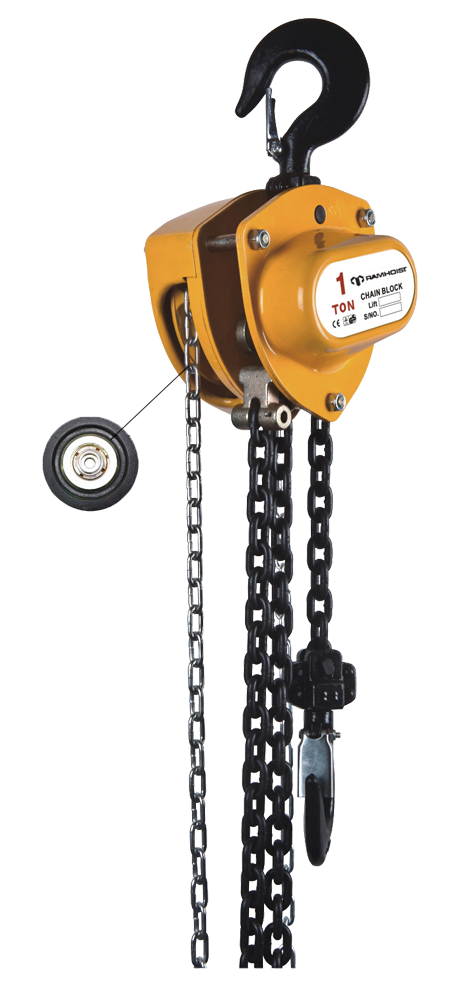

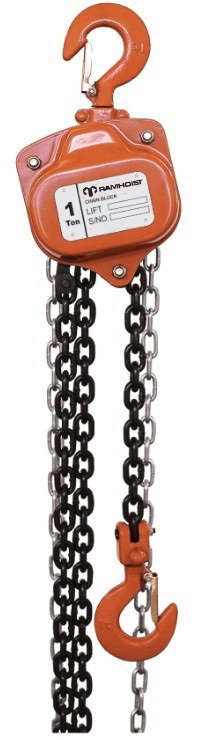

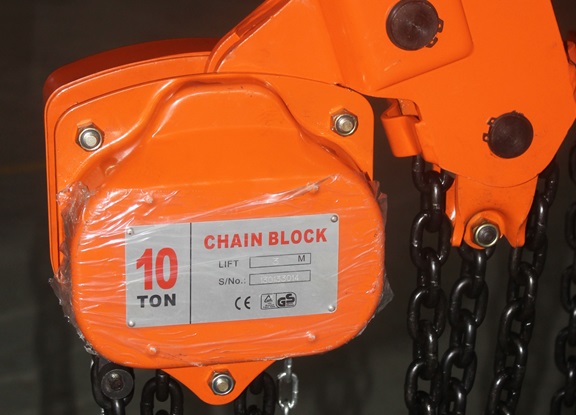

VT Chain Blocks are a portable lifting device easily operated by hand, which can be attached to a trolley of any type as a traveling chain blocks and one kind of using simply and carrying easily manual hoisting machinery. VT Chain Blocks have the same technology as japanese vital chain blocks but with much lower price.

• Rational and advanced structure, dainty material with high toughness and strength

• Unique and exquisite design with beautiful appearance and famous reputation

• Compact design, small volume and size, light weight with big component strength

• Easy to carry and transport, use, operate and store, convenient for maintenance

• High safety, high reliability, high durability, sold well both domestic and overseas

• Good even excellent performance, simple steps but complex producing and treatment

• Efficient which saves labor, time and effort, economical and affordable prices

• Equipped with hardened load chain for flexibility and long wear-resistance

• Low headroom and lightweight steel construction even in confined spaces

• Common-used parts, universal and strong compatibility with wide application

• High and strict tested under 1.25 times the working load limit for security

• Advanced spray processing technology both inside and outside are painted

• Weston-type load brake requires no lubrication but with smooth operating and lifting

• Adopt weight inspection to ensure the performance of each part to give full play

• Adopt high-quality grade 80 alloy steel and top & bottom hook with heavy duty bolts

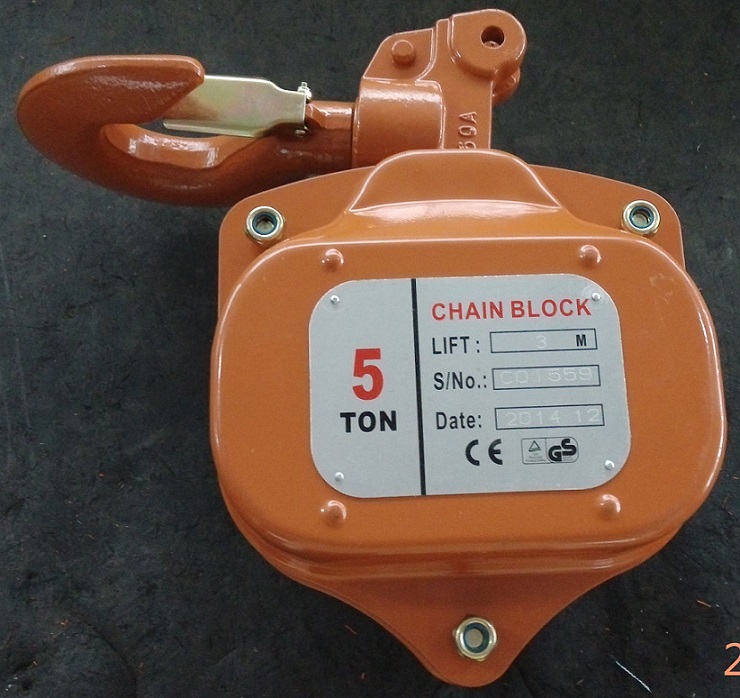

Capacity 0.5Ton-50Ton

Standard Lift 2.5m, 3 m

Use Lifting Up/Down

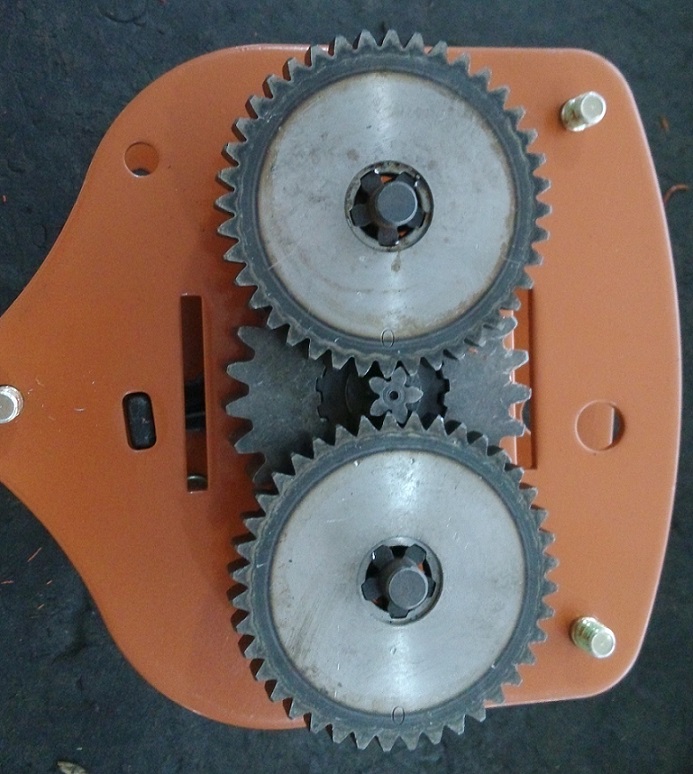

Drive Mode Gear

Warranty 1 year

Condition New

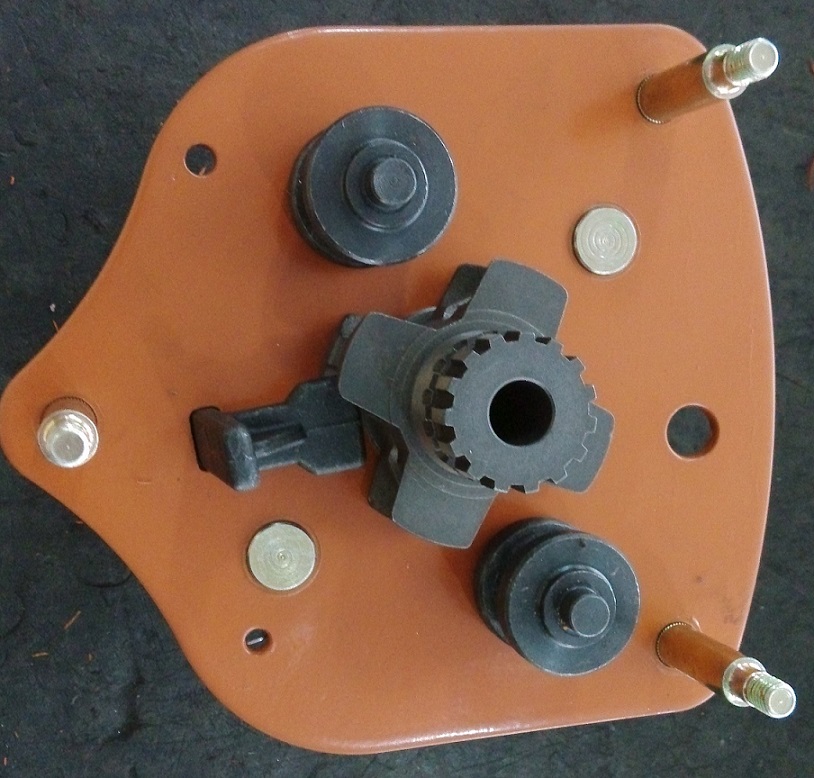

Inner part detail Double pawl

Color Orange, red, yellow, blue

Certification CE certificate, CE Standard

Hook material Forged alloy steel

Chain material G80 alloy steel chain

Power supply Manual

Surface treatment Galvanized

Sling Type Chain

Application Small cranes

Operation Hand Operated

H.S. Code 84251900

Package Cartons with pallet

VT Chain Blocks are a portable lifting device easily operated by hand, which can be attached to a trolley of any type as a traveling chain blocks and one kind of using simply and carrying easily manual hoisting machinery. After absorbing the advanced technology in the world, VT chain blocks are improved on the basis of HSZ series. Except for the traditional characteristics of HSZ series chain hoist, VT series need less hand-pull force, and they are safer, more beautiful and applicable. VT chain blocks adopt high mechanical efficiency and small chain tension and with chains equipped with latches and protection system for safety and security, this series use double pawl, double guide and are also in the framework style. More safety and hand pull lighter.

VT chain blocks are equipped with the most popular block chain--superior grade 80 load chains and forges and heat treated load hooks with batch traceability and stretch indicators, and 360 degree hand rotation with stroke to ratchet indicators. There are also double pawl brake linings, forged safety latch and sealed roller bearings. With fine and beautiful appearance and reasonable structure, they are environmental-friendly with stable operation and durable in use and service. VT chain blocks are convenient manual lifting machinery, which are suitable for the short distance lifting of small equipment and goods, and the weight is generally not more than 100 ton. the chain blocks' shell material is highquality alloy steel, strong wear resistance and high safety performance.VT chain blocks are innovated symmetrical arrayed high speed synchronous gears, and are made of international standard gear steel. Compared with common gears, they are more wearable and steadier, and more laborsaving. The main components are all made of high class alloy steel, with high precision and security. Adopt advanced plastic plating technology inside and outside, it looks like a new one after years of operations. All VT chain blocks have safe and reliable braking functions with gear case and hand wheel cover resistant to external shocks and double enclosure to keep out rain water and dust for a long lifespan.

Load chain in chain block is one of the most critical parts, the abuse that this chain receives can be the difference in a minor accident or a catastrophe, yet it is probably the most overlooked part of a block. Load chain should be inspected daily, weld spatter, a nick, gouge, or stress can greatly reduce the capacity of the load chain. Please inspect your load chain and make sure you always make a safe lift. What’s more, due to the crushing effect grab hooks have upon chain, the design factor of all assemblies must be reduced by 20% for Grab Hook applications. This is a vital type chain block and there are different models such as VC-A, VC, HS-VT, HSZ-VT, HSZ-A622 for this chain block, all means this vital type.

VT chain blocks are widely applied in factories, mines, farms, construction sites, agricultural production, and in wharfs, docks and storages for fixing machines, lifting cargos, loading and unloading goods. They are especially advantageous for lifting work in the open air and places where no power supply is available.

The chain blocks can be attached to a trolley of any type as a traveling chain block. They are also suitable to monorail overhead conveying system, hand travelling crane and jib crane. Our products are widely applied in household, outdoor traveling, aerospace, warehouse, manufacturing industry and construction industry. VT chain block can also be used with all kinds of manual single-track driving vehicles, which can be used in single rail overhead transportation, manual single-beam bridge crane and cantilever crane.

VT Chain blocks are also called alloyed steel gear VT manual chain blocks, good price VT type chain blocks with forged hooks, hand tools chain block lifting equipment alloyed steel gear, hand operated hoists, Mechanical hoists and Manual hoists. VT chain block are the hot selling chain block in china market and maybe the most popular manual chain block.

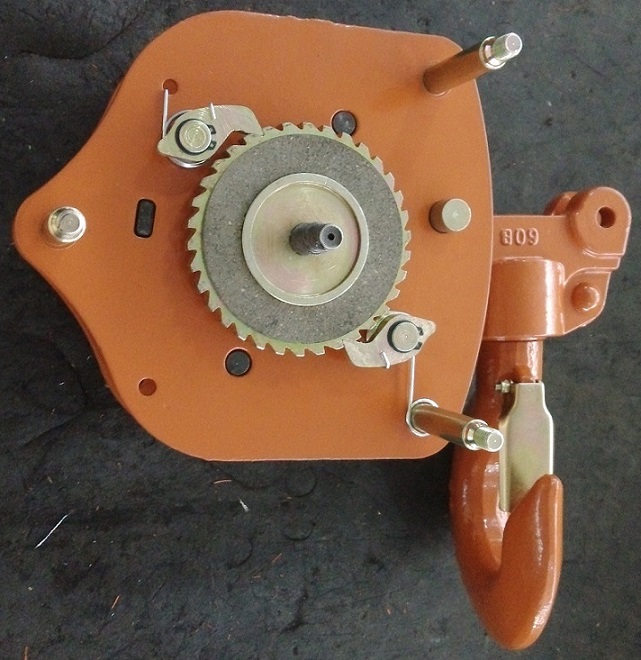

1. Gear

Gears are innovated symmetrical arrayed high speed synchronous gears, and are made of international standard gear steel. Compared with common gears, they are more wearable and steadier, and more laborsaving. Standard international gear steel is two times as wear-resisting degree as the ordinary chain block, rotation is more stable and hand pulling force is lighter. They have high precision toughness gears.

2. Chain

Adopt high strong chain for strength and practicality including Grade 80 galvanized load chain and hand chain and high precision welding technology, meet ISO3077-1984 international standard. They are fit for gusty overload work conditions; bring your hands a better feeling; multi-angle operation. They change the ordinary chain block only vertical downward pull and are fit to greater scope. Standard hand chain drop is 2 feet less than lift (example: 10 foot lift hoist has 8 foot hand chain drop). Standard chain lengths 3mtr & 6mtr with longer drops are available on request.

Hand Chain: material A3, 30 grades, galvanized (not polished)

Lifting chain: material 20MN2, G80 grade, black (for bulk order the color is normally black but not galvanized as sample, black is stronger than galvanized, galvanized is just for pretty but loading is somewhat weaker and brittler

3. Hook

Made of high-class alloy steel, it has high strength and high security by using the new design. and make sure the goods will not be decoupled. Hooks for Load chain guide mechanism are finely fabricated from wrought iron. Forged swivel hooks with latches reduce twisting of chain and unintentional unhooking of load when chain is slack.

4. Limit switch

Using limit switch components are in design to protect the chain and ensure the security. Both upper and bottom hooks have limit switch part prevent chain escaping.

5. Components

The main components are all made of high-class alloy steel, with high precision and security.

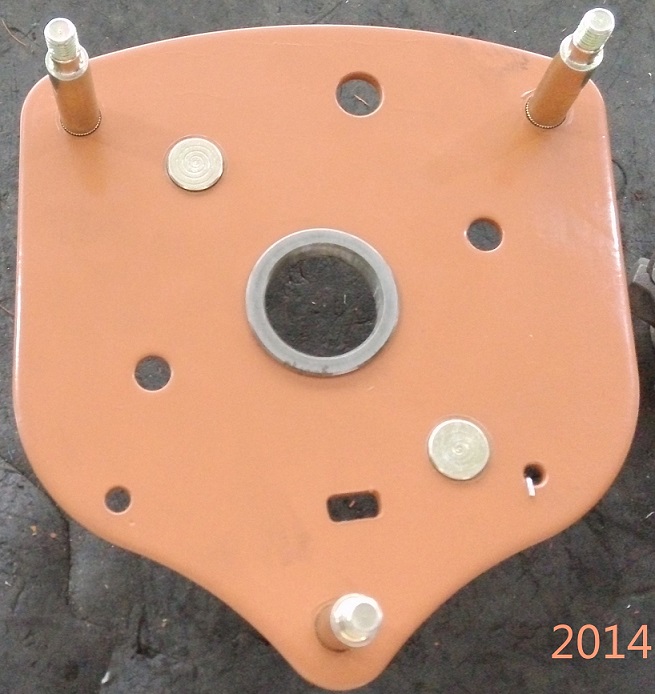

6. Body

Fine design, modern and beautiful appearance; accord with human body engineering, the light machine body and activities of small interface, adapt to the environment widely with less weight and smaller work area compare to ordinary chain block.

7. Plastic plating

Adopt advanced plastic plating technology inside and outside, it looks like a new one after years of operation.

8. Enclose

The encloses are made of high-classed steel, more firm and dexterous.

9. Default bearing

Needle bearing.

10. Remarks

The limited load capacity are loaded in our products for attract the attention of operators for security.

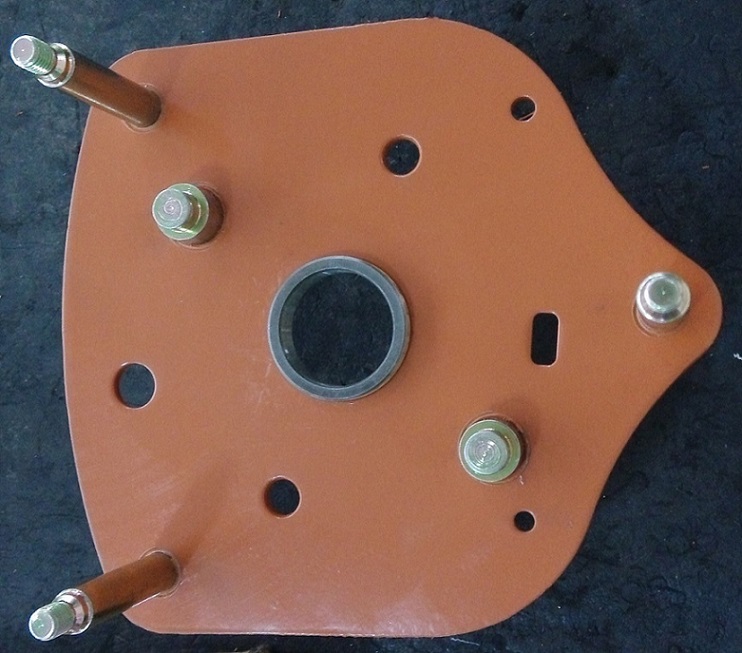

11. Bolts

VT chain blocks adopt Heavy duty bolt through design.

12. Gear box

It has anti-external impact of gear box.

13. Outer cover

It adopt high strength can resist corrosion with double cover to keep out rain and dust so that they have durable long life. Hand wheel cover with guide slots minimizes jamming and slipping

14. Brake

VT chain blocks have safe and reliable braking performance (mechanical clutch), double pawl spring, enhancing the hoist durability enhancement.

15. Overload protection

Overload protection available upon request.

16. Safety latches

Cast steel safety latches are available for ensuring the safety of operators.

17. Bottom hook fitted bearing.

18. Load limit

In order to avoid the overloading, there is a load limit

19. Round hand wheel

20. Inner structure

Others

1. Caution

It must be recognized that certain factors in the usage of chain and attachments can be abusive and lessen the load that the chain or attachments can withstand. Some examples are twisting of the chain, disfigurement, deterioration by straining, usage, weathering and corrosion, rapid application of load or jerking applying excessive loads, and sharp corners cutting action.

2. Operation

3. Package

Package use the standard carton, colored carton or ply wooden case.

4. Remark:

These types of VT chain blocks use double pawl, double guide and also are used in the framework of the style. More safety and hand pull lighter

5. It's a matter of great pleasure to inform you that we are having cordial business relation with many different fields corporations and manufacturers throughout the world. It is needless to emphasis that in view of our vast experience in the line we are in a position to meet your valued requirements of Lifting Equipment and Hand Tools and Items of every description and specifications at moderate price. Sincerely welcome your inquiry and trail order. We are looking forward to the firm and long-term business relationship with you.

6. When considering a hoist, ask if the manufacturer can produce test certs and metallurgical makeup or if they do independent testing as RAMHOIST Lifting does. After a chain failure you will want to work with a company that can walk back every step of the hoists manufacturing and rigging, RAMHOIST Lifting has this capability by the intense Quality Control we implement on every hoist.

7. This is only a part of what it takes to keep your workplace accident free. You can read more about hoists safety here.

8. VT chain blocks differ from other traditional manufacturers and trading company. On one hand, we have professional team which can research cost-effective and hot-selling products, catering to various customer demands in different market. On the other hand, with hundreds of tested products, CE certificates, advanced design, strong package and high efficiency logistics system, we can satisfy our clients around the world. As the development of globalization and internationalization strategy, we will cooperate with customers all over the world to achieve success and mutual benefits.

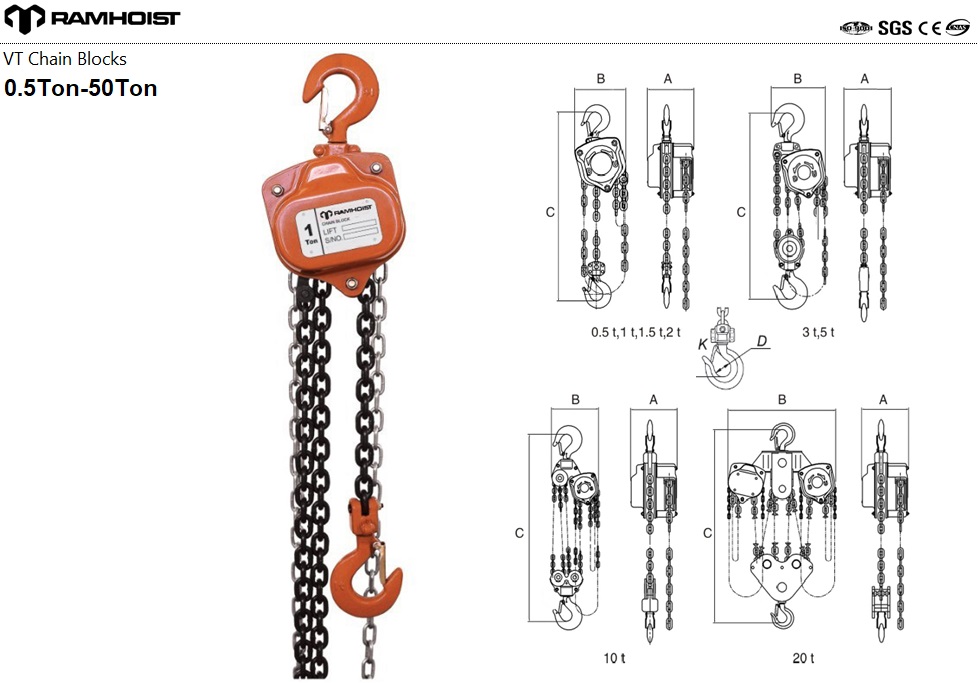

9. there is no relation for 0.5T and 1T, cause hoist body is different (some northern manufacturers use 1T hoist body instead of 0.5T since they don’t have 0.5T mould)

there is no relation for 1.5T and 2T, cause hoist body is different

7.5T and 10T are made up of 1 piece of 5T body, the difference is chain falls and hook

20T are made up of 2 pieces of 5T body, the difference is chain falls and hook

[hoist body= chain block body only( bare block---without load chain and hand chain)]

5t, 2 chain falls, 1 body

7.5t, 3 chain falls, 1 body

10t, 4 chain falls, 1 body

15t, 6 chain falls, 1 body

20t, 8 chain falls, 2 bodies

30t, 12 chain falls, 2 bodies

50t, 20 chain fall, 2 bodies

|

Workshop of chain block and lever hoist

PVC chain bag come along with VT chain block delivered to Spain

Specifications

Type | Capacity(t) | Standard Lift (m) | Effort required to lift full load (N) | Load Chain | Test Load (t) | Weight(kg) | Additional Weight per 1m Lift(kg) |

Diameter (mm) ×chain falls | |||||||

VT005 | 0.5 | 2.5 | 200 | 5 × 1 | 0.75 | 8.4 | 1.5 |

VT01 | 1 | 320 | 6.3 × 1 | 1.5 | 12 | 1.8 | |

VT015 | 1.5 | 360 | 7.1 × 1 | 2.25 | 16.2 | 2.1 | |

VT02 | 2 | 3 | 365 | 8× 1 | 3 | 20 | 2.3 |

VT03 | 3 | 385 | 7.1× 2 | 4.5 | 24 | 4.2 | |

VT05 | 5 | 435 | 9 × 2 | 7.5 | 41 | 5.1 | |

VT075 | 7.5 | 435 | 9 × 3 | 11.25 | 61 | 7.7 | |

VT10 | 10 | 435 | 9 × 4 | 15 | 79 | 10.2 | |

VT20 | 20 | 435×2 | 9× 8 | 30 | 193 | 20.4 | |

VT30 | 30 | 435×2 | 9 × 12 | 45 | 220 | 30.6 | |

VT50 | 50 | 435×2 | 9 × 24 | 75 | 1092 | 61.2 |

Dimensions (mm)

Type | Capacity (t) | A | B | C | D | K | |

VT005 | 0.5 | 131 | 127 | 270 | 35 | 30 | |

VT01 | 1 | 140 | 158 | 317 | 40 | 34 | |

VT015 | 1.5 | 161 | 187 | 399 | 45 | 38 | |

VT02 | 2 | 161 | 187 | 414 | 50 | 41 | |

VT03 | 3 | 161 | 210 | 465 | 58 | 48 | |

VT05 | 5 | 186 | 253 | 636 | 64 | 52 | |

VT075 | 7.5 | 186 | 344 | 740 | 72.5 | 56 | |

VT10 | 10 | 207 | 398 | 798 | 85 | 64 | |

VT20 | 20 | 215 | 650 | 890 | 110 | 85 | |

VT30 | 30 | 350 | 680 | 1380 | 110 | 85 | |

VT50 | 50 | 406 | 962 | 2578 | 170 | 130 | |