Explosion-proof Electric Chain Hoists (anti-explosion electric chain hoists) are kind of new style and small lifting equipment, which are ideal tools to lift heavy objects, load and unload, maintain equipment. This kind of EX type electric chain hoists are designed and manufactured in accordance with the requirements stipulated in the guidelines for explosion-proof plant-use electric equipment and facilities.

• Compact body-small cubage and size and lightweight, easy to transport and store

• Smooth, mature, stable, comfortable, simple, convenient and ergonomic operation

• Safe use and operation with high technology advantages and high quality work team

• Enhanced durability, high reliability with wet and dust resistance for long lifespan

• Have normal, fast, accurate lift speed which will give customer excellent performance

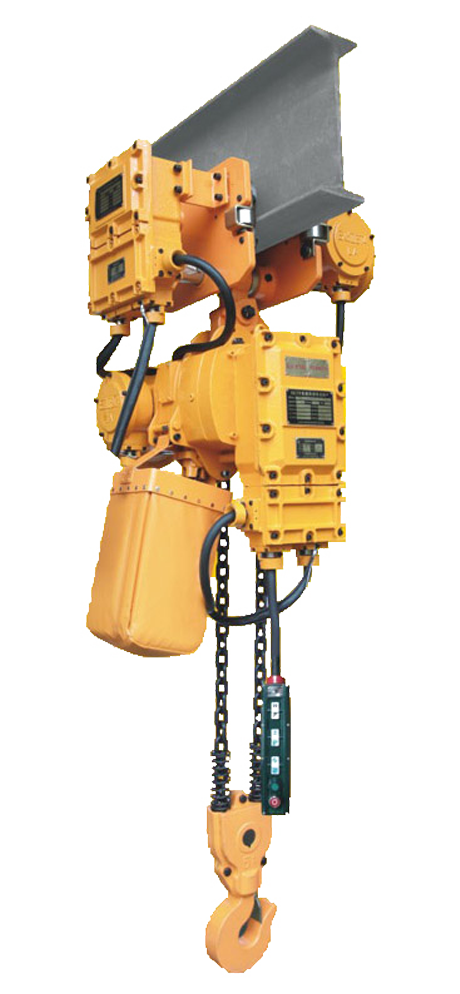

• Especially suitable for those dangerous and tough situations with explosive risk

• Equipped with good quality overload protection device which is available upon request

• Made of hard aluminum alloy with high-strength Japanese imported load chain

• Reversing single speed controls for hoist and trolley provide security to the operations

• Durable baked enamel paint protections can highly provide more safety to our hoists

• Easier maintenance, high efficiency with decent and affordable price for customers

• Nice appearance, unique design with great reputation among the world market

• Spark-resistant components can make our hoists become more safe and reliable

• Excellent after-sale serve, market support and protection are the advantages of hoists

• 12 months warranty is the most important commitment we provided to our customers

• Environmental-friendly with low noise and least pollution for our operation sites

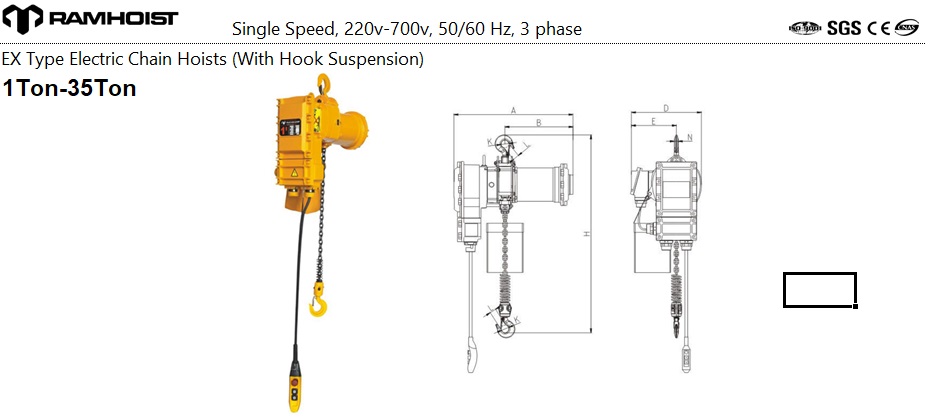

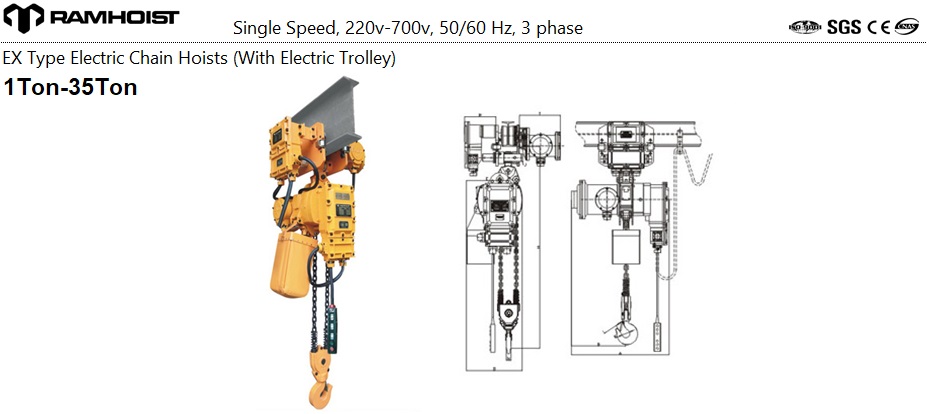

Capacity 1Ton-35Ton

Standard Lift 3 m

Use Lifting Up/Down

Drive Mode Motor

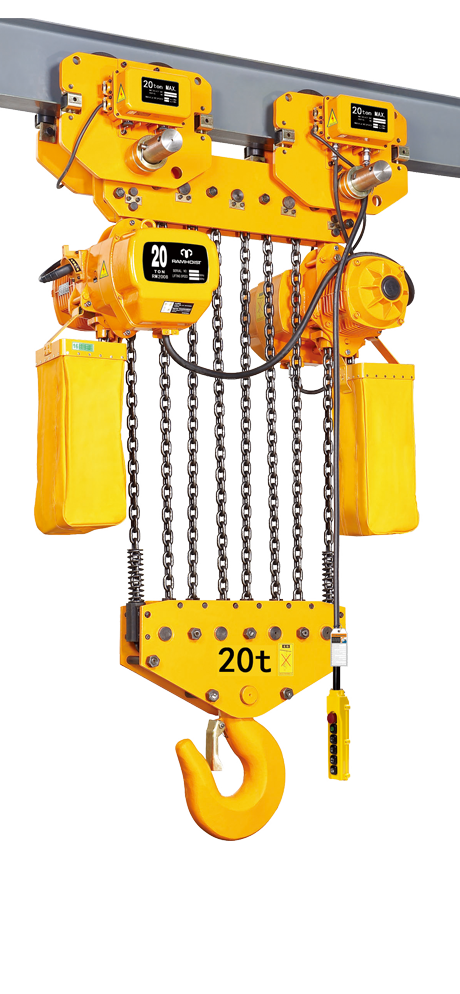

Type With hook suspension/ with electric trolley

Sling Type Chain

Chain falls 1, 2, 3, 4, 6, 8, 10, 12, and 16

Trademark Ramhoist

Power source Electric

Condition New

Frequency 50-60HZ

Usage Construction

Operation With pedant cable push button or remote control

Power Supply 220v-700v, 50/60 Hz, 3 phases, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84251100

Package Plywood case/wood case

EX (Explosion-proof) Electric Chain Hoists are kind of new style and small lifting equipment, which are ideal tools to lift heavy objects, load and unload, maintain equipment. This kind of explosion-proof electric chain hoists are designed and manufactured in accordance with the requirements stipulated in the guidelines for explosion-proof plant-use electric equipment and facilities. The most prominent feature of explosion-proof electric chain hoists is that they have excellent performance and are very suitable for the explosive areas and tough areas, which can ensure safety under the premise of improving working conditions and also production efficiency.

Explosion-proof electric chain hoists are small tonnage, low lifting height of the wire rope electric hoists’ best alternative products. The applications of explosion-proof electric chain hoists are limited to the following operating conditions. For example, the explosion-proof construction where ignition temperature and explosion class categorize for ambient steam or gas. There is one thing that need to be mentioned is that please note that this electric chain hoists does not satisfy the requirements for coal mine explosion-proof equipment. Moreover, the coupling are installed on the 2-stage transmission gear are designed to prevent overloading of the electric chain hoist and the high strength hoisting chain makes the hoisting more safe and stable. Thanks to the special anti-explosion treatment, it makes the electric chain hoists can adapt to more flammable, explosive and dustier working environment. Explosion-proof electric chain hoists are reference and absorb the advantages of similar products abroad and at home with an easy maintenance and practical uses.

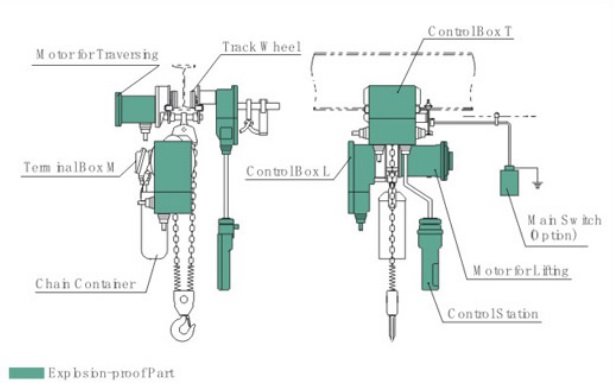

Between explosion-proof electric chain hoist and ordinary electric chain hoist, there are many differences. For instance, all explosion-proof electric chain hoists and normal electric chain hoists belong to electric hoist which lifting by chain. Assembled with transmission, explosion-proof electric chain hoists are equipped with hanger and motor, which belong to three most advanced axial structures. The most prominent difference between explosion-proof electric chain hoist and electric chain hoists is that explosion-proof electric chain hoist has the advantages of explosion-proof, anti-sparks, anti-fog, dust-proof and higher safety.

Our explosion-proof electric chain hoists have been sold to many countries in the world, with different kinds, besides, we also sell many electric rope hoist, explosion-proof rope hoist and so on, if you or your customers have inquire, welcome to leave message on our website or send mail to us, look forward to your friendly cooperation. What’s more, the products can be designed by request to meet customers’ satisfaction and we will offer you satisfied after-sale service and the engineers are available to service machinery overseas. And all of our products are absolutely meet the international standard like CE and ISO9001. The surface color is orange or black, and there are other choices as you required.

Explosion-proof electric chain hoists are widely applied for being mounted on single beam, bridge, gantry and arm cranes, which can lift construction materials in factories, mines, harbors, cargo storage, shops, agriculture, double beam cranes, gantry cranes, bridge cranes, tower cranes, single grinder cranes, lifting platforms, small cranes, electric power, places with flammable mixtures, machinery manufacturing, warehousing logistics, shipbuilding, bridge construction and industrial plants, construction building sites, docks and warehouses. What’s more, they are well accepted in various industrial fields, tough areas and situations, especially for low occasions and the presence of dust, wet and rotten gas and other dangerous environments.

Explosion-proof electric chain hoists are also called explosion proof heavy duty electric chain hoists, ex-proof hoists, explosion-proof electric hoists, anti-explosion electric chain hoists, anti-explosion electric hoists, Electric sparkproof chain hoist, explosion prevention electric chain hoists, safe chain hoists, electric lifting hoists, monorail hoists, powered hoists, powered chain hoists.

With Hook Suspension With Electric Trolley

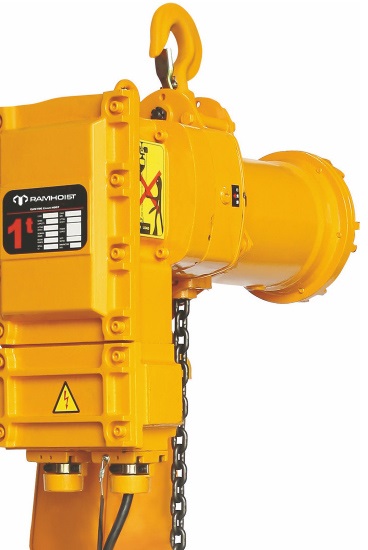

Using the squirrel cage motor for driving and made of aluminum alloy, explosion-proof electric chain hoists' power are using our new disc brake motor. The motor has advantages of small size, reliable braking, sensitive and so on. All kinds of voltage can be custom-made, and the common voltage is 200V-660V, 50HZ/60HZ and 1P/3P.

2. Explosion Proof Device

One of the most prominent feature of explosion-proof electric chain hoists is that they are very suitable for explosive environments but they still have excellent performance and have no emergency, which ensuring the safety and reliability. According to the various explosive air and material and temperature, the explosion proof can make changes to deal with. They have the explosion proof control box, explosion proof control button with safe and stable structure. All the main components are all made of high-class alloy steel, with high precision and security. And with the slight design, beautiful appearance and compact framework, they are very friendly to users.

3. Shell | Enclose

The shell is too hard to be broken because it adopts the aluminum alloy, light but hard. And with the cooling fin, it is easy and quick to bring the heat out. They are tough enough so that they can be used in the extreme weather and can resist corrosion and wet/dry. Adopting the advanced plastic plating technology inside and outside, it looks like a new one after years of operation. Made of high-classed steel, the enclose is more firmly and dexterous. The integral enclosed structure is applicable to places like chemical plants and electroplate factories.

4.Machinery Loading Limiter

High quality machinery loading limiter is used to make sure the safety of our explosion-proof electric chain hoists, when the operations of lifting loads.

5. Braking System

The braking system belong to electromagnetic braking system with double brakes, which ensure the complete security when emergency happens and reduce the harm to the least degree for the equipment. They adopt side magnetic braking device, ensuring lock the hoists and the mechanical braker and dual braking system ensure much more safety.

6. Up and Down Limiter | Limit Switch Device

With up and down limit switch, it is helpful to prohibit the chains from exceeding for safety. With this limiter, the height and length can be easily adjusted and very comfortable to use. The limit switch device is installed where the weigh is lifted on and off to make motor to stop automatically.

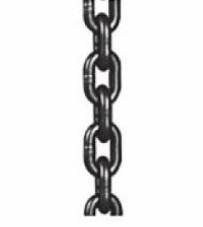

7. Chain

Explosion-proof electric chain hoists adopt high-strength, high precision-welding technology and hard imported Japanese FEC load chain which is hard to break and can bear a large amount of load. With low headroom and lightweight steel construction, it makes the electric chain hoists easy to install and operate, even in confined spaces.

8. Electromagnetic Contactor

With Schneider Electric (TESSIC), they can be used safely under high frequency and can be installed on Variable-Vrequency Drive (VFD Electric). They are very suitable for single phase power supply. And the

inverse phase sequence protecting device is available. It is special electrical installation which controls the circuit not to work in case of wiring error in the power supply. Even under high frequency, they can also be used safely.

9. Handle Control

The handle control is equipped with emergency stop button in case of sudden danger or unexpected risk. The push button on it is waterproof, light and durable.

10. Wireless Remote Control

Wireless remote control can stop the operations immediately especially in some possible and potential dangers. Compared with ordinary handle control, it is more easy and convenient to use.

11. Hook

The hook is made of high-class alloy steel and it has high strength and high security, and by using the new design, it will never escape. Experienced hot forging with perfect strength, it is hard to break. Besides, the operation safety of lower hook is ensured by its 360 degrees rotation and safety tongue piece.

12. Gear

Made of alloy steel, experiencing through heat treatment, the level of protection grade is the highest. The coupling transmission gears are equipped to prevent overloading of the electric chain hoist and the high strength hoisting chain makes the hoisting more safe and stable.

13. Chain Bag

The chain bag adopts the good quality material of canvas, and is used the storage of chain to make sure reliable operation to workers.

14.Cable

The cable connects the some components to our explosion-proof electric chain hoists. High quality cable can ensure the accurate operation of load assignments.

15.Warning Tag

Warning tag is pasted onto the shell, and has the function of warning workers the operations which is not allowed.

16.Electric Trolley

Trolley is an optional component of our products. It is used for the type with electric trolley, and intended to provide steady movements to hoists automatically.

17.Wheel

Universal trolley wheel, made of the standard steel, is used on flat or tapered flange beams, driving for moving the electric trolley smoothly.

Others

1. The parameters/ technical data includes models, capacity, standard lifting height, lifting/travelling speed, lifting/travelling, motor, power, rotation speed, working level, phases, voltage, frequency, operating speed, load chain falls, chain specification, test load, net weigh and gross weight.

2. Configurations

①One speed for lifting motion, or optional two speed for lifting motion

②One speed for trolley travel, or optional two speed for trolley travel

③Degree of protection for motor: IP55

④Load moment limiter

⑤Pendant control station that contains an emergency stop button

3.Optional Configurations

①Upper Limit and lower limit switch

②Platform trolley providing shorter headroom

③Remote control system

④High degree protection

⑤Fire-resistant function: copper hook, copper lift wheel, anti-derail copper roller

⑥Anti-rotation hook

4. In explosive atmospheres of various ignitable gases and vapors, hazardous or classified manufacturing and processing areas, special attention must be required.

5. The section following shows the explosion-protected construction.

6. Accordingly, electric parts have sufficient strength to withstand the internal pressure indicated in JB/T 10222-2011. Other detailed specifications such as gap, depth of gap and locking construction are also made to meet the above standard.

7. The standards of explosion-proof electric chain hoists meet the highest level---"GB12476, 1-2000 dust environment explosion-proof electrical equipment dust explosion-proof electrical equipment, national standards "GB10222-2001 explosion-proof electric chain hoists", GB3836, 1-2000 "sexual environment with explosion-proof electrical equipment-Flameproof Electrical Equipment "d". What’s more, the electric chain hoists with explosion-proof ratings of DIIBT4, DIICT4 and DIPA20TAT4 are very suitable for use in hazardous locations where there is a mixture of sexual dust in the factory an where there is presence of aggressive mixtures. We are reliable and can be trusted.

8. Packaging & Delivery

①Inner package: Bubble film or stretch film.

②Outside package: Cartons or wooden cases.

9. Site photos:

Specifications

|

Type

|

Capacity (t)

|

Lifting Speed (m/min)

|

Standard Lift (m)

|

Lifting Motor

|

Load Chain

|

Test Load (t)

|

Weight (kg)

|

Additional Weight per 1m Lift (kg)

|

||||

|

50Hz

|

60Hz

|

Power (kw)

|

Rotation Speed (r/min)

|

Diameter (mm)×chain falls

|

||||||||

|

EX0101S

|

1

|

6.8

|

8.2

|

3

|

1.5

|

1440 (50Hz) 1728 (60Hz)

|

7.1 × 1

|

1.25

|

61

|

1.1

|

||

|

EX0102S

|

1

|

3.4

|

4.1

|

0.8

|

6.3 × 2

|

1.25

|

52

|

1.6

|

||||

|

EX01501S

|

1.5

|

8.8

|

10.6

|

3.0

|

10.0 × 1

|

1.875

|

108

|

2.3

|

||||

|

EX0201S

|

2

|

6.8

|

8.2

|

3.0

|

10.0 × 1

|

2.5

|

115

|

2.3

|

||||

|

EX0202S

|

2

|

3.4

|

4.1

|

1.5

|

7.1 × 2

|

2.5

|

73

|

2.2

|

||||

|

EX02501S

|

2.5

|

5.4

|

6.5

|

3.0

|

11.2 × 1

|

3.125

|

116

|

2.8

|

||||

|

EX0301S

|

3

|

5.4

|

6.5

|

3.0

|

11.2 × 1

|

3.75

|

122

|

2.8

|

||||

|

EX0302S

|

3

|

4.4

|

5.3

|

3.0

|

10.0 × 2

|

3.75

|

131

|

4.7

|

||||

|

EX0303S

|

3

|

2.2

|

2.6

|

1.5

|

7.1 × 3

|

3.75

|

85

|

3.3

|

||||

|

EX0502S

|

5

|

2.7

|

3.2

|

3.0

|

11.2 × 2

|

6.25

|

151

|

5.6

|

||||

|

EX07503S

|

7.5

|

1.8

|

2.2

|

3.0

|

11.2 × 3

|

9.4

|

266

|

8.4

|

||||

|

EX1004S

|

10

|

2.8

|

3.4

|

3.0×2

|

11.2 × 4

|

12.5

|

300

|

11.2

|

||||

|

EX1506S

|

15

|

1.9

|

2.2

|

3.0×2

|

11.2 × 6

|

18.75

|

400

|

17

|

||||

|

EX2008S

|

20

|

1.4

|

1.7

|

3.0×2

|

11.2 × 8

|

25

|

480

|

22

|

||||

|

EX2510S

|

25

|

1.1

|

1.3

|

3.0×2

|

11.2 × 10

|

31.25

|

540

|

28

|

||||

|

EX3012S

|

30

|

0.9

|

1.1

|

3.0×2

|

11.2 × 12

|

37.5

|

1050

|

34

|

||||

|

EX3516S

|

35

|

0.7

|

0.8

|

3.0×2

|

11.2 × 16

|

43.75

|

1250

|

45

|

||||

Dimensions (mm)

|

Type

|

Capacity (t)

|

Headroom

|

A

|

B

|

D

|

E

|

I

|

J

|

K

|

L

|

M

|

N

|

|

H

|

||||||||||||

|

EX0101S

|

1

|

600

|

600

|

330

|

300

|

176

|

Ф40

|

31

|

Ф40

|

31

|

24

|

24

|

|

EX0102S

|

1

|

670

|

460

|

230

|

280

|

205

|

Ф40

|

31

|

Ф40

|

31

|

24

|

24

|

|

EX01501S

|

1.5

|

800

|

725

|

350

|

430

|

265

|

Ф49

|

40

|

Ф49

|

40

|

30

|

30

|

|

EX0201S

|

2

|

800

|

725

|

350

|

430

|

265

|

Ф49

|

40

|

Ф49

|

40

|

30

|

30

|

|

EX0202S

|

2

|

750

|

600

|

330

|

300

|

230

|

Ф59

|

42

|

Ф59

|

42

|

30

|

30

|

|

EX02501S

|

2.5

|

845

|

675

|

325

|

430

|

320

|

Ф59

|

42

|

Ф59

|

42

|

35

|

35

|

|

EX0301S

|

3

|

845

|

675

|

325

|

430

|

320

|

Ф59

|

42

|

Ф59

|

42

|

35

|

35

|

|

EX0302S

|

3

|

950

|

675

|

325

|

430

|

320

|

Ф59

|

42

|

Ф58

|

42

|

35

|

35

|

|

EX0303S

|

3

|

950

|

580

|

290

|

380

|

205

|

Ф59

|

45

|

Ф59

|

45

|

35

|

35

|

|

EX0502S

|

5

|

1030

|

675

|

325

|

430

|

325

|

Ф60

|

45

|

Ф60

|

45

|

43

|

43

|

|

EX07503S

|

7.5

|

1200

|

675

|

325

|

505

|

320

|

Ф85

|

31

|

Ф85

|

80

|

50

|

50

|

|

EX1004S

|

10

|

1400

|

725

|

350

|

890

|

445

|

Ф85

|

80

|

Ф85

|

80

|

50

|

50

|

|

EX1506S

|

15

|

1360

|

725

|

350

|

1030

|

/

|

Ф110

|

70

|

Ф110

|

80

|

85

|

85

|

|

EX2008S

|

20

|

1250

|

725

|

350

|

1220

|

/

|

Ф110

|

70

|

Ф110

|

80

|

85

|

85

|

|

EX2510S

|

25

|

1700

|

725

|

350

|

1315

|

/

|

Ф140

|

80

|

Ф140

|

100

|

95

|

95

|

|

EX3012S

|

30

|

1640

|

915

|

458

|

1380

|

/

|

Ф140

|

90

|

Ф140

|

100

|

95

|

95

|

|

EX3516S

|

35

|

1790

|

915

|

458

|

1600

|

/

|

Ф200

|

100

|

Ф200

|

140

|

135

|

135

|

Specifications

|

Type

|

Capacity (t)

|

Lifting Speed (m/min)

|

Standard Lift (m)

|

Lifting Motor

|

Traversing Motor

|

Load Chain

|

Test Load (t)

|

I - beam (mm)

|

Weight (kg)

|

Additional Weight per 1m Lift (kg)

|

|||||

|

Power (kw)

|

Rotation (r/min)

|

Power (kw)

|

Rotation Speed (r/min)

|

Traversing Speed (m/min)

|

Diameter (mm)×chain falls

|

||||||||||

|

50Hz

|

60Hz

|

50Hz

|

60Hz

|

||||||||||||

|

EX0101S

|

1

|

6.8

|

8.2

|

3

|

1.5

|

1440 (50Hz) 1728 (60Hz)

|

0.4

|

1440 (50Hz) 1728 (60Hz)

|

11

|

13

|

7.1 × 1

|

1.25

|

58-153

|

103

|

1.1

|

|

EX0102S

|

1

|

3.4

|

4.1

|

0.8

|

0.4

|

6.3 × 2

|

1.25

|

58-153

|

101

|

1.6

|

|||||

|

EX01501S

|

1.5

|

8.8

|

10.6

|

3.0

|

0.4

|

10.0 × 1

|

1.875

|

82-178

|

157

|

2.3

|

|||||

|

EX0201S

|

2

|

6.8

|

8.2

|

3.0

|

0.4

|

10.0 × 1

|

2.5

|

82-178

|

164

|

2.3

|

|||||

|

EX0202S

|

2

|

3.4

|

4.1

|

1.5

|

0.4

|

7.1 × 2

|

2.5

|

82-178

|

122

|

2.2

|

|||||

|

EX02501S

|

2.5

|

5.4

|

6.5

|

3.0

|

0.8

|

11.2 × 1

|

3.125

|

100-178

|

177

|

2.8

|

|||||

|

EX0301S

|

3

|

5.4

|

6.5

|

3.0

|

0.75

|

11.2 × 1

|

3.75

|

100-178

|

183

|

2.8

|

|||||

|

EX0302S

|

3

|

4.4

|

5.3

|

3.0

|

0.8

|

10.0 × 2

|

3.75

|

100-178

|

192

|

4.7

|

|||||

|

EX0303S

|

3

|

2.2

|

2.6

|

1.5

|

0.75

|

7.1 × 3

|

3.75

|

100-178

|

146

|

3.3

|

|||||

|

EX0502S

|

5

|

2.7

|

3.2

|

3.0

|

0.8

|

11.2 × 2

|

6.25

|

100-178

|

234

|

5.6

|

|||||

|

EX07503S

|

7.5

|

1.8

|

2.2

|

3.0

|

0.75

|

11.2 × 3

|

9.4

|

100-178

|

369

|

8.4

|

|||||

|

EX1004S

|

10

|

2.8

|

3.4

|

3.0×2

|

0.8

|

11.2 × 4

|

12.5

|

150-220

|

440

|

11.2

|

|||||

|

EX1506S

|

15

|

1.9

|

2.3

|

3.0×2

|

0.75×2

|

11.2 × 6

|

18.75

|

150-220

|

400

|

17

|

|||||

|

EX2008S

|

20

|

1.4

|

1.7

|

3.0×2

|

0.75×2

|

11.2 × 8

|

25

|

150-220

|

480

|

22

|

|||||

|

EX2510S

|

25

|

1.1

|

1.3

|

3.0×2

|

0.75×2

|

11.2 × 10

|

31.25

|

150-220

|

540

|

28

|

|||||

|

EX3012S

|

30

|

0.9

|

1.1

|

3.0×2

|

0.75×2

|

11.2 × 12

|

37.5

|

150-220

|

620

|

33.6

|

|||||

|

EX3516S

|

35

|

0.7

|

0.8

|

3.0×2

|

0.75×2

|

11.2 × 16

|

43.75

|

150-220

|

700

|

50

|

|||||

Dimensions (mm)

|

Type

|

Capacity (t)

|

Headroom

|

A

|

B

|

D

|

E

|

I

|

K

|

L

|

N

|

J

|

Q

|

R

|

T

|

|

|

H

|

|||||||||||||||

|

EX0101S

|

1

|

650

|

600

|

330

|

300

|

176

|

Ф40

|

Ф40

|

31

|

24

|

31

|

/

|

224

|

298

|

|

|

EX0102S

|

1

|

695

|

560

|

300

|

280

|

205

|

Ф40

|

Ф40

|

31

|

24

|

31

|

/

|

224

|

299

|

|

|

EX01501S

|

1.5

|

770

|

725

|

350

|

430

|

265

|

Ф49

|

Ф49

|

40

|

30

|

40

|

/

|

224

|

300

|

|

|

EX0201S

|

2

|

770

|

725

|

350

|

430

|

265

|

Ф49

|

Ф49

|

40

|

30

|

40

|

/

|

224

|

301

|

|

|

EX0202S

|

2

|

740

|

600

|

330

|

300

|

236

|

Ф59

|

Ф59

|

42

|

30

|

42

|

/

|

224

|

302

|

|

|

EX02501S

|

2.5

|

840

|

725

|

350

|

430

|

265

|

Ф59

|

Ф59

|

42

|

35

|

42

|

/

|

224

|

303

|

|

|

EX0301S

|

3

|

840

|

725

|

350

|

430

|

265

|

Ф59

|

Ф59

|

42

|

35

|

42

|

/

|

224

|

304

|

|

|

EX0302S

|

3

|

920

|

725

|

350

|

430

|

320

|

Ф58

|

Ф59

|

42

|

35

|

42

|

/

|

224

|

305

|

|

|

EX0303S

|

3

|

920

|

600

|

330

|

350

|

205

|

Ф59

|

Ф59

|

45

|

35

|

45

|

/

|

224

|

306

|

|

|

EX0502S

|

5

|

1015

|

725

|

350

|

430

|

325

|

Ф60

|

Ф60

|

45

|

43

|

45

|

/

|

224

|

307

|

|

|

EX07503S

|

7.5

|

1200

|

725

|

350

|

500

|

320

|

Ф85

|

Ф85

|

80

|

50

|

31

|

/

|

224

|

308

|

|

|

EX1004S

|

10

|

1200

|

725

|

350

|

890

|

890

|

Ф85

|

Ф85

|

80

|

50

|

80

|

430

|

224

|

309

|

|

|

EX1506S

|

15

|

1360

|

725

|

350

|

1030

|

535

|

Ф110

|

Ф110

|

80

|

85

|

70

|

520

|

224

|

310

|

|

|

EX2008S

|

20

|

1470

|

725

|

350

|

1220

|

630

|

Ф110

|

Ф110

|

80

|

85

|

70

|

520

|

224

|

311

|

|

|

EX2510S

|

25

|

1500

|

725

|

350

|

1450

|

725

|

Ф140

|

Ф140

|

100

|

95

|

80

|

680

|

224

|

312

|

|

|

EX3012S

|

30

|

1640

|

915

|

458

|

1500

|

840

|

Ф140

|

Ф140

|

100

|

95

|

90

|

400

|

224

|

313

|

|

|

EX3516S

|

35

|

1790

|

915

|

458

|

1600

|

950

|

Ф200

|

Ф200

|

140

|

135

|

100

|

440

|

224

|

314

|

|