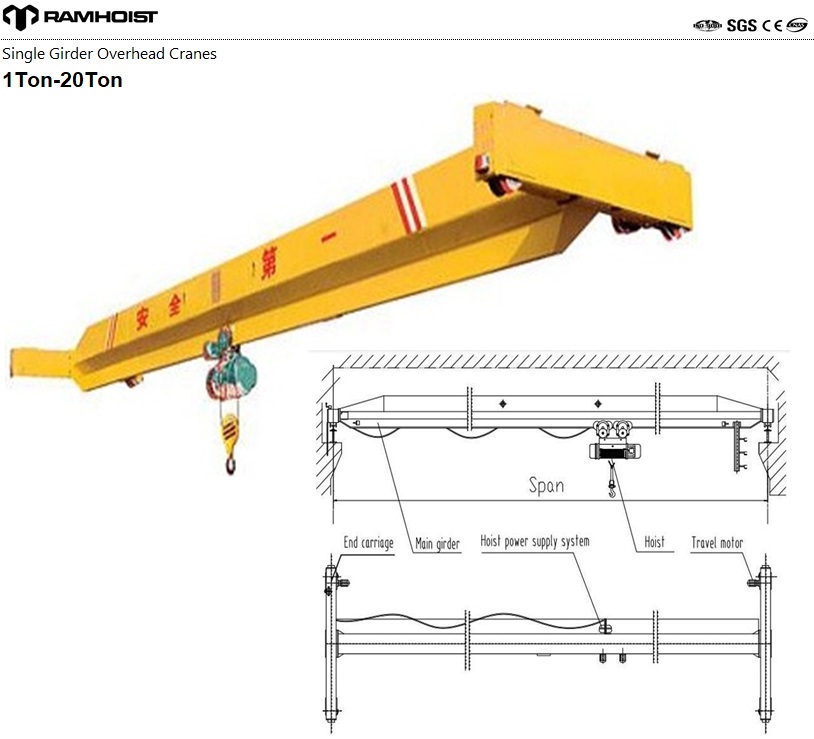

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection/both ends in the cement column or metal bracket shaped like a bridge, which suspended from the workshop, warehouse etc and travel under I-section or H-section steel beams. Please contact us for Single girder overhead crane design and Single girder overhead crane parts.

• Designed with more reasonable and reliable structure, higher strength steel as a whole

• Small dimension, light weight, dependable and optimum performance and no pollution

• Easy handling and operation, little noise, few faults and highly improved cost-effectiveness

• Energy-conservation, environment protection, low maintenance and higher working efficiency

• Small and light wheel load, low-sway load is controlled and positioned easily and exactly

• Low consumption of power reduces the costs, and excellent exchange ability for components

• Safe, powerful, reliable, durable and affordable, longer utility life-span, and service life

• Favourable travel characteristics and minimum wear of crane runway and travel wheels

• Travel limit switches which reduces harmful loading on end stops and unnecessary load swing

• Wide selection of operational speeds, to highly meet customers’ different requirements

• Designed in accordance with international standard, DIN, FEM, ISO and conform to JB/T1306-94

• One year warranty is the most important commitment, which we can provide to our customers

• Sub-assembly characteristic are tested before assembly, providing absolute safe to workers

• Optimised headroom via main girder connection variants make the operation become compact

Capacity 1Ton-20Ton

Span 7.5-31.5m

Standard Lift 6 m

Use Lifting Up/Down, Traversing Left/Right

Drive Mode Motor

Class Insulation F

Working Class A3-A5

Work Moisture <85%

Sling Type Wire Rope or Chain

Operation Pendant control, remote control or cabin control (driver's room, open or closed type)

Contact Continuity 40%ED

Power Supply 220v-660v, 50/60 Hz, 3 phase, single or dual voltage

Ambient Temperature -20~40℃

Control Voltage 24v, 36v, 42v, 48v, 110v

Crane Driving IP55

H.S. Code 84261120

Package Plywood case (girder and end truck are packed by rain-proof plastic, electric hoist and all other things are packed by firm wooden case or crates and plywood cases)

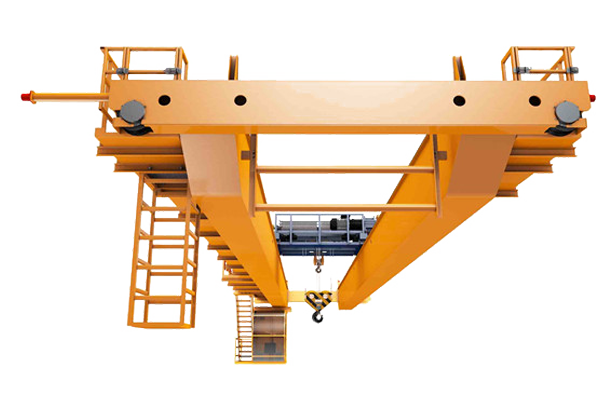

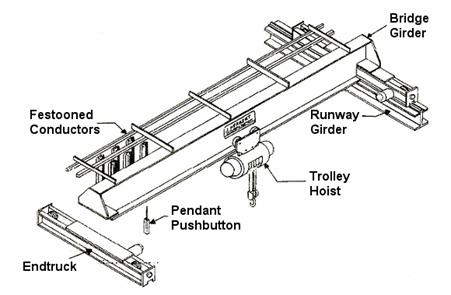

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection/both ends in the cement column or metal bracket shaped like a bridge, which suspended from the workshop, warehouse etc and travel under I-section or H-section steel beams. The bridge is laid along the track on both sides of the viaduct, so that they can make full use of the space under the bridge to lift the material without the hindrance of the ground equipment. Single girder overhead cranes consist of main bridge girder (single), end truck, electric hoist and electric system to help move heavy loads for 3 directions: Up-Down, Left-Right, Forward-Backward. Single girder overhead cranes are designed to assist with a wide range of lifting tasks and moving operations which will contribute to your daily productivity and overall success and proved to be a powerful and reliable solution for assorted industries while serving multiple applications in a diverse set of environments. They are the most popular, pragmatic and cost efficient lifting cranes (light duty track traveling crane).

The main role of single girder overhead cranes is timely and safely complete the object displacement by intermittent and cycle work, with electric trolley or other means of lift devices such as grab or electromagnet. They are important tools and equipments for material handling to achieve mechanization and automation. They also have the functions of reducingthe burden on workers during modern industrial production process, improving labor productivity and efficiency, saving the cost of the workshop. Besides, they have become indispensable lifting production to a certain extent and suit the tailor-made requirements of customers.

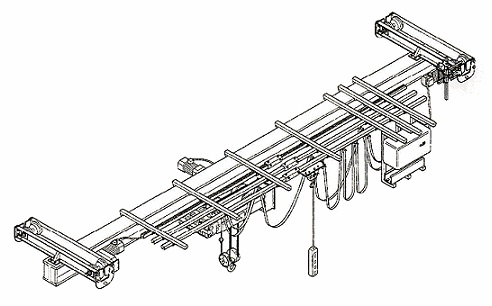

Using high-quality components can reduce failure rate and maintenance costs. The system benefits from a travelling motor gear box ensuring that the motor starts quietly and smoothly whilst offering 1 or 2 travelling speeds and variable travelling speeds. Latching devices allow direct transfer of the hoist trolley between the crane and a suspension monorail, flexible connections between the crane girder and end carriages enable single-girder cranes to operate on tracts that are not parallel. There are also top running end-carriages that feature direct drive wheels, rubber buffers and the end carriages are fastened with a plate bolted onto the girder. Lifting mechanism, trolley and crane can be controlled independently and work synchronously or individually. Various parameters tested to ensure strong construction, smooth operation and high load bearing capacity. Besides, safe slide wire/cable provides high conductivity and small voltage drop power, current collector slide speed is swift.

Our single girder overhead cranes also come standard with travel limit switches, they feature maximum rigidity and minimum deadweight. This maximizes crane runway loading and enables a more cost-effective building design and overall system solution. And environment which requires special used crane instead. Ramhoist crane packages are pre-engineered, complete crane component packages utilizing cutting edge technology. Plug-in cabling and bolted structural connections simplify assembly. What’s more, there are normal headroom (general type, also called LD type) and low headroom (European type) for both Top Running Single Girder Cranes and Under Running Single Girder Cranes.

Due to their various main girder connection variant, the single girder overhead cranes are applicable to transfer, assembly, check and repair as well as load and unload various materials in the various indoor and outdoor environment such as factory, plant, warehouse, stockyard, mine, machinery manufacturing, concrete industry, assembly repair, production workshop, garage, metallurgical steelmaking field, petroleum, petrochemicals, ship building, electric power, paper making, railway transportation construction field, civil aviation, port/harbor and logistics turnover etc, especially for the applications that require precise positioning of the material handing, large parts and precision assembly, even in buildings with low ceilings. However, this type of single girder overhead cranes are banned to be used in some dangerous environment, such as, combustible/ flammable, explosive, or corrosive gas

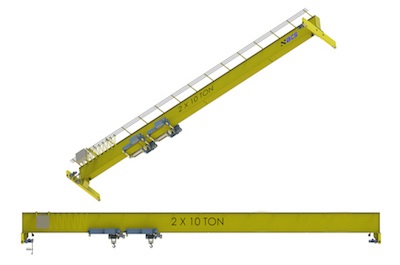

Single girder overhead cranes also named single girder overhead travelling crane, single girder electric overhead crane,single-girder overhead travelling cranes, single girder bridge cranes, single bridge cranes, single beam cranes, single beam overhead cranes, single beam bridge cranes, single girder crane, single girder suspension bridge cranes, single beam hung cranes, warehouse single girder hanging overhead cranes, warehouse single beam cranes, single girder hanging bridge cranes, single girder EOT cranes, single girder electric cranes, single beam EOT cranes. There are Top running Single girder overhead crane and underhung Single girder overhead crane, and manual single girder overhead crane is also available, of which the Top running Single girder overhead crane is most favoured by customers. Pls download below Single girder overhead crane for Single girder overhead crane Single girder overhead crane specifications and Single girder overhead crane dimensions, Single girder overhead crane price will be sent to you after design, 10 ton single girder overhead crane and single girder overhead crane 5 ton is best sold.

1. Bridge Girder | Main Girder

Horizontal beam of the crane bridge for hoist traversing is linked and supported by the end trucks.The frame of crane beam is either no-weld U-shape for general type (normal headroom) with one stop molding rolled beams and channels, or square box frame for europen type (low headroom) with rolled section (enclosed computer-optimised box-section), torsion resistant welded diaphragm plate for reinforced connection and have non-destructive test. Both are simplified open kind design and with tight, robust, solid, rational and high strength/rigidity structure by Q235 or Q345 steel plate (similar with foreign steel plate Fe3 or Fe52) and with advanced technology, outstanding design, auto production, best grade and premium material which pass shot blasting ensures high efficiency and low noise operations. Low deadweight reduces investment layout, it has smaller body to get more lifting space and optimal/best use of the room under the bridge.

European type is different structure and main girder is box type. The advantages are reducing itself height, to some extent increasing the crane lifting height, while general type means the main girder is normal U-shape.

European type

General type

2.Bolting and Welding

Main girder and end girder adopts bolted connection to ensure strength, they are manufactured under the guidance of our experts who strictly follow the norms of industry at every stage and use modern machines and crane buffer block is included.

In view of important welding seam and stress is more than tension weld of 70% allowance stress, conducting fault detection check and take out 5% weld length by ultrasonic test. Inspection report provided to user.

3.Painting

All steel is treated by sand blasting before doing paintings, there are 3 layers of paintings and the bottom layer is epoxy zinc painting to prevent from rusting. It has beautiful outlook and lustre for a long service life after Primer and finishing painting. Color is according to your demands and average thickness is about 100 microns and should be average on surface.

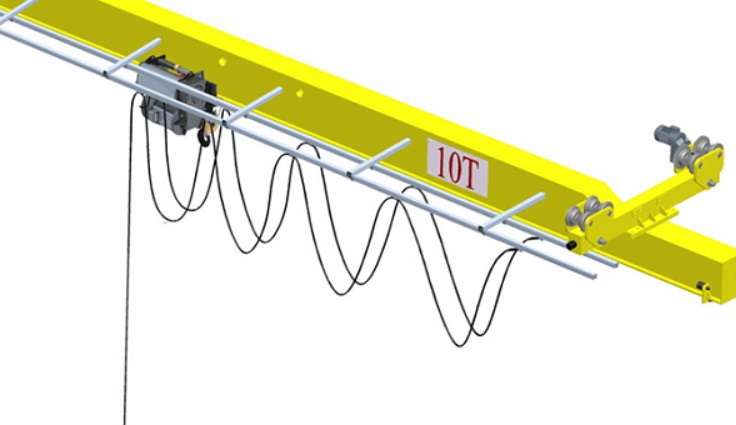

4.Electric Hoists

They are the lifting mechanisms/components of the cranes with single or double lifting speed of normal headroom or low headroom (close headroom/short headroom) designed to maximize available height (vertical clearance) and assure maximum hook travel as well as they also minimize the beam-to-hook distance, which all travels along the bridge.

The hoists are mounted on the main girder for crane lifting, there are two basic types of hoists. One is wire rope hoist which is very durable and will provide long term, reliable usage, and the other type is chain hoist which used for lower capacity, lighter duty applications and for projects in which cost is a primary deciding factor.

For wire rope hoist, there are CD1 model, MD1 model, HC model, Europe type electric hoist, variable frequency drives on both hoist and trolley is available, in china, with CD1 and MD1 electric hoist also called LD type single girder overhead crane which is the most popular crane in developing countries since it is much cheaper than with Europe mode hoist.

The trolley and crane adopt three-trinity driving mechanism, frequency stepless speed regulating, hard-tooth surface, disc brake. Main traveling mechanism adopts soft start cage motor. Shrouded DSL system for trolley power feeding, smooth and quiet operation. Its traveling speed can be designed dual-speed and frequency control or other types of speed.

5.Motor

The cross and long traveling motor with thermal protection and currency protection, has soft start function, and motor protection class is IP54. It is F class insulation and equipped with overload protection equipment. (optional)

6.Overload Protection/Load-limiting Device/ Overload Limiter

If the material is over the capacity, the crane will give a sharp warning for protection itself.

7.Emergency Brake

If the operation staff encounter some emergency situation, we could start the emergency brake/stop system to protection the related treasure.

8.Electric protection

The electric protection consist of short circuit protection, circuit self-check protector, lose phase protection, phase control relay, circuit flow phase lack protection, low-voltage protection, power failure protection, over current protection, thermal protection of electric motors, sound and light signaling/alarm devices/ siren light. All these protections have the same function of making sure our products’ safety and security.

9.End Trucks | End Carriages | End Beams

Located on either side of the span in cement column or metal bracket, the end trucks with gear motors house the wheels on which the entire crane travels. There are two sets of end trucks and gearboxes for one set of single girder overhead crane, specially designed gearbox adopts oblique gears and self lubrication.

European type: End beam is a tubular type, adopt good quality parts. Especially European wheel group is a key component of such parts.

General type: General crane end beam by splicing.

European type

General type

10.Limit Switch

Our single girder overhead cranes equipped with many different limit switches, like mechanical limit switch, two-position switches for hook lifting and lowering mechanisms, cross bar limit switches which include height limit, rail end stop limit for traveling and long traveling limit switch.

11.Wheels

These wheels travel on the runway beam allowing access to the entire length of the bay.

Wheels of highly wear-resistant spheroidal-graphite cast iron include wheel bearing, wheel, bearing box, and bearing. The material is ZG430-640 high strength cast steel, 60#, 65Mn, 42CrMo, 45# or according to your demands.

12.Bearing

Bearing is deep groove ball bearing and bearing friction coefficient is small, high speed limit. It is an important part in wheel. Bridge crane wheel assembly are technically advanced and successfully used in different industries.

13.Shaft

High-quality shaft is an essential component of end trucks’ wheels.

14.Inverter

Inverter from famous brand such as ABB can make lifting and traveling in any speed you want specifically for your work.

15.Electric control box

Standard is CHINT, Shihlin, Schneider, Yaskawa. ABB electric elements and the protective grade of electric control box shall not less than IP54-- insulation class is normally IP55, movable control box that moves along the crane and is independent from the hoist. Control stick could be connected with trolley, freely move on main girder separately and can also control the travelling speed according to the different depth of buttons.

16.Nonpolar speed adjustment control

Nonpolar speed adjustment control (Electric contactless module speed regulation controlling for travelling) which result in stable travelling and small sway of crane. Radio control and predicative maintenance device options available. Optional radio control with power and signal transmission via energy chain system, it with display and proportional pushbuttons.

17.Festoon

One electric festoon system running the length of the bridge beam. Power supply to the crab by means of highly flexible flat cable with protective earth conductor. Cable is hung on the coil holder for hoist power supply, normal we equipped flat type cable, also have explosion-proof type.

18.Pendant Control

Pendant control and cable with quick-connect plug, and control pendant suspended for separate travel on the crane girder with display for installation monitoring.

19.Hook

High quality hook can completely make the load assignments become more safe and reliable.

20.Control Panel

Control panel with variable frequency drives for both bridge and trolley, is sealed and IP 55 protected which has 3 optional: cabin with joystick panel, wireless control panel or pendent control panel.

21.Cabin

There are full field of view cabin suspend under the main girder. There are joint control desk or single control box packed within the cabin, assemble the sidelong ladder between the cabin and moving table.

Others

1.Warning

People without driving license or after drinking shall not be allowed to operate and the operation must be focused, not talking, smoking or doing anything unrelated, the crane is not allowed to use overload.

2.Maintenance Precautions

First, need to regulate the operation, certificate posts; Second, regular maintenance, add lubricants, to ensure that the machine can be normal, safe operation; Third, to comply with the “ten hanging” criteria, prohibit overload and to lift people. Through the normal operation of the crane, reasonable maintenance, can reduce the crane failure, to ensure the normal operation of the machine and extend the service life.

3.Two Different types

①Top Running Single Girder Cranes | Top Rider Single Girder | Single Girder Top Running Overhead Cranes | Top Running Bridge | Single Girder Top Running Bridge Crane (SGTR)

The top riding single girder cranes are similar to the top rider double girder crane. Top running overhead cranes are much heavier than under hung equipment. For top-running systems, the end trucks are supported on rails, which are attached to the top of the crane runway. Besides, as the best and efficient lifting solution in large coverage facility, top running overhead crane or bridge crane can be designed in both single girder, double or box girder, there are enough options to suit your demands.

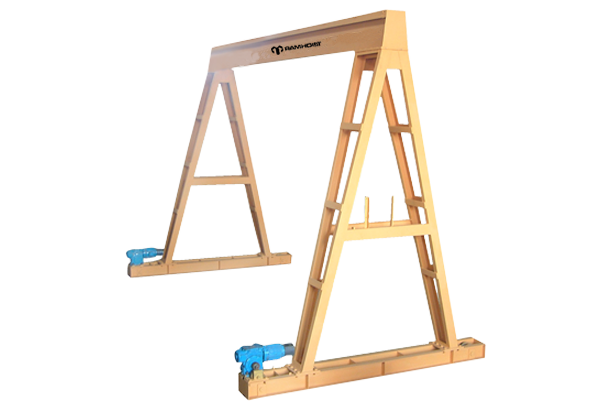

②Under Running Single Girder Cranes | Underhung Bridge Cranes | Single Girder Motorized Underhung Cranes | Underhung motorized bridge cranes | Underhung hoist overhead crane | Single Girder Underhung Bridge Crane (SGUH)

Under Running Single Girder Cranes offer excellent side approach and are the excellent choice applying to works and storehouses where it is ≥100 mm height between the rail surface and the rafter of roof truss.

4.European type overhead crane VS General type overhead crane

European type equipped with low headroom hoist/trolley and more advanced on structure design. Compared with general type overhead crane, the limiting distance is minimum from hook to wall, and headroom is the lowest and minimum, which makes cranes work more close to the front. The net height is lowest, can maximum the lift height and highest possible hook position can be achieved, which increases effective working space of workplace. European single girder overhead crane is compact lifting machinery designed and manufacturing in the strict according with FEM, DIN and ICE standard. Compared with general overhead crane (bridge crane), the weight is reduced by about 15-30% of common crane, max wheel pressure is reduced by about 10-30%. Lifting height is reduced by about 20%-25%, and hook limit is smaller so the working space is bigger.

Optimum utilisation of the available height and space thanks to compact travelling hoist design and large hook path, thus reduce construction and operating costs. The crane is very expedient equipment for material handling in little production divisions and where there headroom is very low.

5.Low-energy & free-maintenance

With German motor, the total power can be 20% lower than normal crane, save energy. Composite transmission mechanism has less mid device, the efficiency can be higher. Frequency control speed, the can be low-high speed 1:10, which will improve the working efficiency with more than 20%. Free maintenance and easy maintenance design will reduce the maintenance cost for you. Components which are imported from abroad, the break down rate is very low and will reduce your cost when using the crane.

6.Intelligentized

Safety monitor, which is called the crane black box, it will record every operating.

Electrical anti-swaying system, which can help the crane working with precise position control.

|

Quotation for single girder overhead crane 10T-S6m, H8m

Quotation for single girder overhead crane 10T-S9.5m, H5.5m and 10T-S12m, H5.5m

Quotation for top running single girder overhead crane 10T-S12m, H6m with Electric wire rope hoist

Quotation for top running single girder overhead crane 10T-S12m, H6m with Electric chain hoist

Quotation for under running single girder overhead crane 10T-S12m, H6m with Electric wire rope hoist

Quotation for under running single girder overhead crane 10T-S12m, H6m with Electric chain hoist

Specifications

Lifting Capacity (t) | 1,2,3,5,10 | 16,20 | |||||||||||

Span (m) | 7.5-31.5 | ||||||||||||

Overhead Crane Travelling Mechanism | Travelling Speed(m/min) | 20 | 30 | 45 | 60 | 75 | 20 | 30 | 45 | 60 | 75 | ||

Reducer Ratio | 58.78 | 39.38 | 26.36 | 19.37 | 15.88 | 58.78 | 39.38 | 26.36 | 19.37 | 15.88 | |||

Motor | Model | ZDY21-4 | ZDY21-4 | ZDY122-4 | ZDY131S-4 | ZDY112L1-4 | |||||||

Power(kw) | 2*0.8 | 2*1.5 | 1.5*2 | 2.2*2 | 2.2*2 | ||||||||

Rotation (m/min) | 1380 | 1380 | |||||||||||

Lifting Mechanism | Electric Hoist Model | CD1/MD1 | CD1/MD1/HC | ||||||||||

(Electric Hoist) & Electric Hoist Travelling Mechanism | Lifting Speed (m/min) | 8,8/0.8 7,7/0.7 | 3.5 3.5/0.35 | ||||||||||

Lifting Height (m) | 6 ,9 ,12, 18, 24, 30 | 12,18,24,30 | |||||||||||

Travelling Speed (m/min) | 20 (30) | 20 (30) | |||||||||||

Motor | Taper Squirrel-cage type | Taper Squirrel-cage type | |||||||||||

Work Duty | A3-A5 | ||||||||||||

Power Supply | 380V 50HZ three phase or according to your requirements | ||||||||||||

Wheel Diameter (mm) | 270 | 370 | |||||||||||

Width of Trail (mm) | 37-70 | 37-70 | |||||||||||

-

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection…...

-

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder cr…...

-

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes…...