacquer abiding; 380 volts control circuit heat treatment of the forming roller chain plate steel guide to operate, easy maintenance, With positive and negative two-way and 24-hour use designed accords with 30,000 tons of lifting equipped with adjustable screw limit switches, reliable performance higher, Hoisting height can reach 38 meters minimum 161 safety design coefficient chain galvanized processing, is not easy to rust lubricating grease installed in gear box, prevent oil droplets penetration to the stage on the motor seal in the aluminum gourd cylindrical shell, within the rims permanent protect motor suits with various controller and circuit connected distributor.

Our Upside-down (theatrical/stage) type was designed by using the latest technology for handling theatrical and stage equipment. These high quality, low-headroom, full-featured hoists provide reliable performance for use in theaters, concert halls, arenas and studios, Stage electric hoist is specifically for large-scal performances, lighting hangers, loudspeaker sets, large set design, also applies to other temporary occasions such as lifting mobile advertising legislation licensing installation and small construction sites.... to be positioned with precision and total safety.The (N)RM Electric Chain Hoist can improve efficiency in the most demanding of work environments and satisfy even the most demanding of customers.

This model Electric chain hoists are widely used in factories, workshops, warehouses, mines, Bridges, construction and other occasions for materials hoisting, equipment installation, etc. Especially are suitable for high-rise building construction and welding storage tank with a number of crane.

1. Intensive aluminum case|Shell

They are made of Light aluminum alloy -- die-cast aluminum alloy through compression casting formation, updated moulded hoist case has more morden and beautiful appearance, which can attract one’s attention more.

The integral enclosed structure with plastic and mat black non-reflecting coating is applicable to use in the terrible work environment with a high heat dissipation rate and all tightness design. such us chemical plants, electroplating factories, and other places.

Hoist body being anti-dust and anti-water (protection class is IP55)

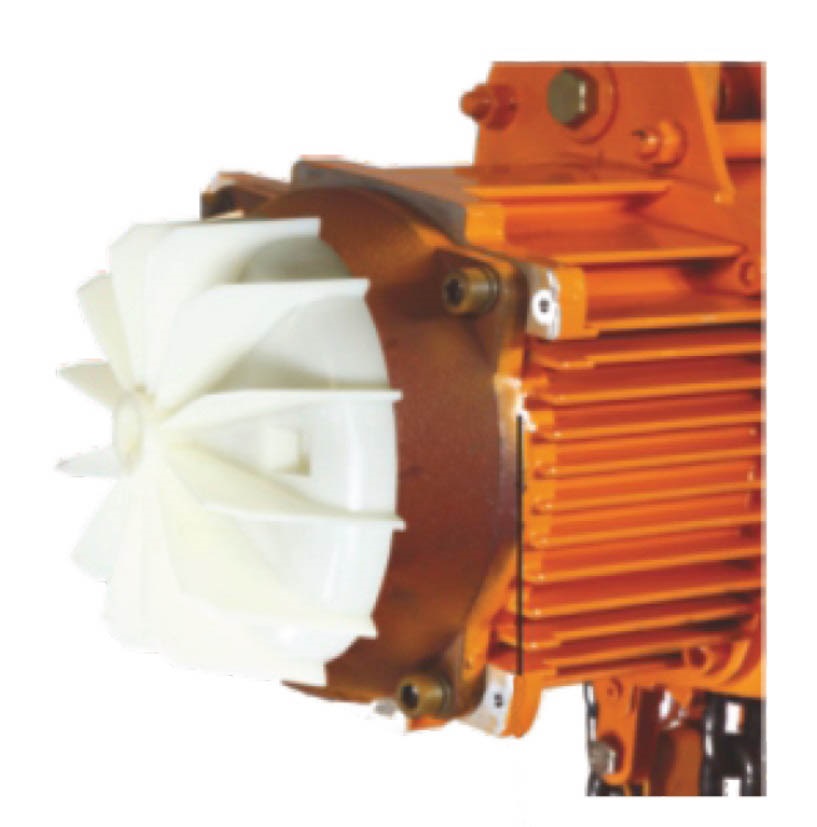

2. High frequency motor with cooling fan

The high frequency motor with cooling fan can reduces the motor temperature during frequent operation and increases short-time rating and repeated rating. Besides, class F insulated motor makes high frequency use possible.

the cooling fan is specially designed to ensure quick heat dissipation with the rate up to 40% and continuous service.

3. Unique Fins

Unique fins of motor frame with high efficiency on motor cooling.

4. Advanced suction rotary motor brake|Electromagnetic brake system

Suction rotary motor brake made of non-asbestors (brake linings) reduces maintenance times greatly and can precisely and effectively make the hoist stop running, even when there is a lack of power.

Generally speaking, only when alternating current/direct current brake is installed can the brake work with power off and the hoist work with power on, thus the load won’t fall due to the closed circuit of motor.

Heavy duty design for reliabie operation. Direct acting for positive load holding and spotting, Independent heavy-duty DC brakes of hoist motors are able to eliminate heat rise and control the load securely.

5. Mechanical brake

It comes along with above Electromagnetic brake to form dual brake system, which respond instantly and dependable positive braking power, enable long service life.

6. Upper/lower Limit switch

It is preventive against over lifting or over falling, once it happens, the switch can put a stop to the working hoist.

Limit switching device, fitted at both top and bottom ends, Adjustable to regulate upper and lower load travel, switch off power automatically and the motor automatically stop, to prevent load chain from running out and ensure the safety; Brass nuts standard for improved repeatability and chain positioning.

7. Anti-phase relay|Phase error relay

The anti-phase relay device protects machine from damage when power connection is in wrong way.

A specially designed current-post, prevent motor from running at incorrect wire connection, in other words, when the phase is incorrectly connected.

8. Overload clutch|friction clutch|Safety clutch(inside the hoist)

Overload clutch also called special over-rolling protection device soaked in the oil prevents the hoist extremely rolling up or being overloaded and ensures the life- span of hoist. As emergency overload happening, the protection clutch will function

It prevents damage to the hoist by automatically engaging in the event of an excessive overload. When the overload clutch engages, the motor is allowed to continue turning protecting both you and the hoist.

9. Overload Protector (outside the hoist) – optional

Overload protection device designed to avoid adverse consequences caused by overloading

Overload Protector is available, it is in the event of the operator's safety and product from damage, Helps protect hoist, operator, and supporting structures from damaging overloads, chain jamming and reverse phasing.

insulation is F grade. Single use or multiple operating with one control cabinet;

10. Mechanic electromagnetic

It locks switch of high performance.

11. Hand switch|Push button|Emergency stop button

An ergonomic shape design ensures hand switch operated friendly, the button with a light soft operating sensation satisfied the operator not fatigued after a long period operation.

E-stops (Emergency stop button) -- users can shut off power supply by operating the emergency stop button in the case of emergency)

Durable buttons (protection class is IP65) are convenient to operate, they are designed for low voltage control to ensure security.

12. Control case cover fixed with hinge

The Control case cover fixed with hinge is convenient for spot examination or maintenance. All the electric switch groups are installed on the same board.

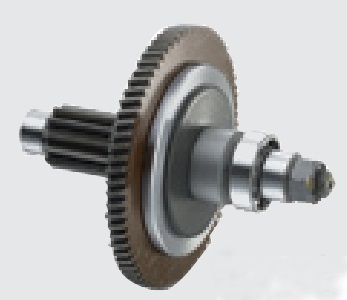

13. First stage helical gear|Low-noised transmission gear|Precise spiral gear|Precision machined alloy steel gears

First stage helical gearing provides a dependable and longer quieter life by reducing gear tooth impact and virabtion to a minimum. Precision machined gears made of intensive alloy steel heat treated which increases the overall hardness and strength for strength & durability and soaked in the oil (Oil Bath-Lubricated) for running smoothly so that the hoist will serve longer life noiselessly and quieter operation by reducing friction, vibration and heat.

14. Chain

It is made of FEC80 ultra heat treatable aluminum alloy steel enhancing anti-fatigue and anti-wear performance

The surface of chain is dealt with case carburization which contains Si Ni Mo. The inside material is softened. It is resistant to corrosion, rain, water, sea water, chemical and other bad conditions. Chain galvanized processing, not easy to rust, more reliable performance

15. Original Chain Guide

The unique chain guide originally devised makes it possible that the load chain can freely lift and fall.

MC Nylon is applied for Load Chain Guide to ensure the load chain proper fitting the load sheave during operation and protect the load sheave from wet and dirt.

Upper Composite Chain Guide - Improves chain life and reduces chain noise.

Lower Chain Guide - Features easy capacity conversion.

16. Chain wheel

Running in chain wheel, the chain is free from dropping off and jumping so that it is more stable.

17. Chain End Stop Assembly

Fits below dead end link on lifting chain for added measure of protection.

18. Chain bag/container

Light, handsome and durable. Canvas chain bag is highly durable.

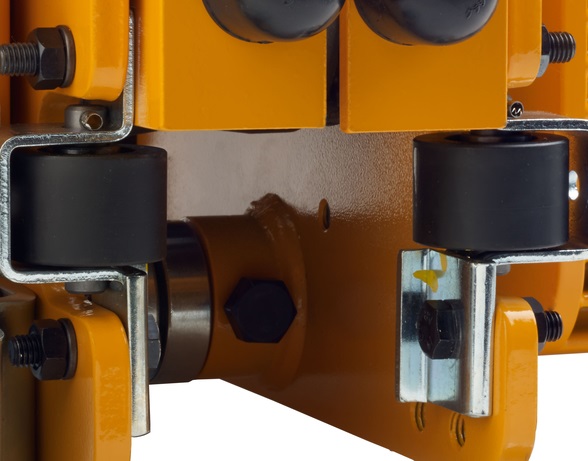

19.Side-Guide Roller System

Designed for very smooth travel along the beam, the motorized trolley uses an innovative side-guide roller system that keeps the load controlled and on track while traversing.

20. Five-Pocket Load Sheave|Unique load sheave

Increased number of deep-groove pockets reduce chain vibration, chain wear, increase chain life and provides true vertical lift, Increased chain and sheave engagement 25% over hoists with conventional four-pocket sheaves. 5 pockets standard, 6 pockets on smaller body hoists.

Provides smoother lifting and reduces chain wear.

21. Hooks

High strength and most tensile safety hook, withstand accidental overload shock without fracture, overweight will only gradually deformation-- guarantees the hook will not break and deform gradually under a sudden extra-load; Hooks with fully hot forged and heat treatment allow to be swiveled 360 and are equipped with safety latch (safety tongue piece) to ensure proper hooking the load.

22. External pins

External pins allow for quick change from hook to lug for trolley mount configurations on most models.

23. Bearing

High quality bearings can improve the mechanical performance

24. Transformer

24V/36V transformer device

25. Contactor

Self lock heavy duty contactor prevents up and down activating at the same time

26. Multi-plug

Regular Power Plug Multi cable cab be both supported for V6,by using the Multi cable,the real-time loading data can be displayed on the handheld.

27. Built-in inverter for Dual speed hoists

Adopts built-in inverter to make hoist in dual speeds reduce swing in operation and helps electric chain hoist start steadily and stops slowly, the standard speed ratio is 4:1 and can be adjusted.

28. Duty Cycle

H-4 duty rated for heavy duty application. 2M+ FEM class. 50% Duty Cycle or 300 on/off per hour.10:1 mechanical design factor

29. Others

Inverse phase sequence protectin device

Particularly designed and equipped for inverted or normal positions.

Special design of excellence load chain collection whether normal or inverted position. Load spectrum conforms to FEM 2m / ISO M5 covering a wide range of applications.

Operating with highly efficiently motor of 40%ED is quiet, light weight and suitable for

variable application.

24/36V/48V Low Voltage Control: The low voltage control can protect operators from electrical shocks.

Optional 110 Volt for long cable runs without voltage drop.

30. Different Types

With Hook Suspension

With Electric Trolley

Twin hook

Upside-down/theatrical/stage type

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Load Chain | Test Load (t) | Weight (kg) | Additional Weight per 1m Lift (kg) | ||||

50Hz | 60Hz | Power (kw) | Rotation Speed (r/min) | Diameter (mm) × chain falls | ||||||||

(N)RM002501S | 0.25 | 9 | 10.8 | 3 | 0.4 | 1440 (50Hz) 1728 (60Hz) | 4.0 × 1 | 0.313 | 37 | 0.4 | ||

(N)RM00501S | 0.5 | 7.8 | 9.4 | 0.75 | 6.3 × 1 | 0.625 | 47 | 0.8 | ||||

(N)RM0101S | 1 | 7.2 | 8.6 | 1.5 | 8.0 × 1 | 1.25 | 61 | 1.1 | ||||

(N)RM0202S | 2 | 3.6 | 4.3 | 1.5 | 8.0 × 2 | 2.5 | 73 | 2.2 | ||||

(N)RM0301S | 3 | 5.4 | 6.5 | 3.0 | 11.2 × 1 | 3.75 | 122 | 2.8 | ||||

(N)RM0502S | 5 | 2.7 | 3.2 | 3.0 | 11.2 × 2 | 6.25 | 151 | 5.6 | ||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | I | J | K | L | M | N |

H | ||||||||||||

(N)RM002501S | 0.25 | 300 | 455 | 210 | 225 | 120 | Ф31 | 18 | 31 | 18 | 13 | 13 |

(N)RM00501S | 0.5 | 450 | 565 | 280 | 300 | 195 | Ф32 | 25 | 32 | 25 | 17 | 17 |

(N)RM0101S | 1 | 500 | 595 | 320 | 300 | 176 | Ф40 | 31 | 40 | 31 | 24 | 24 |

(N)RM0202S | 2 | 600 | 595 | 320 | 300 | 245 | Ф49 | 35 | 30 | 35 | 30 | 30 |

(N)RM0301S | 3 | 630 | 785 | 395 | 465 | 295 | Ф59 | 42 | Ф59 | 42 | 35 | 35 |

(N)RM0502S | 5 | 880 | 785 | 395 | 465 | 360 | Ф60 | 45 | Ф60 | 45 | 43 | 43 |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Load Chain | Test Load (t) | I - beam (mm) | Weight (kg) | Additional Weight per 1m Lift (kg) | |||||

Power (kw) | Rotation speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) × chain falls | ||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||

(N)RM002501S | 0.25 | 9 | 10.8 | 3 | 0.4 | 1440 (50Hz) 1728 (60Hz) | 0.4 | 1440 (50Hz) 1728 (60Hz) | 20 | 24 | 4.0 × 1 | 0.313 | 58-153 | 79 | 0.4 |

(N)RM00501S | 0.5 | 7.8 | 9.36 | 0.75 | 0.4 | 6.3 × 1 | 0.625 | 80-160 | 89 | 0.8 | |||||

(N)RM0101S | 1 | 7.2 | 8.6 | 1.5 | 0.4 | 8.0 × 2 | 1.25 | 80-160 | 103 | 1.1 | |||||

(N)RM0201S | 2 | 5.4 | 6.48 | 1.5 | 0.4 | 10.0 × 1 | 2.5 | 82-178 | 164 | 2.3 | |||||

(N)RM0202S | 2 | 3.6 | 4.3 | 1.5 | 0.4 | 8.0 × 2 | 2.5 | 82-178 | 122 | 2.2 | |||||

(N)RM0301S | 3 | 5.4 | 6.48 | 3 | 0.4 | 10 | 12 | 11.2 × 1 | 3.75 | 100-180 | 183 | 2.8 | |||

(N)RM0302S | 3 | 2.8 | 3.4 | 1.5 | 0.4 | 10.0 × 2 | 3.75 | 110-180 | 192 | 4.7 | |||||

(N)RM0502S | 5 | 2.7 | 3.24 | 3.0 | 0.75 | 11.2 × 2 | 6.25 | 110-180 | 234 | 5.6 | |||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | J | K | L | M | N | R | T | P | Q | |

H | |||||||||||||||

(N)RM002501S | 0.25 | 300 | 455 | 210 | 225 | 18 | 31 | 18 | 13 | 13 | 142 | 231 | 206 | 111 | |

(N)RM00501S | 0.5 | 450 | 565 | 280 | 300 | 25 | 32 | 25 | 17 | 17 | 142 | 231 | 206 | 111 | |

(N)RM0101S | 1 | 460 | 595 | 320 | 300 | 31 | 40 | 31 | 24 | 24 | 142 | 231 | 206 | 111 | |

(N)RM0201S | 2 | 560 | 645 | 330 | 320 | 36 | 49 | 35 | 30 | 30 | 142 | 231 | 237 | 127 | |

(N)RM0202S | 2 | 660 | 595 | 320 | 300 | 35 | 30 | 35 | 30 | 30 | 142 | 231 | 265 | 140 | |

(N)RM0301S | 3 | 710 | 785 | 395 | 465 | 42 | Ф59 | 42 | 35 | 35 | 142 | 231 | 265 | 140 | |

(N)RM0302S | 3 | 680 | 645 | 330 | 320 | 43 | Ф59 | 42 | 35 | 35 | 142 | 231 | 265 | 140 | |

(N)RM0502S | 5 | 940 | 785 | 395 | 465 | 45 | Ф60 | 45 | 43 | 43 | 142 | 231 | 237 | 127 | |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Load Chain | Test Load (t) | I - beam (mm) | Additional Weight per 1m Lift (kg) | |||||

Power (kw) | Rotation speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) × chain falls | |||||||||

50Hz | 60Hz | 50Hz | 60Hz | |||||||||||

(N)RM00501S | 0.25 + 0.25 | 7.8 | 9.36 | 3 | 0.75 | 1440 (50Hz) 1728 (60Hz) | 0.4 | 1440 (50Hz) 1728 (60Hz) | 20 | 24 | 6.3 × 1 | 0.625 × 2 | 80-160 | 0.8 |

(N)RM0101S | 0.5 + 0.5 | 7.2 | 8.6 | 1.5 | 0.4 | 8.0 × 2 | 1.25 × 2 | 80-160 | 1.1 | |||||

(N)RM0201S | 1 + 1 | 5.4 | 6.48 | 1.5 | 0.4 | 10.0 × 1 | 2.5 × 2 | 82-178 | 2.3 | |||||

(N)RM0301S | 1.5 + 1.5 | 5.4 | 6.5 | 3.0 | 0.4 | 10 | 12 | 11.2 × 1 | 3.75 × 2 | 100-180 | 2.8 | |||

(N)RM0502S | 2.5 + 2.5 | 2.7 | 3.24 | 3.0 | 0.75 | 11.2 × 2 | 6.25 × 2 | 110-180 | 5.6 | |||||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | P | U | S | K | L | R | T | N | |

H | ||||||||||||||

(N)RM00501S | 0.5 | 450 | 660 | 320 | 200 | 206 | 111 | 3000 | Ф32 | 25 | 142 | 231 | 17 | |

(N)RM0101S | 1 | 550 | 660 | 350 | 200 | 206 | 111 | 3000 | Ф40 | 31 | 142 | 231 | 17 | |

(N)RM0201S | 2 | 550 | 780 | 440 | 260 | 206 | 111 | 3000 | Ф40 | 31 | 142 | 231 | 24 | |

(N)RM0301S | 3 | 650 | 870 | 310 | 300 | 265 | 140 | 3000 | Ф59 | 42 | 142 | 231 | 35 | |

(N)RM0502S | 5 | 850 | 870 | 310 | 300 | 296 | 156 | 3000 | Ф60 | 45 | 142 | 231 | 43 | |

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Load Chain | Test Load (t) | Weight (kg) | Additional Weight per 1m Lift (kg) | ||||

50Hz | 60Hz | Power (kw) | Rotation Speed (r/min) | Diameter (mm) × chain falls | ||||||||

(N)TNRM101S | 1 | 7.2 | 8.6 | 3 | 1.5 | 1440 | 8.0 × 1 | 1.25 | 61 | 1.1 | ||

Dimensions (mm)

Type | Capacity (t) | Headroom | A | B | D | E | K | L | N | |||

H | ||||||||||||

(N)TNRM101S | 1 | 400 | 595 | 320 | 300 | 230 | Ф40 | 31 | 24 | |||