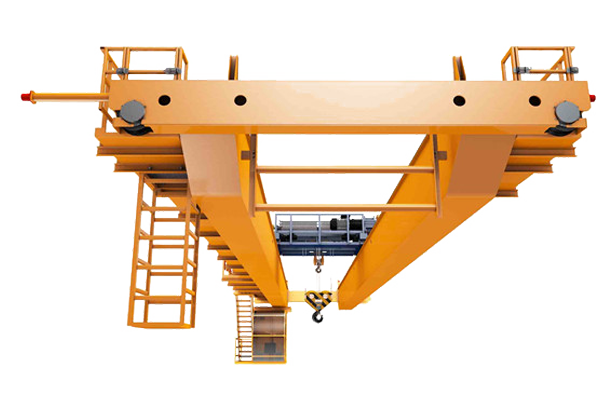

Double girder gantry cranes normally with hook are used for loading, unloading and moving materials which adopt latest technologies and optimum grade raw materials that are designed with fixed rails on ground and different height legs traveling in both directions, trolley mechanism running on double beam, hoisting mechanism lowering and raising loads. We are one of the most famous double girder gantry crane manufacturers in china and for double girder gantry crane design please let us know.

• Reasonable and optimum structure avoiding dead weight and dipping cost of the equipment

• Favorable performance, advanced technology, attractive appearance, high working efficiency

• High crane stability, excellent durability, robustness and reliability, electricity save

• Large loading capacity and cost less than a overhead crane, environmentally friendly

• High work duty and high quality, can bear heavy capacity and for long time work

• Quickly, easily assembled and disassembled, suit for both outdoor and indoor load works

• Efficient and well performance, flexible and safe operation, minimum and easy maintenance

• Equipped with all the necessary safety device including safety interlocks and others

• Using the steel material of Q235B or Q345B which provides a long service life to the crane

• Welded box girder and simplified open kind design after appropriate analysis and study

• Low head room which in turn has the function of decreasing the cost of the shed/building

• Wheel group is equipped with high-quality forged wheel with steel cover, famous brand motor

• Wide selection of operational speeds, different heights and capacities to meet customer’s needs

• Offered with a VVVF drive for extended moving activity to avoid impact load works

• No need column and runway beam, just travel on the ground makes the jobs more safe

• Rigorously tested on well defined parameters to ensure proper functionality and

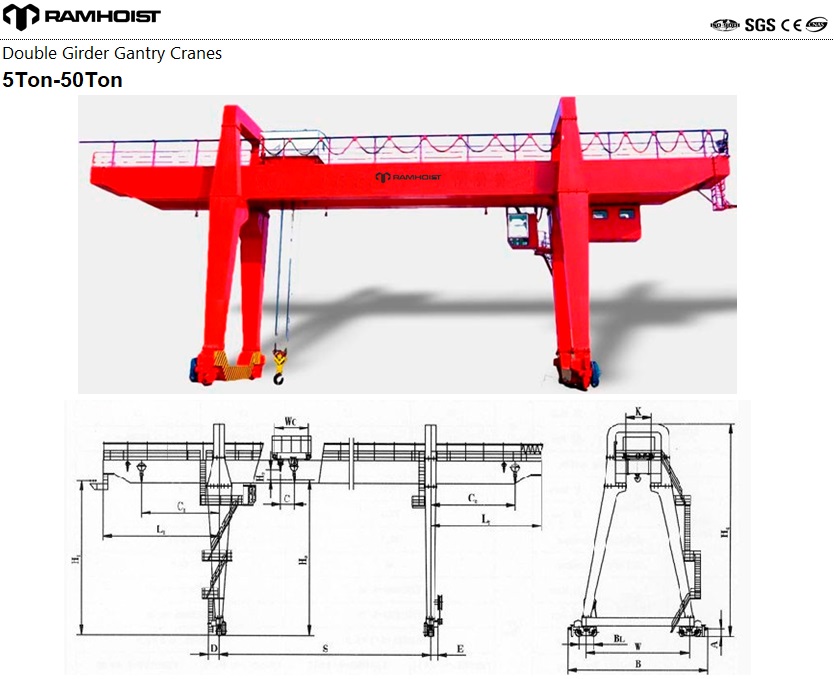

Capacity 3Ton-50Ton

Span 18m-35m

Standard Lift 6 m

Use Lifting Up/Down, Traversing Left/Right

Drive Mode Motor

Moving Mode: Wheel

Sling Type Wire rope

Hoisting Motor Includes YZR/YZP/Three in-one model

Operation Remote or pendant control on the ground, or driver's cabin control (open or close)

Power Supply 220v-700v, 50/60 Hz, 3 phase, single or dual voltage

Warranty 12 months

Control Voltage 24v, 36v, 42v, 48v, 110v

Steel Structure Box type or truss type

Working Temperature -40°С to +40°С

Color According to your need

Certification ISO, CE, SGS

H.S. Code 8426193000

Double girder gantry cranes normally with hook are used for loading, unloading and moving materials which adopt latest technologies and optimum grade raw materials. Double girder gantry cranes are designed with fixed rails on ground and different height legs traveling in both directions, trolley mechanism running on double beam, hoisting mechanism lowering and raising loads. Our double double girder gantry cranes can also carry out some special operations by equipped with various special lifting tools such as grab or electromagnetic chunk (lifting magnet), or simultaneously use with the two or three.

Double girder gantry cranes are composed of gantry, crane crab, trolley traveling mechanism, cab and electric control system. Outdoor operation gantry cranes are also equipped with rail clamp, weight restriction device, limit device, anchor device, anemometer, corrective devices as required. These components’ advantages are all introduced in the back. What’s more, most gantry cranes’ installations are outdoors and open space applications.

Double girder gantry cranes are adapted to applications where overhead runways would be not possible, costly to erect and difficult to maintain in alignment. A gantry crane can be moved to new locations with less trouble and expenses than an overhead crane and its runway where the installation is only temporary. It is similar to a top running overhead crane except the bridge which is supported by legs and the rails are at ground level. It is an excellent alternative for permanent overhead travelling cranes inside of factories (indoor overhead cranes), the additional leg structure makes the crane more expensive but this is offset by the considerably cheaper low level rails, also it is comparatively easy and inexpensive to extend and increase the length of the runway/track thus makes the advantage more apparent, working area of cranes then enlarged and enable them particularly suitable to work for large outdoor stockyards. General speaking, it minimizes investment of new building by eliminating need of increased foundational and structural considerations. What’s more, safety hazard arising from travelling on low level rails is taken care of easily compared to the obstruction caused by the building structure columns. It also can be disassembled and moved to a new location easily.

Compared with single girder gantry cranes, double girder gantry cranes have more heavy capacity and higher work duty, and long reliable service for all applications is provided. More details about single girder & double girder crane, Please keep us informed. Double Girder Gantry Cranes are divided into several types according to its usage: U-type double girder gantry crane, A-type double girder gantry crane, Truss type double girder gantry crane. They can be made into Full double girder gantry cranes or Semi double girder gantry cranes. Besides, U-type double girder gantry crane and A-type double girder gantry crane are so named by leg shape. We provide all these types to our customers, and meet their requirements as much as possible.

Double girder gantry cranes are applied to general materials handling, assembly, repair and transferring service along the floor mounted railway in outdoor/open freight yards, loading areas, warehouses, workshops, mine enterprises, open storages, stock grounds, container depots, steel plants, process plants, cement plants, railway freight stations, railway terminals, rail sideways, coal fields, material stocks, docks, quays, wharfs, harbors, ports, concretes, woods, marbles, granites, ship-buildings, metallurgical factories, engineering industries, transformer industries, cable industries, subsidiary thermo-hydroelectric power plants, especially applicable to long, large, bulky cargo.

Double girder gantry cranes also called double girder electric gantry cranes, double girder semi gantry crane, double girder goliath cranes or double girder full portal cranes built especially to heavy duty specifications to serve in different capacity and bridge led axles which are determined by engineers that meet demands of high duty cycles and multiples shift operation, double girder cranes are used when heavy loads, wide spans or high working frequency are required than single girder gantry cranes. Please check double girder gantry crane specification in above PDF file.

1. Structure | Gantry

Gantry crane frame steel portal structure which is simple torsion-free welded box-shape or truss structure with standard deflection. It mainly consists of main beam, supporting legs, end beams, saddle, cantilever (optional), trolley traveling track, bottom cross beam and other components. The main beam, end beam, legs, saddle, bottom cross beam are connected together by high strength bolts to achieve perfect construction stability. The track is at the side of each girder, main beam and end beam with wheels are driven by motors.

Painting: Two coats of primer before assembly & two coats of synthetic enamel after testing.

① Main Girder | Main beam | Main bridge beam

Material: Q235 or Q345 carbon steel (similar to Fe37 or Fe52)

Minimum plate thickness > 6mm.

The load bearing crane girder is part of the frame structure, which together with the legs at either end, forms a travelling bridge, it is installed from above, perpendicularly to the supports (legs).

Strong main beam camber is (1 ~ 1.4) S / 1000, and the maximum camber position is controlled in range 1/10 of the span middle.

It has welding box type or truss type. ANSYS finite element calculation method for systematic analysis and calculation is applied for main girder cross section.

② Supporting legs | Landing legs

The leg is divided into type A and type U according to user’s requirements, one rigid leg/rigid support and one flexible leg/flexible support which allows to compensate irregularities of crane runways at the expense of special hinges is ok for large span.

It is made up of upper and lower flange, steel plate or welded steel support. Upper flange is large while lower flange is small, thus the legs become variable cross-section structure with upper big and lower small, which influences bearing loads of vertical and horizontal directions.

In crane legs there has sound and light warning, emergency stop button box and crane rail clamp.

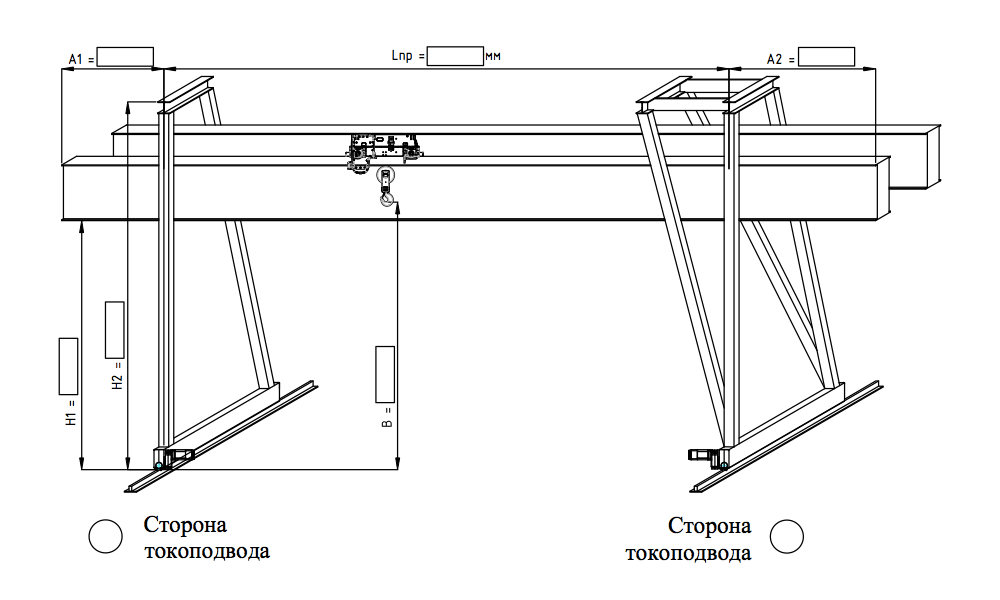

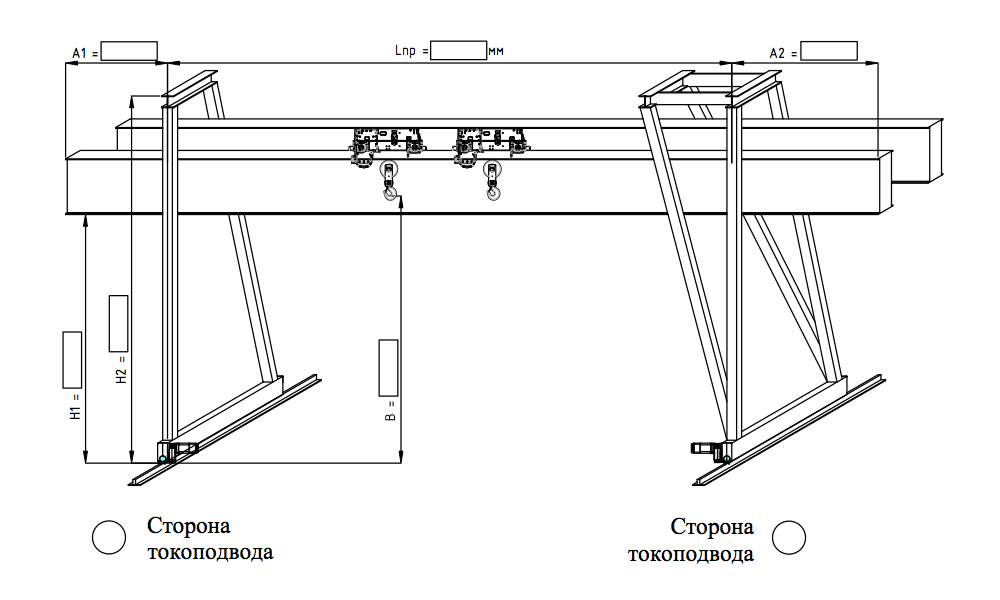

③ Cantilever | Extension | Overhang

Double cantilever (both ends), single cantilever(one end) and non-cantilever according to customers’ request.

This crane presents new, different look and appearance by having extensions of the sides or without extention.

④ Saddle

No saddle when no cantilever

⑤ End truck|End beam|Ground beam

It runs on ground rails, which eliminates the need for a overhead runway

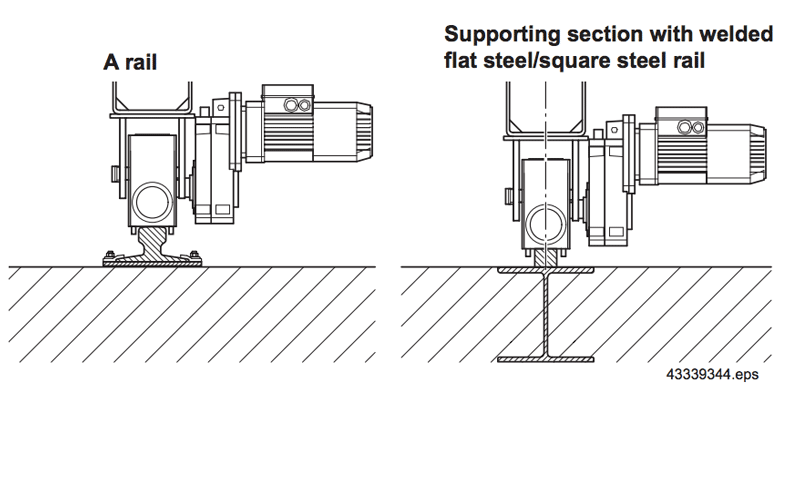

⑥ Rail track |Runway | Track

Gantry crane rides on two parallel rail tracks on the supports welded into the box-type or tube-type structure.

2. Hoisting Mechanism | Lifting mechanism | Lifting device

Hoisting mechanism (main hoisting unit) is mainly single & double speed wire rope hoist or electric winch with trolley mounted on main bridge beam with compact, safe, reliable layout and easy maintenance. The operating principle is motor acts through gear shifting and then drives drum through drum coupling. Hoists material by hook through wire rope winding system and hook stop hoisting when the brake is closed after power off, which keeps the lifting object still in the air, wound rotor motor is equipped with fully functional protection device and will be effectively protected for overcurrent and short circuit fault, it is heavy duty YZR model motor which is top brand in China and also very famous in the world. Thermistor is applied in lifting motors and double (variable) speed /motor overheating protection / frequency inverter driven motors is also available as per your request.

Hoisting mechanism mainly consists of: reel, lifting motor, lifting reducer, brake, wire rope and hook (or grab, electromagnetic chuck) and other components.

It includes main and auxiliary lifting mechanisms which arranged in the same trolley frame and each set with separate driving device. Main and auxiliary lifting mechanisms not only can finish the lifting and handling independently, but also can be coordinated to complete the work of turning over object.

3. Trolley traveling mechanism

Its operating principle is motor outputs power which drives wheels via drive shafts and couplings and shifts speed by reducer when brake is open after power on, then trolley travels forward and backward and will stop moving when the power off and brake closed.

It consists of traveling motor, running reducer, wheel sets and other components. The trolley equipped with stopper device, rail clearer, buffer, traveling limit and other safety devices.

with one trolley

with two trolleys

4. Trolley frame

It is steel plate welded combination structure with sufficient strength and rigidity to ensure normal work and without deformation under load. Sealed rain cover with daylighting measures is applied for outdoor work trolley.

5. Crane traveling mechanism | Bridge travelling unit

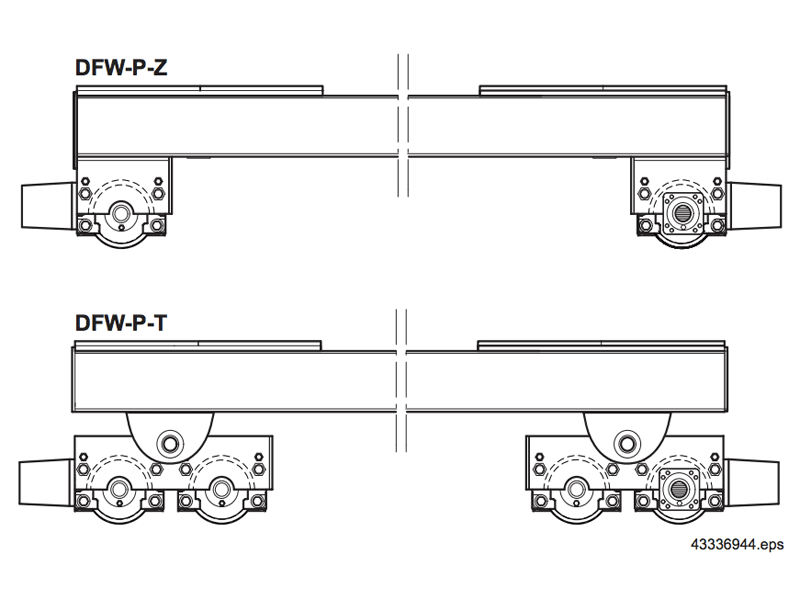

It’s a separate drive compared to trolley traveling, with four wheels or eight wheels or more in special circumstances depending on lifting capacity and accordingly wheel load. wheel and angle bearing box with roller bearing (45º split structure bearing box) mounted on the balance wheel set.

Crane traveling mechanism consists of motor, brake, reducer, wheel sets, drive shafts, couplings and other components.

four wheels or eight wheels (2 pcs)

wheel blocks moving on rail or square

6. Control panel

Modular design, easy to install and maintain, reliable operation, fuse less circuitry, ducted wiring and compact terminals. Frequency inverter control system is available.

7. Control method

1.Ground control

2.Remote control /radio control

3.Cabin control

It is the workplace for manipulating crane by operator, which welded of steel plate and steel and mounted on a bracket below the main beam with solid and reliable connection. Durable, safe, rigid, reliable, comfortable and beautiful. Tempered and toughened glass for the window is fitted on front and two sides, maximum elevation 55 ~ 60 ° and maximum angle 70 ~ 75 ° for driver’s adjustable seat, driver fixed maximum positive perspective 120 °, front seat rotating angle up to 270 °, all are to ensure the operator vision. Besides, fire extinguisher, air condition, acoustic alarm and interphone in the cabin are available.

It is fitted with an emergency stop button (emergency switch) located in the power distribution cabinet for emergency cut off the whole crane power supply to stop any movement once any dangerous happened, just press it, all movements can be switched off by actuating the emergency-off switch at the control station via a main contactor.

Doors of driver’s cabin and bridge frame has electrical interlock protection device.

Anobstructed walking and active space guaranteed driver quickly and safely withdraw in accident situations.

8. Zero protection

When it starts to operate or power is restored, the controller must first be placed in the zero position, the motors can only start after pressing the start button.

9. Ladder, platform and walkway

Safe, stable and reliable ladder, platform and walkway are needed for operation, inspection, repairing which has enough work space, non-slip platform walkway around 1050mm high equipped with railings for which can afford 1kN load from any direction without causing plastic deformation.

10. Reducer

Three-in-one reducer for easy maintenance is adopted for long travel and cross traverse mechanism.

11. Gear box

It is made of accurate hob cut helical / spur gears & pinions having hardness 250 to 350 BHN made from carbon alloy steel. All gears & pinions running on anti-friction type ball, roller bearings in totally enclosed oil bath giving constant splash lubrication. The helical / Spur gear designed for adequate strength and optimum wear resistance for smooth operation & long life.

12. Brake

Independent Hydraulic Brake makes the crane more safe and easier to control

13. Overload load limiter | Overload protection | Overload protector | Over-weight protection

The display device will automatically alarm and warn when load reaches 90% of rated; power supply of hoisting mechanism will be automatically cut off and only the lowering motion is possible when the load reaches 105%.

14. Limit Switch | Lifting height limit device |Rising limit position protection device

Prevents over traveling in all motions, automatically cut off lifting power supply when hoisting to a limit position.

15. Stroke limiter

Automatically cut off power when crane and trolley traveling to the limit position and equipped at both sides of crane and trolley traveling mechanism, Long and cross travel limited by means of preliminary and final limit switches

16. Electricity installation

Electricity installation we use different type systems such as cable carriage, sliding wire, c type cornice feeding, enclosed conducting busbar and cable drum.

17. Electrical parts

SIEMENS Brand or Schneider Brand etc.

18. Earth conductor

A protective earth conductor is fitted as standard.

19. Rubber buffer

Top quality long time bearing polyurethane materials buffer

20. Warning indicator

Flashs lights and warns sound.

21. Anti-theft locks

Four anti-theft locks: two parking locks (manual anti-theft locks are installed by the shift change of crane operator) and two automatic locks (automatic anti-theft locks come into action upon power failure)

22. Special storm anchors (outdoor use)

It is used for outdoor duty goliath cranes under storm condition to prevent toppling of crane.

23. Anemometer (outdoor use)

Turn off the crane power supply at the maximum wind load

24. Aviation obstruction lights (outdoor use)

Install aviation obstruction lights on the top when crane lifting height exceeds 30m.

25. Under crane lighting | lightning protection device (outdoor use)

Set up lightning protection device too when crane used outdoor without high-rise buildings

26.Electric equipment

For crane and winch power supply

27.Winch

With heavy capacity and high work duty, it was developed specifically for lifting that requires accuracy and smooth movement.

28.Wheel group

29. More safety components

Shaft-broken protection, overturn-proof, Wireless infra-detector for anti-collusion, End switch of lifting gear and crane& trolley traveling gear, Voltage lower protection function, Phase sequence protection function, Rain cover for outside hoist, driving units, electrical cubicle.

Others

1.Package

Electric hoist and crane parts will be packed by plywood crate, main girder packed by water-proof cloth.

2.Parameters

The crane will be taken synchronized or corrective protective measures when span is more than 40m

Working grade: When its load handling device is hook, the crane working level is A2 ~ A6, when it is grab or electromagnetic chuck, the crane working level is A4 ~ A7, It is according to the use frequency.

Relative humidity: no more than 95% when the temperature is +40 centigrade

Wind speed: ≤20m/s when working, ≤44m/s when off work

It is applicable in windy, hot, cold environment but not suitable for lifting blazing & melting metal or toxicant as well as explosion-proof or insulating working conditions.

Crane traveling lane is supposed not to slope more than 1% and not more than 3% for local slope. The ground slope on two sides of the span should be in the same direction.

3.Girder division

Make main girder divided into two or more parts which are convenient to transport by container (Max. length: 11.8m/pc for 40GP and 40HQ, 5.8m/pc for 20GP) and assembled with strong bolt after coming to site.

4.Factors to consider when selecting your crane

Capacity, Span, Lift height, Power supply, Traveling distance

Do you need us to provide rail and cable?

Do you need canteliever? If so, then Left cantilever: __m? Right cantilever: __m?

If you can supply below information that will be more helpful and suggest which type is more suit for your case: like double girder or single girder?

Which material to lift?

Any special requirement on lifting speed, hosit traveling speed and crane traveling speed?

Woring condition: temperature? any corrosive gas or material? any explosive gas or material?

Work frequency: like how many times/day, hours/time?

The introduction of different types of Double girder gantry cranes

① U type Double Girder Gantry Crane

U type is more convenient to move large size/volume goods because of the large support leg space from middle position to cantilever without any dimensional restrict by leg and usually equipped with lifting spreader, which is popularly used in lifting and transporting containers and hydropower station with very large wheel gauge, the structure eliminates saddle frame and the crane overall height is reduced for certain lifting height. When this crane is used for lift stoplog, lifting mechanism will be with two lift points.

This type gantry crane adopts U type door frame and consists of main parts, namely, bridge structure, traveling mechanism, cart and electric equipment.

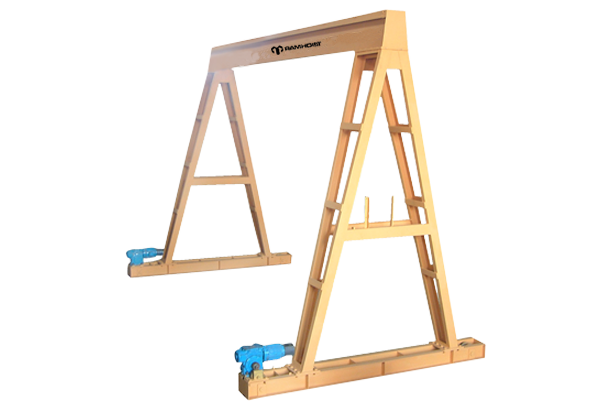

② A Type Double Girder Gantry Crane

A type designed with maximum flexibility and minimum maintenance for structural and rail, the open design is easy for imperfection inspection if needed

This type Gantry Crane adopts A-type door frame, individual drives are adopted for traveling mechanism on each end of the crane. All movements of the crane are controlled in the cabin.

③ Truss Type Double Girder Gantry Crane

Both main girder and support leg are truss type which has lighter dead weight for greatly reducing wind resistance and bearing strong wind pressure that is more suitable for open area, truss type also has less cost.

④ Semi Double Girder Gantry Crane | Double Girder Semi Gantry Crane | Double Girder semi-portal cranes | Semi Double Girder Goliath Crane

Semi gantry crane (double girder, single leg) mainly differ from full Gantry cranes is that it does not have an integrated articulated leg which compensates any movements. It is a hybrid of a top running crane and a goliath with one end of the bridge supported by a high level gantry and the other by a leg running on a low level track, which used typically in the area adjoining a building and the high level gantry is integral with the building structure. It is therefore suitable for outdoor stockyards alongside a building but also for indoor use where a full span of the building is not required.

Double girder Mobile Gantry Crane | Double beam Mobile Gantry Crane

Double-beam, rubber-tired mobile gantry cranes were developed to meet the growing need for cost-effective lifting solutions among those who lift heavy, bulky items from production to transport and can address customers’ material handing challenges. They comes with spreader assemblies which provide critical link between gantry crane and loads being lifted and become versatile so that they meet specific lifting needs and even multiple lifting needs. The cranes provide high-quality performance, efficiency and adaptable design, and they incorporate both advanced engineering and customer-driven design features.

Specifications

Lifting Capacity (t) | 10 | 16 | 20/10 | 30/10 | 36/16 | 50/10 | |

Span (m) | 18-35 | ||||||

Lifting Height (m) | 10-13 | ||||||

Working duty | A5 | ||||||

Speed (m/min) | Lifting | 8.5 | 7.9 | 7.2/10.4 | 7.5/10.4 | 7.8/10.5 | 6/10.4 |

Trolley travelling | 43.8 | 44.5 | 44.5 | 41.9 | 41.9 | 38.13 | |

Crane travelling | 37.6/40 | 38/36 | 38/36 | 40 | 40/38 | 38 | |

Motor | Lifting | YZR180L-6/17 | YZR225M-8/26 | YZR225M-8/26 | YZR280S-10/42 | YZR280M-10/55 | YZR280M-10/55 |

YZR200L-6/26 | YZR200L-6/26 | YZR225M-6/34 | YZR200L-6/26 | ||||

Trolley | YZR132M1- | YZR132M2- | YZR132M2- | YZR132M1- | YZR132M1- | YZR132M1- | |

6/2.5*2 | 6/4*2 | 6/4*2 | 6/4*2 | 6/6.3*2 | 6/6.3*2 | ||

Crane | YZR160L-6/13*2 | YZR160L-6/13*2 | YZR160L-6/13*2 | YZR160M2- | YZR160L-6/13*4 | YZR160L-6/13*4 | |

YZR160M1- | YZR160M2- | 6/8.5*4 | YZR160M2- | ||||

6/6.3*4 | 6/8.5*4 | 6/8.5*4 | |||||

Weight (t) | Trolley | 9 | 9.5 | 12 | 16 | 18 | 24 |

Total | 63.2-100 | 78-106 | 79-120 | 95-108 | 106-155 | 195 | |

Wheel Pressure (KN) | 225-295 | 255-373 | 208-289 | 324-334 | 314-363 | 452 | |

Operation Model | cabin | ||||||

Working temperature | -20-40℃ | ||||||

Steel Track | 43kg/m | 50kg/m | |||||

Power Source | 3-phase A.C 380V 50HZ (As your demand) | ||||||

-

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection…...

-

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder cr…...

-

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes…...