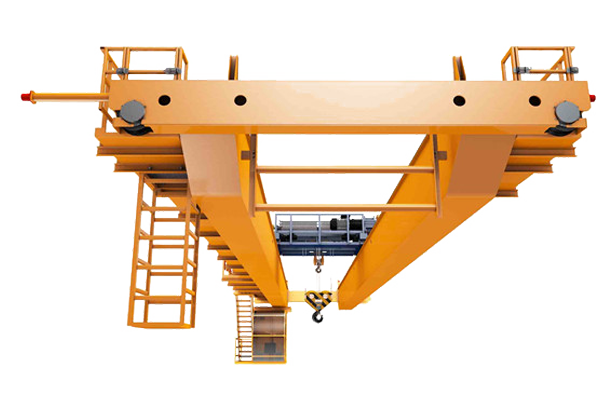

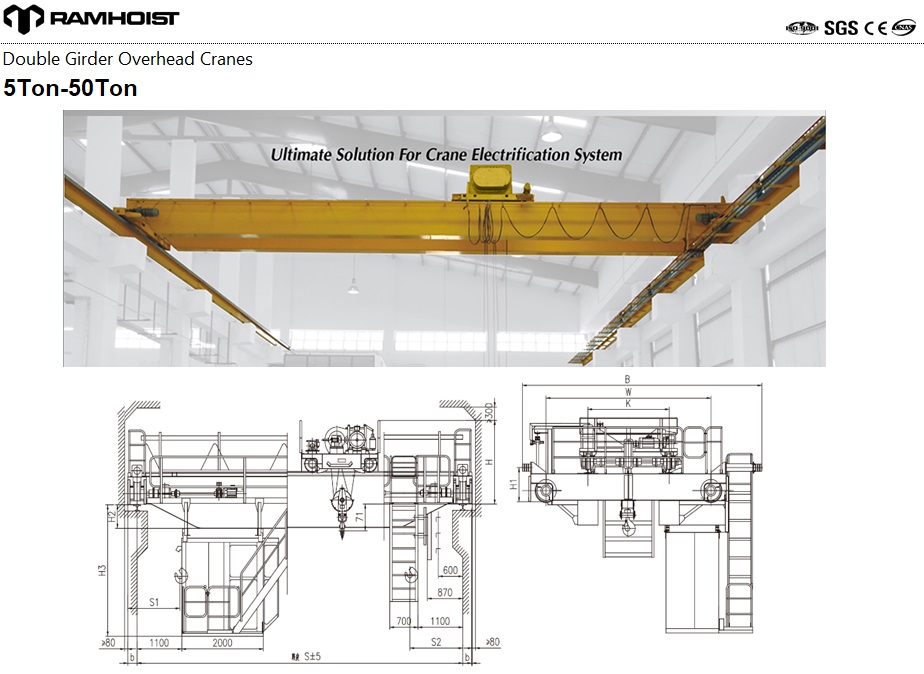

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder crane to be used. They also provide higher hook heights because the hoist is placed between the two cross girders rather than below (under the cross girder). Top running double girder overhead crane is mostly used here and we are similar type of demag double girder overhead crane but with much lower price.

• Designed with more reasonable structure and higher strength steel as a whole

• Small dimension, light weight, optimum and dependable performance and low maintenance

• Longer utility life-span, higher working efficiency and high-quality of components

• Easy to hand and operate, few faults and improved cost-effectiveness, long service life

• Low noise, energy-conservation, environment protection, pollution-free, reliable and affordable

• Small and light wheel load, low-sway load is controlled and positioned easily and exactly

• Low consumption of power which can reduce the costs to make products be used longer

• Favourable, safe and powerful travel characteristics get consumers’ enthusiasm attention

• Excellent exchange ability for parts and components makes the maintenance become easier

• All motions of crane and hoist are independently, and also can be run simultaneously

• Soft starting motor makes the cranes start and stop more steadier and smoother than others

• 42CrMo alloy forged wheels provide the products great shock resistance and wear resistance

• Wide selection of operational speeds completely meets the consumers’ different requirements

• Minimum wear of crane runway and travel wheels provide a long service life to cranes

• Optimised headroom via main girder connection variants makes products become more durable

• Equipped with traveling limit switch and other safety devices provide fully safe to the load jobs

Capacity 5Ton-50Ton

Span 10.5-31.5m

Standard Lift 12 m

Use Lifting Up/Down, Traversing Left/Right

Drive Mode Motor

Control Voltage 24v, 36v, 42v, 48v, 110v

H.S. Code 84261120

Material Steel Plate

Sling Type Wire Rope or Chain

Work Duty A3~A5

Power Supply 220v-660v, 50/60 Hz, 3 phase, single or dual voltage

Package Plywood case (girder and end truck are packed by rain-proof plastic, electric hoist and all other things are packed by firm wooden case or crates and plywood cases)

Certification ISO, CE, SGS

Color As you required

Warranty 12 months

Operation Pendant control, remote control or cabin control (open or closed type), driver's room

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder crane to be used. Double girder overhead cranes also provide higher hook heights because the hoist is placed between the two cross girders rather than below (under the cross girder), this adds up to 3 feet more for the items lifted off the floor. Double girder overhead cranes are also excellent solutions for handling large loads with long spans. Full length walkways can also be provided for easier servicing of the crane.

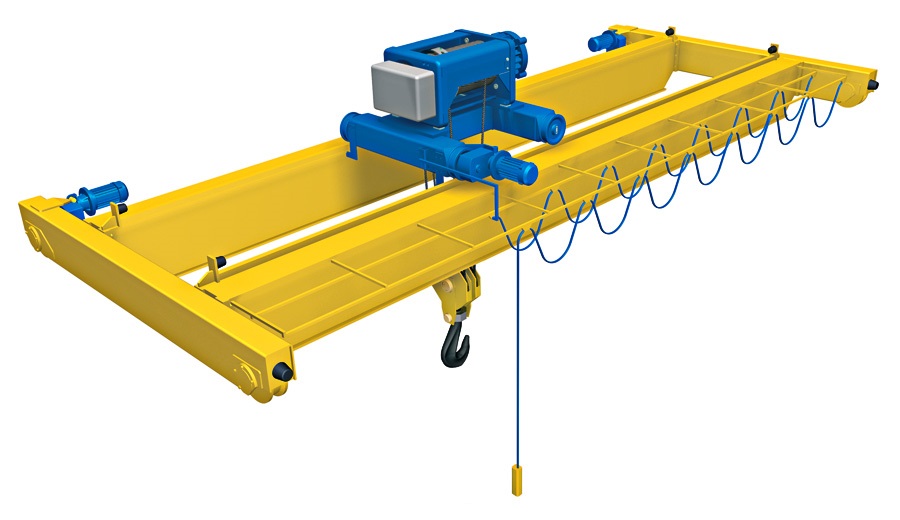

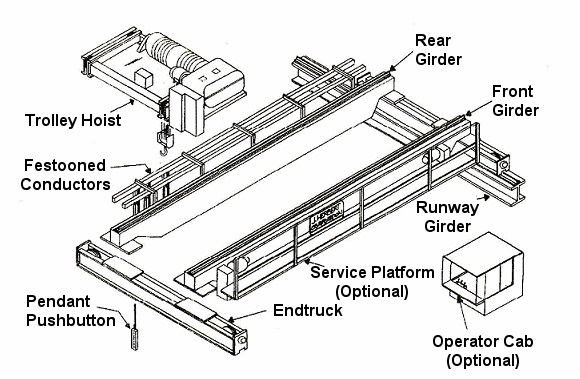

Double girder overhead crane consists of two end trucks with gear motors, two bridge girders, trolley hoist unit (or electric winch), electric panel, push button station, which include safety equipment of cross bar limit switches, overload limiter, siren light, etc. In these components, bridge girders (main girder) are beam or box, trolley hoist is double girder, festoon flat cable power supply system or energy chain supply power of the hoist, trolley or festoon flat cable power supply system supply power of the crane, two-speed motors on lifting and travelling mechanisms or stepless speed control by means of frequency inverters, and 3 types of control for you choose: independent overhead control box with buttons, or remote radio control, or cabin. What’s more, in order to ensure the high-quality of our double girder overhead cranes, the parts all adopt from well-respected names. We provide maintenance and operating pamphlet to our customers, which makes our overhead cranes become easy to hand and easy to change the parts.

Our double girder overhead cranes are designed by professional workers to show outstanding and excellent performance. The structure of our crane kits is made of rectangular steel tube or steel plate. Besides, the steel’s material is national standard Q345B or Q235B, which can provides more safety to the load works and prolongs our products service life. Main girder is the principal horizontal beam of the crane bridge which supported by end trucks, and it has the function of supporting the trolley hoist. End truck is located on either side of the bridge. The high-quality wheels of end truck ensure the whole crane to travel. It is an important component of double girder overhead cranes, which can support the main girder or the trolley cross members. Trolley is a unit which carry the hoist mechanism to travel on the bridge rails. It is have the function of transport the load safely.

Double girder overhead cranes also can be called bridge cranes, which consist of the assembled structure which spans between parallel rails or runway tracks, and are adapted to carry a suspended load horizontally along the runway. Bridge cranes can be top running or under-hung with single or double girder configurations. They also incorporate hoists on trolleys to move the load laterally as well as vertically. Bridge cranes can be mobilized via push trucks, geared, or motorized end trucks.

Compared with single girder overhead cranes, double girder overhead cranes have many own advantages. The maximum lifting load is more higher than others. Besides, the variable frequency control of big or small trolleys makes running become more stability, reliable and safety. The design of reasonable structure minimizes abrasion and maintenance of cranes during using, also ensures good running status of hoist.

They are widely used in petrochemical, metallurgical workshop, machinery manufacturing shop, petroleum, building materials, ports, electronics, paper making and other industries workshops, yards, warehouses,etc. Besides, double girder overhead cranes support CMAA Class C, D, E, F, Mill Duty Hot Metal and Magnet applications.

They are also named Double girder top running overhead cranes, Top running Double girder overhead crane kits with hoist, Double girder bridge cranes, Double girder overhead travelling crane, Double girder bridge overhead cranes. It is a totally new but not used crane, Please check above for downloading specification, double girder overhead crane design, drawings and price will be sent on your request.

Our double girder overhead cranes are made of Q235 or Q345 carbon structural steel. Besides, all steel plates for them must have shot blasting. High-quality steel material can fully prolong products’ service life.

2.Reinforcement Structure

Main girder with strong box type and standard camber. There are the reinforcement plate inside the main girder, which makes the main girder has a well performance.

3.Main Girder

The shape of main girder are beam or box to completely meets customers’ requirements. It is made of high-quality steel which can ensure it be used longer, and also provide more security to the load assignments.

4.Wheel

Double girder overhead cranes are equipped with high quality forged or casting wheel, which will have heat treatment to ensure wheel’s performance. The wheel is made of good material which can protect our double girder overhead cranes totally from rust and corrosion.

5.Division Part

Division part is convenient for transport by container, main girder are divided. The 3 times connection steel plates and high strength bolts can ensure the division parts’ rigidity, also can provide customers great products.

6.Electric Winch

With heavy capacity and high work duty, electric winch was developed specifically for lifting that requires accurate and smooth movement.

7.Trolley hoist

It is assembled with reducer, motor, brake, trolley frame, pulley, hook, drum, rain cover and other parts. It includes cross traveling mechanism and lifting mechanism. Trolley hoist is suitable to the double girder overhead crane with European or normal type, and can load the hoist to move freely along the main girder.

8.End truck

High-performance end truck with wheels is driven by motor, which has a function that run along the track to usefully help the crane move longitudinally. It is connected to main girders by high-strength bolts. The wheels with roller bearings and permanent lubrication. Motor with smooth starting and stopping characteristic.

9.Cabin

It is the workplace for manipulating crane by operator, which welded of steel plate and steel and mounted on a bracket below the main beam with solid and reliable connection. The cabin is closed and open type, air-conditioning provided, interlocked circuit breaker provider, and SIEMENS smart control panel if needed.

10.Electric panel box

It is used for winch and crane power supply, which can operate or stop double girder overhead cranes immediately and timely.

11.Reducer

Reducer is widely used in turbines, shaft liners and axletrees. It is good resistance to wear, with high precision in dimensions,low noise, advanced centric running castings, air vent and high precision.

12.Hook

Forged steel hook provides more safety and security to our overhead cranes. It is an important equipment to lift the loads, and a solid hook can highly increase the number of maximum lifting loads.

13.Cable reel

Directly for the overhead crane used for coiling cable, a cable retracting function, and provide power for crane.

14.Safety Devices

Lifting height limit device

Emergency stop function

Weight overload protection device

Wireless infra-detector for anti-collusion

Double girder overhead crane traveling limit switch

Voltage lower protection function

Phase sequence protection function

Warning indicator: flashing lights and warning sound.

Specifications

Lifting Capacity (t) | Main Hook | 5 | 10 | 16 | 20 | |

Auxiliary Hook | 3.2 | 5 | ||||

Span | 10.5-31.5 | |||||

LIfting Height (m) | Main Hook | 16 | 16 | 16 | 12 | |

Auxiliary Hook | 18 | 14 | ||||

Speed | Main Hook Lifting | A5 | 11.3 | 8.5 | 7.9 | 7.2 |

A6 | 15.6 | 13.3 | 13 | 12.3 | ||

Auxiliary Hook Lifting | 16.7 | 19.5 | ||||

Trolley Traversing | 37.2 | 43.8 | 44.6 | 44.6 | ||

Bridge Traversing | A5 | 89.8/91.8 | 90.7/91.9/84.7 | 84.7/87.6 | 84.7/87.6 | |

A6 | 92.7/93.7 | 115.6/116/112.5 | 112.5/101.4 | 112.5/101.4 | ||

Max. Wheel Load (kn) | A5 | 74-125 | 102-160 | 141-205 | 163-231 | |

A6 | 75-126 | 104-162 | 145-211 | 167-239 | ||

Rail Recommended | 38 kg/m | 43 kg/m | 43 kg/m or QU70 | 43 kg/m or QU70 | ||

Wheel Diameter of Trolley (mm) | φ160 | φ160 | φ160 | φ160 | ||

Wheel Diameter of End Carriage (mm) | φ160 | φ200 | φ250 | φ250 | ||

Operational Model | Cabin; remote control; ground handle | |||||

Working Duty | A5,A6 | |||||

Power Supply | 380v, 50Hz, 3phase or customized | |||||

Weight (kg) | Trolley | A5 | 2126 | 3424 | 6227 | 6856 |

A6 | 2224 | 3562 | 6427 | 7180 | ||

Total Weight | A5 | 12715-31405 | 14270-34405 | 19128-39428 | 19947-41497 | |

A6 | 12991-31596 | 14719-34699 | 20045-41315 | 20984-44225 | ||

-

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection…...

-

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder cr…...

-

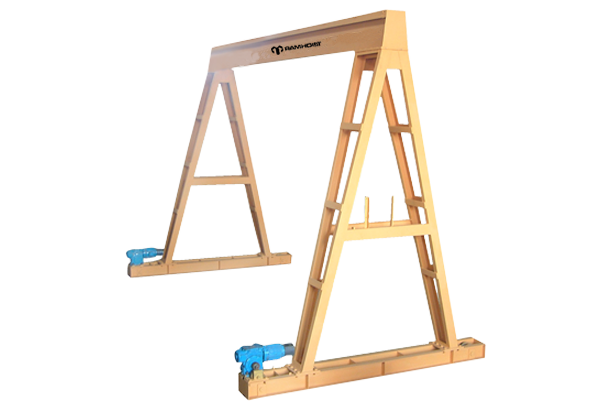

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes…...