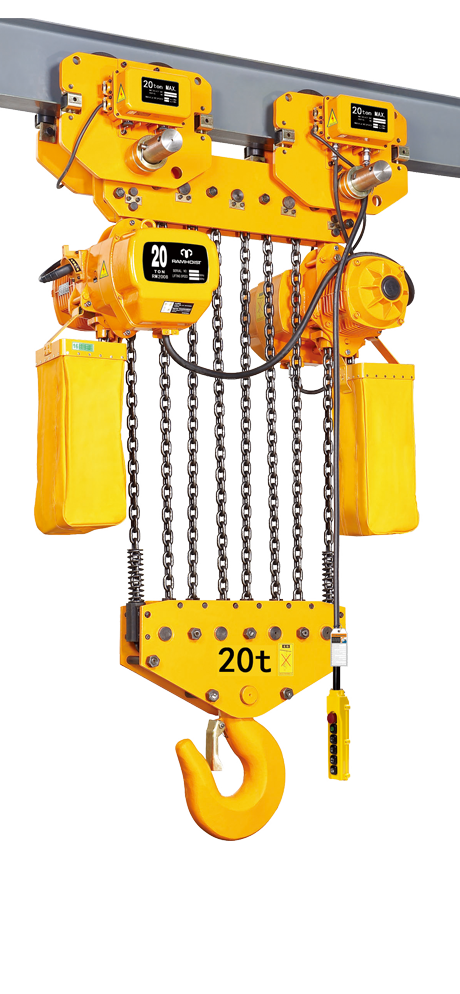

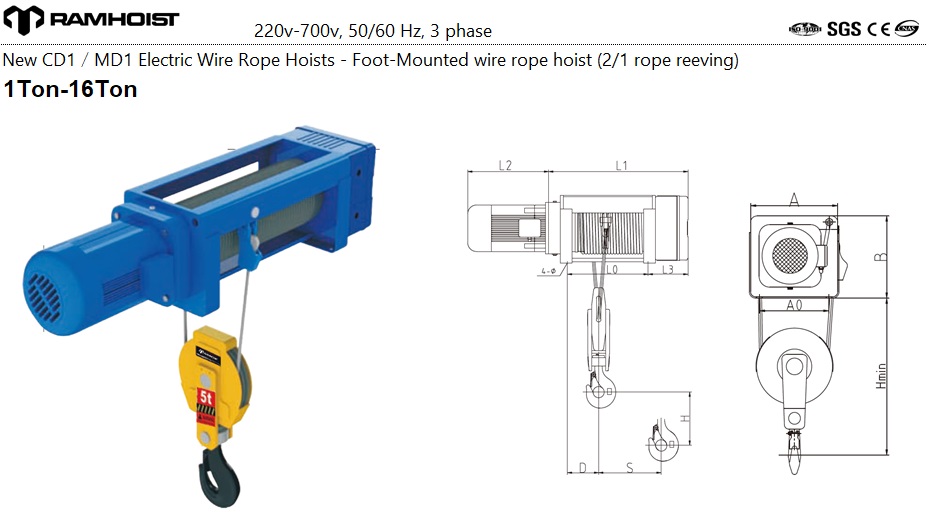

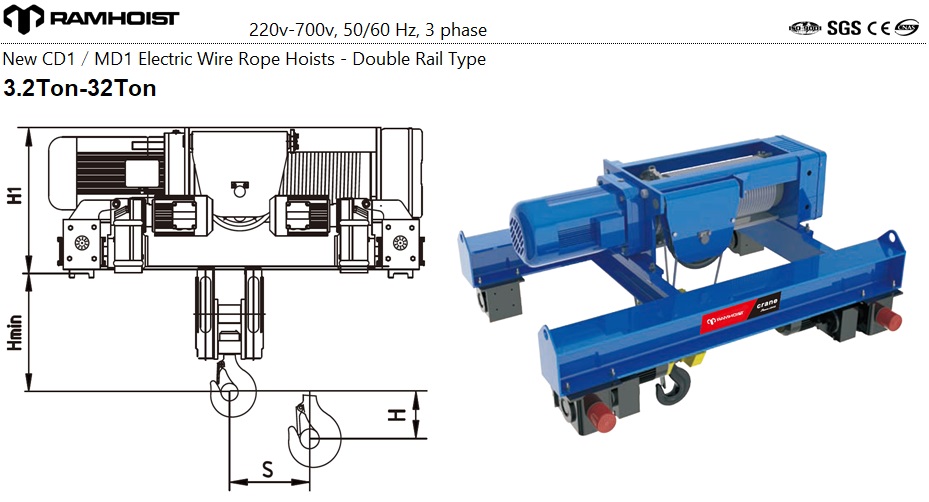

New CD1/MD1 Electric Wire Rope Hoists are light and small-sized lifting equipment satisfying the needs of lifting heavier cargoes, which are updated by traditional CD/MD series and keep the traditional advantage of low price and high performance, the appearance is somewhat the same but reliability and quality are improved a lot, As one of china electric wire rope hoists suppliers, we always supply high quality products.

• Compact square structure, small in size and light in weight with high strength

• Modular and rugged construction, good unitized capability with wide application

• Convenient and multiform fundamental mode change combination optional

• Smooth starting and stopping with comfortable operation and excellent performance

• Safe and reliable traveling, stable can move steadily with long lifespan in use

• Low noise and good view, environmental-friendly with unique elegant appearance

• Convenient maintenance, excellent exchangeability for parts and components

• Energy saving, labor saving, time and effort saving, reduce energy consumption

• Novel and Humanization design, enjoy great reputation among markets

• Easily portable, easy to transport, carry, store and easy for maintenance

• Adopt high quality control electric component with low malfunction with quadrate style

• Convenient and diversified transformation fundamental mode change combination

• Hassle free functioning, Trouble free operation and ease of adjustment

Capacity 1Ton-16Ton

Standard Lift 6 m

Type Electric hoist

Use Lifting Up/Down, Traversing Left/Rights

Drive Mode Motor

Sling Type Wire Rope

Condition New

Certification CE, ISO9001:2000

Material Steel

Operation method Ground/remote

Protect switch Including

Color Blue

Warranty 1 year

Operation With pedant cable push button or remote control

Power Supply 220v-700v, 50/60 Hz, 3 phase, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84251100

Transport Iron box, wooden box

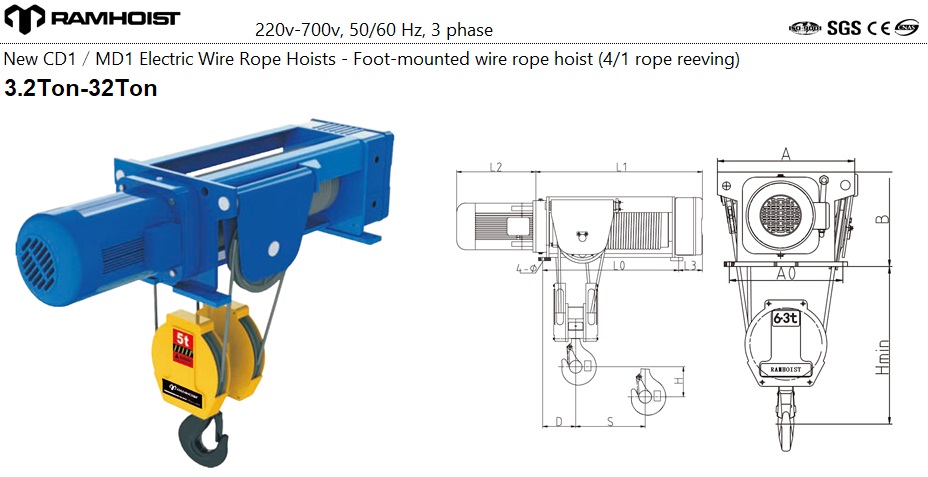

New CD1/MD1 Electric Wire Rope Hoists (Foot-Mounted wire rope hoist (2/1 or 4/1 rope reeving) are light and small-sized lifting equipment hoisting to satisfy the needs of lifting heavier cargoes. they are updated by traditional CD/MD electric wire rope hoists and keep the traditional advantage such as low price and high performance, the appearance is somewhat the same, but reliability and quality is improved a lot and are liked by more and more CD/MD hoists’ customers. New CD1/MD1 Electric Wire Rope Hoists adopt modular design which allows it to be universal in its application (can be used virtually anywhere) where loads, equipment or system parts/sections need/have to be lifted, moved or hoisted.

The universal usability is increased by the fact that the foot-mounted hoist can be rotated around the drum axis into any position---The hoist can be turned around its longitudinal axis into any required rope pay-off position. Supplied as an integral unit the hoist is simply installed using 4 bolts through the pre-drilled mounting holes. There is no need for complicated alignment of motors, gearboxes and rope drum, the heavy duty fully machined frame ensures all critical alignments are factory set. This Electric Wire Rope Hoist-Foot Mount can be mounted on foot, on wall or other fixed places from different directions of the hoist; and can be mounted either supported on top of a beam or suspended under a beam, and therefore has no trolley and cannot be moved across the beam. It can be double speed on hoisting and can also be controlled by inverter. All units feature ensure enhanced safety, precision control and productivity.

The trolley uses F series helical gear reducer drive unit on both sides of the drive wheel transmission torque through a six-rowed steel, big transmission torque and high reliability avoid flat key shear failure, and this transmission is in favor of the installation of hoist trolley mechanism. Hoist body no falling off cable--the cables are arranged in the electric wire rope hoists interior by various method in order to make more beautiful appearance and compact structure, hoist mechanism frame is square welded structure with high versatility, it can be quickly transformed into foot-mounted electric wire rope hoists, the modular design of the electric control box as the theme uses first class brand of electrical components, with wrong phase, default phase and over-current protection, if the power supply wiring is wrong, it can automatically stop the circuit and prevent accidents effectively, frequency control system also could be adopted at the same time and make it more flexible and controllable, lay type contact wire rope adopted is safe, reliable and with long service life.

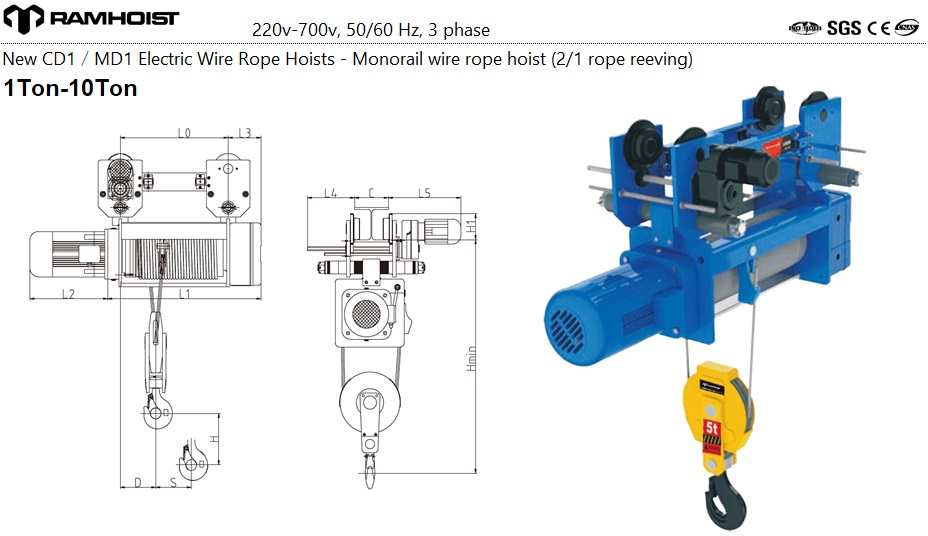

Our Foot-Mounted wire rope hoists (Travelling type steel wire rope hoist 1/2 fall for single girder or monorail) are characterized by low noise, compact structure, omitting the intermediate shaft, The square appearance (it has its particular advantage for compact quadrate structure and simpler design) is easier to install and fix, the lifting mechanism use planetary gear adjust speed, making the structure compact, lightweight, installed in the hoist drum effectively reduce the dimensions of shell, square box structure changed appearance. All the components include equipment; two speeds/one speed of lifting and travelling; all motors with brakes; load limiter; end switches; galvanized rope; hook

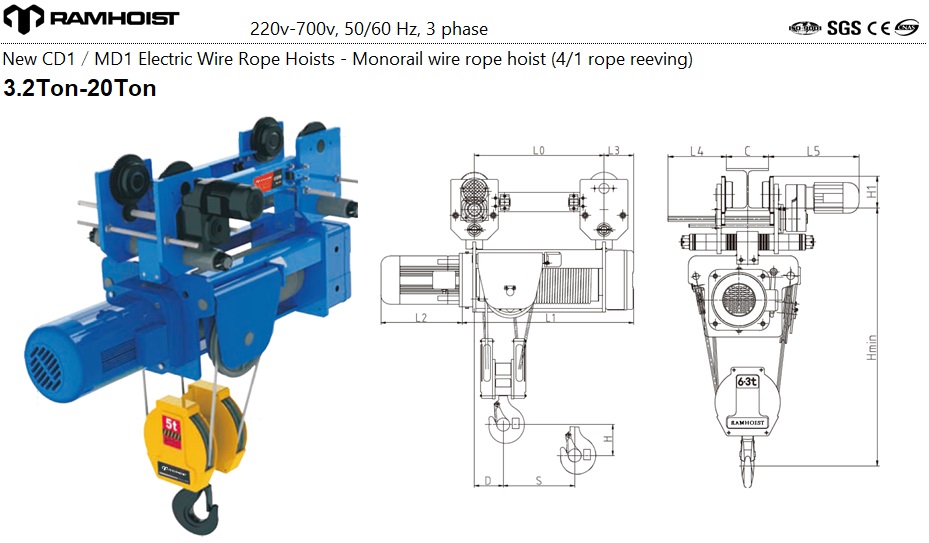

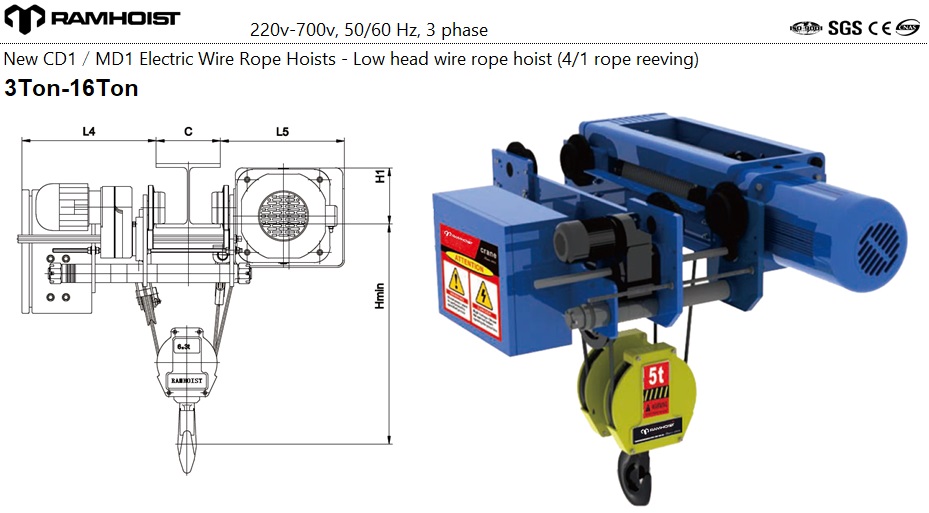

Standard Headroom/Monorail wire rope hoist (2/1 or 4/1 rope reeving) is the Foot Mounted wire rope hoist/base Mounted wire rope hoist plus electric trolley, Designed to travel horizontally along a beam with a standard headroom configuration, for single girder applications, which also called Single Girder Trolley Hoist, single Standard headroom monorail design enables the hoist to operate directly under and parallel with the crane or runway beam. The hoist is suspended via drive trolley. Unique drive layout type, completely abandon the traditional form of the long drive shaft, realize extremely smooth transmission, These electric wire rope hoists with monorail electric trolleys are small sized lifting equipment, They are ideal for replacing an existing overhead crane hoist and provide the option of single or dual speed operation for applications where precision is key. What’s more, Standard headroom monorail hoist, of exceptional design complemented by assured and interchangeability quality components and examined on various quality aspects by our experts which prevents rope slackening and easy change of rope, with Easily accessible separate brake, motor, drum, gear box & panel unit it is a hoist that adopt square simpler design, features ultra compact and favourable dimensions to provide optimum room and clearance when operating in confined areas. Besides, This standard headroom wire rope electric hoist by ours comes complete with its own trolley and is available with 2 or 4 falls of wire rope, in other words, Reeving: 2/1 or 4/1.The 2 fall models are available with SWL from 1t up to 10t; and the 4 fall models with SWL from 3.2t up to 20t.

Altitude less than 1000m, Lifting height is 6m-30m, working duty is A3, ambient temperature is -20~40°C, Air relative humidity should not more than 85% (+25°C), non corrosive gases, high temperatures should not be lifting or toxic, flammable and explosive materials. The type monorail hoist is our most frequently ordered hoist in the lower Safe Working load, These hoists tend to be the most economic choice for many standard applications of material flow. The hoists feature two direct drive cross travel motors. The cross travel trolley is adjustable to suit various flange widths. Beside, we offer you every model in two versions. One with a single normal speed, which can satisfy normal application, the other one provides two speeds: normal speed and low speed.

New CD1/MD1 electric wire rope hoists are widely applied for precise loading and unloading, mounding sand box, maintenance of machine tools, repairing work, lifting various heavy materials, in double beam cranes, gantry cranes, bridge cranes, tower cranes, single grinder cranes, small cranes, in diverse industrial applications such as the factories, mines, docks, warehouses, steel mills, cargo storage areas and shops, construction sites, etc. This Foot or Base Mounted Wire-Rope Hoist can be fixed directly to a gantry type framework which renders it a static hoist, it is possible however to mount this hoist onto a suitable trolley system, such as a crab unit trolley, turning it into a mobile lifting hoist, be used to replace an irreparable hoist on a crab unit.New CD1/MD1 electric wire rope hoists are also called Standard headroom monorail hoists, Monorail Travelling Wire rope Electric Hoists, High Speed Monorail Wire Rope Electric Hoists with Trolley, Normal Headroom Hoists, Crane Hoister, Wire Rope Hoists, Single Beam/Tracks, Steel rope hoists, quadrate style wire rope hoists, standard headroom rope hoists, standard headroom trolley hoists, Under-slung Hoist(SINGLE RAIL), Travelling type steel wire rope hoists 1/4 fall for single girder or monorail, Travelling type steel wire rope hoists 1/2 fall for single girder or monorail, foot mounted electric wire rope hoists, base mounted electric wire rope hoists, electric wire rope hoists base mounted, foot mounted crab units, fixed electric wire rope hoists, common foot mounted hoists.

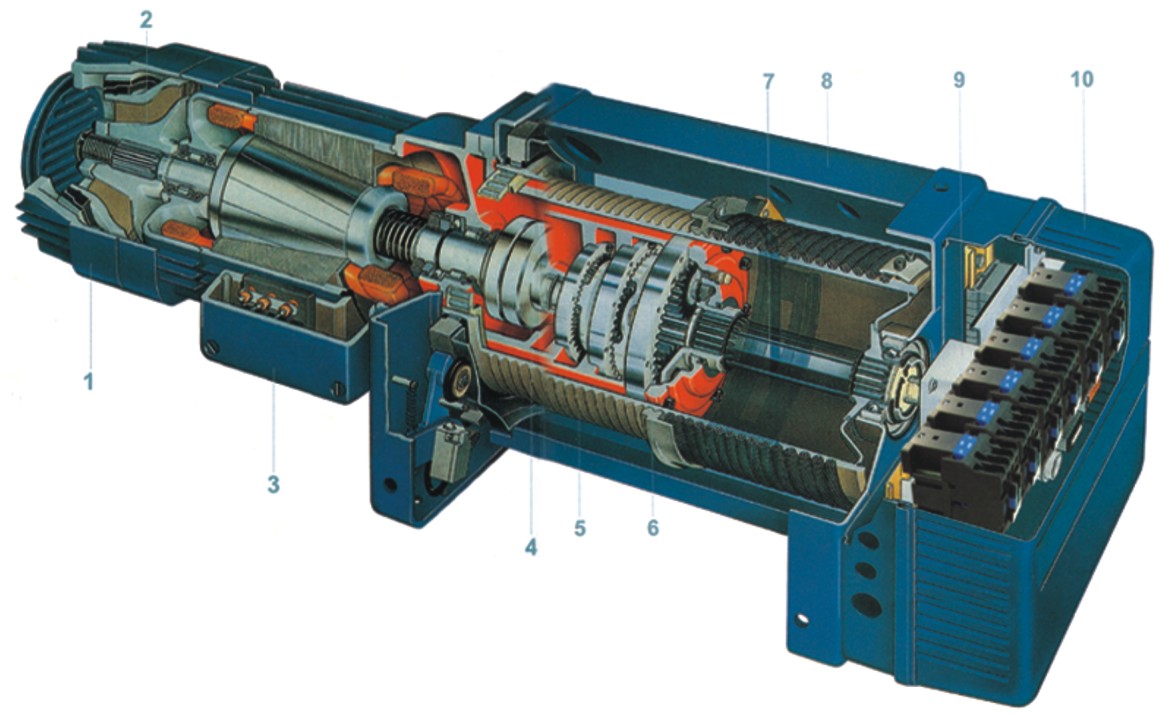

The lifting motor comes from China top brand motor from Nanjing with the best quality motors, bigger torque, so it can be adapted to moving frequently, the Maximum torque is 2.4-3 times more than the rated torque. Motors are equipped which has safety limiter in both up and down directions. Rugged asynchronous electric lifting motors with conical rotor and fail safe integrated cooling fan brake. Lifting motor uses tapered rotor motor with braking (Conic rotor brake motor, Unique column rotor-taper breaking wheel motor with disk), Proven electric motor with conical rotor and built-in brake with asbestos-free lining, with strong staring torque to adapt frequent direct staring in the intermittent work, to brake asynchronous motor and does not need extra arrester. The motor’s load duration factor is 25% and it uses B grade and F grade insulation and its grade of protection is IP44/IP54. The electric wire rope hoists adopt high efficient energy-saving motor and asbestos free brake system. Motor has the thermal protection device (Hoist motor protection - built-in thermal protection sensors), optional, which will automatically cut off to prevent damage when the temperature is too high, it protects your equipment and ensures maximum hoist life. Compact, high efficient, low noise and reliable braking original cylindrical rotor - cone brake wheel motor with low power consumption, it is a conical motor with conical brake or cylindrical motor with disc brake Sturdy pole change motors with cylindrical rotors and integrated safety brakes. Motors can be supplied either with cylindrical type with disc brake or tapered rotor conical motors, depending on application or customer preference. Motor has the thermal protection device, which will automatically cut off to prevent damage when the temperature is too high Imported Brake motor for long life multispeed options. High safety and reliability is secured by our load limit protection device, which can avoid overload-induced adverse consequences.

2. Speed reducer

The electric wire rope hoist use helical gear three stage reducer (Third-class dead axel helical gear transmission structure is adopted) which uses planetary speed-down drive for high effective, low yawp long using life, Gear and shaft (The special long transmission shaft) are made by alloy steel and high carbon steel and through proper heat treatment to ensure its reliability, high mechanical efficiency and service life. Case and case cover with precise assembly and good seal are made of quality cast iron, the reducer is independent, so it’s easy to load and unload it. Permanently oil bathed 3 stage planetary speed reducer with heat treated bevel geared teeth for quiet operation. Box body and cover are made of cast iron to ensure hoist's good damping performance and reliable sealing. The planetary gear reducer is adopted to ensure high transmission efficiency.

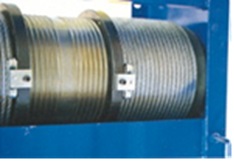

3. Rope drum

Rope Drum is made of cast iron or seamless steel tube, using/with the help of spline transferring power. Its shell is welded with steel plate. The drum device is the central part of hoist. Grooved drum, seamless pipe of adequate length to be wounded minimize in one layer and to provide proper support for the rope to minimize abrasive wear is provided. Drum shaft resolves on ball bearings for ensuring smooth running. Rope drum is the central heart of a hoist. The upper side is linked with traveling mechanism through equalizing beam. Both ends are connected with lifting brake and motor respectively. The lower side works together with hook through wire rope. Up front of the cover, limiting stopper guide-rod and heavy punch stop block are installed. Drum Shaft resolves on Ball Bearings for ensuring smooth running. Rope drum is the central heart of a hoist. The upper side is linked with traveling mechanism through equalizing beam. Both ends are connected with lifting brake and motor respectively. The lower side works together with hook through wire rope. Up front of the cover, limiting stopper guide-rod and heavy punch stop block are installed. Accurately machined rope drum is made of cast iron or seamless steel tube/pipe ensures longevity, using/with the help of spline transferring power. Its shell is welded with steel plate. The drum device is the central part of hoist.

4. Rope guide

Rope Guide is in two halves,ensuring easy accessibility. It encircles the Drum completely so that the rope may not uncoil even when the Hoist is in unloaded condition. The rope guides of ours is thickened and dilated, so that it is not easy to be damaged. Rope guide can arrange the wire rope to reeving on drum orderly, to prevent the wire rope from winding disorderly. With the advanced guide rope technology from previous CD/MD types and add technology from overseas, the guide rope unit is very reliable and safe.

Robust 2 part rope guide featuring a guide ring and pressure spring. Introducing foreign advanced rope guide with Unique and sturdy rope guide arrangement, reliable performance, it encircles the drum completely so that the rope may not uncoil even when the hoist is in unloaded condition. The rope guides of ours is thickened and dilated, so that it is not easy to be damaged. Rope guide can arrange the wire rope to reeving on drum orderly, to prevent the wire rope from winding disorderly. The rope guide reduces wear on the rope and rope drum. It is also easy to install, reducing maintenance requirements for the unit as a whole. The rope guide is manufactured using high quality materials and bearings.

5. Limit switch

Limit switch devices are fitted at both top & bottom ends (Upper and lower limit switch), switch off power automatically to prevent load chain from running out. Advanced mechanical rotary limit switch devices with high accuracy are fitted at both top & bottom ends (Upper and lower limit switch), switch off power automatically to prevent load chain from running out. Precision geared limit switch for reliable hoist cut-off. Rotary Limit Switch to limit hoisting motion positively the machine uses cam limit at both ends to insure precision.

6. Safety brake

The dual-disk electromagnetic brake features automatic brake (self-braking) in the event of a power failure. Spring loaded mechanical brake guarantees immobilization of load in case of a power outage

As best of free brake linings designed for approx.1 million braking operations make for long maintenance intervals. Electromechanical, Conical disc type, 100% failsafe maintenance free Brake, eliminates need of coil & thereby coil burning and down time problems. The dual-disk electromagnetic brake features automatic brake (self-braking) in the event of a power failure. It is a Failsafe disc brake, spring loaded mechanical brake guarantees immobilization of load in case of a power outage.

7. Traveling mechanism

Traveling mechanism is made of electric crab, traveling motor, traveling reducer, driven crab and so on. Main engine hangs under the traveling mechanism moving reciprocally. The normal traveling speed is 20 or 30m/min. If the lift capacity is 1~5t and the lift height is or more than 12m, another driven crab is installed.

8. Electric device

The electric device consists of electric control box, button switch, limiting stopper, connecting wires and so on, of each Electrical component with high quality control. The normal operating voltage of button switch is 380V or 36V.Pressing the correct button can control the hoist through controlling on and off of the relay in the control box,according to the direction symbols on the button switch. The control has wired type and wireless type or cord operation and cordless remote control which can be chosen by your requirement, Its features are with waterproof protection, light and durable with load voltage control. Low voltage control 36V is standard.

9. Steel wire rope

It uses GB1102-74(6*37+1) hoist steel wire rope which is durable and with good strength in use as the lifting medium.

Hoisting ropes comply with the exporting standards. The leading rope taken by the Drum does not slip sideways when slack. The factor of safety, on the nominal breaking strength of the rope is six.

Ropes are of high endurance class and galvanized.

Precision machined rope grooves to extend wire rope life, Rope fleet angel up to 4 degrees without contact between the rope and rope guide.

10. Hook block

Lifting hook is forged with specialized steel, heat treated and fracture resistant, In case of dangerous overloading or abuse, the hook does not fracture but will slowly yield. In the use of trust ball bearing, lifting hook is linked with shell through hook beam making lifting hook go slick. If lifting capacity is five ton or less than five ton, slide wheel is single. If lift capacity is ten ton or more than ten ton, slide wheels are double. The Hook Block is tested to 150% of full load before assembly, with 360 degree rotation and high bearing strength, In addition, the lifting hook is designed to prevent accidental slippage.

Spring loaded safety latch.

Most tensile safety hooks: Both the top and bottom hooks are made of high tensile alloy steel with special treatment; It guarantees the hook will not break and deform gradually under a sudden extra-load.

In the use of trust ball bearing, lifting hook is linked with shell through hook beam making lifting hook go slick. If lifting capacity is five ton or less than five ton, slide wheel is single. If lift capacity is ten ton or more than ten ton, slide wheels are double. The Hook Block is tested to 150% of full load before assembly, with 360 degree rotation and high bearing strength, In addition, the lifting hook is designed to prevent accidental slippage, Operator friendly and easy to use, Two grip recesses for ergonomic.

11. Gear

By adopting Japanese technology, they are innovated symmetrical arrayed high-speed synchronous gears, and are made from international standard gear steel. Compared with common gears, they are more wearable and steadier, and more labor saving. Gear unit with planetary gear drive in oil bath is available. Each Geared Shaft assembly is supported on ball or roller bearings, to ensure smooth, low-friction operation. Light weight gear units with silent running flat bevelled gears deliver the torque required.

12. Gear box

The planetary gearbox (2 or 3 stage) adopts casing of automotive technology and has specially treated gears for high wear-resistance. Each Geared Shaft assembly is supported on ball or roller bearings, to ensure smooth, low-friction operation. They adopt 3 grade fixed axle inclined gears structure with long life. The gears and gear shaft made by the alloy steel of heating treatment, high strength box cover made by high quality cast iron, Assembly rigor, good seal. The gear reducer become to be a single part, loading and unloading is extremely convenient, Reliable drive, high mechanical efficiency. It is used for electric wire rope hoists lifting, under 16 ton capacity always use round shape gear box, more than 16 ton capacity always adopt square shape. Planetary Gear Box giving smooth and low noise operation, Gear Box inside the drum making the design Compact

13. Trolley wheel

Trolley wheel adopt 45 carbon steel, with frequency treatment, stronger and thicker.

14. Surface

Through special treatment, the surface is more bright and smooth.

15. Electric control box

It has device with up an down stroke protection of break off limiter and can cut off main circuit in an emergency,

which ensures safe operation of electric wire rope hoists, Electric elements are of long service life and operational safety. Control Box: Ergonomic Controller - Ergonomic Handle for two stage and step-less function, Optional Display, Control Cables adjustable in length by 4 m

16. Control button

Pushbutton swith is rain-proof plastic for severe impact and corrosive atmosphere resistance and mechanically interlocked.

17. Structure

1. Lifting motor | 6. Planetary gearbox |

Others

1. Factors to consider when selecting your hoist:

Capacity (tons)

Height of Lift (m)

Hoisting Speed (m/min)

2. Parameters

Classification: M3

Insulation grade: F

Suspension varieties: Hook, motorized trolley

Operating temperature: -20 to 40 ℃ (-4 to 104 °F)

Operating humidity: 85% RH or less.

Working System Intermediate FC=25%

Protection class (hoist and push button): IP44 and IP54

Noise (single/ dual speed): 81dB.

Color: Default Color is Blue

3. High precision and super mechanical spin limit

High quality electric control component with low malfunction

The special drive composition method is very stationary which saves the usual long transmission shaft

Mode of protection IP54 - protected against dust and splashing water

Light Duty K≤ 0.125

Medium Duty 0.125≤ K≤ 0.25

Heavy Duty 0.25≤ K≤ 0.5

Very Heavy Duty 0.5≤ K≤ 1

Working group ISO

Average operating time in hours per day: Tm=( 2× average hook travel(m)× cycles per hour× number of working hours per day) / [60× lifting speed(m/min)]

Additional options available:

Overload protection device

True vertical lift - 4/2 Reeving

Control equipment "Telemecanique"

Hoists for cold climatic zones - air temperature from -40C to +40C, humidity 30% to 95%

Additional electric brake

4. Average operating time in hours per day: Tm=( 2× average hook travel(m)× cycles per hour× number of working hours per day) / [60× lifting speed(m/min)]

5. Additional options available:

Overload protection device

True vertical lift - 4/2 Reeving

Control equipment "Telemecanique"

Hoists for cold climatic zones - air temperature from -40C to +40C, humidity 30% to 95%

Additional electric brake

Dual voltage is available.

single or dual speed

Geared Couplings for better transmission

Overload sensor ensures safety

Ability to operate in various environmental conditions

Fully comply with the newly international standards.

Overload sensor ensures safety

Manufactured in ISO 9001:2008 certified company

2/1 reeving also available upon request for increased lift heights and quick lift speeds of electric wire rope hoists.

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Wire Rope | Test Load (t) | Classific-ation | Weight(kg) | ||||

Power (kw) | Rotation Speed (r/min) | Diameter (mm) | ||||||||||

50Hz | 60Hz | |||||||||||

(N)CMD1-3A | 1 | 8.4 | 10.1 | 6 | 1.5 | 1380 (50Hz) 1656 (60Hz) | 7.4 | 1.25 | M4 | 156 | ||

8.4/2.1 | 10.1/2.5 | 1.5/0.4 | ||||||||||

(N)CMD1-4A | 2 | 7.2 | 8.6 | 3 | 11 | 2.5 | 266 | |||||

7.2/2.4 | 8.6/2.9 | 3/1 | ||||||||||

(N)CMD1-5A | 3.2 | 7 | 8.4 | 4.5 | 13 | 4 | 351 | |||||

7/1.6 | 8.4/1.9 | 4.5/1.1 | ||||||||||

(N)CMD1-6A | 5 | 7.6 | 9.1 | 7.5 | 15 | 6.25 | 487 | |||||

7.6/1.8 | 9.1/2.2 | 7.5/2.0 | ||||||||||

(N)CMD1-7A | 8 | 8 | 9.6 | 13 | 18 | 10 | 759 | |||||

8/2 | 9.6/2.4 | 13/3.4 | ||||||||||

(N)CMD1-8A | 10 | 4 | 4.8 | 13 | 18 | 12.5 | 765 | |||||

4/1 | 4.8/1.2 | 13/3.4 | ||||||||||

(N)CMD1-9A | 16 | 6 | 7.2 | 18.5 | 22 | 20 | 1020 | |||||

6/1.5 | 7.2/1.8 | 18.5/4.7 | ||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | L2 | Ф | A | A0 | B | L3 | S | |||

Hmin | ||||||||||||

(N)CMD1-3A | 1 | 455 | 300 | 13 | 278 | 215 | 253 | 163 | 0.0161H | |||

500 | ||||||||||||

(N)CMD1-4A | 2 | 578 | 350 | 18 | 335 | 265 | 310 | 181 | 0.0174H | |||

535 | ||||||||||||

(N)CMD1-5A | 3.2 | 649 | 380 | 18 | 370 | 300 | 346 | 198 | 0.0182H | |||

600 | ||||||||||||

(N)CMD1-6A | 5 | 739 | 460 | 26 | 408 | 325 | 381 | 226 | 0.0191H | |||

645 | ||||||||||||

(N)CMD1-7A | 8 | 799 | 520 | 26 | 480 | 370 | 455 | 249 | 0.0194H | |||

620 | ||||||||||||

(N)CMD1-8A | 10 | 799 | 520 | 26 | 480 | 370 | 445 | 249 | 0.0194H | |||

620 | ||||||||||||

(N)CMD1-9A | 16 | 1000 | 580 | 26 | 635 | 465 | 553 | 249 | 0.02H | |||

920 | ||||||||||||

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Wire Rope | Test Load (t) | Classific-ation | Weight(kg) | ||||

Power (kw) | Rotation (r/min) | Diameter (mm) | ||||||||||

50Hz | 60Hz | |||||||||||

(N)CMD1-4A | 3.2 | 3.6 | 4.3 | 6 | 3 | 1380 (50Hz) 1656 (60Hz) | 11 | 4 | M4 | 335 | ||

3.6/1.2 | 4.3/1.4 | 3/1 | ||||||||||

(N)CMD1-5A | 6.3 | 3.5 | 4.2 | 4.5 | 13 | 7.875 | 471 | |||||

3.5/0.8 | 4.2/1.0 | 4.5/1.1 | ||||||||||

(N)CMD1-6A | 10 | 3.8 | 4.6 | 7.5 | 15 | 12.5 | 661 | |||||

3.8/0.9 | 4.6/1.1 | 7.5/2.0 | ||||||||||

(N)CMD1-7A | 16 | 4 | 4.8 | 13 | 18 | 20 | 1028 | |||||

4/1 | 4.8/1.2 | 13/3.4 | ||||||||||

(N)CMD1-8A | 20 | 4 | 4.8 | 13 | 18 | 25 | 1035 | |||||

4/1 | 4.8/1.2 | 13/3.4 | ||||||||||

(N)CMD1-9A | 32 | 4 | 4.8 | 18.5 | 22 | 40 | 1310 | |||||

4/1 | 4.8/1.2 | 18.5/4.7 | ||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | L2 | Ф | A | A0 | B | L3 | S | |||

Hmin | ||||||||||||

(N)CMD1-4A | 3.2 | 531 | 350 | 18 | 485 | 395 | 323 | 120 | 0.0174H | |||

535 | ||||||||||||

(N)CMD1-5A | 6.3 | 619 | 380 | 18 | 520 | 430 | 358 | 134 | 0.0182H | |||

600 | ||||||||||||

(N)CMD1-6A | 10 | 689 | 460 | 26 | 588 | 468 | 393 | 161 | 0.0191H | |||

645 | ||||||||||||

(N)CMD1-7A | 16 | 760 | 520 | 26 | 720 | 540 | 472 | 176 | 0.0194H | |||

620 | ||||||||||||

(N)CMD1-8A | 20 | 760 | 520 | 26 | 720 | 540 | 472 | 176 | 0.0194H | |||

620 | ||||||||||||

(N)CMD1-9A | 32 | 1100 | 580 | 26 | 710 | 540 | 553 | 249 | 0.02H | |||

920 | ||||||||||||

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load (t) | I - beam (mm) | Classific-ation | Weight (kg) | |||||

Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) | ||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||

(N)CMD1-3A | 1 | 8.4 | 10.1 | 6 | 1.5 | 1380 (50Hz) 1656 (60Hz) | 0.37 | 1380 (50Hz) 1656 (60Hz) | 20/5 | 24/6 | 7.4 | 1.25 | 110-180 | M4 | 282 |

8.4/2.1 | 10.1/2.5 | 1.5/0.4 | 0.37/0.1 | ||||||||||||

(N)CMD1-4A | 2 | 7.2 | 8.6 | 3 | 0.37 | 11 | 2.5 | 110-180 | 392 | ||||||

7.2/2.4 | 8.6/2.9 | 3/1 | 0.37/0.1 | ||||||||||||

(N)CMD1-5A | 3.2 | 7 | 8.4 | 4.5 | 0.37 | 13 | 4 | 110-180 | 475 | ||||||

7/1.6 | 8.4/1.9 | 4.5/1.1 | 0.37/0.1 | ||||||||||||

(N)CMD1-6A | 5 | 7.6 | 9.1 | 7.5 | 0.55 | 15 | 6.25 | 130-180 | 636 | ||||||

7.6/1.8 | 9.1/2.2 | 7.5/2.0 | 0.55/0.13 | ||||||||||||

(N)CMD1-7A | 8 | 8 | 9.6 | 13 | 0.75 | 18 | 10 | 140-180 | 951 | ||||||

8/2 | 9.6/2.4 | 13/3.4 | 0.75/0.18 | ||||||||||||

(N)CMD1-8A | 10 | 4 | 4.8 | 13 | 0.75 | 18 | 12.5 | 140-180 | 960 | ||||||

4/1 | 4.8/1.2 | 13/3.4 | 0.75/0.18 | ||||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | L2 | L3 | L5 | L4 | H1 | S | |||||||

Hmin | |||||||||||||||

(N)CMD1-3A | 1 | 121 | 300 | 138 | 375 | 282 | 121 | 0.0161H | |||||||

500 | |||||||||||||||

(N)CMD1-4A | 2 | 121 | 350 | 147 | 375 | 282 | 121 | 0.0174H | |||||||

535 | |||||||||||||||

(N)CMD1-5A | 3.2 | 121 | 380 | 161 | 375 | 282 | 121 | 0.0182H | |||||||

600 | |||||||||||||||

(N)CMD1-6A | 5 | 151 | 460 | 194 | 429 | 278 | 151 | 0.0191H | |||||||

645 | |||||||||||||||

(N)CMD1-7A | 8 | 179 | 520 | 211 | 434 | 308 | 179 | 0.0194H | |||||||

620 | |||||||||||||||

(N)CMD1-8A | 10 | 179 | 520 | 211 | 434 | 308 | 179 | 0.0194H | |||||||

620 | |||||||||||||||

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load (t) | I - beam (mm) | Classific-ation | Weight (kg) | |||||

Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) | ||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||

(N)CMD1-4B | 3.2 | 3.6 | 4.3 | 6 | 3 | 1380 (50Hz) 1656 (60Hz) | 0.37 | 1380 (50Hz) 1656 (60Hz) | 20 | 24 | 11 | 4 | 110-180 | M4 | 459 |

3.6/1.2 | 4.3/1.4 | 3/1 | 0.37/0.1 | 20/5 | 24/6 | ||||||||||

(N)CMD1-5B | 6.3 | 3.5 | 4.2 | 4.5 | 0.55 | 20 | 24 | 13 | 7.875 | 130-180 | 624 | ||||

3.5/0.8 | 4.2/1.0 | 4.5/1.1 | 0.55/0.13 | 20/5 | 24/6 | ||||||||||

(N)CMD1-6B | 10 | 3.8 | 4.6 | 7.5 | 0.75 | 20 | 24 | 15 | 12.5 | 140-180 | 850 | ||||

3.8/0.9 | 4.6/1.1 | 7.5/2.0 | 0.75/0.18 | 20/5 | 24/6 | ||||||||||

(N)CMD1-7B | 16 | 4 | 4.8 | 13 | 2×0.75 | 20 | 24 | 18 | 20 | 150-180 | 1302 | ||||

4/1 | 4.8/1.2 | 13/3.4 | 2×0.75/0.18 | 20/5 | 24/6 | ||||||||||

(N)CMD1-8B | 20 | 3.2 | 3.8 | 13 | 2×0.75 | 20 | 24 | 18 | 25 | 150-180 | 1310 | ||||

3.2/0.8 | 3.8/1.0 | 13/3.4 | 2×0.75/0.18 | 20/5 | 24/6 | ||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | L2 | L3 | L5 | L4 | H1 | S | |||||||

Hmin | |||||||||||||||

(N)CMD1-4B | 3.2 | 1105 | 350 | 147 | 375 | 282 | 121 | 0.0174H | |||||||

535 | |||||||||||||||

(N)CMD1-5B | 6.3 | 1225 | 380 | 161 | 379 | 278 | 151 | 0.0182H | |||||||

600 | |||||||||||||||

(N)CMD1-6B | 10 | 1314 | 460 | 194 | 434 | 308 | 179 | 0.0191H | |||||||

645 | |||||||||||||||

(N)CMD1-7B | 16 | 1412 | 520 | 250 | 434 | 186 | 179 | 0.0194H | |||||||

620 | |||||||||||||||

(N)CMD1-8B | 20 | 1412 | 520 | 250 | 434 | 186 | 179 | 0.0194H | |||||||

620 | |||||||||||||||

Specifications

Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load (t) | I - beam (mm) | Classific-ation | Weight (kg) | |||||

Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) | ||||||||||

50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||

(N)CMD1-4D | 3 | 5 | 6 | 6 | 3 | 1380 (50Hz) 1656 (60Hz) | 0.37 | 1380 (50Hz) 1656 (60Hz) | 20 | 24 | 11 | 3.75 | 110-180 | M4 | 459 |

5/1.6 | 6/1.9 | 3/1 | 0.37/0.1 | 20/5 | 24/6 | ||||||||||

(N)CMD1-5D | 5 | 5 | 6 | 4.5 | 0.55 | 20 | 24 | 13 | 6.25 | 130-180 | 624 | ||||

5/1.2 | 6/1.4 | 4.5/1.1 | 0.55/0.13 | 20/5 | 24/6 | ||||||||||

(N)CMD1-6D | 10 | 4 | 4.8 | 7.5 | 0.75 | 20 | 24 | 15 | 12.5 | 140-180 | 850 | ||||

4/1 | 4.8/1.2 | 7.5/2.0 | 0.75/0.18 | 20/5 | 24/6 | ||||||||||

(N)CMD1-7D | 16 | 4 | 4.8 | 13 | 2×0.75 | 20 | 24 | 18 | 20 | 150-180 | 1302 | ||||

4/1 | 4.8/1.2 | 13/3.4 | 2×0.75/0.25 | 20/5 | 24/6 | ||||||||||

Dimensions (mm)

Type | Capacity (t) | Headroom | L2 | L3 | L5 | L4 | H1 | S | |||||||

Hmin | |||||||||||||||

(N)CMD1-4D | 3 | 700 | 330 | 135 | 374 | 450 | 175 | 0.0174H | |||||||

(N)CMD1-5D | 5 | 875 | 380 | 135 | 420 | 490 | 185 | 0.0182H | |||||||

(N)CMD1-6D | 10 | 1000 | 460 | 145 | 458 | 520 | 210 | 0.0191H | |||||||

(N)CMD1-7D | 16 | 1030 | 520 | 190 | 590 | 562 | 325 | 0.0194H | |||||||

Specifications

| Type | Capacity (t) | Lifting Speed (m/min) | Standard Lift (m) | Lifting Motor | Traversing Motor | Wire Rope | Test Load (t) | Hmin (mm) | H1 (mm) | S (mm) | Classific-ation | Weight (kg) | |||||

| Power (kw) | Rotation Speed (r/min) | Power (kw) | Rotation Speed (r/min) | Traversing Speed (m/min) | Diameter (mm) | ||||||||||||

| 50Hz | 60Hz | 50Hz | 60Hz | ||||||||||||||

| (N)CMD1-5BS | 3.2 | 7 | 8.4 | 6 | 4.5 | 1380 (50Hz) 1656 (60Hz) | 0.37 | 1380 (50Hz) 1656 (60Hz) | 20 | 24 | 13 | 4 | 212 | 783 | 0.0182H | M4 | 435 |

| 7/1.6 | 8.4/1.9 | 0.37/0.1 | 20/5 | 24/6 | |||||||||||||

| 6.3 | 3.5 | 4.2 | 4.5/1.1 | 0.55 | 20 | 24 | 7.88 | 700 | |||||||||

| 3.5/0.8 | 4.2/1.0 | 0.55/0.13 | 20/5 | 24/6 | |||||||||||||

| (N)CMD1-6BS | 5 | 7.6 | 9.1 | 7.5 | 0.55 | 20 | 24 | 15 | 6.25 | 302 | 818 | 0.0191H | 600 | ||||

| 7.6/1.8 | 9.1/2.2 | 0.55/0.13 | 20/5 | 24/6 | |||||||||||||

| 10 | 3.8 | 4.6 | 7.5/2.0 | 0.75 | 20 | 24 | 12.5 | 312 | 830 | 1250 | |||||||

| 3.8/0.9 | 4.6/1.1 | 0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| (N)CMD1-7BS | 8 | 8 | 9.6 | 13 | 0.75 | 20 | 24 | 18 | 10 | 362 | 892 | 0.0194H | 900 | ||||

| 8/2 | 9.6/2.4 | 0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| 16 | 4 | 4.8 | 13/3.4 | 2×0.75 | 20 | 24 | 20 | 290 | 1042 | 1900 | |||||||

| 4/1 | 4.8/1.2 | 2×0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| (N)CMD1-8BS | 10 | 6.4 | 7.7 | 13 | 0.75 | 20 | 24 | 18 | 12.5 | 362 | 892 | 1380 | |||||

| 6.4/1.6 | 7.7/1.9 | 0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| 20 | 3.2 | 3.8 | 13/3.4 | 2×0.75 | 20 | 24 | 25 | 290 | 1042 | 2500 | |||||||

| 3.2/0.8 | 3.8/1.0 | 2×0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| (N)CMD1-9BS | 16 | 6 | 7.2 | 18.5 | 2×0.75 | 20 | 24 | 22 | 20 | 420 | 1100 | 0.02H | 2050 | ||||

| 6/1.5 | 7.2/1.8 | 2×0.75/0.25 | 20/5 | 24/6 | |||||||||||||

| 25 | 3 | 3.6 | 18.5/4.7 | 2×0.75 | 20 | 24 | 31.3 | 360 | 1250 | 3000 | |||||||

| 3/0.75 | 3.6/0.9 | 2×0.75/0.18 | 20/5 | 24/6 | |||||||||||||

| 32 | 3 | 3.6 | 18.5/4.7 | 2×0.75 | 20 | 24 | 40 | 3600 | |||||||||

| 3/0.75 | 3.6/0.9 | 2×0.75/0.18 | 20/5 | 24/6 | |||||||||||||