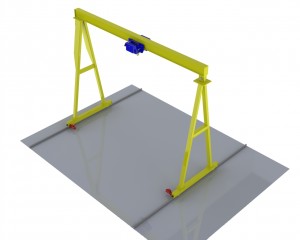

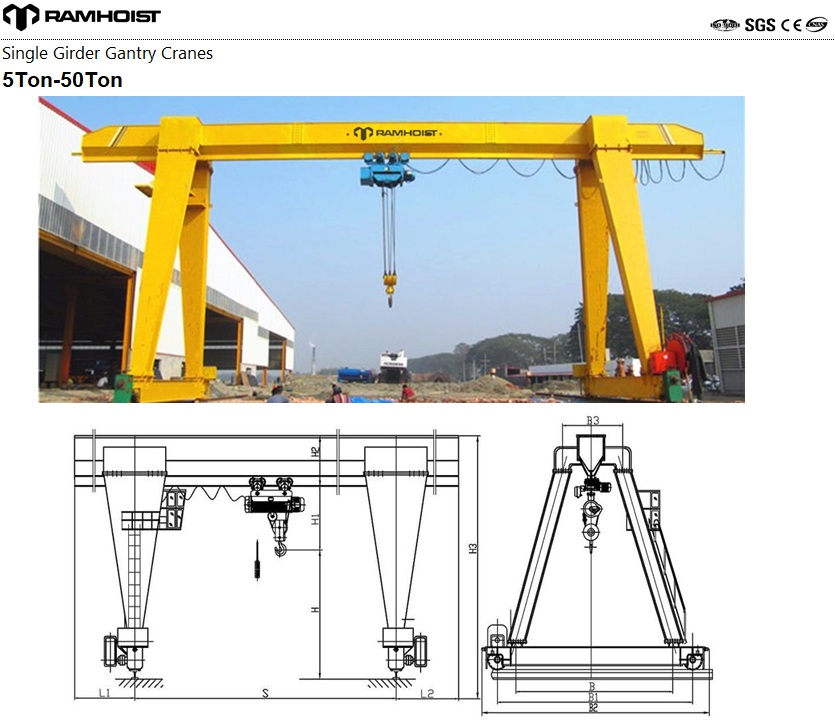

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes in small production units and operated on floor mounted rails. The head room of single girder gantry cranes is normal or low and these can be fitted in different floor areas. Single girder gantry crane design will be sent to you after knowing your actual situation.

• Simple, reasonable and compact structure, light weight and space-saving

• Easy, convenient, quick installation and maintenance, excellent exchangeability for parts

• Steady and smooth, safe and reliable traveling, smooth starting and stopping

• Low noise, commodious cabin and good view, favorable and versatile operating performance

• Ideal supplement to bridge cranes but lower the investment on structure and space

• Single speed or dual speed, large room to cross for goods supplied due to the shape of legs

• Equipped with overloading protection, loading and unloading with easy in production Line.

• Security system and anti-swaying technology which make the crane become more secure

• Emergency stop and current overload protection system provide more safety to load works

• Advanced technology, a much greater bridge weight than an equivalent overhead crane

• Hook with latch which has a function of prevent the goods from falling down

• Environmentally friendly, voltage lower protection function and reduce energy consumption

• Sub-assembly characteristics are tested beforebassembly gives safety-promise to customers

• Main lifting motor with thermal protection provides a high-efficiency to the crane

• High-quality motor, reducer and electric component are all come from well-known brand

• Flexible support legs could be disassembled as several pieces for convenient transportation

• More energy conservation and electricity save comparing with the overhead crane system

Capacity 3Ton-20Ton

Span 12m-30m

Standard Lift 6 m

Use Lifting Up/Down, Traversing Left/Right

Drive Mode Motor

Work Duty A3~A5

Duty Group Class C or D

Moving Mode: Wheel

Working Temperature -20--+40 centigrade

Sling Type Wire rope

After sales-services Yes

Operation Remote or pendant control on the ground, or driver's cabin control (open or close)

Color According to your specific demands

Power Supply 220v-700v, 50/60 Hz, 3 phase, single or dual voltage

Control Voltage 24v, 36v, 42v, 48v, 110v

申报要素

H.S. Code 8426193000

英文品名: GANTRY CRANE

中文品名: 龙门架

用途:吊装

结构类型:钢构拼接

品牌:无

型号:5T (按实际来)

| DOWNLOADS |

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes in small production units and operated on floor mounted rails. The head room of single girder gantry cranes is normal or low and these can be fitted in different floor areas. Single girder gantry cranes are fitted with crane duty motors and are suitable & compatible for frequent starting, reversing and braking.

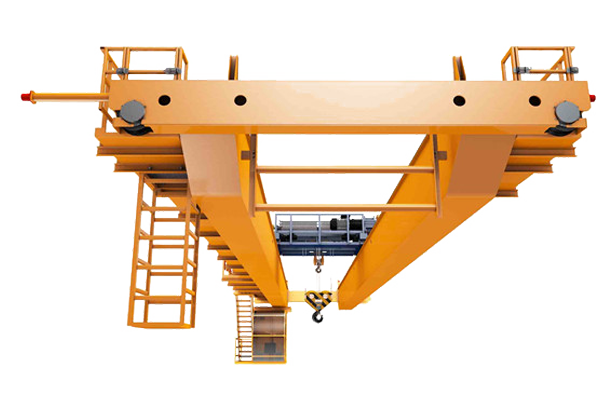

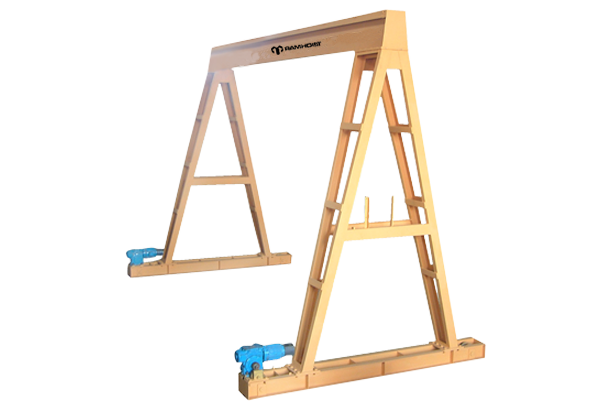

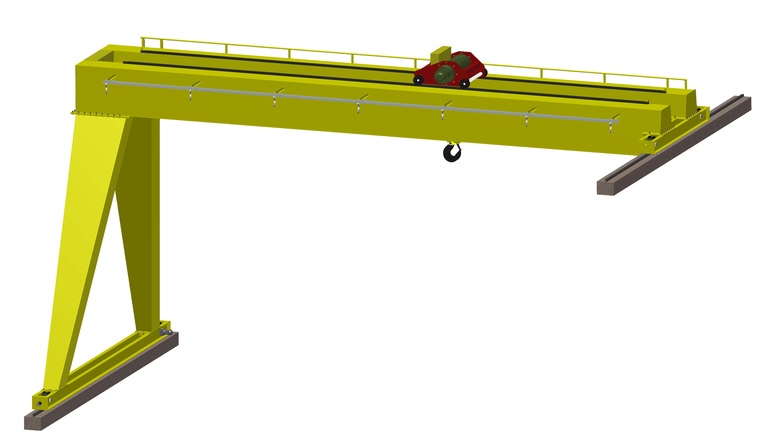

Our single girder gantry cranes designed by qualified engineers and manufactured by qualified boilermakers, electricians and fitters. What’s more, we can design according to your requirement, also can supply you the technology to weld the girder in your country. Single girder gantry cranes consist of main girder, a two legged A-frame support, possible cantilevers, bottom end beams, electric hoist and electric control. The cranes are modular design and have the advantages of easy installation and maintenance with reliable operation, fuse less circuitry, ducted wiring and compact terminals. Ramhoist can design and fabricate all types and sizes of gantry cranes as we know the rated load, crane’s span and lifting height, like full gantry cranes, semi-gantry cranes and portable gantry cranes, including, single girder, double girder, single leg, double leg, and cantilever styles for indoor or outdoor service.

Single Girder Gantry Cranes are self propelled cranes running on rails and traveling along the rails installed at ground level or set into the floor, they are rail-operated or track travelling small and medium-sized lifting equipment, the utility model is an ideal choice for indoor and outdoor lifting operations. They also can be used together with other lifting appliance for special purpose.

Referred to as portal cranes, gantry cranes are so named because they are constructed on top of a gantry – a structure designed to support a bridge. Different from overhead cranes, which don’t have supporting legs, sing girder gantry cranes are outfitted with supporting legs and don’t need support from the building structure or other steel supporting columns. The gantry cranes used for workshop material handling can be portable, mobile, or stationary, which means there are workshop portable gantry crane and fixed gantry crane. As portable gantry cranes, they can be produced with steel or aluminum or with both of them, and they can move freely within the working area during the operations to lift and move materials.

According to different situations, single girder gantry cranes have three types: MH single girder gantry crane, truss type single girder gantry crane, L single girder gantry crane. The differences of these three types are explained in the back in details.Single girder gantry cranes with the runway located on the floor can be used where the overhead crane or bridge is not practical or isn’t installed; overhead runways structure are unavailable, columns cannot be accommodated in open areas, existing factory structure cannot bear the wheel loads of the overhead crane; or loads needs to be handled outside the crane span and when the relocation of the crane is required after the work at a certain site is completed.

Single girder gantry cranes are widely used to indoors and outdoors with application such as open ground, warehouse, workshop, steel plants, engineering industry, cable industry, granite industry, cement pipe industry, cement plants, highway, ports, container depots, pulp & paper, bulk storage areas, open yard, shipyards, precast yards, rail yards, mining maintenance, hydroelectric power station, bridge construction, infrastructure. It is also a ideal choice for use in a rented factory or in multiple work place.Single girder gantry cranes also called single girder door cranes, goliath cranes, single beam gantry cranes, single girder electric gantry cranes, single girder electric hoist gantry cranes, single girder electric hoist gantry cranes, single beam electric hoist gantry cranes, long traveling single girder gantry cranes, rail mounted single girder gantry cranes, single girder mechanical gantry cranes, portal cranes, electric hoist hanging type gantry cranes, Single girder semi gantry crane, Single girder travelling gantry crane, overhead gantry crane, small gantry crane, adjustable gantry crane, mobile gantry crane, rubber tyred gantry crane, rail mounted gantry crane, harbor freight gantry crane.

1. Main girder | Main beam | King post

The top main girder is mounted on two A shape columns which are further resting on wheel mounted end carriages, the main girder and end beams are connected with the high strength bolt of 10.9 grade. It is made of steel and the steel plate's built-up beam with Q235B or Q345B high-quality carbon steel which improves the carrying capacity. The primer and finishing painting are normal yellow or customized colour. Besides, the average thickness is about 100 microns.

Main girder and below support leg have two types: box-shape or truss-shape

Box-shape crane: Single girder gantry crane with box is widely used with standard CD MD Electric Hoist as the lifting mechanism, and the electric hoist traversing along the lower flange of the I-Steel of the main girder, which is made up of high quality steel plates such as C-steel and I-steel. It is a medium-size crane which travels in track, with the advantages of compact structure, good rigidity, strong lifting capacity and slim body.

For European type, the main beam uses square structure. Compared with the traditional I-beam welded beam, it is with higher strength, electric hoist on it run more stable.

Truss-shape crane: truss single girder gantry crane are different from the box type crane, The truss single girder gantry is made of steel bars, while Box-shape is made of steel plates. The structure of single girder gantry crane with steel truss is cheaper and much lighter than box-crane. When the building is inadequate to support a bridge crane, truss is almost the best solution, with advantage of small windward side and high wind resistance, light dead weight, low cost and nice appearance

2. A-frame support | Support legs

A-frame support structure with a girder mounted on top on which an electric hoist is mounted. It moves along a fixed line, which means that any hoisted or transported cargo or products must be brought under the crane’s ‘operating area’, a space in which the crane can operate back and forth, left and right. It is made up of Q235/Q345 carbon structural steel, and it is the strong box type with two coats of paint.

3. Cantilevers (With/Without)

A projection structure at one end or two end which is used for transporting a load beyond the gantry support structure and meets the requirement of loading and unloading on side area. Single girder gantry cranes’ custom-engineered lifting solutions can be designed with two side cantilever, one side cantilever or no cantilever.

4. End Carriages | Bottom end beams | Ground beams

Line boring one piece end carriages made of Q235/Q345 carbon structural steel and with Nanjing brand motor are to ensure precise alignment and smooth travelling motions, along with above three items, they are made up of gantry frame.

Vacuum casting wheel, inter medium quenching by top technique machinery

5. Electric hoist | crab+trolley

Strong crab+trolley to lift, move, transport heavy loads (materials), they are lifting mechanism and traveling mechanism, normally CD/MD type or European type electric hoist are used, for European type. Limit distance from hook to both sides is short but has large working arrange. With lower height above the rail, it makes full use of space of factory building.

Its main components are as follows:

1). Motor

Special for crane use, it is made by the best factory in china--Nanjing Special Motor Factory for CD/MD wire rope hoist or imported from Germany for European type wire rope hoist.

2). Overload protection device

If the material is over the capacity, the crane will give a sharp warning for protection itself. Overload protection provided to help in preventing the condition of overloading.

3). Limit switches

To prevent over hoisting and over lowering of hook.

4). Buffer

High quality long-time bearing polyurethane materials buffer.

5). Control

Room control or remote control to avoid any injure to the operation staff.

6). Voltage lower protection

Voltage lower protection function to adopt the cases that without stable voltage supply.

7). Emergency stop system

If the operation staff encounter some emergency situations, we could start the emergency brake system to protect our operator and equipment.

8). Current overload protection system

It is also called Circuit self-test protection device,protecting the current lacking of any phase.

9). Phase sequence protection function

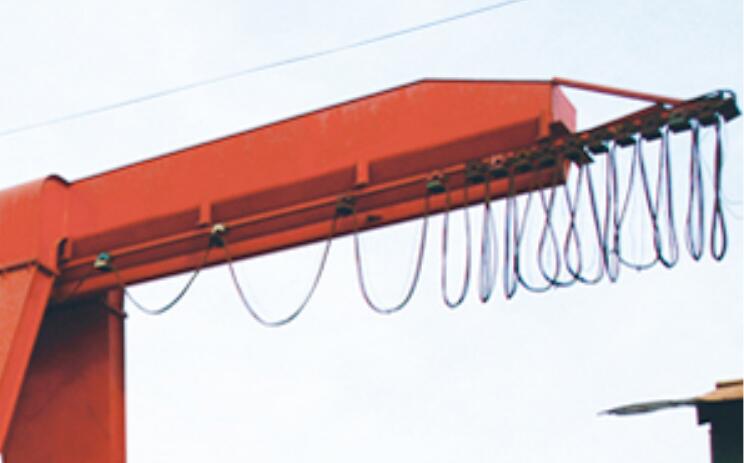

6. Power supply systems

Cable reel or conductor rail power supply systems [cable drum type or line sliding contacting type (bus-base)] and electrical control box

7. Bottom flanges

Full penetration sub-arc welded bottom flanges for the ultimate in strength and fatigue resistance.

8. Optional

Electronic Control and Recording Status of the Hoist and Crane

Anti-Collision ultrasonic Sensor

Anti-Sway System

Load Display Indicator

Twin Hoists on Same Crane

Joystick Wireless Remote Control

Energy Chain

Storm Lock

Girder Mounted flood Lights

ESR System(Extended Speed Range System)

ASR System(Adapted Speed Range System)

Windproof and rainproof devices

Onboard maintenance platform

Audio-Visual Signalling Devices

Rail Sweeps

Others

1.Package

Electric hoist and crane parts will be packed by plywood crate, main girder packed by water-proof cloth.

2.Remark

Remote control = radio control = ground wireless remote control

Pendant control = ground cable handle

Driver's cabin control = cabin control = cab control = room Control

Remote control and pendant control belong to ground control, driver's cabin control also called room control, we can mix the two control model together with use.

3.Factors to consider when selecting your crane

Capacity/rated load (tonnes)

Span (the clear distance between your building columns) with cantilever or not? (m)

Height of Lift (hook center to ground) (m)

Have you installed the rails? Do you need us supply the rails? How long is it?

Power supply: voltage

Working condition: which material to lift? Temperature?

Would be better if you have drawings of your plant

4.Use and Maintenance

Test: Under no-load conditions and power, start the operation mechanism control system and check whethere safety devices are sensitive and accurate, adjust to secure before use.

Shall not exceed the rated capacity and not be pulled oblique hanging crooked

User should be regularly checked whether all parts of the crane abnormal

Lubrication: lifting equipment lubrication will directly affect the normal operation of the crane and the production process, to prolong life and promote safe production parts, Lubrication is a must.

Flammable, explosive, corrosive gas and blend deleterious article are forbidden in the workplace.

5. High quality enamel paint with optional 2-pak or client specific systems.

Overseas installation, commissioning and training services is available; technical advisory for any time.

Internal or external bracing.

Industry leading Hyperspeed and i-Glide technology optional across the entire range.

6.Single vs Double Girder Gantry Cranes

When choosing which option to have installed in your factory or on your worksite, it’s important to do some research into which option – the single girder or double girder gantry cranes – are best suited to accommodate your requirements. The single girder option has a single beam across the top and is best suited to relatively lighter loads up to 20 tonnes on tasks that don’t usually last longer than a few hours. However, if you’re looking to lift, transport or hoist significantly larger loads up to 100 tonnes at a time, then the double girder gantry crane is better suited to your needs. Supported by two beams, the enhanced strength and stability of the double girder cranes enable it to be used for tasks lasting eight hours or longer.

Single girder gantry crane has full gantry crane and Semi gantry crane, which are as follows:

1. Full gantry crane

①A (MH) Type Single Girder Gantry Crane

It is suitable for indoor and outdoor use and with strong box type, which can be designed with two side cantilever, one side cantilever or no cantilever. The surface of facing wind is very small because of its steel-piping leg. The crane equipped with steel wire rope hoist, hoist traversing under the main girder

Single girder, Double leg

② Truss Type Single Girder Gantry Crane

Crane main girder and support leg are both truss type and can bear strong wind pressure and is applied where the speed of wind is high (since the main beam and support leg of Truss-type gantry crane is hollow, they are more stronger to stand up to wind). It can be designed with full truss type or main girder with truss type, and it is more suitable for open area. The crane equipped with steel wire rope hoist, hoist traversing under the main girder.

③ L Type Single Girder Gantry Crane

Crane leg is ‘L’ type, the obvious feature of L type single leg is welding structure in order to increases the work space which makes the crane more convenient for handling cargo with long length. The frame adopts box-type welding mechanism, which is more convenience for large size goods from middle position move to cantilever without any dimensional limit of support leg. The crane can equipped with bridge, L type support leg, crane travelling organ, trolley, electric equipment. Power supply can be two forms: cable car and cable reel.

2. Semi-gantry gantry crane | light duty single girder semi gantry crane | Workshop single girder semi gantry crane

Semi-gantry crane (single girder, single leg) is a small or middle scale gantry crane with one side of crane girder supported by one unilateral leg (on one side column) which can travel on the ground track (rail), and the other side supported on the bracket track, which could save cost and space of the factory. In other words, semi gantry crane only has supporting legs on one side of the crane and the other side needs the support from the workplace building structure support, while full gantry crane has supporting legs on both sides of the crane, this semi gantry crane can also be designed with or without cantilever.

With one leg moving on the floor rails, the other end running on the runway beam, this is a very suitable design for very wide factory space where owner requires 2 operational bays without having the need to incur a high cost to build continuous runway beam and columns in the centre of the factory.

Semi gantry crane is a regular crane similar to full gantry crane but with lower price than gantry crane and more adaptable for the workshops without enough space to apply the full gantry cranes. They can minimum the cost and take full advantage of the existing building construction and are widely used at open ground such as engineering industry, ports, granite industry, steel yards, cement pipe industry, open yard, storages places, container depots and shipyards.

Specifications

Lifting Capacity (t) | 3 | 5 | 10 | 16 | 20 | ||

Operational Method | Pendant push button control, cabin control or remote control | ||||||

Speed (m/min) | Lifting | 8 ,8/0.8 | 8,8/0.8 | 7,7/0.7 | 3.5 | 3.5 | |

Cross Travelling | 20 | 20 | 20 | 20 | 20 | ||

Crane Travelling | Ground | 20 | 20 | 20 | 20 | 20 | |

Cabin | 30,40 | 30,40 | 30,40 | 30,40 | 30,40 | ||

Motor (type /kw) | Lifting | ZD41-4/4.5 | ZD141-4/7.5 ZDS10.8/4.5 | ZD151-4/13 ZDS11.5/4.5 | ZD151-4/13 | ZD152-4/18 | |

Cross Travelling | ZDY12-4/0.4 | ZDY121-4/0.8 | ZDY21-4/0.8×2 | ZDY121-4/0.8×2 | YZD-4/0.8×4 | ||

Crane Travelling | Ground | ZDY21-4/0.8×2 | YZR132M1-6/2.2×2 | YZR160M1-6/6.3×2 | YZR160M1-6/6.3×2 | YZR160M1-6/6.3×2 | |

ZDY21-4/1.5×2 | YZR132M2-6/3.7×2 | YZR160M2-6/8.5×2 | YZR160M2-6/8.5×2 | ||||

Cabin | ZDR22-4/1.5×2 | YZR132M2-6/3.7×2 | YZR160M1-6/6.3×2 | YZR160M2-6/8.5×2 | YZR160M2-6/8.5×2 | ||

ZDR24-4/2.2×2 | YZR160M1-6/5.5×2 | YZR160L2-6/11×2 | YZR160L2-6/11×2 | ||||

Electric Hoist | CD1/MD1 | CD1/MD1 | CD1/MD1 | CD1 | HC | ||

Lifting Height (m) | 6,9,12 or other height | ||||||

Working Duty | A5 | ||||||

Power Supply | 380V 50HZ 3phase AC | ||||||

Span (m) | 12,16,20,24,30 | ||||||

Working Temperature | -20-40℃ | ||||||

Cantilevers | According to your demand, but not more than 1/3 of span | ||||||

Steel Track Recommended (Kg/m) | 43 | 43 | 43 | 43 | 50 | ||

-

Single girder overhead cranes are light small lifting overhead cranes or bridge cranes with two-side connection…...

-

Double girder overhead cranes are used when capacity and span requirements are too great for a single girder cr…...

-

Single Girder Gantry Cranes are used for material handling (loading, unloading or grabbing materials) processes…...